Overview

This article delves into the diverse types, applications, and installation tips for fan motor controllers, underscoring their critical role in enhancing energy efficiency and performance. By examining the functionality of various controller types, such as Triac devices and Variable Frequency Drives, it provides a comprehensive understanding of how these technologies operate.

To avoid common pitfalls, the article offers essential guidelines for selecting and installing these controllers, ensuring that readers can make informed decisions. This focus on practical advice not only highlights the importance of these devices in reducing power consumption but also emphasizes their contribution to improving system reliability.

In summary, understanding fan motor controllers is vital for anyone looking to optimize energy use and enhance performance in their systems. By following the outlined tips and insights, readers can effectively implement these technologies, leading to significant improvements in efficiency and reliability.

Introduction

Understanding the complexities of fan motor controllers is crucial for anyone aiming to boost energy efficiency and operational performance across various applications. These devices not only regulate fan speeds but also play a significant role in reducing power consumption, which translates into substantial cost savings and environmental advantages. Yet, with a variety of types available and potential installation challenges, how can one ensure they are making the right choice? This article explores the different types, applications, and essential installation tips for fan motor controllers, providing readers with the insights needed to optimize their systems effectively.

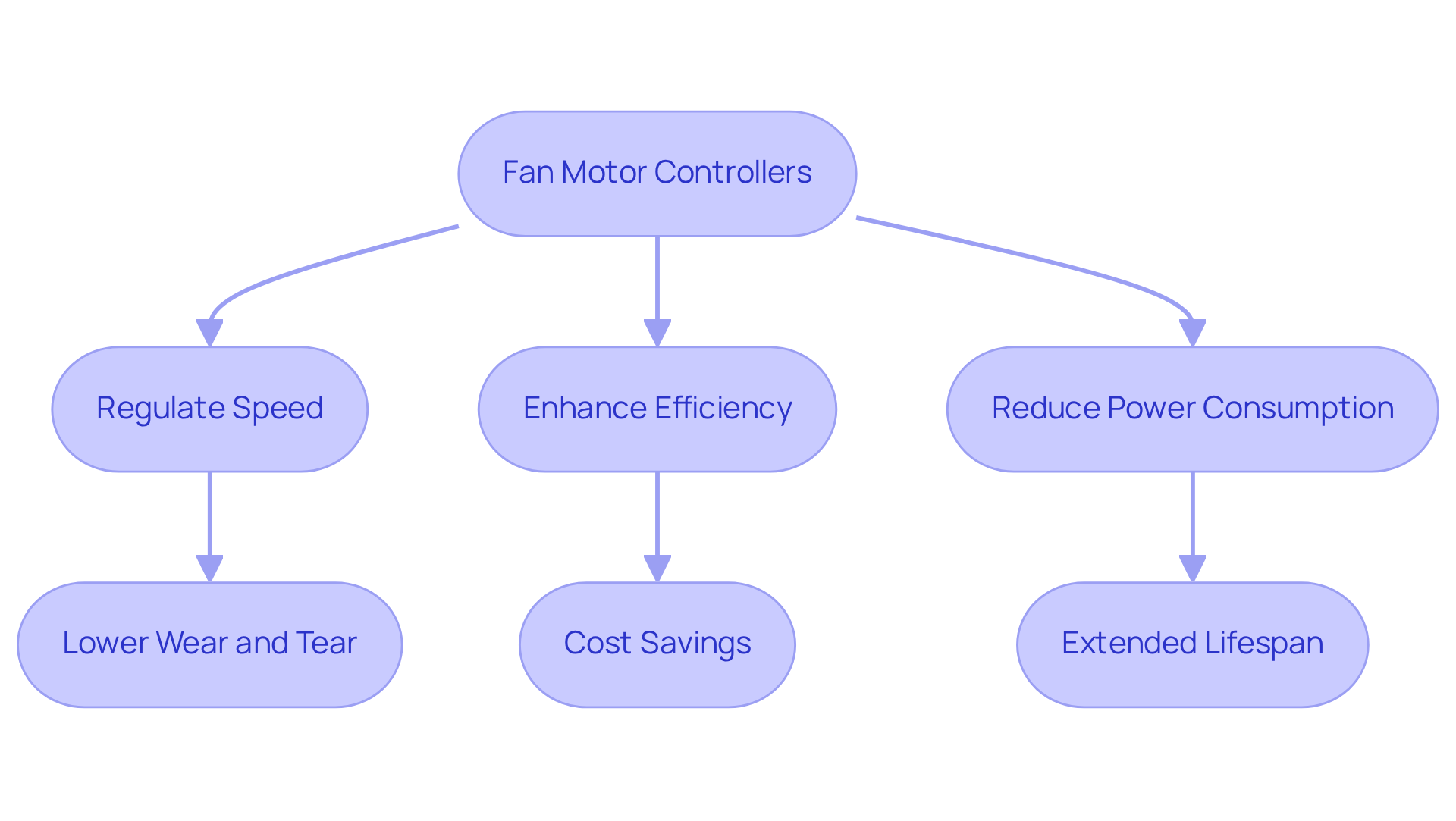

Define Fan Motor Controllers and Their Purpose

