Overview

This article delves into the essential practices for electronics engineers aiming to master fan technologies. Selecting the right fan types and integrating them seamlessly into electronic designs is crucial. Engineers face the challenge of optimizing cooling solutions while ensuring compliance with industry standards. To address this, we explore various fan types and their functions, highlighting critical factors such as airflow, noise levels, and energy efficiency.

Understanding these elements is vital for engineers to make informed decisions. For instance, airflow directly impacts cooling performance, while noise levels can affect user experience. Energy efficiency is not just a regulatory requirement; it also contributes to the overall sustainability of electronic designs. By considering these factors, engineers can enhance their designs and meet industry expectations.

In conclusion, mastering fan technologies involves a strategic approach to fan selection and integration. By focusing on airflow, noise, and energy efficiency, engineers can optimize their cooling solutions effectively. This knowledge empowers engineers to create innovative designs that stand out in the competitive electronics landscape.

Introduction

In the fast-paced realm of electronics, effective thermal management stands as a critical factor in ensuring device performance and longevity. Engineers face the challenge of navigating a complex landscape of fan technologies, each presenting unique advantages tailored to specific applications. With a multitude of options at their disposal, how can they identify the best practices for selecting and integrating these cooling solutions? This article explores essential strategies that electronics engineers can adopt to master fan technologies, optimize cooling efficiency, and enhance overall system reliability.

