Overview

This article delves into the critical differences between fans configured in series versus those arranged in parallel. Understanding these configurations is essential for optimizing operational efficiency, airflow dynamics, redundancy, energy efficiency, noise levels, maintenance needs, and cost implications.

When considering fan arrangements, the choice between series and parallel configurations can significantly impact performance. Series configurations excel in high-resistance environments, where increased pressure is paramount. In contrast, parallel setups shine in low-resistance situations, where maximizing airflow is crucial. This distinction is vital for engineers tasked with selecting the appropriate fan arrangement tailored to specific application requirements.

By examining these configurations, engineers can make informed decisions that enhance system performance. The article concludes that recognizing the operational context is key to guiding the selection process, ensuring that the chosen fan arrangement aligns with the demands of the application. This knowledge empowers professionals to optimize their systems effectively.

Introduction

Understanding the complexities of fan configurations is essential for engineers focused on optimizing cooling systems. The decision between series and parallel fan setups significantly influences airflow dynamics, energy efficiency, noise levels, and maintenance requirements. As engineers examine these configurations, they encounter a crucial question: how do these arrangements impact overall system performance and operational costs? This article delves into ten key insights that clarify the advantages and challenges of fans in series versus parallel, offering vital guidance for informed decision-making in engineering applications.

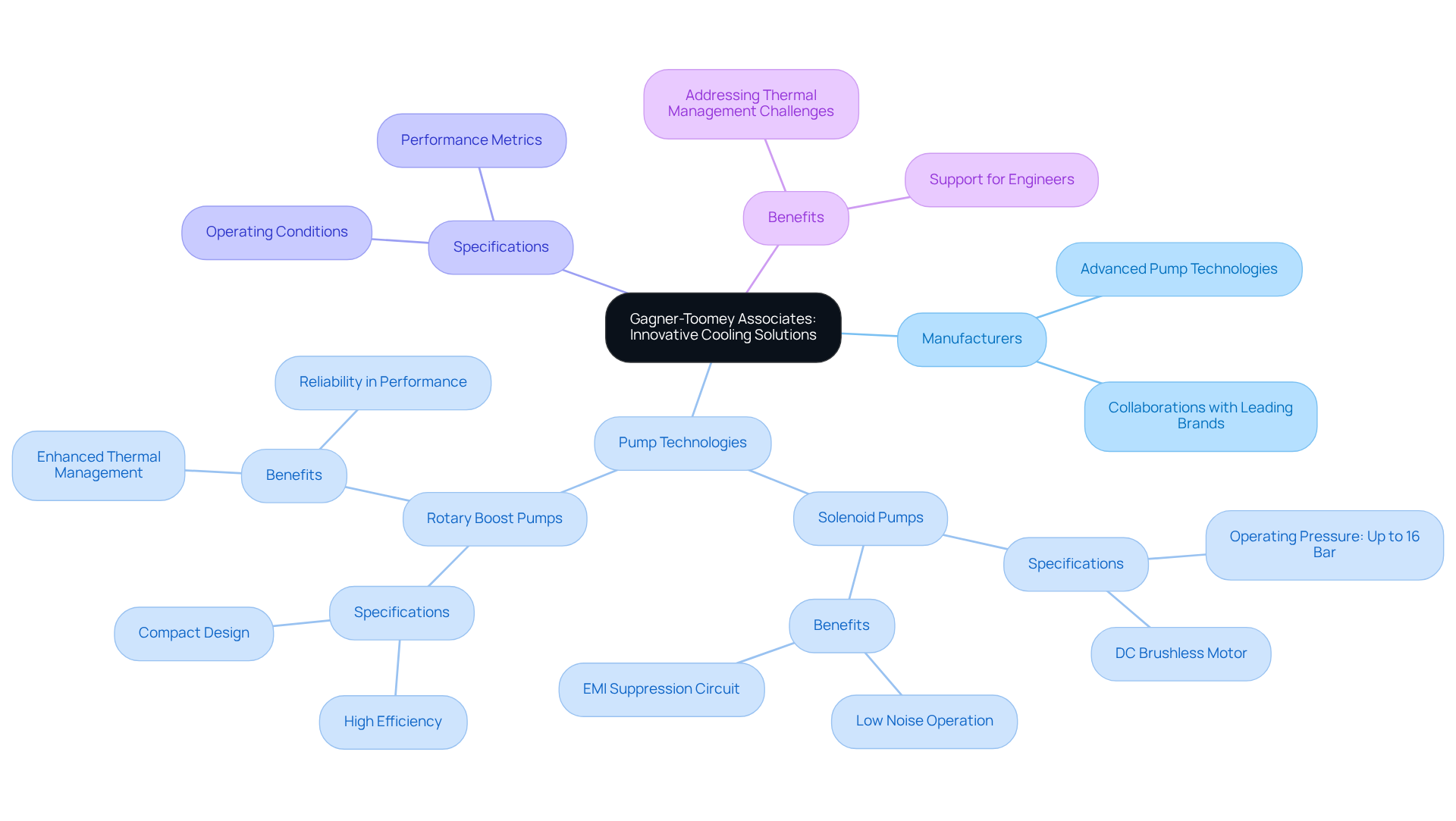

Gagner-Toomey Associates: Innovative Cooling Solutions for Engineers

Gagner-Toomey Associates stands at the forefront of delivering cutting-edge cooling solutions specifically designed for engineers in the electronics sector. The company represents a diverse portfolio of manufacturers, showcasing advanced pump technologies, including solenoid and rotary boost pumps. This ensures that engineers have access to the latest innovations in cooling, power management, and interconnect solutions.

These precision pumps are capable of operating up to 16 Bar and feature a DC brushless motor, EMI suppression circuit, and low noise operation. Such specifications complement Gagner-Toomey’s offerings, effectively addressing complex thermal management challenges. Their unwavering dedication to innovation positions them as a reliable ally for engineers striving to enhance performance in electronic frameworks.