The role of fan motor controllers is crucial in regulating the speed and operation of electric fans by adjusting the voltage or frequency supplied to the motor. This precise control over airflow not only enhances efficiency but also significantly reduces power consumption. For instance, reducing a fan’s speed by fifty percent can lower its power usage to as little as one-eighth of its original level, demonstrating the substantial savings achievable through effective fan management.

The primary objective of the fan motor controller and similar devices is to improve performance, cut power costs, and extend the lifespan of fans by minimizing wear and tear on components. In HVAC systems and industrial cooling applications, the fan motor controller is vital for maintaining optimal comfort levels and operational efficiency. By dynamically adjusting the fan motor controller to optimize fan speeds based on thermal requirements, these devices can lead to savings of up to 50% during low-load conditions.

Real-world examples highlight the effectiveness of fan regulators in reducing utility expenses. For example, Sabey Data Centers has successfully implemented strategies that resulted in over a 25% reduction in carbon emissions, underscoring the environmental advantages of advanced fan control technologies. Industry leaders emphasize that integrating PWM fan regulators not only enhances cooling efficiency but also boosts system reliability by preventing overheating and extending the lifespan of electronic components.

The importance of fan motor controllers in energy efficiency cannot be overstated. They represent a critical investment for engineers and facility managers who seek to achieve sustainable operations while maximizing comfort and performance across various environments.