Understand Fan Technologies: Types and Functions

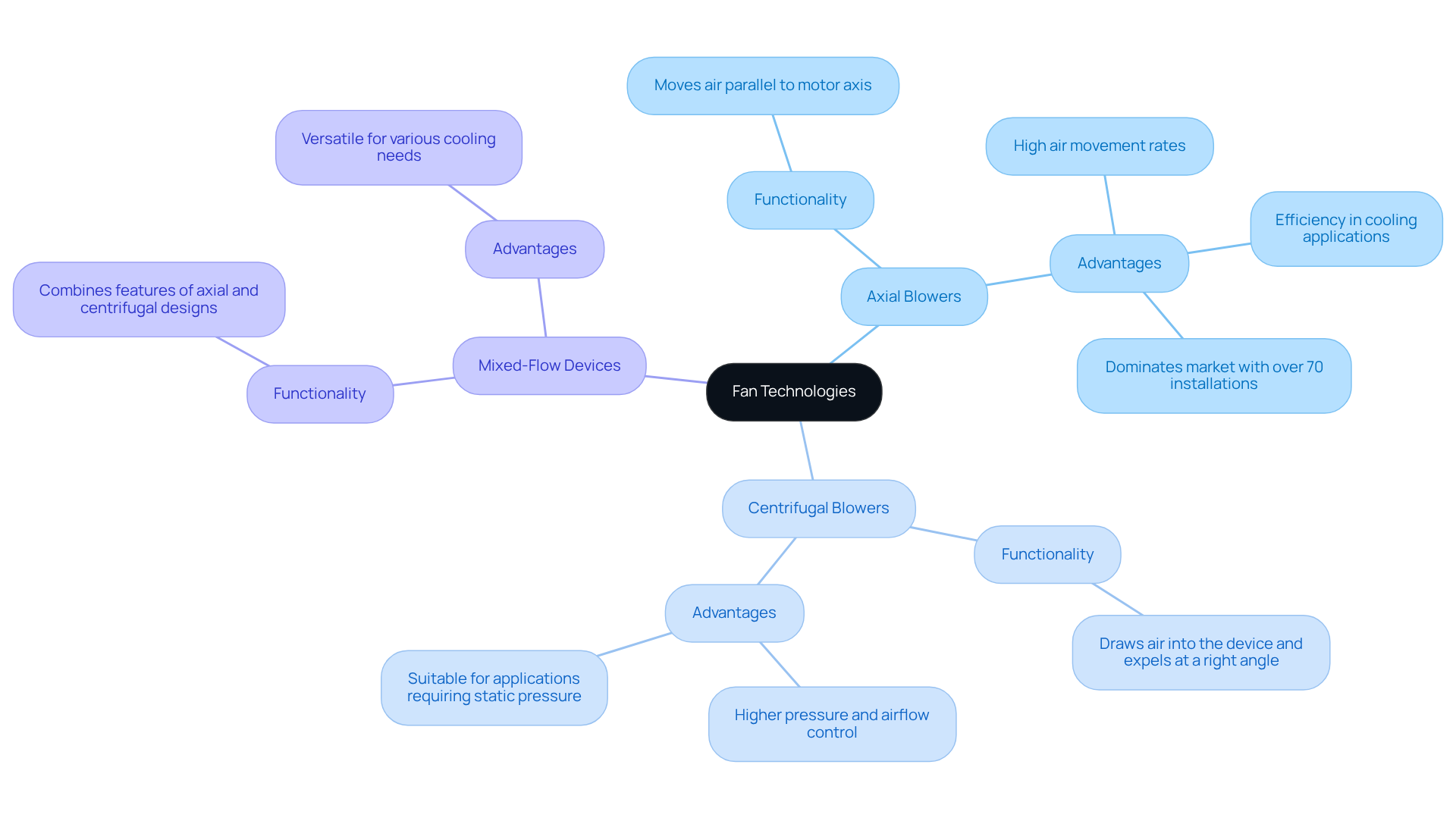

In the electronics sector, cooling devices are primarily classified into three categories: axial, centrifugal, and mixed-flow. Axial blowers are engineered to move air parallel to the motor axis, making them ideal for cooling applications due to their ability to deliver high air movement rates efficiently. Centrifugal blowers, on the other hand, draw air into the device and expel it at a right angle, which is particularly advantageous for applications requiring higher pressure and airflow control. Mixed-flow devices combine features from both axial and centrifugal designs, providing versatility for various cooling needs.

Gagner-Toomey Associates stands out as the world’s largest producer of standard and custom air-movers, offering an extensive product line of DC input tube axial units (sizes from 15 – 280mm) and centrifugal blowers (sizes from 15 – 225mm) optimized for performance, efficiency, and low noise. Understanding these fan little types is crucial for engineers who aim to optimize airflow and cooling efficiency tailored to specific design requirements. For instance, axial blowers dominate the market for electronics cooling applications, representing over 70% of installations due to their efficiency in managing heat in consumer electronics and IT equipment.

When selecting ventilators, engineers must also consider additional factors such as noise levels, energy efficiency, and physical dimensions. In consumer electronics, fan little noise is particularly important, as sound levels can significantly impact user experience, while high-efficiency fans are preferred in energy-sensitive applications. Furthermore, many models offer IP protection upon request, enhancing their suitability for diverse environments. Gagner-Toomey’s extensive portfolio, which includes miniature blower solutions and integrated cooling systems, empowers professionals to stay informed about the latest trends in fan technologies, including advancements in IoT integration and noise-reduction features. This knowledge enables informed decisions that enhance product performance and reliability.