Operational Efficiency: Series vs. Parallel Fan Configurations

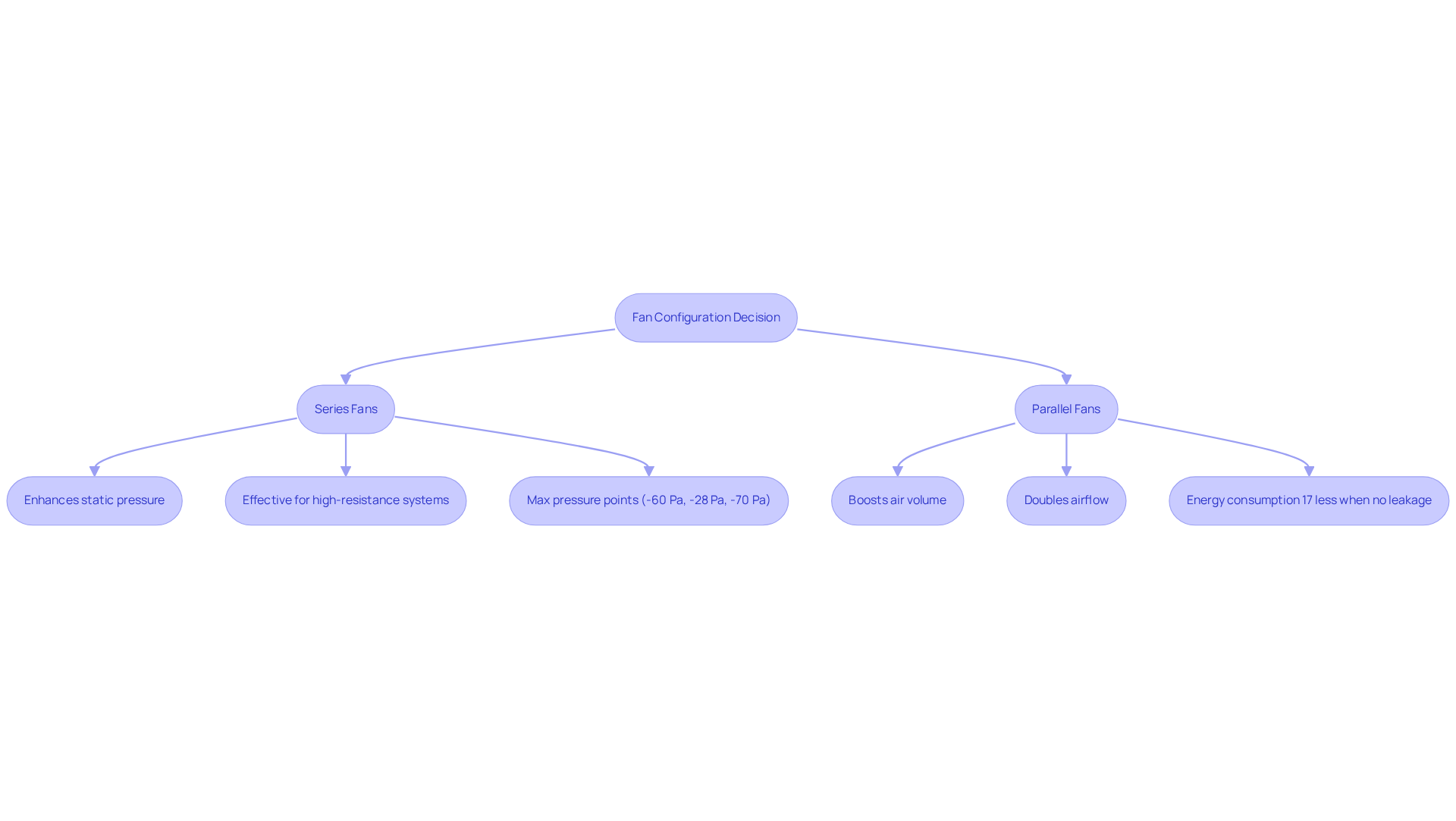

When it comes to operational efficiency, the comparison of fans in series vs parallel setups shows that series fan setups are specifically designed to enhance static pressure, making them particularly effective for high-resistance systems. This configuration allows for increased pressure without necessarily improving ventilation, which is crucial in situations where overcoming resistance is essential. For instance, the highest negative pressure in front of the second fan can reach:

- -60 Pa at 48 m

- -28 Pa at 36 m

- -70 Pa at 60 m

Conversely, parallel arrangements significantly boost air volume, effectively doubling the airflow at a specific pressure level. This characteristic is beneficial in low-resistance setups where the primary goal is to optimize air movement. Engineers must meticulously assess their application requirements, considering factors such as airflow resistance and cooling demands, to determine the best configuration of fans in series vs parallel for optimal performance and efficiency in their cooling systems.

Recent studies reveal that the performance of fans in series vs parallel shows that while series fans excel in high-resistance scenarios, parallel units can outperform in energy consumption under certain conditions, especially when air leakage is minimized. Notably, fans in series vs parallel consume 17% less energy at the parallel terminals when no leakage occurs. Understanding these dynamics is vital for making informed decisions in fan system design.

As highlighted, using fans in series vs parallel will increase pressure n times at a given flow rate, with no additional free delivery flow. Furthermore, it is essential to recognize that air leakage can significantly reduce the airflow from the central air handler, resulting in air bypassing conditioned areas and increasing energy demands.

