Overview

Choosing the right industrial cooler fans is crucial for optimizing performance and ensuring operational efficiency. Key factors to consider include:

- Performance efficiency

- Size

- Noise levels

- Energy consumption

- Durability

- Airflow direction

- Maintenance needs

- Manufacturer support

Each of these elements plays a significant role in effective temperature management across various industrial applications.

For instance, selecting the appropriate fan size is essential for achieving optimal airflow, while prioritizing energy efficiency can lead to substantial cost reductions. By focusing on these aspects, businesses can enhance their operational sustainability and maintain a competitive edge in their respective industries.

Moreover, understanding the maintenance needs and durability of cooler fans can prevent unexpected downtimes, ensuring continuous operation. Manufacturer support is also vital, as it provides the necessary resources for troubleshooting and optimizing fan performance.

In conclusion, by carefully evaluating these factors, organizations can make informed decisions that not only improve temperature management but also contribute to overall operational efficiency. Emphasizing these considerations will lead to better resource allocation and long-term sustainability in industrial environments.

Introduction

Choosing the right industrial cooler fan can indeed feel overwhelming, particularly given the rapid technological advancements and the wide range of applications these fans serve. As industries increasingly prioritize optimal temperature control and energy efficiency, it becomes crucial to grasp the key factors that impact fan performance. What specific criteria should engineers focus on to make the most informed decisions tailored to their unique requirements? This article explores ten essential considerations that will not only simplify the selection process but also significantly boost operational efficiency and sustainability across various environments.

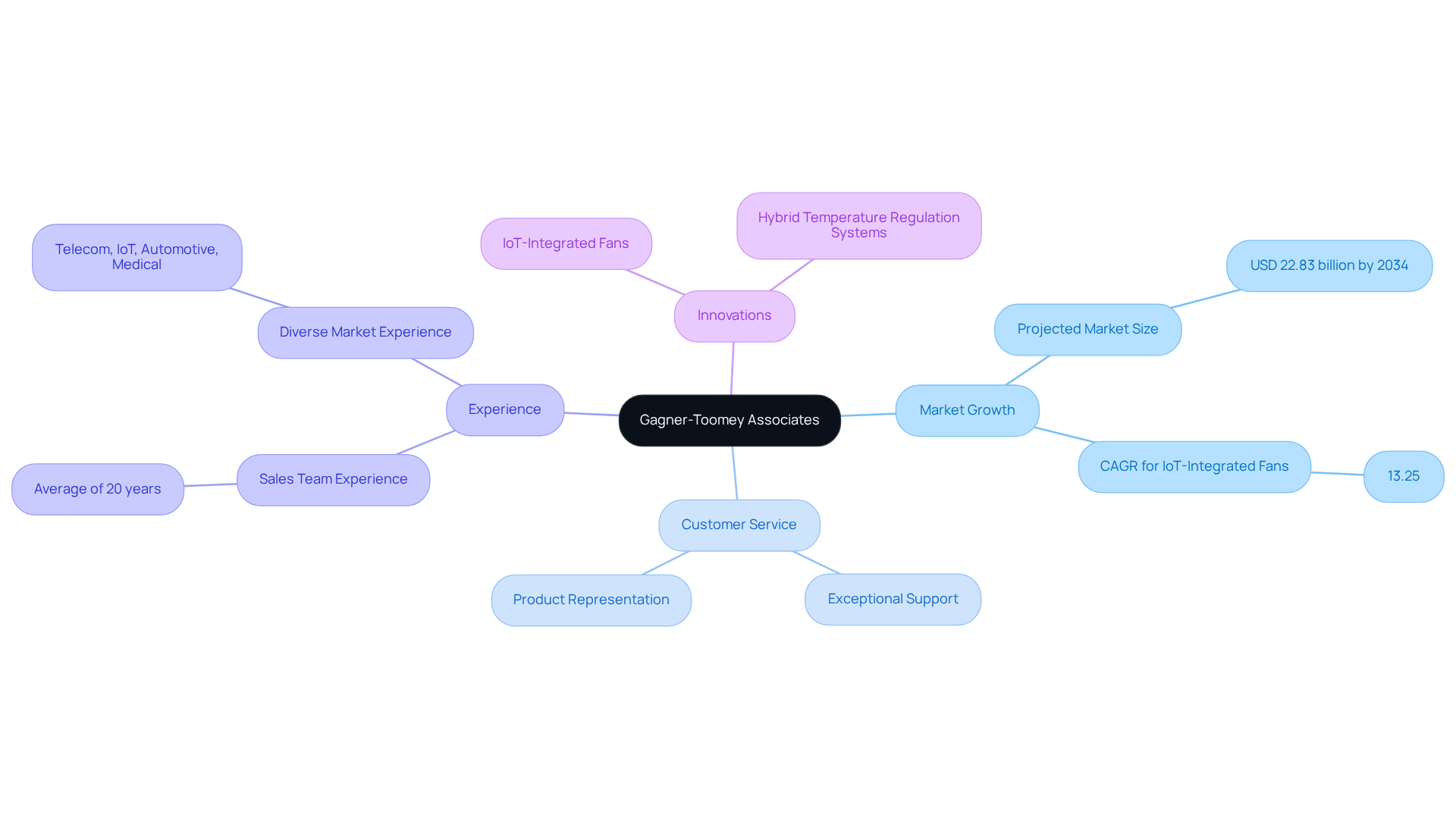

Gagner-Toomey Associates: Expert Solutions for Industrial Cooler Fans

Gagner-Toomey Associates stands out in delivering cutting-edge temperature control solutions tailored specifically for the electronics sector. With a keen focus on performance optimization and energy efficiency, the firm collaborates with a diverse range of top-tier manufacturers to ensure clients have access to the most advanced industrial cooler fans.

As the fan market is projected to grow significantly, reaching an estimated USD 22.83 billion by 2034, Gagner-Toomey Associates remains at the forefront of this evolution. Their unwavering commitment to exceptional customer service and product representation is backed by a sales team boasting an average of over 20 years of experience, establishing them as a trusted partner for engineers seeking effective temperature management strategies.

With extensive experience across various markets, including Telecom, IoT, Automotive, and Medical, the firm is well-equipped to understand the unique challenges engineers face in these sectors. Notably, innovations such as IoT-integrated fans, expected to expand at a CAGR of 13.25%, and hybrid temperature regulation systems—designed to enhance thermal management through real-time monitoring—are reshaping the industry landscape.

Moreover, Gagner-Toomey Associates emphasizes the importance of personalization in temperature control solutions, adapting their offerings to meet the specific needs of engineers. This dedication to excellence and adaptability positions Gagner-Toomey Associates as an essential asset in navigating the complexities of modern temperature control solutions.