Select Appropriate Fan Technologies for Specific Applications

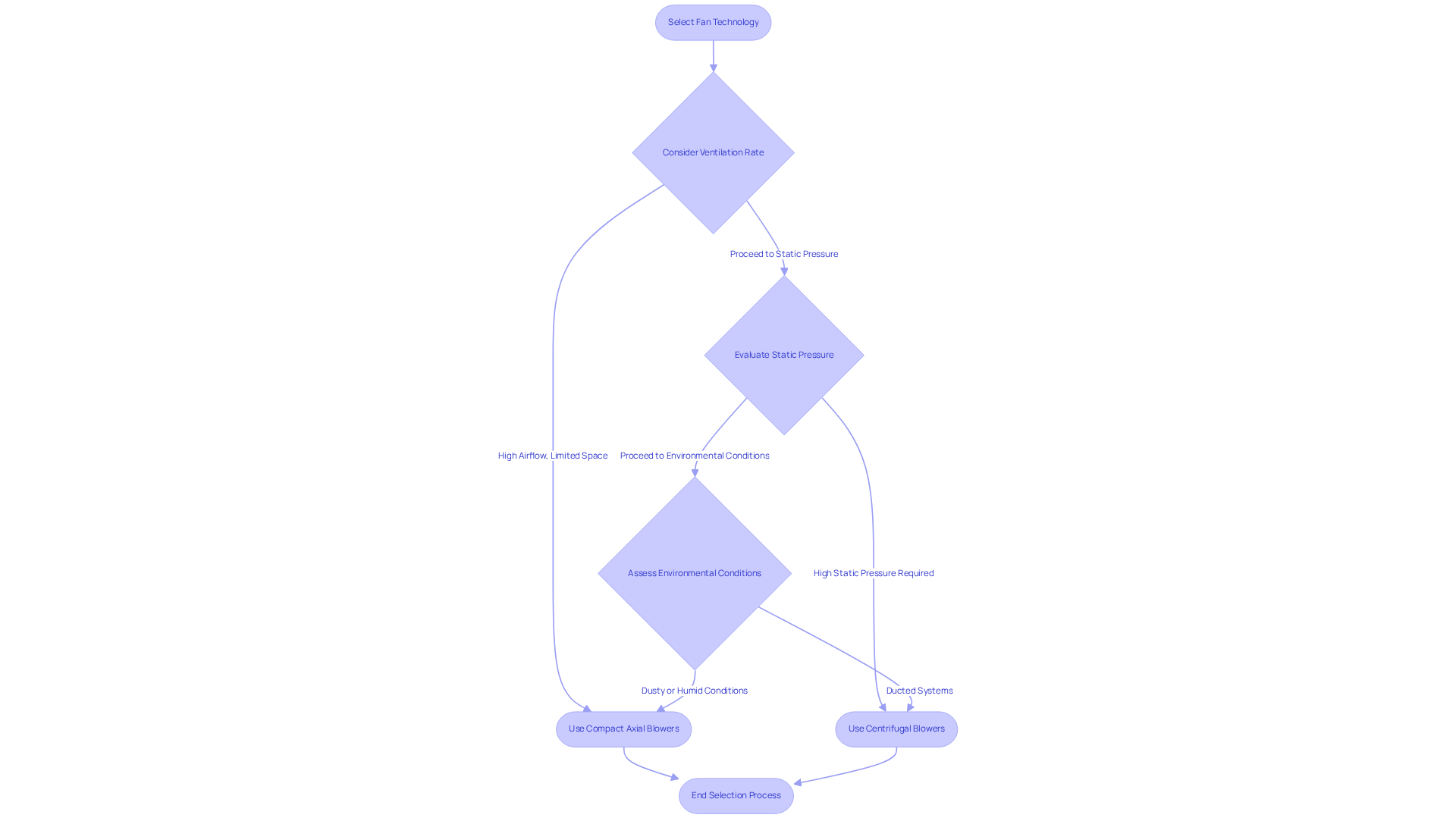

Selecting the right fan little technology is crucial for engineers who aim to meet the specific demands of their applications. Key factors such as ventilation rate, static pressure, and environmental conditions significantly influence this decision. For instance, in high-density electronic setups where space is often limited, compact axial blowers are frequently favored due to their ability to deliver high airflow efficiently. Conversely, applications that require elevated static pressure, particularly in ducted systems, typically benefit from centrifugal blowers, which excel in these scenarios.

Engineers must also consider the operational environment. Fans operating in dusty or humid conditions may require additional protective features or specialized designs to enhance reliability and prevent premature failure. As highlighted by Plasticair Environmental, when selecting an FRP fan, it’s essential to evaluate factors such as the type and concentration of chemicals in the air, required airflow, and operating temperatures.

The integration of fan little selection software has gained traction among electronics specialists, facilitating a systematic evaluation of various fan options based on performance metrics and specific application requirements. This method ensures that the chosen fan technology not only addresses immediate cooling needs but also aligns with broader system design objectives. Ultimately, this contributes to improved efficiency and reliability in electronic systems. Current trends indicate that utilizing such software can lead to better assessments of facility needs and ventilation solutions, empowering engineers to make informed decisions that enhance operational performance.