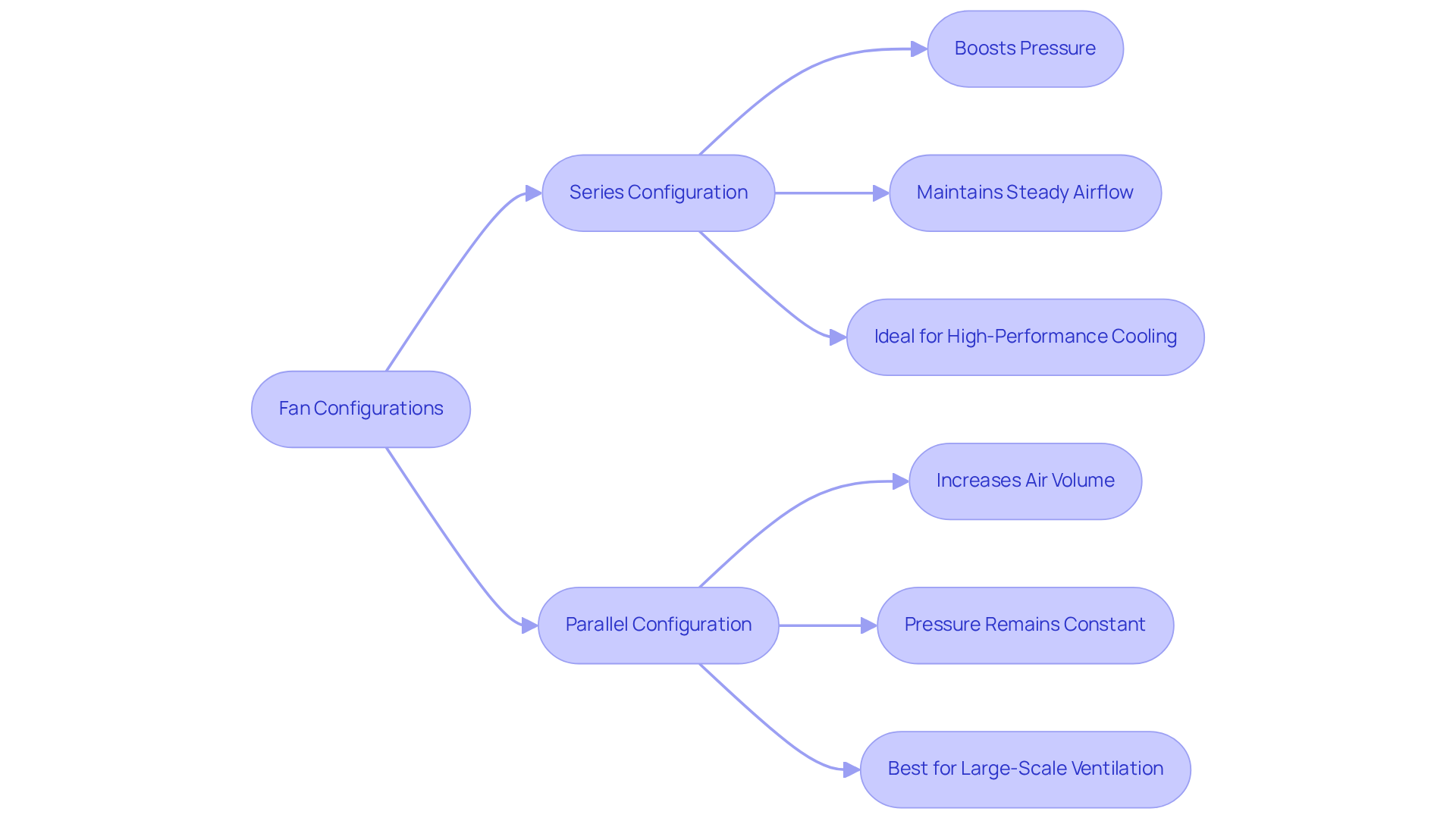

Airflow Dynamics: Understanding Pressure and Volume in Fan Systems

Airflow dynamics in fan mechanisms are fundamentally influenced by the interplay between pressure and volume. In series arrangements, the operation of fans in series vs parallel allows them to work together to boost pressure while maintaining a steady airflow rate. This makes them ideal for applications that require high pressure, such as HVAC systems or industrial processes where overcoming resistance is crucial. For instance, in a cooling system for high-performance electronics, a series setup can effectively push air through restrictive pathways, ensuring adequate cooling. A study indicated that this arrangement can achieve an impressive 83.8% reduction in total thermal resistance compared to other cooling methods, underscoring its effectiveness in thermal management.

On the other hand, the comparison of fans in series vs parallel configurations allows for a significant increase in air volume while keeping pressure relatively constant. This setup is particularly beneficial in scenarios where substantial air movement is essential, like in data centers or large-scale ventilation networks. By distributing the load across multiple fans, engineers can achieve greater airflow without needing additional pressure, thereby enhancing overall efficiency. Experts suggest that the choice regarding fans in series vs parallel setups should be guided by the specific thermal management requirements of the application, ensuring that the selected arrangement can effectively handle the necessary heat loads. Gholam Reza Molaeimanesh noted that hybrid thermal management systems can significantly improve thermal efficiency, which is vital when assessing fan configurations.

Understanding these dynamics is crucial for engineers aiming to optimize heat dissipation through fan configurations. For example, research on parallel-configured heat sinks has shown that maintaining uniform airflow is critical for effective thermal management, as non-uniform flow can lead to hotspots and diminished cooling efficiency. The combination of these insights and statistics emphasizes the importance of making informed decisions in fan design.

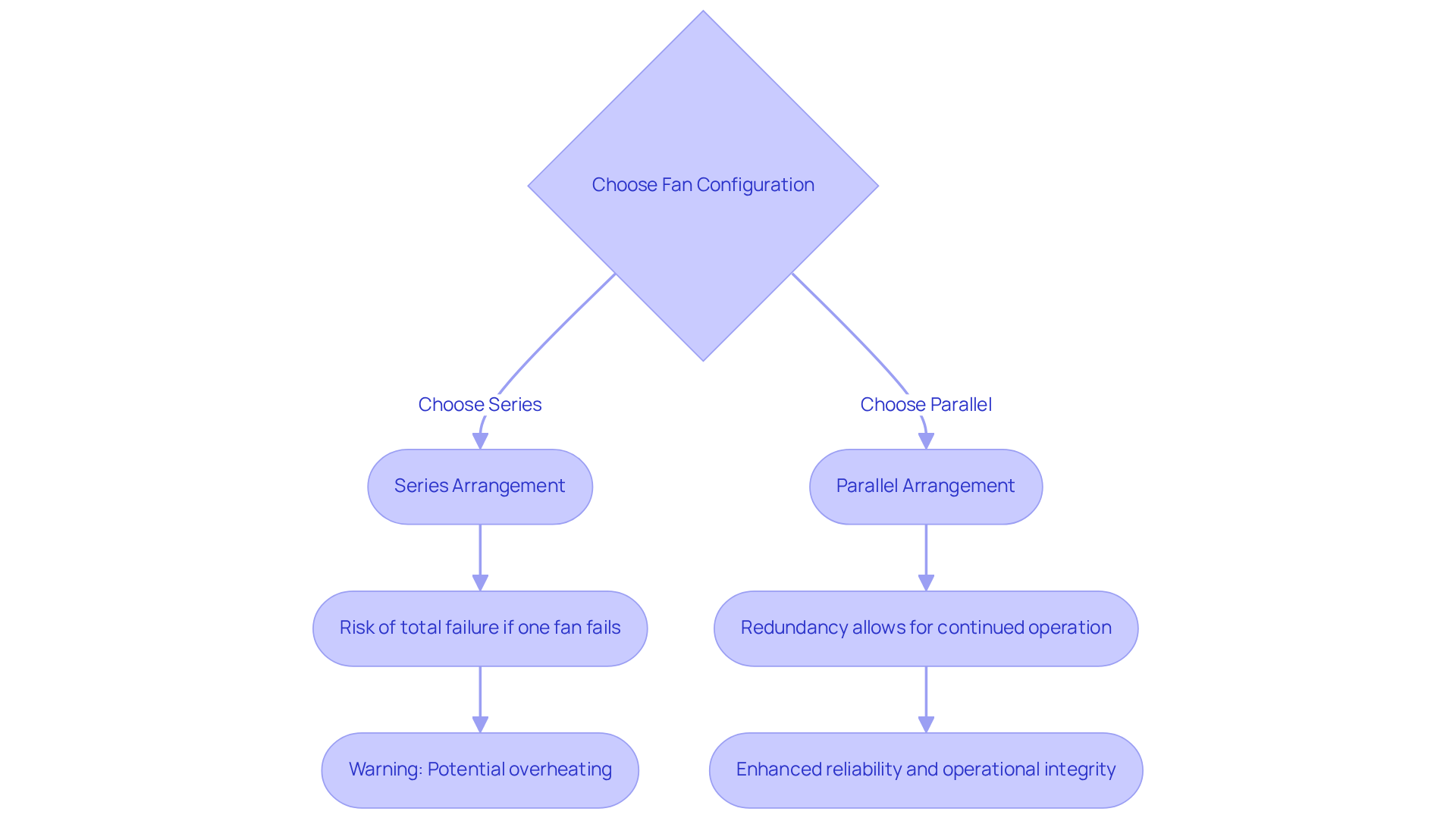

Redundancy and Reliability: Evaluating System Resilience in Fan Configurations

Redundancy in fan configurations is crucial for ensuring the resilience of any setup. When considering fans in series vs parallel arrangements, the parallel setup inherently provides redundancy; if one fan fails, the remaining fans can continue to operate, maintaining airflow and cooling. This design significantly enhances reliability, as evidenced by the successful deployment of parallel fan arrays in various applications, including the IntelliCUBE units. These units not only delivered substantial energy savings but also reduced the likelihood of future fan failures at the New Jersey mall.