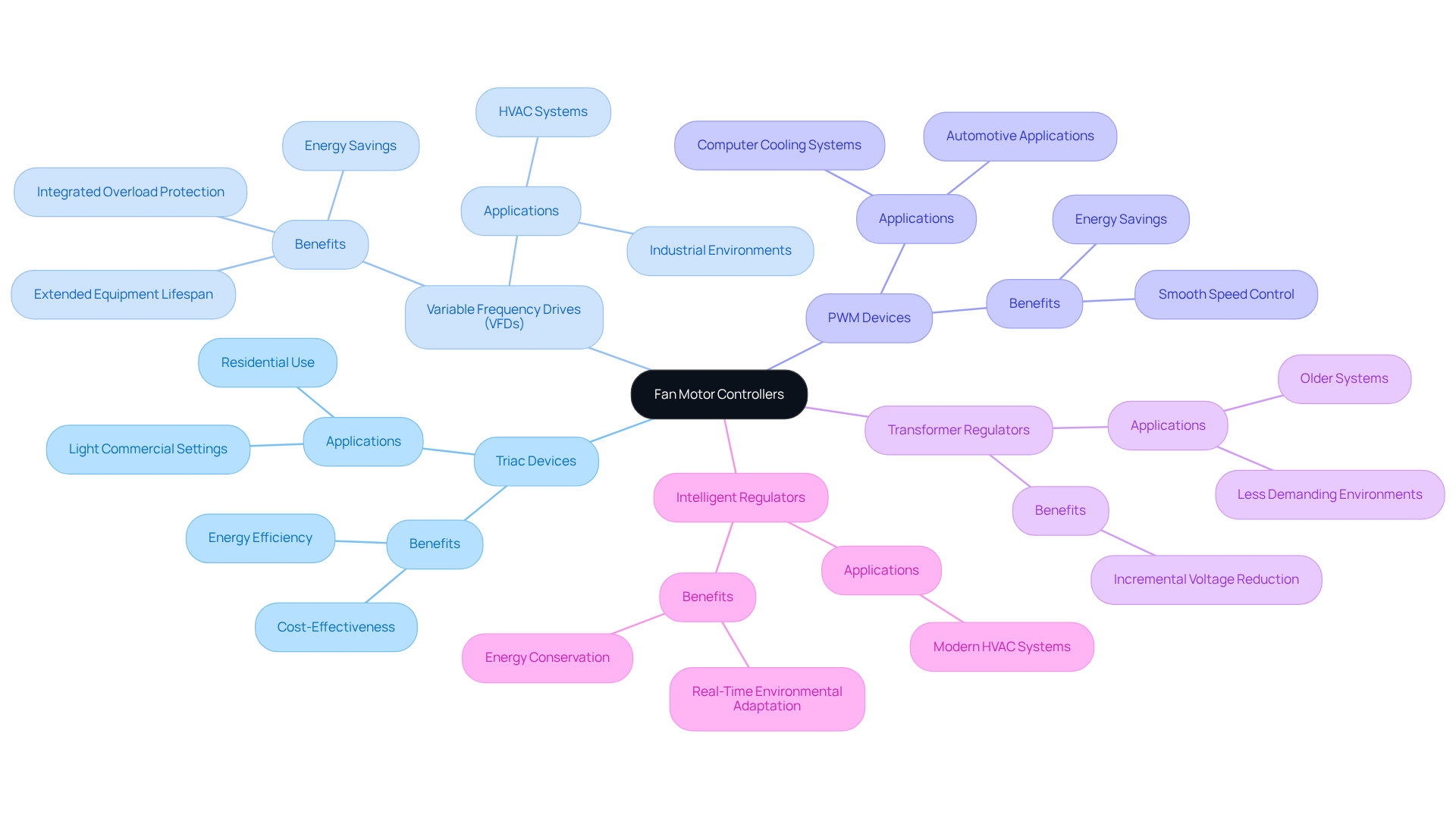

Explore Types of Fan Motor Controllers and Their Applications

Fan motor controllers are essential components in various applications, and they come in several types, each tailored to meet specific needs:

-

Triac Devices: Commonly utilized for AC motors, Triac devices enable variable speed control by adjusting voltage levels. They are particularly suited for residential and light commercial settings, where energy efficiency and cost-effectiveness are paramount. The advantages of the fan motor controller, such as simplicity and affordability, make it a popular choice for many users.

-

Variable Frequency Drives (VFDs): Designed for three-phase motors, VFDs offer precise speed control by varying the frequency of the power supply. Their application is widespread in industrial environments, where they enhance efficiency and performance, significantly reducing energy consumption and operational costs. The variable fan speed regulator market is estimated to be valued at approximately USD 1.2 billion in 2024 and is expected to grow at a CAGR of 8.9% from 2025 to 2033. Fan motor controllers are known to extend equipment lifespan by minimizing mechanical stress during operation, making them invaluable in sectors such as manufacturing and HVAC. As noted by Willis Electrical, “VFDs offer integrated overload protection, which stops engines from operating beyond their safe limits.”

-

The fan motor controller, as a type of PWM device, is effective for DC motors, providing smooth speed control and energy savings. They are frequently employed in computer cooling systems and automotive applications, where precise temperature management is crucial.

-

Transformer Regulators: These devices manage fan speed by reducing voltage in increments, making them suitable for applications where precise speed regulation is less critical. They are often found in older systems or less demanding environments.

-

Intelligent Regulators: Advanced intelligent regulators modify fan speeds according to real-time environmental conditions, such as temperature and humidity. This adaptability makes them ideal for modern HVAC systems, contributing to energy conservation and enhanced comfort.

Each type of device, such as the fan motor controller, offers distinct benefits, underscoring the importance of selecting the appropriate one based on the specific requirements of the application. The growing emphasis on energy-saving solutions and government policies promoting such technologies further highlights the significance of these devices in both residential and industrial settings.