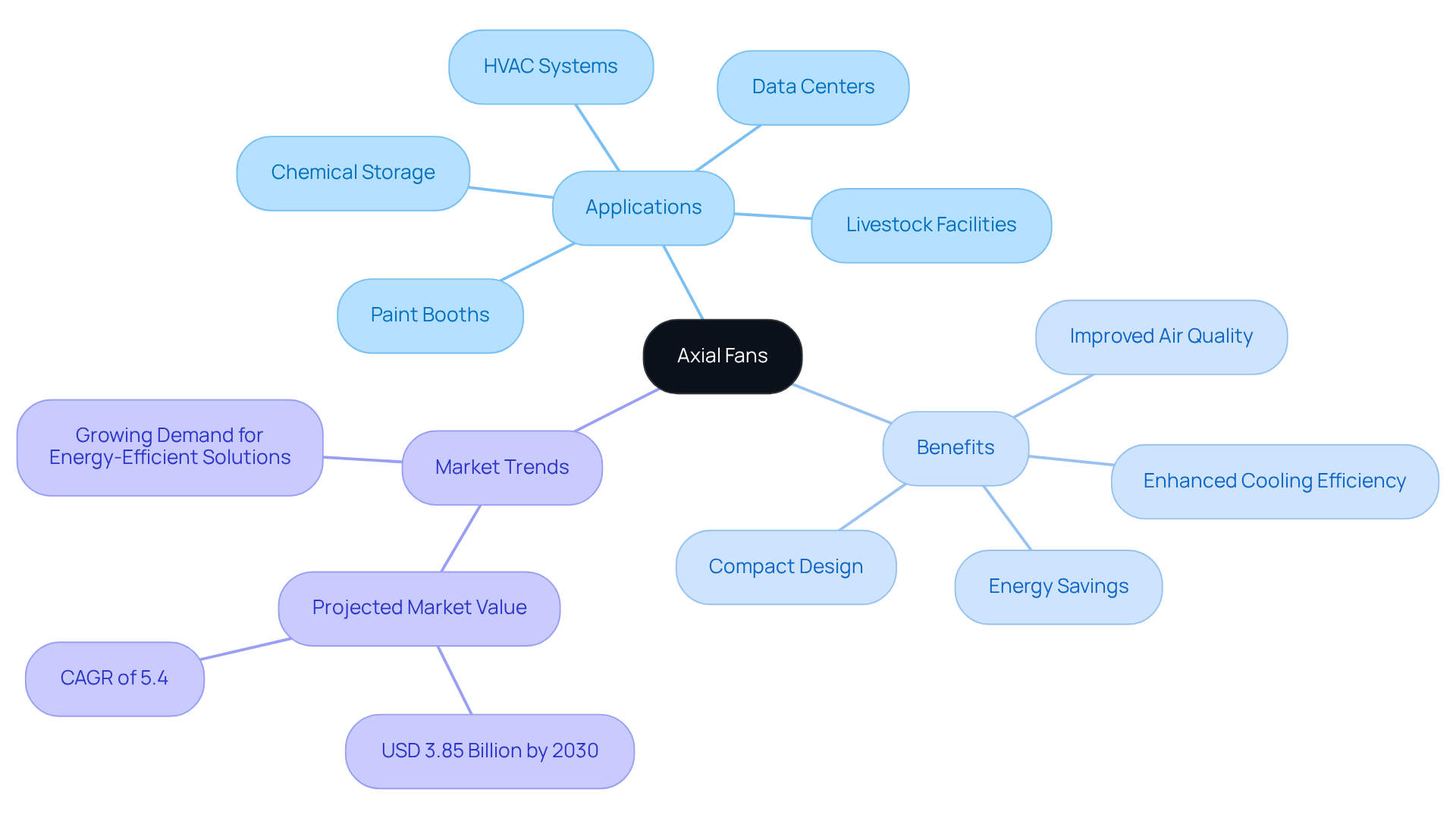

Axial Fans: Efficient Airflow for Compact Spaces

Axial blowers are engineered to move air parallel to their axis, making them exceptionally suited for applications with spatial constraints. This design promotes effective airflow, which is crucial for regulating temperatures in electronic components, HVAC systems, and industrial machinery. As a leading supplier of innovative temperature control solutions, Gagner-Toomey Associates offers a range of industrial cooler fans that play a vital role in maintaining ideal temperatures, particularly in data centers where they help manage the heat generated by multiple servers. Notably, studies show that improving the efficiency of cooling devices by just a few percentage points can yield significant annual energy savings for large data centers, underscoring the importance of selecting high-efficiency models. Furthermore, up to 25% of the overall power budget for high-performance rack systems may be allocated to industrial cooler fans, highlighting their critical role in energy management and cost efficiency.

In HVAC systems, axial blowers are preferred for their compactness and seamless integration into existing setups. They are widely used in various environments, from commercial buildings to industrial facilities, where industrial cooler fans enhance air circulation and cooling efficiency. HVAC experts often stress the importance of selecting the right blower based on its performance characteristics, noting that axial units can outperform conventional centrifugal types in specific scenarios due to their ability to move large volumes of air at lower pressures.

Real-world applications of axial devices in HVAC systems include their deployment in paint booths and chemical storage areas, where they effectively remove harmful fumes and ensure a safe working environment. Additionally, in livestock facilities, axial blowers are strategically placed to draw hot air away from animals, improving their comfort and health. As the demand for energy-efficient solutions rises, industrial cooler fans are increasingly being designed with smart controls and energy-efficient motors, further enhancing their performance and sustainability in industrial applications. The global axial blowers market is projected to reach USD 3.85 billion by 2030, reflecting their growing significance in the industry. Moreover, Gagner-Toomey Associates’ extensive product range, which includes power conversion and EMI solutions, boosts the effectiveness of axial devices, ensuring optimal performance across diverse applications.