In contrast, the arrangement of fans in series vs parallel can introduce risks; the failure of a single fan in a series setup can compromise the entire system’s performance, leading to potential overheating or system shutdowns. Engineers must carefully assess the importance of redundancy against the specific cooling requirements of their applications. For instance, in high-demand environments such as data centers, where cooling is vital, the choice between fans in series vs parallel setups is often preferred to ensure continuous operation.

The reliability of parallel configurations is further supported by industry insights, such as the cooling capacity of CRAH units, which ranges from 20kW to 1 MW. This highlights their effectiveness in maintaining operational integrity, even under challenging conditions. Moreover, the HVAC issues faced at Fox Tower in Portland, where three large plenum fans frequently malfunctioned, underscore the critical need for redundancy in fan setups.

Ultimately, the decision regarding the arrangement of fans in series vs parallel should be guided by a comprehensive understanding of the cooling needs and the desired level of system resilience. By prioritizing redundancy, engineers can enhance the reliability and efficiency of their cooling systems.

Energy Efficiency: Cost-Effective Solutions in Fan Operations

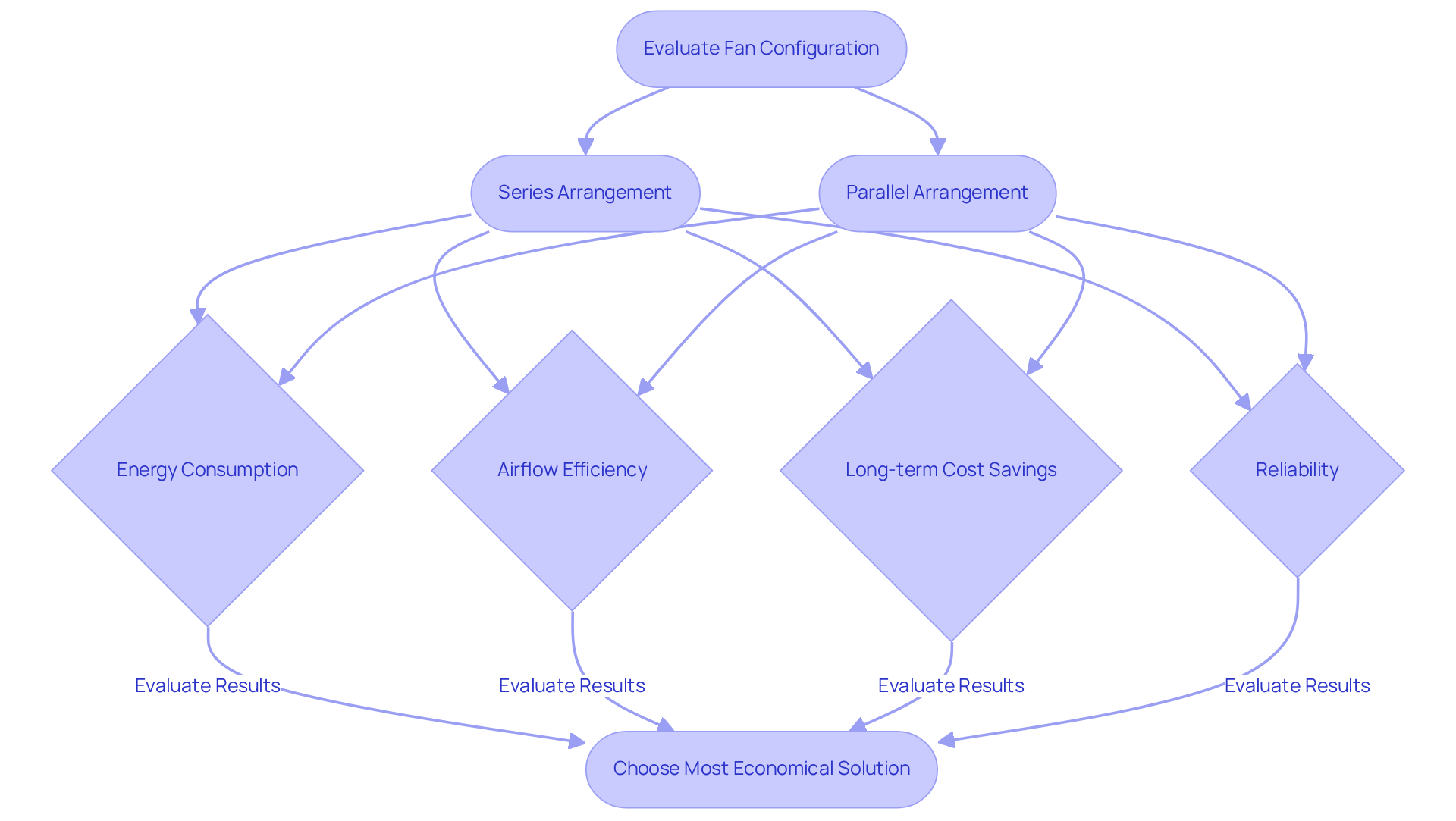

Energy efficiency is crucial in fan operations, particularly in large-scale applications. When comparing fans in series vs parallel arrangements, it is typically found that parallel fan arrangements consume less energy than series systems, as they can maintain the necessary airflow at lower speeds. This not only decreases immediate energy consumption but also results in substantial long-term cost savings. For example, E-JPC fans are relied upon by three of the top four CT scan machine manufacturers, highlighting their reliability and efficiency in demanding environments.

Engineers must carefully evaluate the energy costs associated with fans in series vs parallel configurations to determine the most economical solution for their cooling requirements. By prioritizing energy-efficient fan arrangements, they can enhance operational efficiency while reducing expenses. As Elinco JPC states, “Innovation and long-lasting relationships built on product quality are core tenets of our business,” underscoring the significance of selecting high-quality, efficient products.

Moreover, case studies such as ‘Multi-Fan Setups for Enhanced Cooling’ demonstrate the practical benefits of these configurations, providing real-world context for engineers to consider. By integrating these insights, engineers can make informed decisions that not only optimize performance but also contribute to sustainable practices.