Integrate Fan Technologies Effectively in Electronics Design

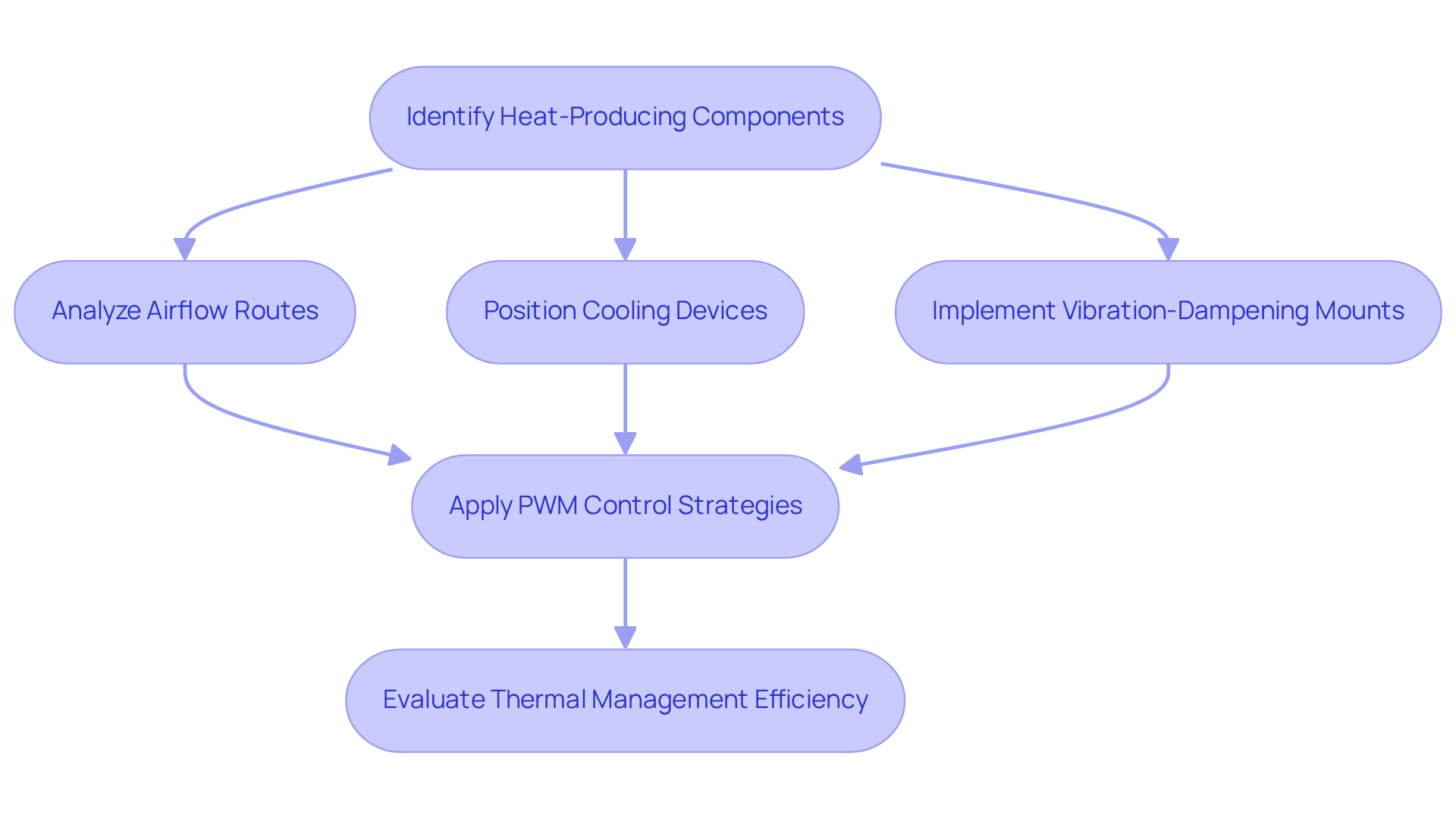

Incorporating little fan technologies into electronic designs is crucial for effective thermal management. Engineers face the challenge of ensuring proper ventilation routes, component positioning, and cooling strategies. By strategically placing fan little devices to allow unobstructed airflow to critical components, they can significantly enhance cooling efficiency. For example, positioning cooling devices near heat-producing parts can greatly improve heat dissipation, which is essential for preventing overheating and ensuring a fan little reliability.