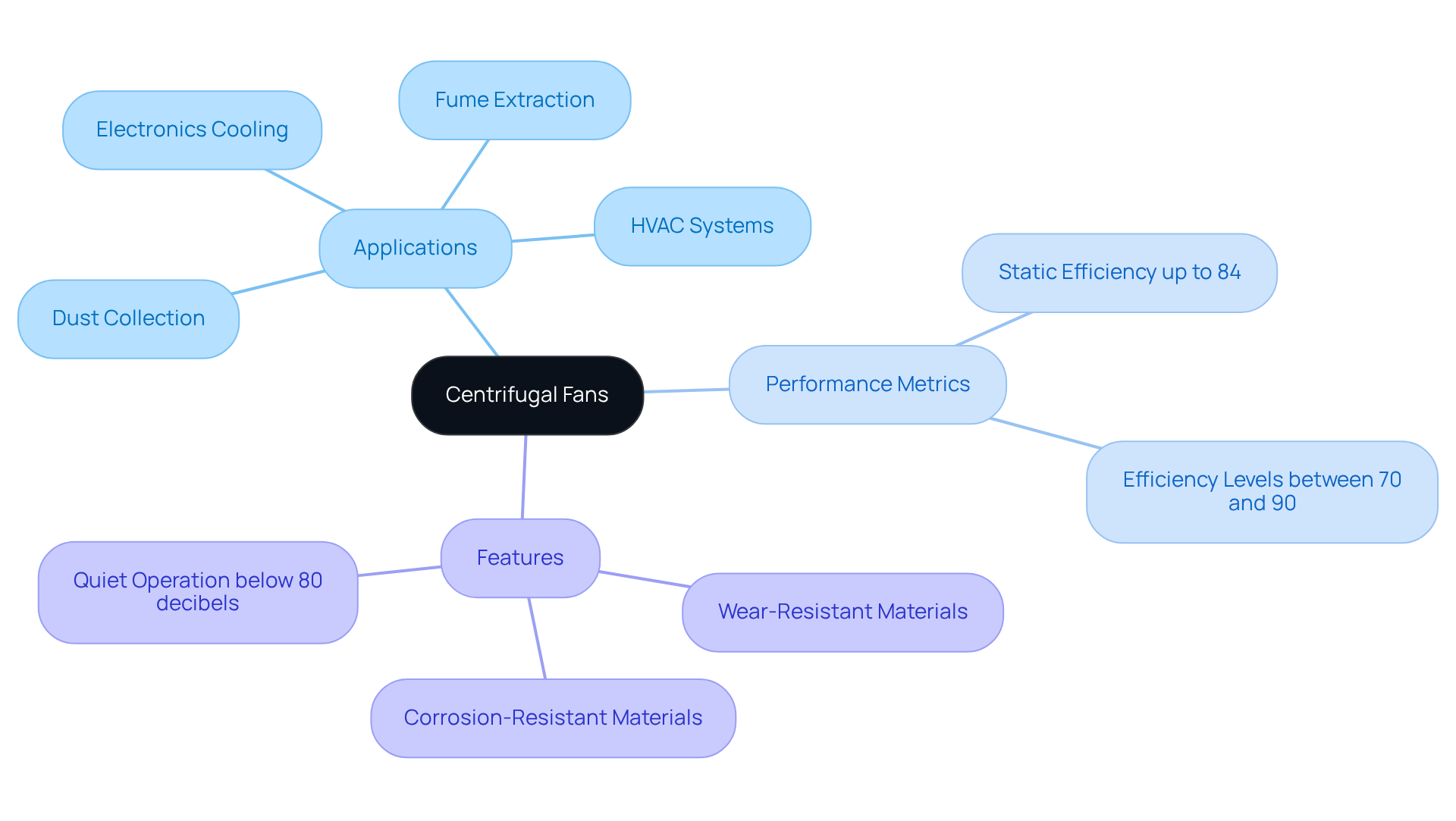

Centrifugal Fans: High Pressure and Versatile Applications

Centrifugal blowers are engineered to pull air into the center and release it at a right angle, generating substantial pressure and airflow. This operational principle makes industrial cooler fans versatile, allowing them to excel in applications such as:

- Dust collection

- Fume extraction

- HVAC systems

- Electronics cooling

Notably, Gagner-Toomey centrifugal blowers are designed to manage greater resistance, making them particularly efficient in environments where airflow must navigate through intricate duct systems or filters.

Industry leaders highlight the flexibility of these centrifugal devices, noting their ability to handle various materials while maintaining performance even in challenging conditions. This capability is vital in HVAC systems, where consistent airflow and pressure are essential for optimal indoor air quality. Furthermore, Gagner-Toomey centrifugal blowers demonstrate exceptional performance metrics in high-pressure situations, often achieving static efficiencies of up to 84%. They maintain efficiency levels between 70% and 90% of rated load, ensuring reliable operation.

Additionally, these blowers can be outfitted with wear-resistant and corrosion-resistant materials, enhancing their suitability for diverse industrial applications. Their quiet operation, typically below 80 decibels, further supports their use in indoor settings, providing comfort without sacrificing performance.

Gagner-Toomey offers an extensive product line of DC input centrifugal fans and blowers, available in sizes ranging from 15 to 225mm. Most models come with IP protection upon request, ensuring that customers can find the right solution for their specific needs.