Noise Considerations: Managing Sound Levels in Fan Systems

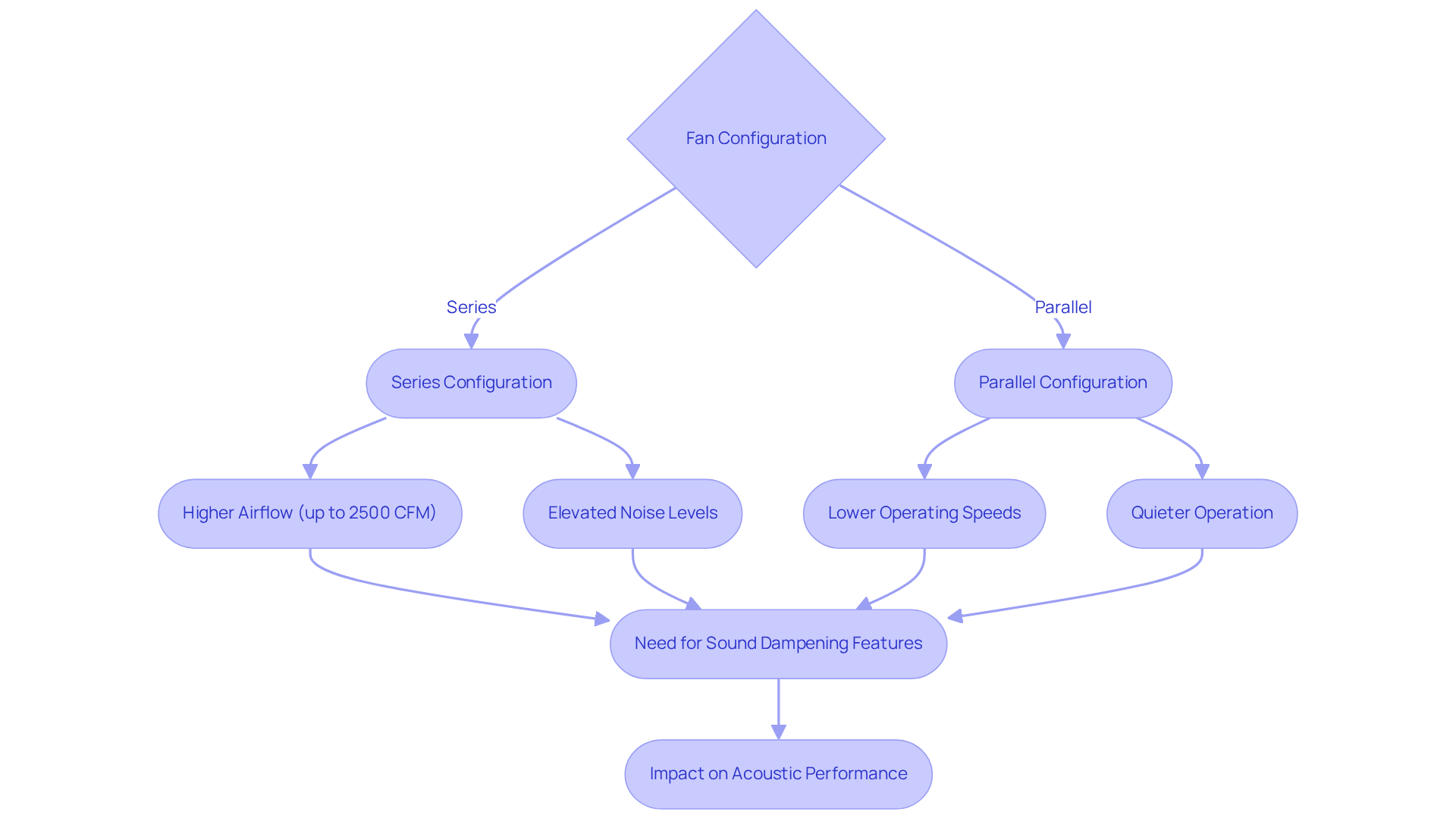

Noise levels in fan systems present a significant challenge, particularly when comparing series and parallel setups. The comparison of fans in series vs parallel shows that series configurations often lead to elevated noise levels due to increased pressure and airspeed, which can pose issues in noise-sensitive environments. For example, while series setups can achieve impressive airflow performance of up to 2500 CFM, this comes at the expense of heightened noise levels.

In contrast, when comparing fans in series vs parallel, the latter typically operates at lower speeds, resulting in a quieter operation. This distinction is crucial for engineers, especially in applications where sound control is paramount. The integration of sound-dampening features, such as the optional integral attenuator and variable-speed ECM fan motors found in VariTrane® VAV Series Fan Powered Terminal Units, can significantly mitigate noise, thereby enhancing overall system performance.

Moreover, the selection of fan arrangement directly influences acoustic performance; series setups may require additional sound-reducing measures to comply with stringent noise standards. Understanding these dynamics empowers engineers to make informed decisions that balance performance with acoustic requirements. Ultimately, this knowledge leads to the creation of more efficient and comfortable environments.