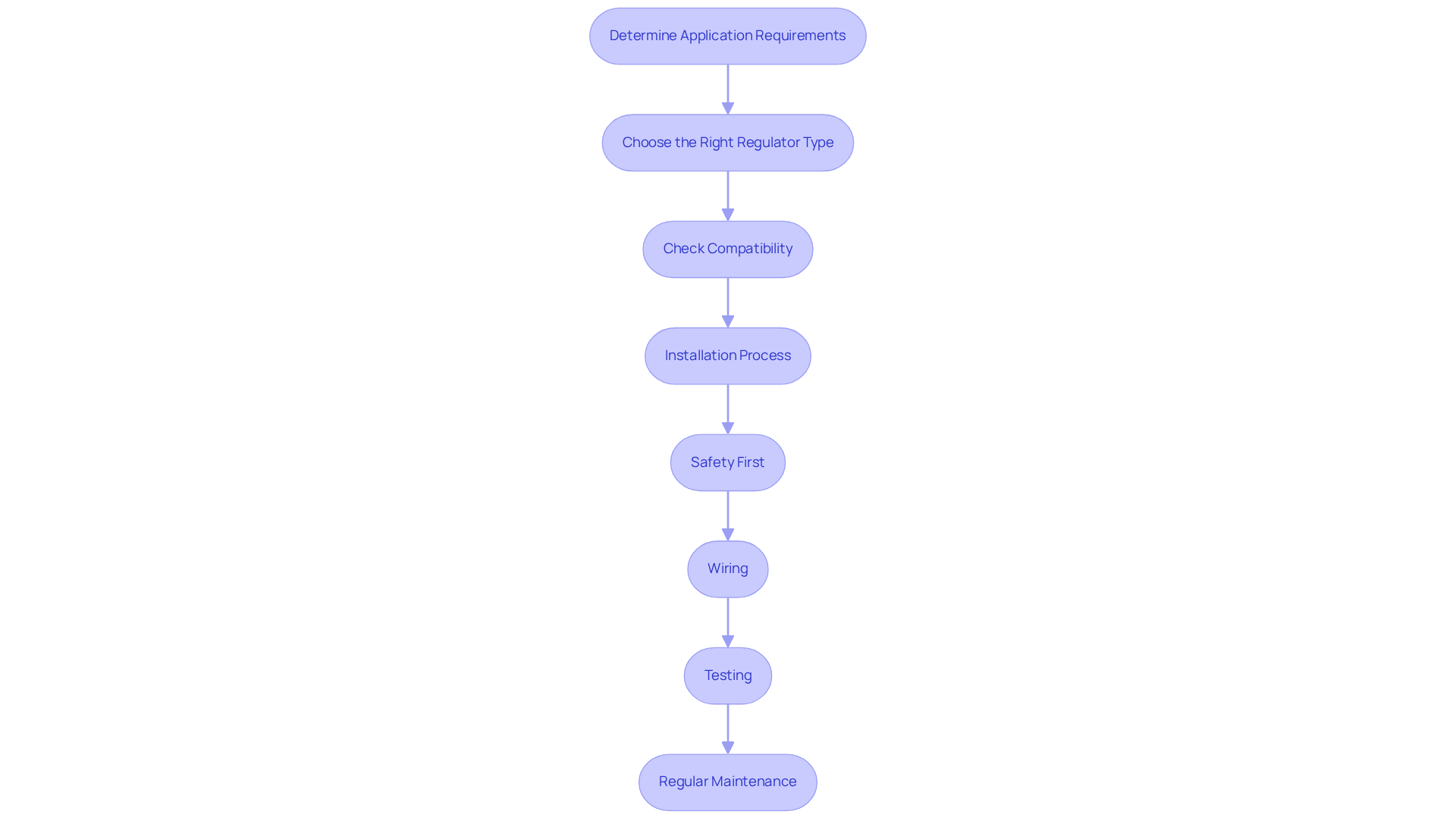

Guide to Selecting and Installing Fan Motor Controllers

When selecting and installing fan motor controllers, it’s crucial to follow these essential steps:

-

Determine Application Requirements: Start by assessing the specific needs of your application. Consider the type of fan, required airflow, and environmental conditions to ensure optimal performance.

-

Choose the Right Regulator Type: Selecting the appropriate regulator type is vital. For instance, variable frequency drives (VFDs) are ideal for industrial applications that demand precise control, while pulse width modulation (PWM) devices are well-suited for DC machines in cooling systems.

-

Check Compatibility: Ensure that the regulator matches the fan specifications, including voltage, current, and type (AC or DC). Compatibility issues can lead to performance inconsistencies; statistics reveal that around 30% of engineers have faced such challenges during installations. Additionally, approximately 30% of engineers have reported performance inconsistencies in PWM systems, underscoring the importance of compatibility with the fan motor controller.

-

Installation Process:

- Safety First: Always disconnect power before installation and adhere to local electrical codes and regulations.

- Wiring: Connect the device according to the manufacturer’s instructions, which typically involve connections for the power supply, fan motor, and control signals.

- Testing: After installation, restore power and evaluate the device to ensure proper operation. Adjust settings as necessary to achieve the desired performance.