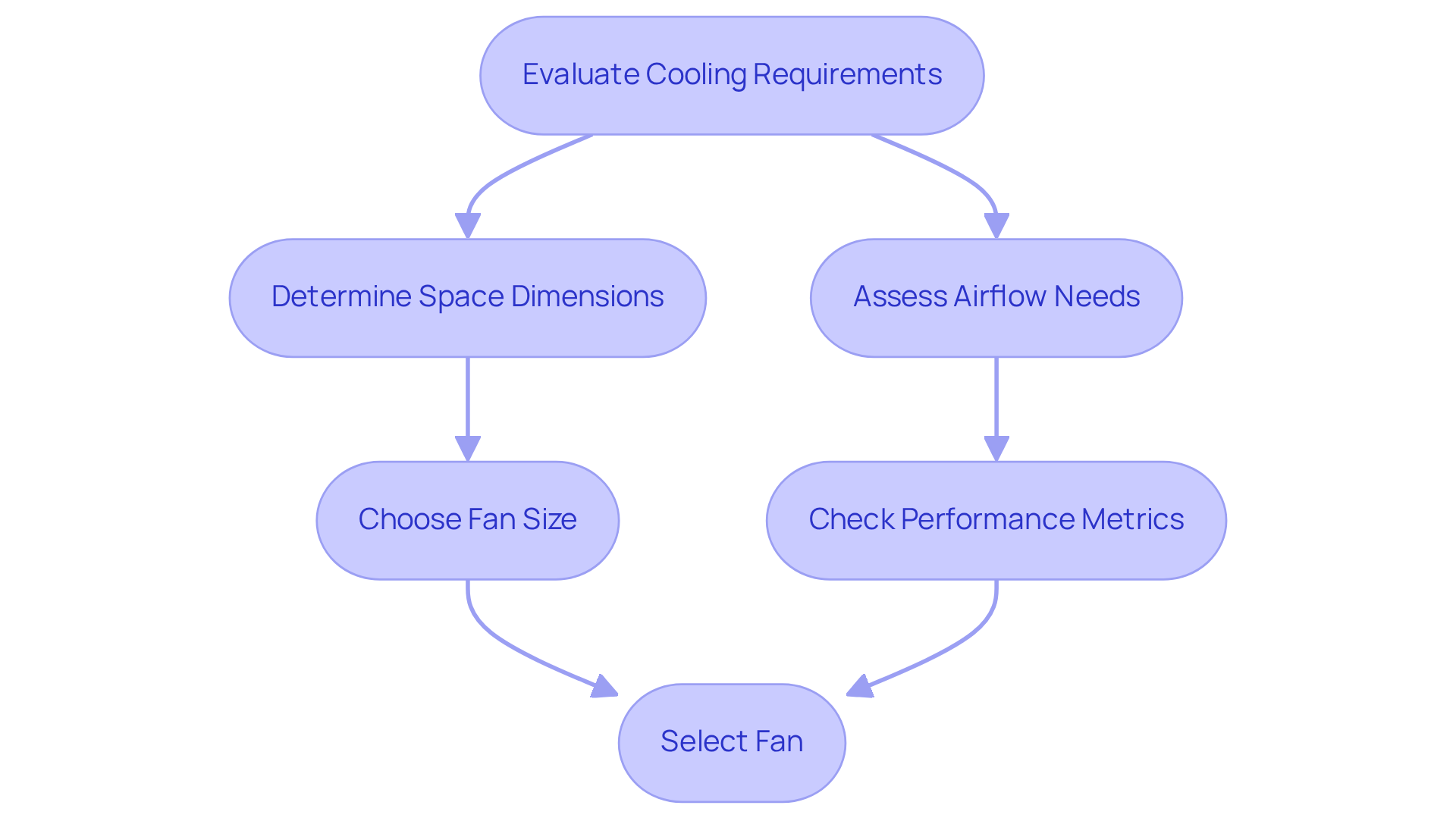

Consider Fan Size: Balance Between Space and Performance

Choosing the correct size for industrial cooler fans is crucial for achieving optimal temperature regulation while maximizing energy efficiency. An undersized fan may struggle to deliver adequate airflow, leading to overheating and potential damage to electronic components. On the other hand, an oversized fan can result in excessive energy consumption and operational inefficiencies. Engineers stress the importance of evaluating both the dimensions of the space and the specific cooling requirements of the application.

For example, a 12-inch fan can achieve approximately 1,654 CFM at a static pressure of 0.05 inH2O, but this capacity diminishes as static pressure increases. Additionally, the ventilation effectiveness rate (VER) for a 12-inch fan at 0.05 inH2O is 8.73 cfm/W, providing a benchmark for assessing fan performance. As one specialist noted, “It is advisable to select a fan that will offer an operating point leaning toward the high flow, low pressure end of the performance curve to sustain propeller effectiveness and to avoid propeller stall.”

Moreover, energy-saving devices can reduce energy usage by as much as 70% compared to conventional AC motors. By meticulously balancing the size of industrial cooler fans with airflow needs, engineers can enhance temperature regulation and lower energy expenses, ultimately leading to more sustainable operations. To implement these principles effectively, engineers should conduct a comprehensive evaluation of their specific cooling requirements and select devices that align with both the physical area and desired energy efficiency outcomes.

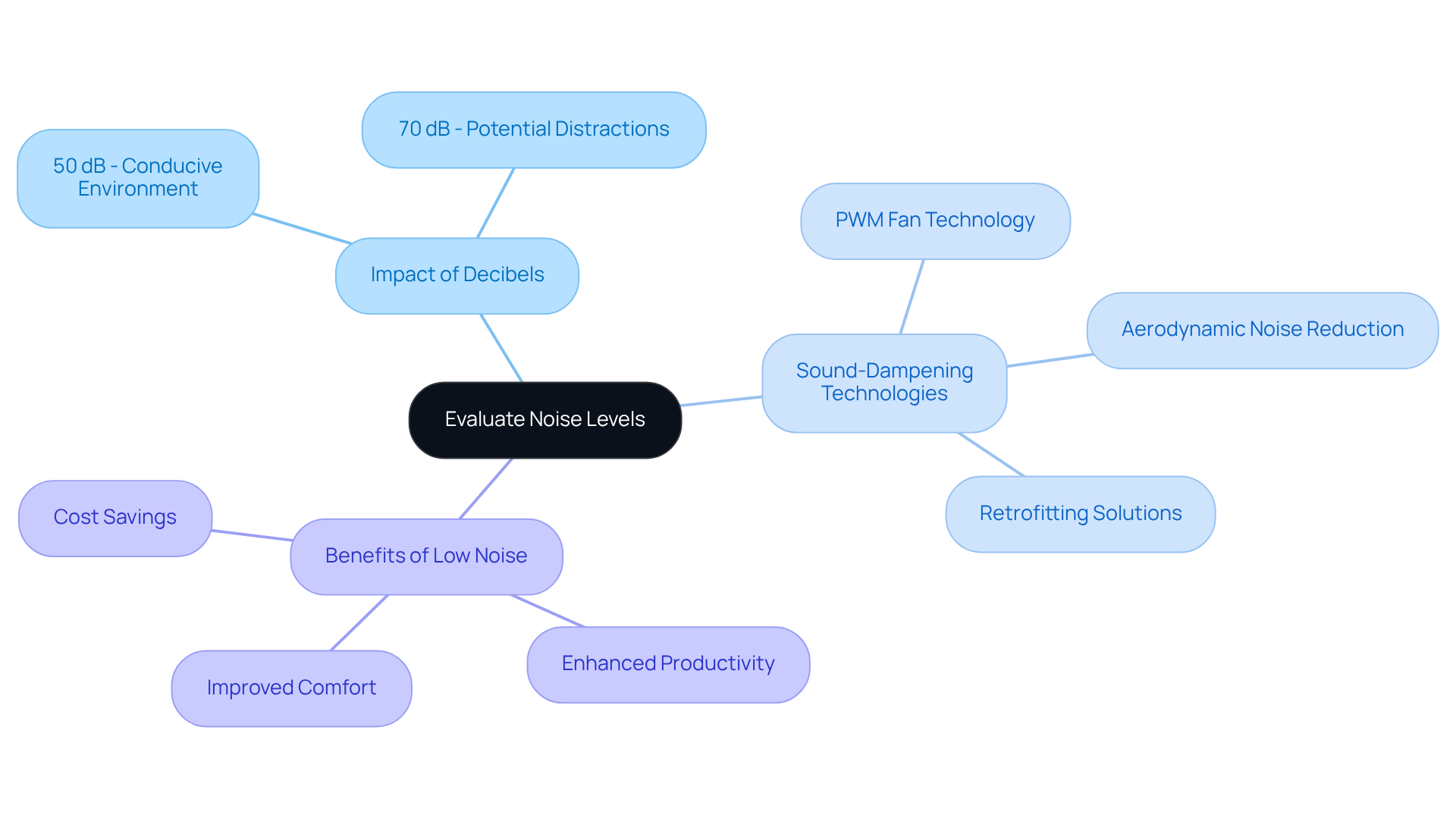

Evaluate Noise Levels: Ensure a Quiet Operation

Noise levels play a pivotal role in selecting industrial cooling devices, especially in environments where silent operation is paramount. Fans are evaluated based on their sound output, measured in decibels (dB). It is essential to choose models that operate within acceptable noise limits tailored to specific applications. By employing sound-dampening technologies or opting for devices engineered for low noise, organizations can significantly enhance the working atmosphere.

To illustrate, consider the impact of a cooling fan operating at 50 dB versus one at 70 dB. The former creates a more conducive environment for tasks requiring concentration, while the latter may lead to distractions and decreased productivity. Therefore, investing in quieter models not only improves comfort but also boosts overall efficiency.

In conclusion, prioritizing noise levels in the selection of industrial cooler fans is not merely a matter of preference; it is a strategic decision that can lead to a more productive and pleasant working environment. Take action now by evaluating your current cooling solutions and considering upgrades that align with your operational needs.