The orientation and mounting techniques of ventilators also play a significant role in minimizing vibration and noise. Employing vibration-dampening mounts can lead to a substantial reduction in operational noise—an important factor in consumer electronics where acoustic comfort is vital. Industry specialists emphasize that optimizing airflow paths, particularly in fan little setups, is essential for achieving effective thermal management in electronic devices.

Advanced control strategies, such as pulse width modulation (PWM), enable dynamic fan speed adjustments based on real-time thermal loads. This approach not only optimizes energy consumption—potentially reducing power usage by up to 30%—but also extends the lifespan of the fans. Real-world applications illustrate that data centers utilizing PWM technology have achieved remarkable improvements in temperature management efficiency, highlighting the significance of these integration practices. By adhering to these guidelines, professionals can enhance the overall functionality and reliability of their electronic devices.

Evaluate and Optimize Fan Performance for Compliance and Efficiency

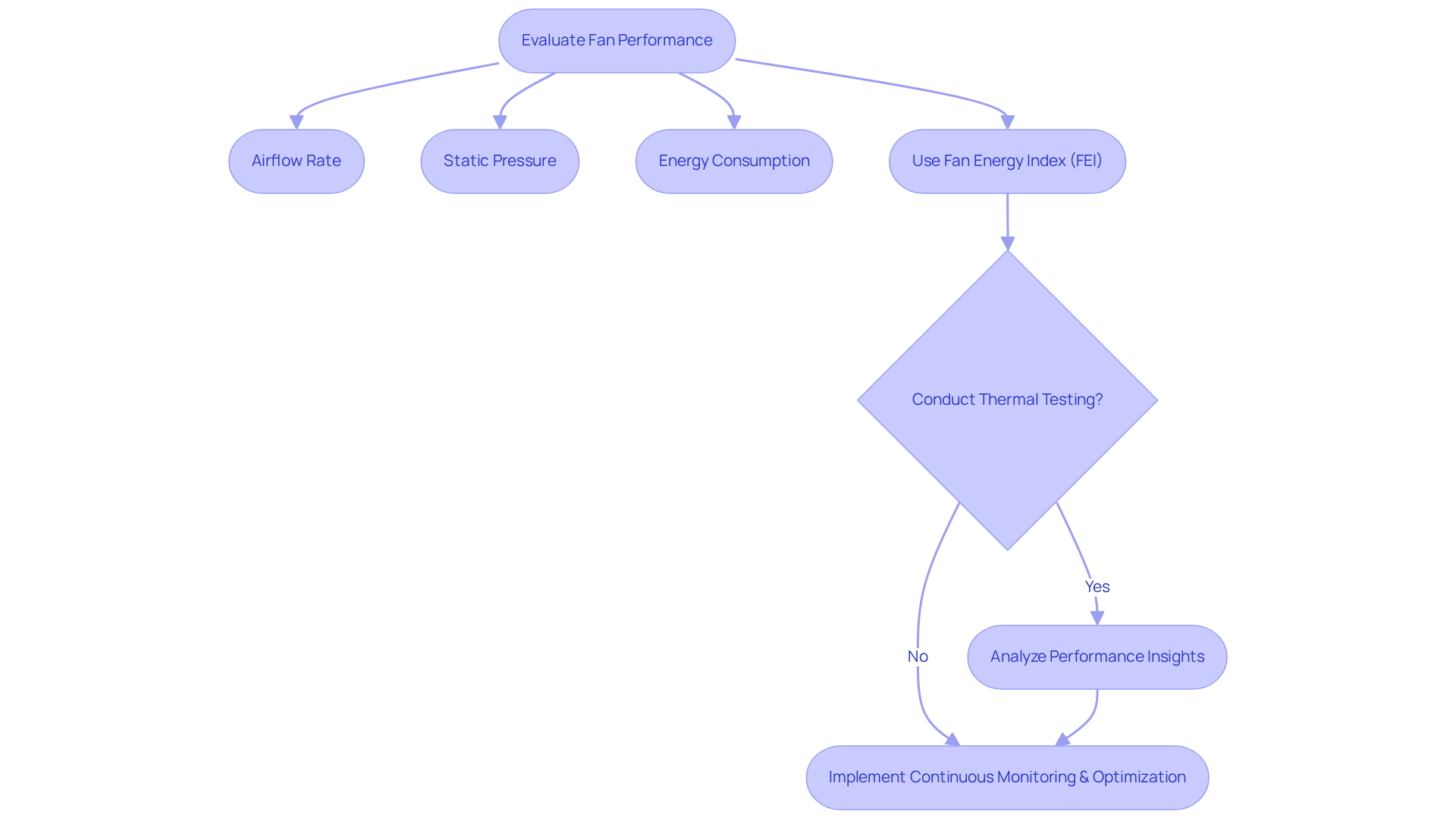

To ensure that fan little technologies operate efficiently and meet industry standards, specialists must regularly assess fan performance using key metrics such as:

- Airflow rate

- Static pressure

- Energy consumption

Tools like the Fan Energy Index (FEI) play a crucial role in evaluating the energy efficiency of fan systems, allowing for straightforward comparisons across different fan technologies.

Conducting thermal testing under various operational conditions yields valuable insights into fan performance and reliability. Engineers should remain updated on relevant industry standards, particularly those established by the IEEE, to ensure compliance and bolster product credibility. By implementing continuous monitoring and optimization strategies, engineers can enhance the efficiency of their fan systems while also supporting their organizations’ sustainability objectives.

Conclusion

Understanding and effectively integrating fan technologies is crucial for electronics engineers aiming to enhance the performance and reliability of their designs. Recognizing the various types of fans—axial, centrifugal, and mixed-flow—enables engineers to make informed decisions tailored to specific cooling requirements. The significance of selecting the right fan technology cannot be overstated; it directly impacts operational efficiency and user experience.

Key practices include:

- Evaluating the operational environment

- Utilizing fan selection software

- Employing advanced control strategies like pulse width modulation (PWM)

