Overview

The article delineates ten significant benefits of centrifugal exhaust fans, underscoring their:

- Energy efficiency

- Improved air quality

- Versatility

- Durability

- Low noise levels

- Ease of installation

- Enhanced airflow

- Cost-effectiveness

- Regulatory compliance

Each benefit is substantiated with compelling evidence and illustrative examples, demonstrating how these fans play a pivotal role in enhancing operational efficiency, promoting sustainability, and ensuring safety across a multitude of applications in both industrial and commercial environments.

Introduction

In the dynamic world of engineering, the quest for efficiency, durability, and performance is paramount, particularly concerning ventilation solutions. Centrifugal exhaust fans have emerged as essential components in optimizing indoor environments, enhancing air quality, and driving energy savings across various applications. Companies like Gagner-Toomey Associates lead the charge in this arena, offering cutting-edge technologies that empower engineers to confront the unique challenges of modern industrial and commercial settings.

These fans significantly improve airflow and ensure compliance with regulatory standards, contributing not only to operational excellence but also fostering healthier and more sustainable workplaces. As the demand for efficient and effective ventilation systems continues to escalate, comprehending the multifaceted benefits of centrifugal exhaust fans becomes crucial for engineers striving to maximize value and performance in their projects.

Gagner-Toomey Associates: Innovative Solutions for Centrifugal Exhaust Fans

in providing for , focusing strongly on optimizing performance and efficiency. By showcasing a diverse array of exceptional manufacturers, the company ensures that professionals have access to the latest technologies and advancements in , , and ventilation systems. This commitment to excellence is evident in their tailored solutions, designed to meet the specific needs of various applications, ranging from industrial to commercial settings.

With a consultative approach and a dynamic culture, Gagner-Toomey Associates empowers professionals by providing that drive success in . Our sales team, boasting over 150 years of combined industry experience, is dedicated to understanding the unique challenges faced by professionals across multiple sectors, including Telecom, Networking, IT/Data Center, and beyond. This extensive experience not only enhances our credibility but also ensures that we deliver optimal outcomes for our clients.

Energy Efficiency: Reduce Operational Costs with Centrifugal Exhaust Fans

, such as those manufactured by Gagner-Toomey Associates, are engineered for exceptional energy efficiency, often achieving static efficiencies of up to 84%. This outstanding performance not only lowers operational costs but also positions these devices as a preferred choice for engineers dedicated to minimizing energy expenditures. By selecting high-efficiency models from Gagner-Toomey Associates, facilities can significantly reduce their energy bills while ensuring , thereby bolstering sustainability initiatives.

Current trends reveal an increasing focus on , with gaining prominence in commercial applications. The U.S. government’s General Services Administration has acknowledged substantial linked to smart ventilation devices, particularly in workplace environments, signaling a shift towards more advanced HVAC solutions. This aligns with findings from the case study titled ” in Commercial Applications,” which underscores the possibilities for energy efficiency within these contexts.

By 2025, typical energy savings from using centrifugal exhaust fans are projected to reach approximately 30%, with many facilities reporting reductions in electricity expenses that contribute to broader sustainability goals. As noted by Laura Wood, Senior Press Manager, ‘The centrifugal exhaust fan segment is expected to grow at the highest CAGR over the forecast period as it offers first-rate energy efficiency along with allowing constant airflow.’ This evolution underscores the importance of integrating advanced centrifugal exhaust fans from Gagner-Toomey Associates into industrial applications, ultimately leading to . Furthermore, professionals should consider the latest trends, such as improved noise reduction, when selecting centrifugal devices to ensure optimal performance and compliance with industry standards.

Improved Air Quality: Enhance Indoor Environments with Centrifugal Exhaust Fans

are essential for enhancing by effectively removing contaminants, humidity, and odors from the environment. Their innovative design enables superior ventilation, facilitating the expulsion of stale air and the introduction of fresh air. This capability is particularly vital in industrial settings, where inadequate air quality can severely impact worker health and productivity.

Recent studies reveal that indoor air pollution levels can be as much as 3.5 times higher than those found outdoors, as highlighted in reports concerning . This underscores the urgent need for robust . According to Lokesh Kumar, “,” emphasizing the gravity of the situation.

By integrating into air circulation systems, engineers can significantly improve air quality, thereby fostering safer and more comfortable work environments. Case studies indicate that facilities utilizing these devices experience , leading to enhanced worker performance and reduced health risks.