Maintenance Needs: Comparing Upkeep for Series and Parallel Fans

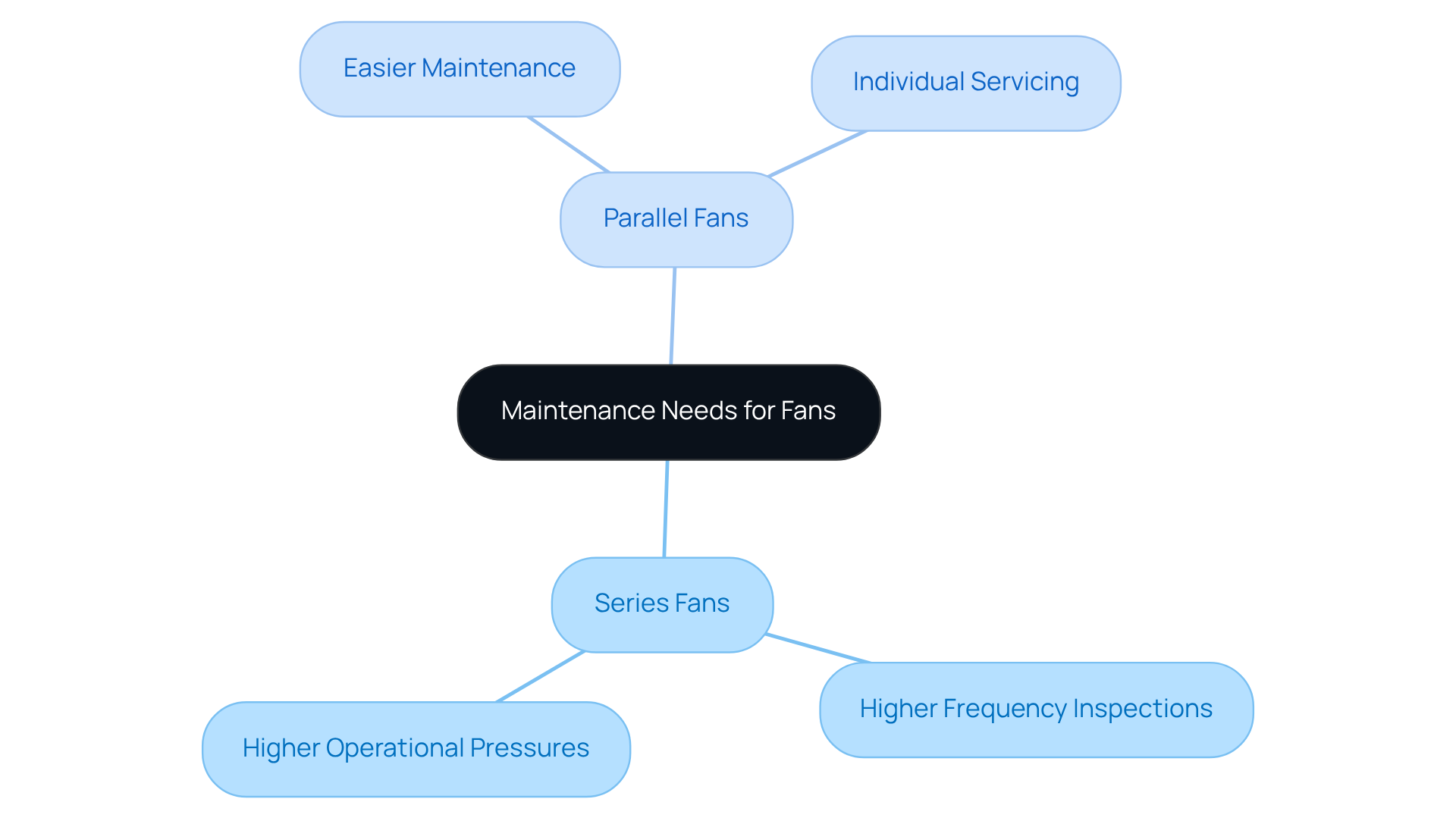

Maintenance needs can vary significantly between fans in series vs parallel setups. The comparison of fans in series vs parallel often shows that series fans necessitate more frequent inspections due to their higher operational pressures. In contrast, when considering fans in series vs parallel, parallel fans tend to be easier to maintain, as they typically allow for individual fan servicing without disrupting the entire system.

To ensure optimal performance, engineers must develop maintenance schedules that align with the specific requirements of their chosen fan configuration. This tailored approach not only enhances reliability but also extends the lifespan of the equipment. By understanding the distinct characteristics of each setup, professionals can implement effective maintenance strategies that mitigate risks and improve operational efficiency.

Cost Analysis: Financial Implications of Fan Configurations

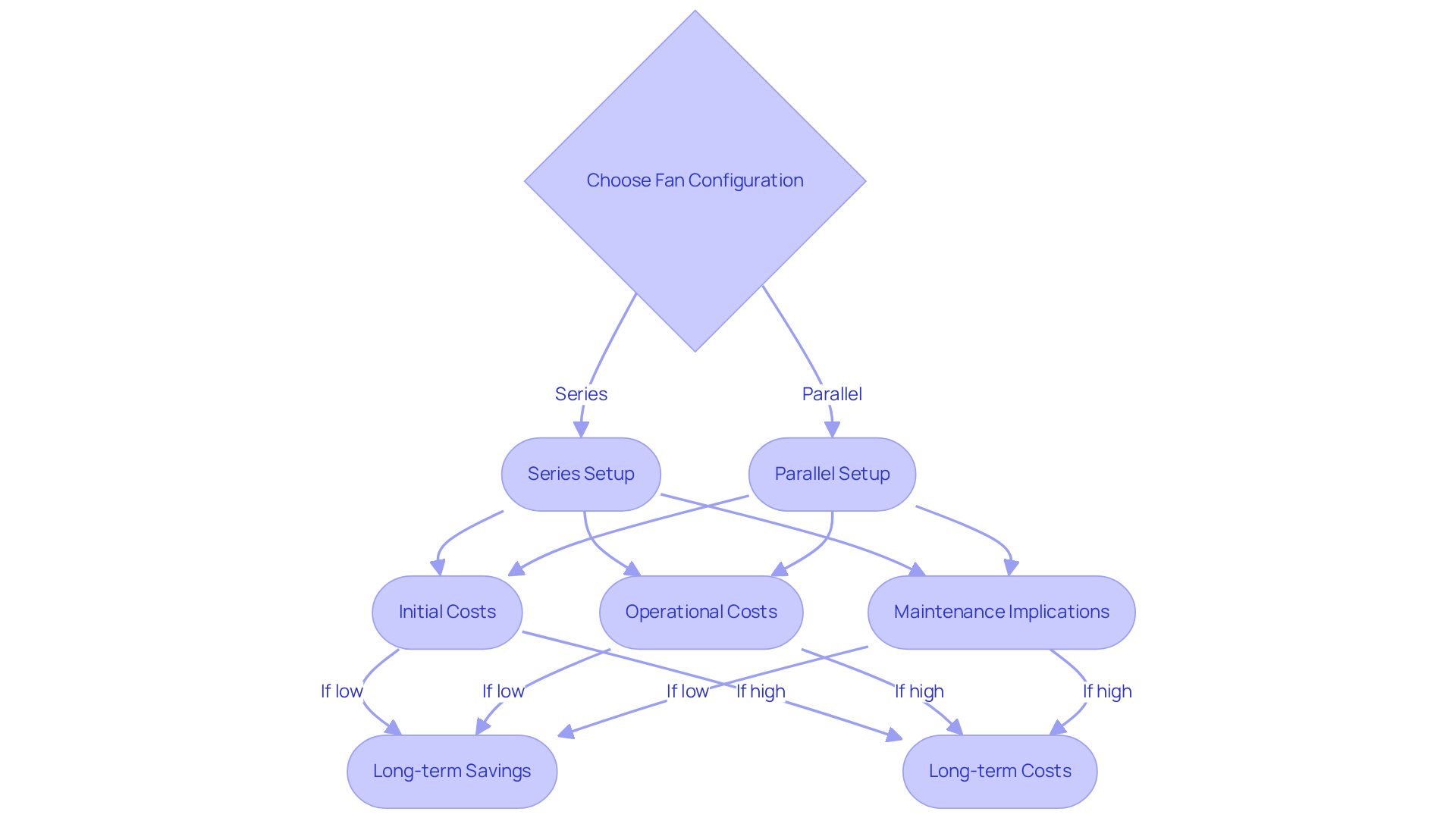

When evaluating the financial implications of fan setups, engineers face a critical decision: balancing initial investments with ongoing operational expenses. The installation of parallel fan setups can be complicated and often requires a higher upfront investment due to the considerations of fans in series vs parallel and the need for multiple fans. Yet, these setups typically yield significant long-term savings through reduced energy consumption and lower maintenance costs.