-

Regular Maintenance: Periodically inspect the device and fan for signs of wear or malfunction. Regular maintenance of the fan motor controller can prevent issues and extend the equipment’s lifespan.

Case studies in industrial environments have demonstrated that proper installation and compatibility checks significantly enhance system reliability and efficiency. For example, the case study titled “Benefits of PWM Fans” outlines the advantages of PWM technology, including energy efficiency and noise reduction. Engineers emphasize that ensuring compatibility is crucial for optimal performance, as it mitigates the risk of thermal-related failures and extends the lifespan of electronic components.

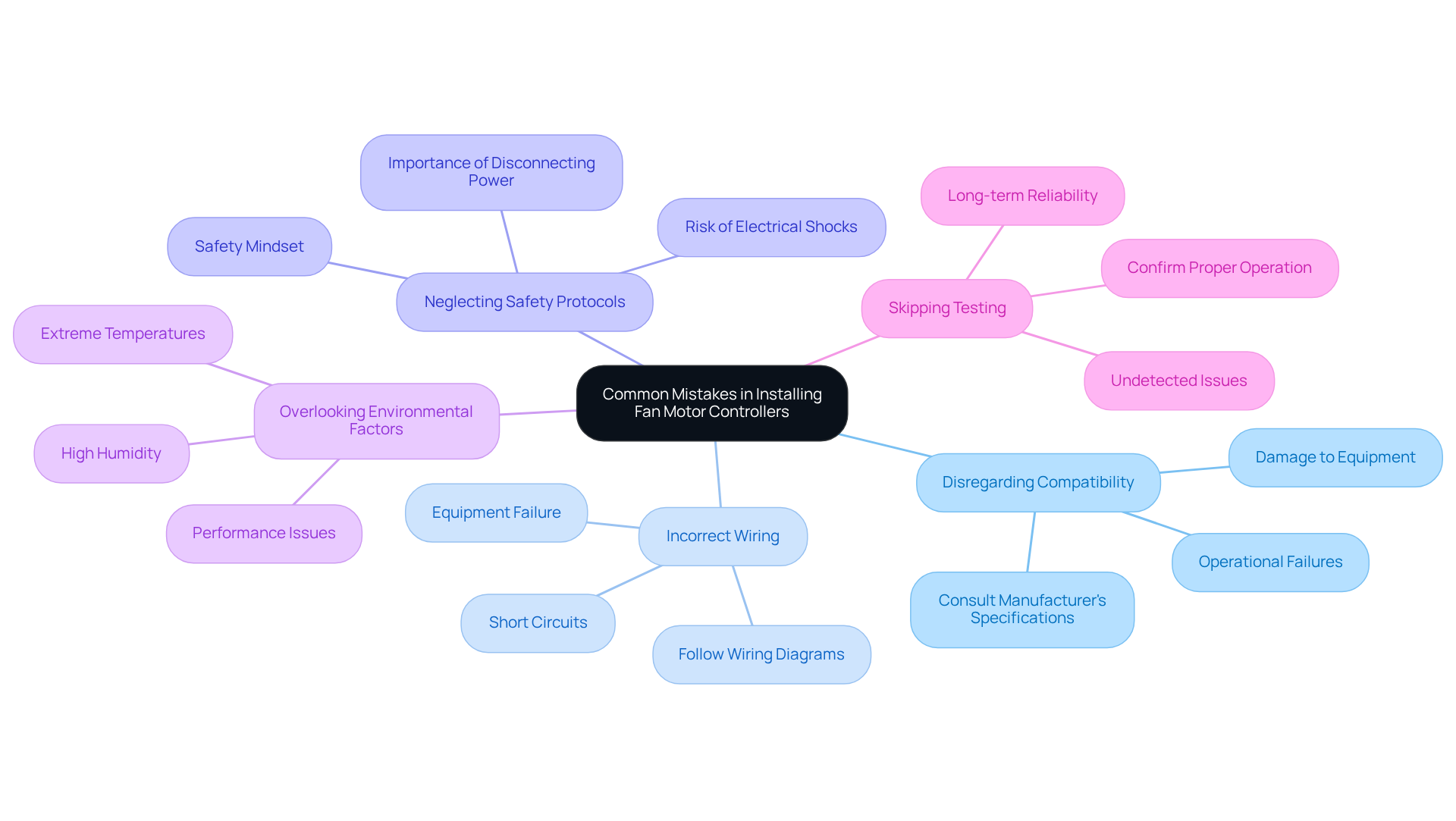

Common Mistakes to Avoid When Installing Fan Motor Controllers

When installing fan motor controllers, avoiding common mistakes is crucial for ensuring safety and optimal performance:

-

Disregarding Compatibility: Confirming compatibility between the device and the fan unit is essential. Neglecting this can lead to operational failures or even damage. Always consult the manufacturer’s specifications to ensure a proper match. Real-world examples illustrate that compatibility failures can result in significant downtime and costly repairs.