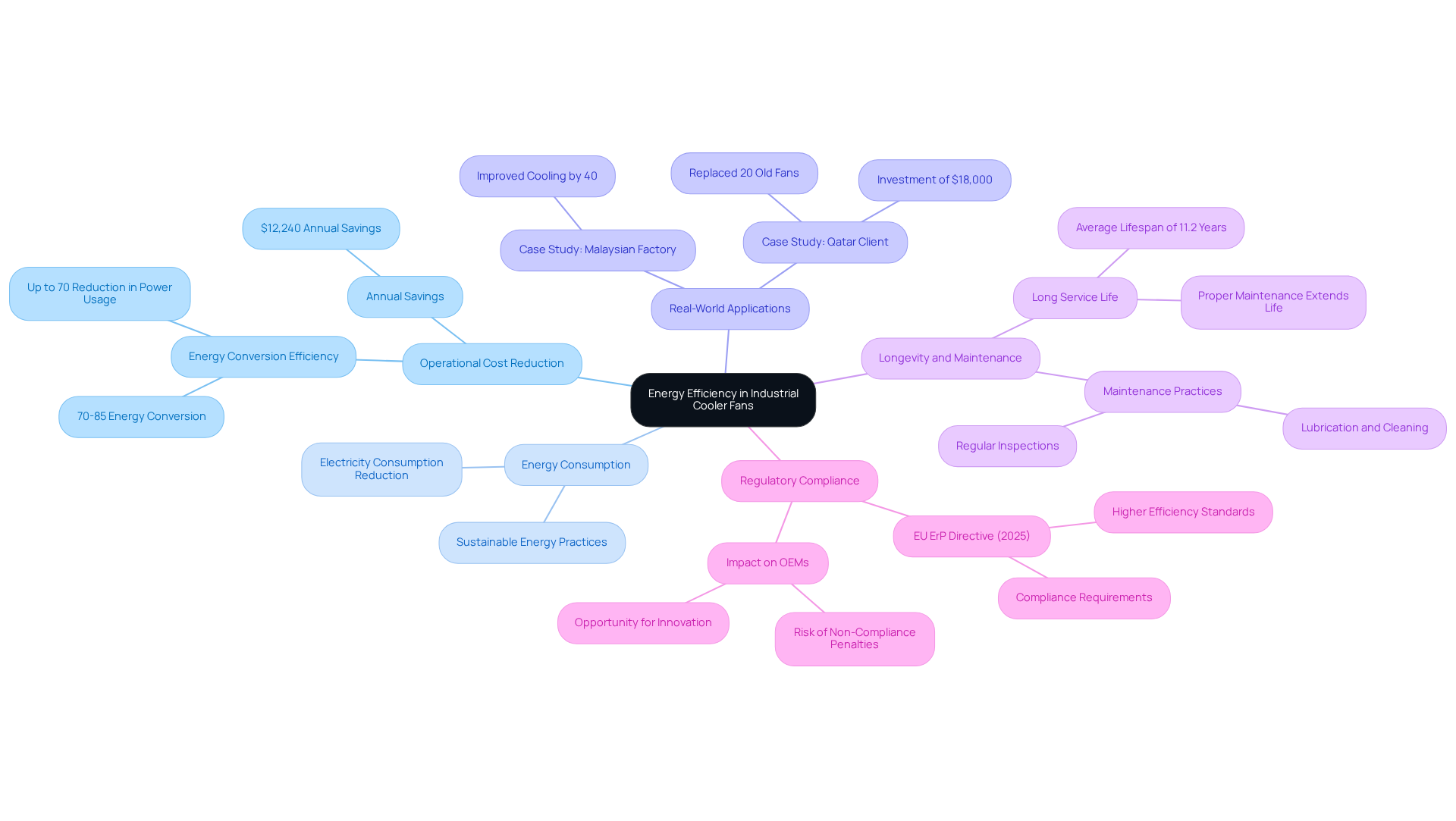

Prioritize Energy Efficiency: Reduce Operational Costs

Focusing on energy optimization in industrial cooler fans is crucial for reducing operational expenses and enhancing sustainability. Industrial cooler fans, often recognized by Energy Star certifications, are engineered to significantly lower electricity consumption. These industrial cooler fans are energy-efficient devices that convert 70-85% of electrical energy into airflow, achieving up to a 70% reduction in power usage compared to conventional models. This shift results in substantial savings on electricity costs.

Experts assert that adopting energy-efficient technologies is not just a trend; it’s a necessity for sustainable development in the electronics sector. Real-world applications underscore these advantages. For instance, a client in Qatar replaced outdated ventilation systems with modern energy-efficient models, resulting in annual savings of $12,240 and a payback period of just 1.5 years.

Moreover, energy-efficient devices offer a long service life when selected and maintained properly, further enhancing their cost-effectiveness. By implementing these technologies, organizations not only reduce their operational expenses but also utilize industrial cooler fans to contribute to minimizing their carbon footprint. This aligns with contemporary sustainability goals and supports broader environmental stewardship initiatives.

Additionally, compliance with the EU ErP Directive (2025) highlights the critical role of these technologies in meeting future energy efficiency standards. Embracing energy optimization is not merely beneficial; it is essential for a sustainable future.