For instance, while a series setup may present a more economical installation option, the decision between fans in series vs parallel can lead to escalating operational costs over time due to increased energy demands and maintenance requirements. As Nailor Sales Representatives emphasize, “Choosing the right terminal unit for your application can have a major impact on occupant comfort.”

A comprehensive cost-benefit assessment is essential for navigating these trade-offs effectively. This ensures that the chosen arrangement aligns with both budgetary constraints and performance expectations. Understanding these financial dynamics is crucial for enhancing efficiency and occupant comfort in electronic applications.

Application Scenarios: Choosing Between Series and Parallel Fans

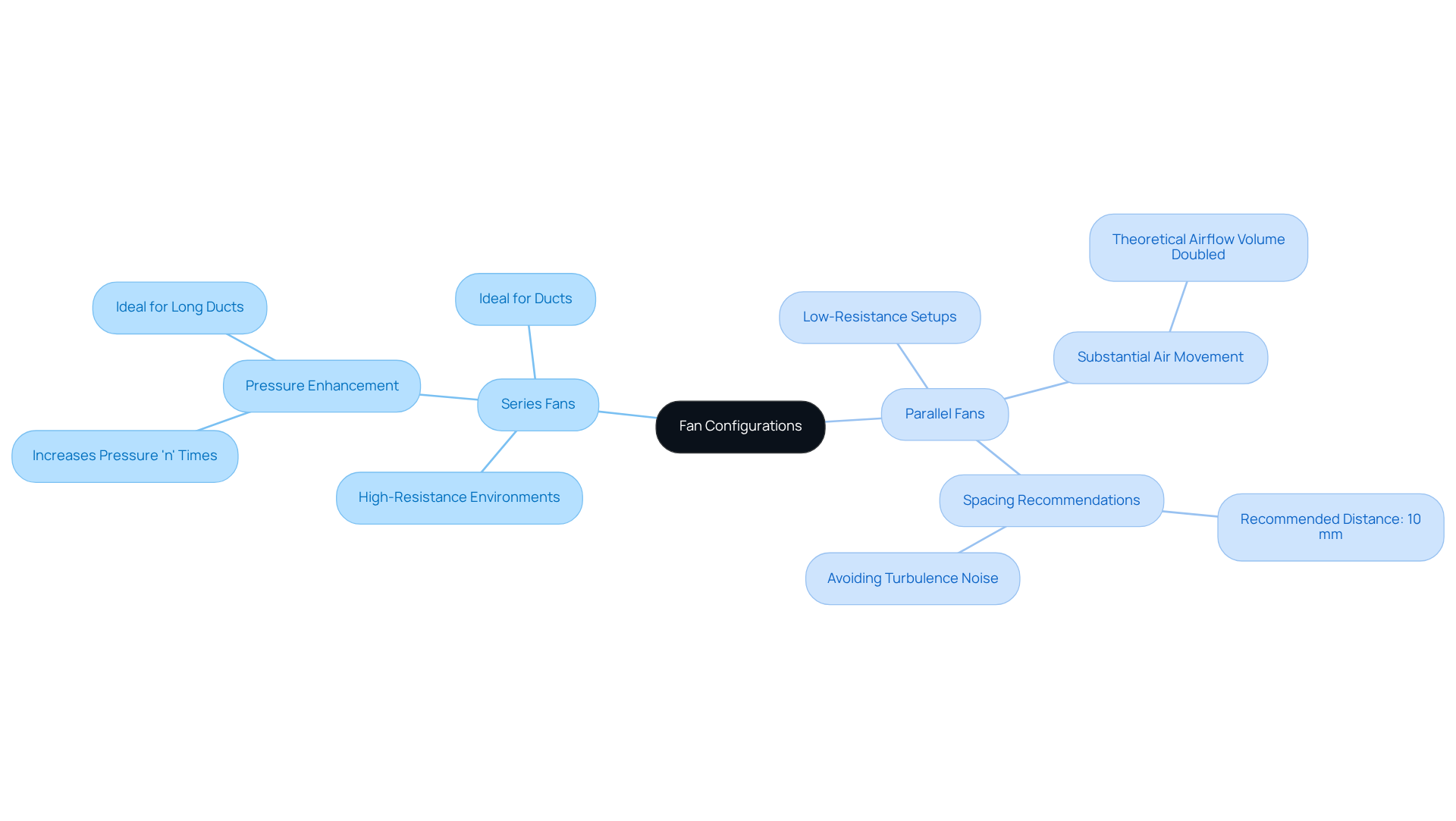

When it comes to fan setups, engineers often face a critical choice regarding fans in series vs parallel configurations. Each option offers distinct advantages tailored to specific requirements. Series setups excel in high-resistance environments, such as HVAC systems, where overcoming ductwork pressure is paramount. By employing ‘n’ blowers in series, pressure can be enhanced ‘n’ times at a given flow rate, making this arrangement ideal for lengthy ducts or systems experiencing significant pressure drops.

Conversely, parallel units shine in scenarios demanding substantial air movement, such as data centers or large industrial spaces. In these cases, the overall air volume can theoretically double compared to a single unit. In low-resistance setups, utilizing multiple fans in series vs parallel significantly boosts air movement without generating additional shut-off pressure, making it a preferred choice for applications like ventilation and fume extraction.

Engineers must meticulously assess their project requirements, considering factors such as airflow needs, resistance, and noise levels. It’s crucial to recognize that positioning fans too closely together in parallel operation can lead to increased turbulence noise. To optimize performance, a recommended spacing of about 10 mm between fans should be maintained.

For effective operation, engineers should also heed insights from industry authorities like Greenheck, who emphasize the importance of proper fan setup in achieving desired system performance. By carefully evaluating these factors, engineers can ensure their fan configurations meet the specific demands of their applications.