-

Incorrect Wiring: Miswiring is a frequent issue that can lead to short circuits or equipment failure. An incorrectly wired relay can cause short circuits, motor damage, and safety hazards. Adhering strictly to the wiring diagram provided by the manufacturer is essential to prevent these problems.

-

Neglecting Safety Protocols: Failing to disconnect power before installation poses significant risks, including electrical shocks. Prioritizing safety by ensuring that all power sources are turned off is non-negotiable. As Rob Long stated, “The real enemy of safety is not non-compliance but non-thinking,” highlighting the need for careful consideration during installation.

-

Overlooking Environmental Factors: Installing devices in extreme temperatures or high humidity can adversely affect their performance. Evaluating the installation environment and selecting a device tailored for those conditions is crucial.

-

Skipping Testing: Failing to test the controller post-installation can leave undetected issues that may compromise functionality. Conducting thorough tests to confirm proper operation before finalizing the installation is essential for long-term reliability.

Engineers emphasize that safety protocols during installation are paramount. As one expert noted, “Safety should never be a priority; it should be a precondition.” This mindset not only protects personnel but also enhances the overall performance of the system. By avoiding these common pitfalls, you can ensure a successful installation that meets both safety standards and operational efficiency.

Conclusion

Fan motor controllers are essential for optimizing the performance and efficiency of electric fans in a variety of applications. By regulating speed and minimizing power consumption, these devices not only boost operational efficiency but also lead to significant energy savings and a longer lifespan for equipment. Understanding the different types of fan motor controllers and their specific applications is crucial for selecting the right device for any environment.

This article explores various types of fan motor controllers, including:

- Triac devices

- Variable Frequency Drives (VFDs)

- PWM controllers

- Transformer regulators

- Intelligent regulators

Each type presents unique advantages tailored to specific needs, whether in residential or industrial settings. Proper selection and installation of these controllers are vital, as outlined in the steps provided and common mistakes to avoid during installation. Emphasizing compatibility, adhering to safety protocols, and conducting thorough testing can significantly enhance reliability and efficiency.

In conclusion, integrating fan motor controllers is not merely a technical necessity; it’s a strategic decision that can yield substantial cost savings and environmental benefits. As industries increasingly prioritize energy efficiency and sustainability, investing in the right fan motor controller becomes more important than ever. Seize the opportunity to enhance system performance and contribute to a greener future by selecting and installing fan motor controllers with care.

Frequently Asked Questions

What are fan motor controllers and what is their purpose?

Fan motor controllers regulate the speed and operation of electric fans by adjusting the voltage or frequency supplied to the motor. Their purpose is to enhance efficiency, reduce power consumption, and extend the lifespan of fans.

How do fan motor controllers improve energy efficiency?

By precisely controlling airflow, fan motor controllers can significantly lower power usage. For example, reducing a fan’s speed by fifty percent can decrease its power consumption to as little as one-eighth of its original level.

What are the primary benefits of using fan motor controllers?

The primary benefits include improved performance, reduced power costs, and extended lifespan of fans by minimizing wear and tear on components.

In what applications are fan motor controllers particularly important?

Fan motor controllers are vital in HVAC systems and industrial cooling applications for maintaining optimal comfort levels and operational efficiency.

How much can fan motor controllers save during low-load conditions?

Fan motor controllers can lead to savings of up to 50% during low-load conditions by dynamically adjusting fan speeds based on thermal requirements.

Can you provide an example of the effectiveness of fan motor controllers?

Sabey Data Centers implemented strategies that resulted in over a 25% reduction in carbon emissions, demonstrating the environmental advantages of advanced fan control technologies.

What additional benefits do PWM fan regulators provide?

PWM fan regulators enhance cooling efficiency, boost system reliability by preventing overheating, and extend the lifespan of electronic components.

Why are fan motor controllers considered a critical investment?

They are a critical investment for engineers and facility managers seeking sustainable operations while maximizing comfort and performance across various environments.