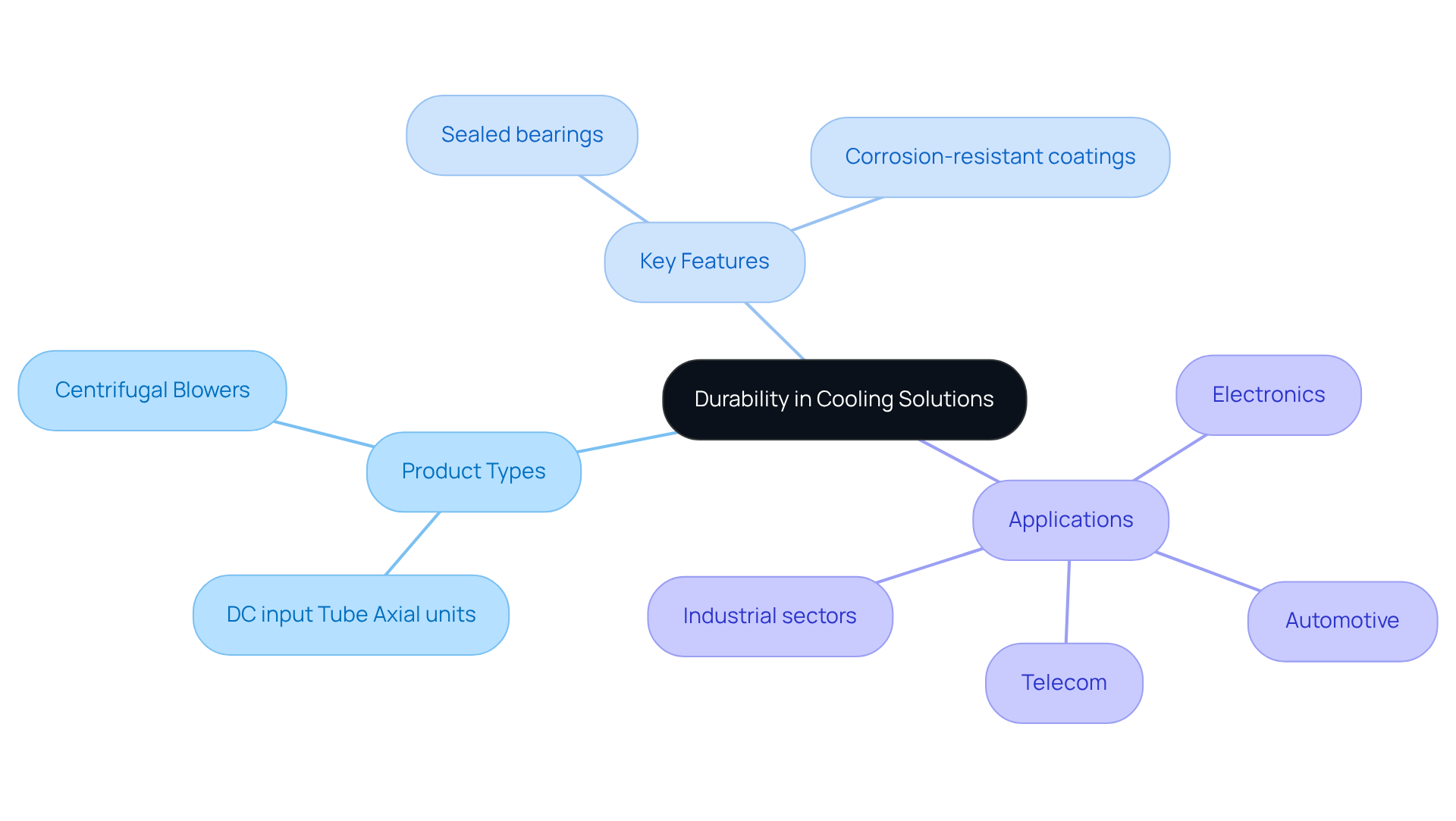

Assess Durability: Choose Reliable Cooling Solutions

Durability stands as a pivotal factor when selecting industrial cooler fans, especially in demanding environments. Gagner-Toomey, the world’s largest manufacturer of standard and custom air-movers, offers an extensive array of products, including:

- DC input Tube Axial units ranging from 15 to 280mm

- Centrifugal Blowers from 15 to 225mm

These industrial cooler fans are meticulously constructed from high-quality materials, engineered to endure harsh conditions such as extreme temperatures, humidity, and dust.

Key features of industrial cooler fans include:

- Sealed bearings

- Corrosion-resistant coatings

These features significantly enhance the lifespan of the fan, ensuring reliable performance over time. The temperature regulation solutions are specifically tailored for a variety of applications, encompassing:

- Electronics

- Automotive

- Telecom

- Industrial sectors

This unwavering commitment to durability and versatility firmly establishes Gagner-Toomey as a premier provider of innovative temperature management solutions for electronics and beyond.

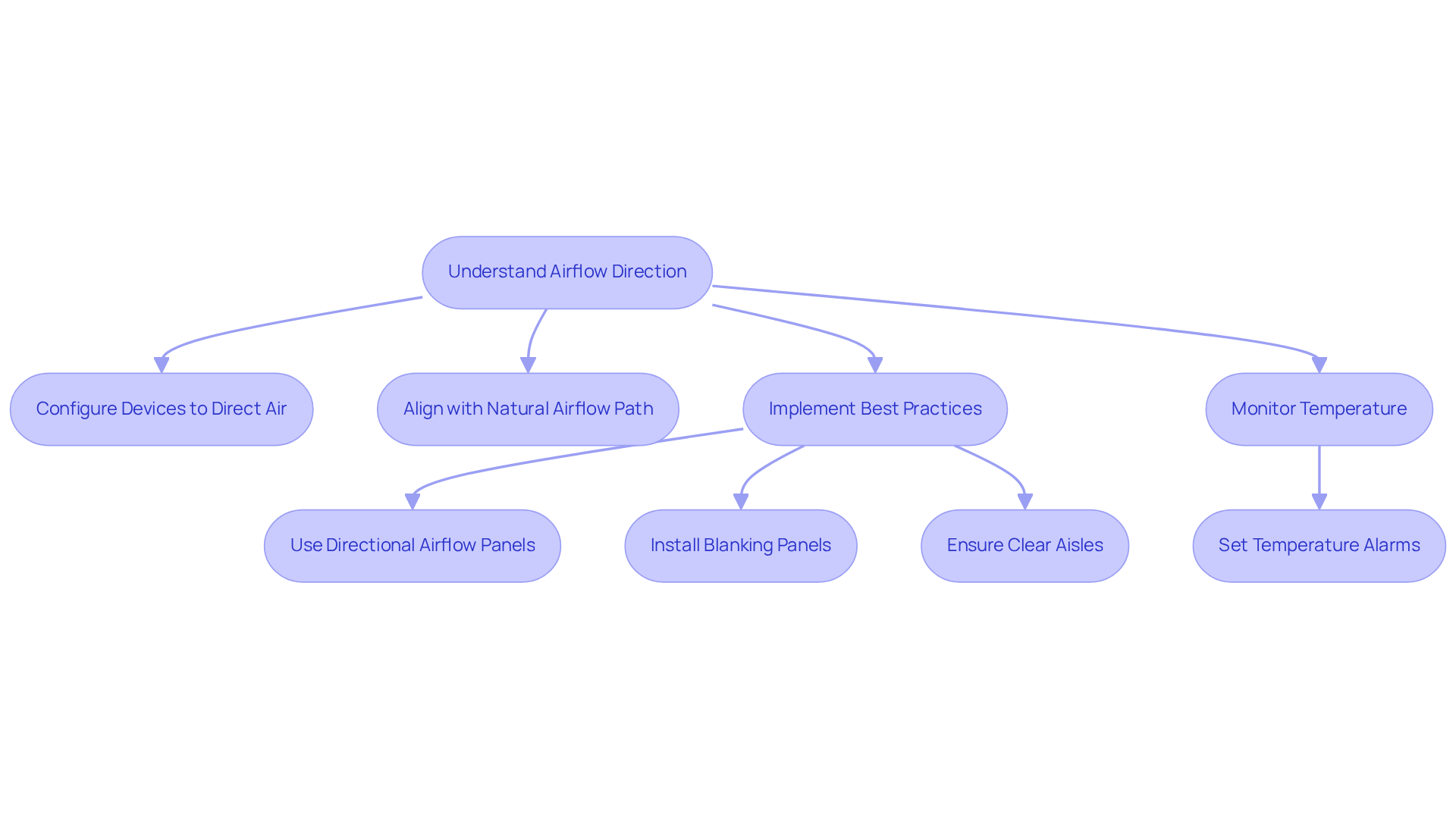

Understand Airflow Direction: Optimize Cooling Efficiency

Optimizing cooling efficiency is fundamentally tied to a comprehensive understanding of airflow direction. Depending on the specific application, devices must be configured to either direct air towards or away from critical components. For example, in data centers, aligning cooling devices with the natural airflow path—typically front-to-back—ensures that cool air is precisely directed where it’s needed. This effectively dissipates heat and maintains optimal operating temperatures, which is vital for the longevity and performance of electronic systems.