Each of these practices optimizes airflow, minimizes noise, and ensures compliance with industry standards. Moreover, continuous monitoring and assessment of fan performance metrics are vital for enhancing system efficiency and supporting sustainability objectives.

In conclusion, implementing best practices in fan technology not only elevates the functionality of electronic devices but also addresses the growing demands for energy efficiency and reliability. As the electronics landscape evolves, staying informed about current trends and advancements in fan technologies empowers engineers to design better, more efficient systems. Embracing these practices is a proactive step toward achieving excellence in electronic design and meeting the challenges of tomorrow’s technology.

Frequently Asked Questions

What are the main types of cooling devices in the electronics sector?

The main types of cooling devices are axial, centrifugal, and mixed-flow fans.

How do axial blowers function?

Axial blowers move air parallel to the motor axis, making them efficient for cooling applications by delivering high air movement rates.

What is the function of centrifugal blowers?

Centrifugal blowers draw air into the device and expel it at a right angle, which is beneficial for applications that require higher pressure and airflow control.

What are mixed-flow devices?

Mixed-flow devices combine features from both axial and centrifugal designs, providing versatility for various cooling needs.

Who is Gagner-Toomey Associates?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering a wide range of DC input tube axial units and centrifugal blowers optimized for performance, efficiency, and low noise.

Why are axial blowers popular in electronics cooling applications?

Axial blowers dominate the market for electronics cooling applications, representing over 70% of installations due to their efficiency in managing heat in consumer electronics and IT equipment.

What factors should engineers consider when selecting ventilators?

Engineers should consider noise levels, energy efficiency, physical dimensions, and IP protection when selecting ventilators.

Why is noise level important in consumer electronics?

Noise levels are important in consumer electronics because they can significantly impact user experience.

What advantages do high-efficiency fans offer?

High-efficiency fans are preferred in energy-sensitive applications, as they help reduce energy consumption.

What trends in fan technologies should professionals be aware of?

Professionals should stay informed about trends such as advancements in IoT integration and noise-reduction features in fan technologies.