Key Takeaways: Essential Differences Between Series and Parallel Fans

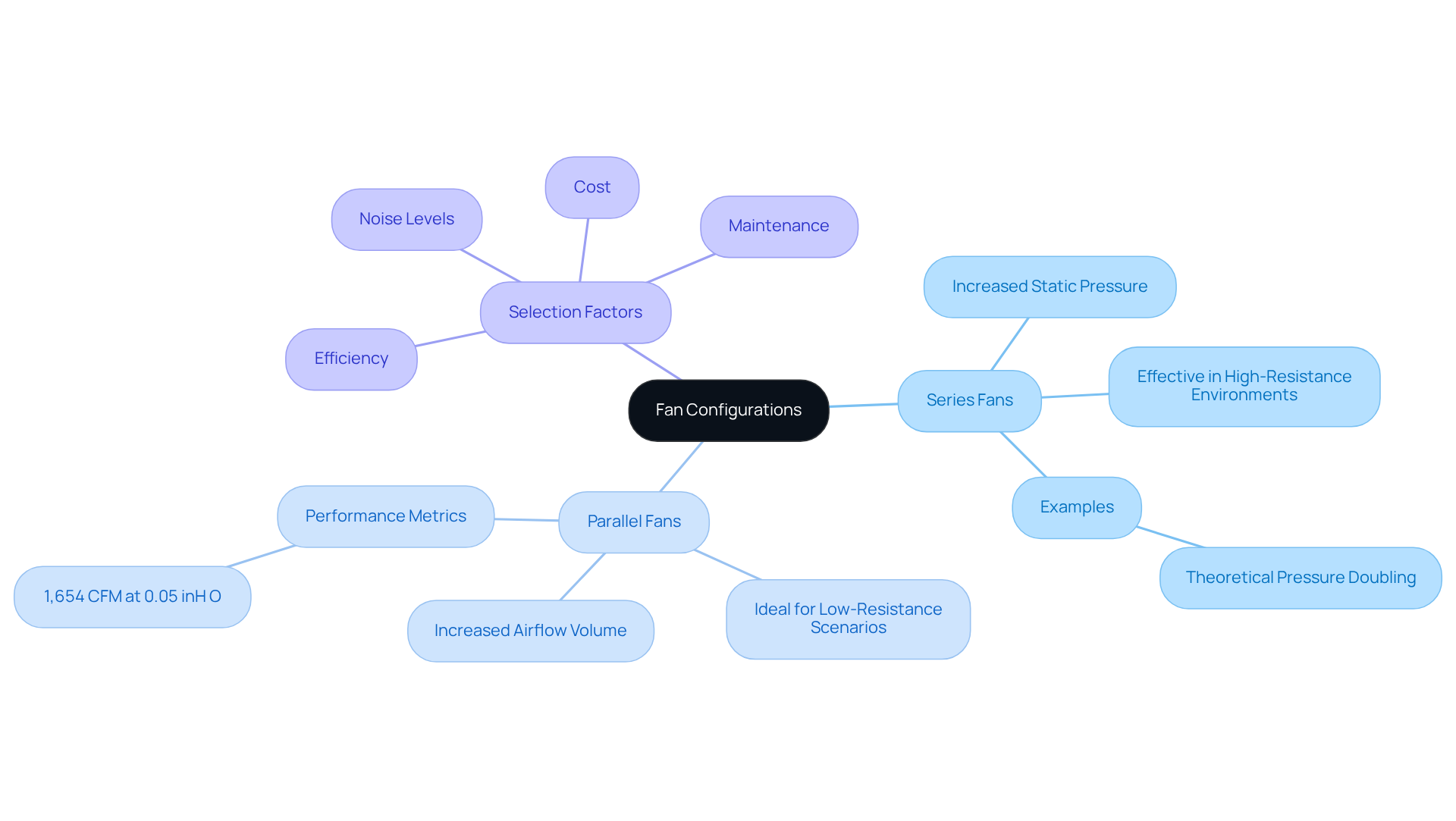

The operational characteristics of fans in series vs parallel configurations offer distinct advantages tailored to specific applications. Series devices are designed to enhance static pressure while maintaining air movement, making them particularly effective in high-resistance environments. For instance, the static pressure in a series configuration can theoretically reach double that of a single fan, which is crucial for systems that must overcome significant resistance to airflow, thereby ensuring optimal performance in demanding conditions.

Conversely, parallel units focus on increasing airflow volume without compromising pressure, making them ideal for low-resistance scenarios. A typical 12-inch fan can achieve approximately 1,654 CFM at 0.05 inH O static pressure, showcasing the potential for enhanced air circulation in applications where cooling efficiency is critical.

When selecting the appropriate fan configuration, engineers must consider several factors, including:

- Efficiency

- Noise levels

- Maintenance requirements

- Overall cost

As noted, “When two fans are installed after each other in a row and the same air passes through both of them, they are acting in series.” Understanding these dynamics empowers engineers to make informed decisions regarding the use of fans in series vs parallel, thereby enhancing the reliability and effectiveness of their cooling systems.

Conclusion

Understanding the intricacies of fan configurations in engineering is crucial for optimizing thermal management systems. The choice between fans in series and parallel presents distinct advantages tailored to specific operational needs. Series configurations shine in high-resistance environments by boosting static pressure, while parallel setups prioritize maximizing airflow volume. Each configuration serves different applications effectively.

Key insights throughout this article underscore the necessity of evaluating factors such as:

- Energy efficiency

- Maintenance requirements

- Noise levels

- Overall cost

when selecting the right fan arrangement. Engineers must thoroughly assess their project specifications to identify the configuration that best meets their cooling demands and operational goals.

Ultimately, the decision between series and parallel fans can profoundly influence system performance, energy consumption, and maintenance efficiency. By leveraging these insights, engineers can make informed choices that enhance the reliability and effectiveness of their cooling systems while also promoting sustainable practices in the electronics sector. Embracing these principles ensures that innovative cooling solutions address the evolving challenges of modern engineering.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative cooling solutions for engineers in the electronics sector, offering advanced pump technologies, including solenoid and rotary boost pumps.

What are the capabilities of the precision pumps offered by Gagner-Toomey Associates?

The precision pumps can operate up to 16 Bar and feature a DC brushless motor, EMI suppression circuit, and low noise operation, effectively addressing complex thermal management challenges.

How do series fan configurations differ from parallel fan configurations in terms of operational efficiency?

Series fan configurations enhance static pressure, making them effective for high-resistance systems, while parallel arrangements boost air volume, effectively doubling airflow at a specific pressure level, which is beneficial in low-resistance setups.

What are the energy consumption differences between series and parallel fan configurations?

Series fans excel in high-resistance scenarios, but parallel units can outperform in energy consumption under certain conditions, consuming 17% less energy at the parallel terminals when no leakage occurs.

How does airflow dynamics relate to pressure and volume in fan systems?

In series arrangements, fans boost pressure while maintaining a steady airflow rate, ideal for applications requiring high pressure. Conversely, parallel configurations increase air volume while keeping pressure relatively constant, beneficial for substantial air movement.

What is the significance of maintaining uniform airflow in thermal management?

Maintaining uniform airflow is critical for effective thermal management, as non-uniform flow can lead to hotspots and diminished cooling efficiency, particularly in parallel-configured heat sinks.

What should engineers consider when choosing between series and parallel fan configurations?

Engineers should assess their application requirements, including airflow resistance and cooling demands, to determine the best fan configuration for optimal performance and efficiency in their cooling systems.