Real-world applications underscore the effectiveness of targeted airflow management. In warehouses, directional blowers have been employed to enhance comfort and energy efficiency by directing airflow towards specific workstations, thereby boosting productivity. Similarly, in outdoor dining areas, these fans provide localized refreshment, creating a more enjoyable atmosphere for guests.

Data shows that maintaining a consistent ambient temperature range of 64.4 to 80.6 degrees F (18 to 27 degrees C) is crucial for data center equipment, as outlined by ASHRAE guidelines. Properly configured airflow not only helps achieve this temperature range but also reduces energy consumption by lessening the load on HVAC systems. By implementing best practices in airflow management—such as utilizing directional airflow panels, brush grommets, rack skirts, and air dams, along with ensuring clear aisles—organizations can significantly enhance temperature control and extend the lifespan of their electronic components. Furthermore, accurately configuring temperature alerts is essential for data center operations to prevent unnecessary alarms or the oversight of critical temperature issues. Employing ENERGY STAR-rated servers and equipment can further lower power and temperature requirements.

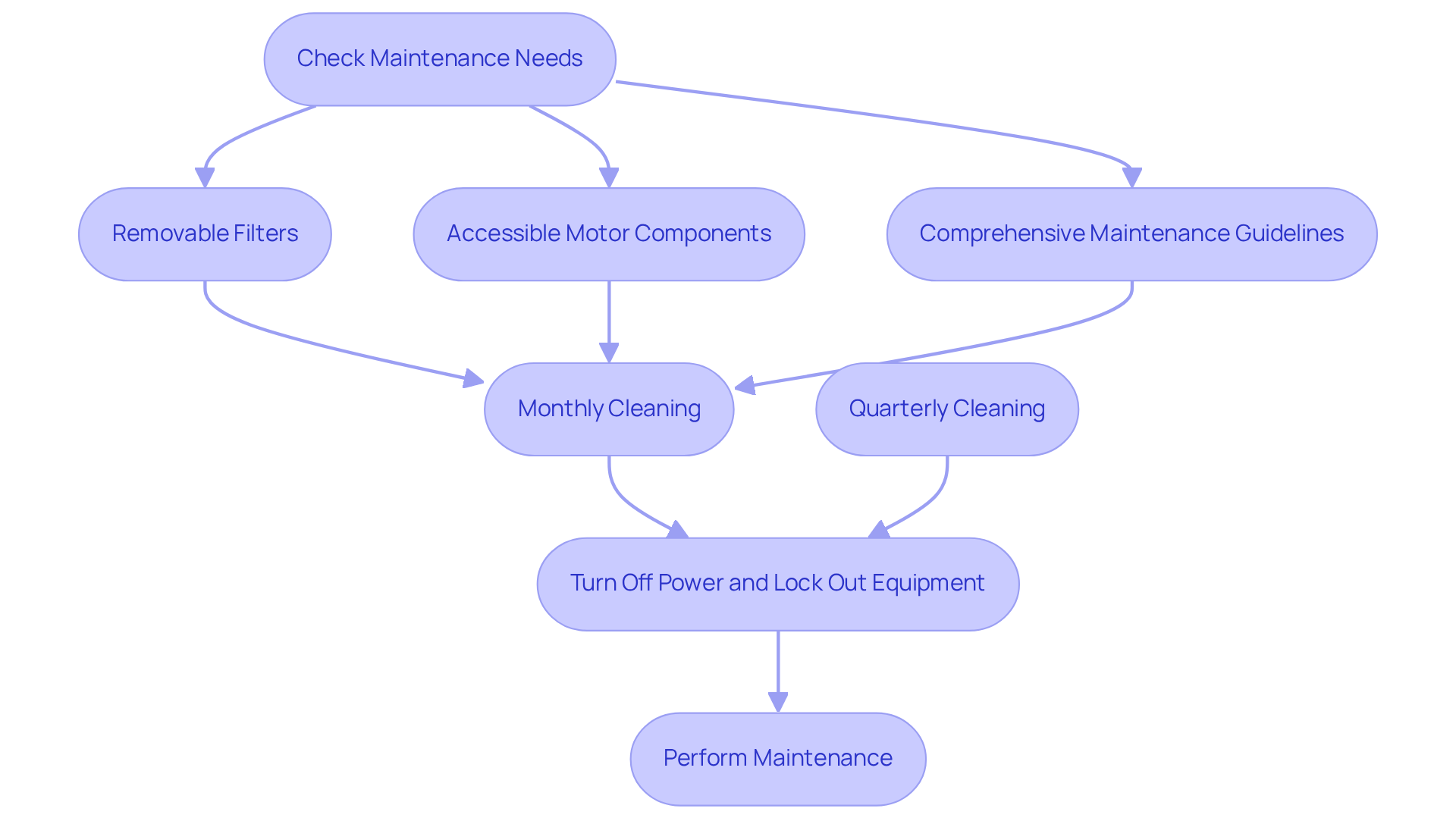

Check Maintenance Needs: Simplify Upkeep and Service

When selecting industrial cooler fans, it is crucial to understand the maintenance requirements of each model. Maintenance-friendly designs, including industrial cooler fans that provide easy access for cleaning and servicing, can significantly reduce downtime and lower overall service costs. Look for key features like:

- Removable filters

- Accessible motor components

- Comprehensive maintenance guidelines

These elements not only simplify upkeep but also ensure consistent performance.

Routine cleaning of industrial fan blades and motors should be performed monthly to quarterly, depending on environmental conditions. Regular maintenance practices for industrial cooler fans, such as filter cleaning and lubrication of moving parts, must be tailored to the specific fan model. Moreover, it is vital to turn off power sources and lock out equipment before conducting maintenance to guarantee safety.

By prioritizing these maintenance-friendly features and practices, engineers can enhance the longevity and efficiency of their cooling systems. This proactive approach not only safeguards equipment but also optimizes operational performance.

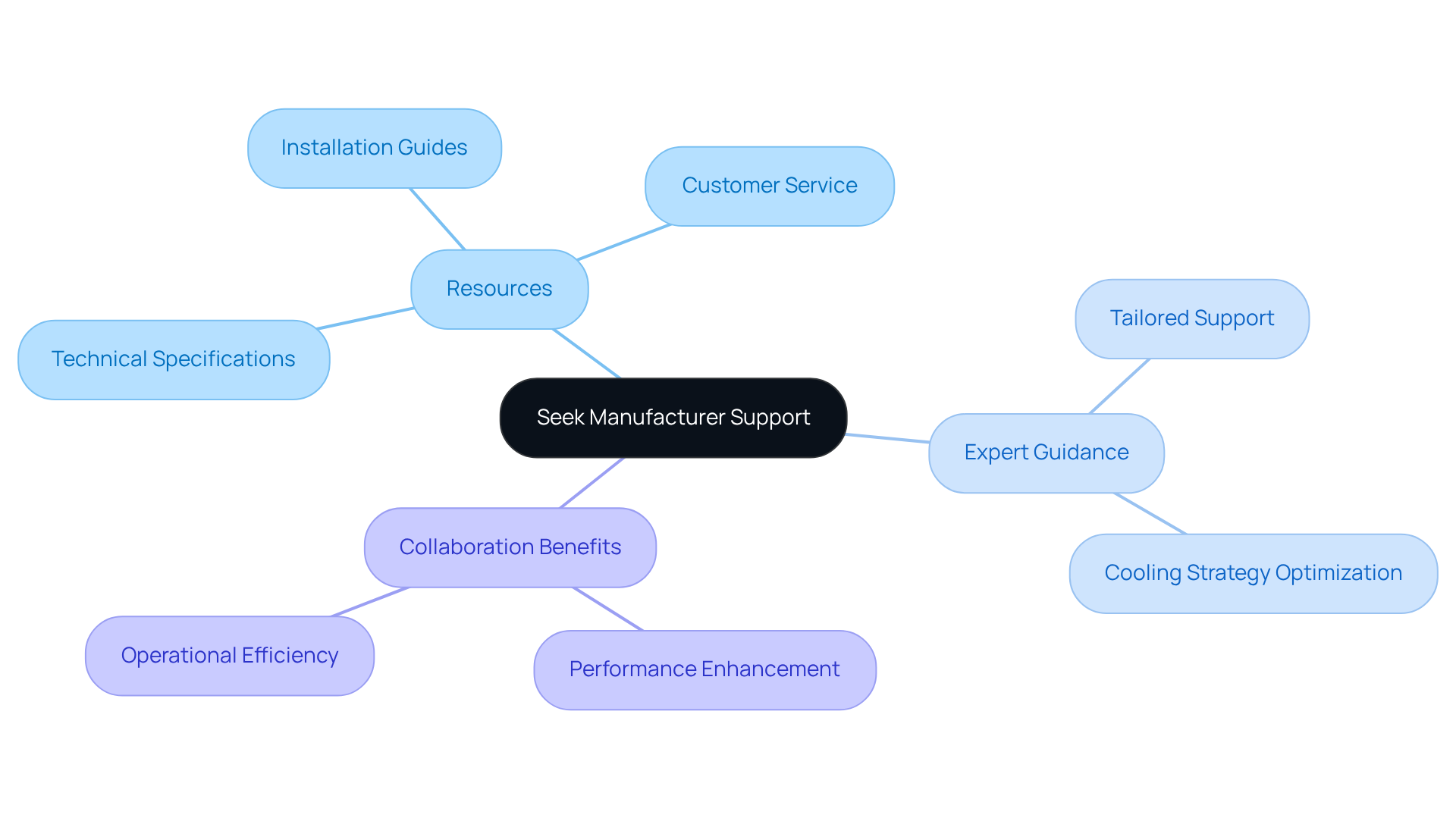

Seek Manufacturer Support: Ensure Expert Guidance and Service

When selecting industrial cooler fans, it is crucial to seek manufacturer support. Reputable manufacturers like Gagner-Toomey Associates offer a wealth of resources, including:

- Detailed technical specifications

- Comprehensive installation guides

- Dedicated customer service

This consultative approach ensures engineers receive expert guidance tailored to their specific needs.

Interacting with producers fosters collaborations that can enhance the performance and reliability of temperature control systems. By leveraging the expertise and resources provided by Gagner-Toomey Associates, engineers can optimize their cooling strategies using industrial cooler fans. This optimization ultimately contributes to improved operational efficiency, making it essential for engineers to engage with trusted manufacturers.

Conclusion

Choosing the right industrial cooler fans is not just a decision; it’s a pivotal factor that can greatly influence temperature regulation, energy efficiency, and overall operational costs. Understanding the various fan types—like axial and centrifugal fans—and their specific applications is crucial for optimizing performance based on your operational needs.

When selecting industrial cooler fans, consider key factors such as:

- Airflow direction

- Fan size

- Noise levels

- Energy efficiency

- Durability

Each of these elements is essential in ensuring that your cooling solutions meet technical requirements while also fostering a sustainable and cost-effective operational environment. Partnering with reputable manufacturers, such as Gagner-Toomey Associates, provides access to expert guidance and support, enhancing the effectiveness of your cooling strategies.

Ultimately, selecting the right industrial cooler fan transcends mere technical choice; it represents a strategic investment in the efficiency and reliability of your cooling systems. By prioritizing these factors, organizations can optimize their temperature management solutions, reduce operational costs, and contribute to broader sustainability goals. Taking the time to assess these considerations will lead to improved performance and longevity of industrial cooling systems. Therefore, it is essential for engineers and decision-makers to act decisively in their selections.

Frequently Asked Questions

What solutions does Gagner-Toomey Associates provide?

Gagner-Toomey Associates specializes in temperature control solutions tailored for the electronics sector, focusing on performance optimization and energy efficiency with advanced industrial cooler fans.

What is the projected growth of the fan market?

The fan market is projected to grow significantly, reaching an estimated USD 22.83 billion by 2034.

What experience does the Gagner-Toomey Associates sales team have?

The sales team at Gagner-Toomey Associates has an average of over 20 years of experience, which establishes them as a trusted partner for engineers.

In which markets does Gagner-Toomey Associates have extensive experience?

Gagner-Toomey Associates has extensive experience across various markets, including Telecom, IoT, Automotive, and Medical.

What innovative products is Gagner-Toomey Associates offering?

The firm offers innovations such as IoT-integrated fans and hybrid temperature regulation systems designed for enhanced thermal management and real-time monitoring.

How do axial fans operate and where are they commonly used?

Axial fans move air parallel to their axis, making them suitable for applications with spatial constraints, such as electronic components, HVAC systems, and industrial machinery.

What is the importance of high-efficiency models in data centers?

Improving the efficiency of cooling devices by a few percentage points can yield significant annual energy savings for large data centers, making the selection of high-efficiency models crucial.

What are the advantages of axial blowers in HVAC systems?

Axial blowers are compact and can seamlessly integrate into existing setups, often outperforming conventional centrifugal types in specific scenarios due to their ability to move large volumes of air at lower pressures.

What applications do centrifugal fans excel in?

Centrifugal fans excel in applications such as dust collection, fume extraction, HVAC systems, and electronics cooling.

What are the performance characteristics of Gagner-Toomey centrifugal blowers?

Gagner-Toomey centrifugal blowers can achieve static efficiencies of up to 84% and maintain efficiency levels between 70% and 90% of rated load, making them efficient in high-pressure situations.

What features do Gagner-Toomey centrifugal blowers offer for diverse applications?

These blowers can be outfitted with wear-resistant and corrosion-resistant materials, and they operate quietly, typically below 80 decibels, enhancing their suitability for indoor settings.

What range of products does Gagner-Toomey offer in centrifugal fans and blowers?

Gagner-Toomey offers DC input centrifugal fans and blowers in sizes ranging from 15 to 225mm, with most models available with IP protection upon request.