Moreover, expert opinions stress the necessity of addressing indoor air quality, especially since OSHA has acknowledged the need for regulations since 1994, yet comprehensive measures remain elusive. As awareness grows, the implementation of [centrifugal exhaust fans](https://gagner-toomey.com/mastering-industrial-centrifugal-fan-selection-and-troubleshooting) becomes increasingly crucial for promoting healthier industrial environments. Engineers are encouraged to consider these devices in their projects to ensure optimal air quality and worker safety.

Versatility: Adapt Centrifugal Exhaust Fans for Various Applications

are remarkably adaptable, capable of , including HVAC systems, industrial airflow, and fume removal. Their proficiency in managing diverse airflow requirements and pressures renders them suitable for both . This inherent flexibility across various settings—from manufacturing facilities to commercial kitchens—ultimately .

Durability: Ensure Long-Lasting Performance with Centrifugal Exhaust Fans

are engineered to endure severe working conditions, ensuring exceptional durability. Their robust construction typically features corrosion-resistant materials, including high-grade stainless steel and , complemented by innovative motor designs that enhance longevity. Recent advancements, exemplified by Rosenberg’s new 250-mm devices, showcase while minimizing operating noise levels, reflecting the evolution of technology in this sector. This resilience translates to , positioning these devices as a .

For example, Airflow Company’s customization capabilities facilitate tailored designs that address the specific demands of various industries, further ensuring reliable performance. By investing in , facilities can achieve consistent operation over extended periods, with an average lifespan often exceeding 10 years, even in challenging environments. Additionally, Rosenberg Canada’s commitment to sustainability is evident in their products, which are designed to . The introduction of Rosenberg’s to further exemplifies ongoing innovations aimed at enhancing durability and performance within the industry.

Low Noise Levels: Maintain Quiet Operations with Centrifugal Exhaust Fans

, making them ideal for environments where noise reduction is paramount. Their design features backward-curved blades and optimized airflow paths, which significantly reduce operational noise. These devices undergo rigorous factory testing to ensure they can withstand continuous operation in various environments, thereby guaranteeing reliability and performance. This is particularly beneficial in commercial and residential settings, where excessive noise can disrupt activities and diminish comfort.

For instance, in hotels and entertainment venues, the use of in maintaining indoor air circulation while minimizing noise, thereby enhancing guest satisfaction. The contribute to their extended service life and durability, underscoring their value in demanding applications. specifically designed for , ensuring a more pleasant experience for users and optimizing overall system performance.

As Mr. Jesse, the Foreign Trade Sales Director, articulates, ‘I reduce the time customers spend choosing products and ensure they have a superb service experience, establishing me as a reliable partner for my clients.’ This expert insight underscores the importance of selecting for optimal performance.

Ease of Installation: Simplify Setup with Centrifugal Exhaust Fans

are designed for effortless installation, offering versatile mounting options and . Numerous models feature pre-drilled holes and adjustable brackets, enabling a rapid and uncomplicated setup. Recent statistics indicate that the has been reduced by as much as 30% compared to traditional models, significantly lowering labor costs and minimizing downtime during project execution. By opting for devices designed for straightforward installation, , ensuring .

As Sir Henry Royce famously stated, ‘.’ This principle aligns with contemporary trends in fan technology, especially regarding the centrifugal exhaust fan, which prioritizes , making it an essential consideration for modern engineering projects.

Case studies illustrate that with have experienced a 25% increase in overall project efficiency, underscoring the .

Enhanced Airflow: Optimize Ventilation with Centrifugal Exhaust Fans

are meticulously engineered to deliver superior airflow, making them indispensable for optimizing . Their distinctive design facilitates the efficient movement of large volumes of air, which is vital for maintaining indoor and comfort. By effectively removing stale air and facilitating the influx of fresh air, these devices are instrumental in .

Engineers can leverage the of centrifugal devices to address the specific ventilation requirements of their projects. For example, a recent study revealed that transitioning employees to a building designed for optimal [indoor air quality](https://gagner-toomey.com/10-benefits-of-heat-exchanger-system-for-electronics-engineers) resulted in an impressive 32% increase in satisfaction regarding air quality. Moreover, with climate change anticipated to raise ozone levels in the U.S. by over 2.3 ppb, the significance of becomes increasingly critical.

Notably, substantial declines in cognitive scores have been documented in conventional office buildings characterized by , underscoring the urgent need for enhanced air quality. As estimated by Harvard assistant professor Joseph Allen, the productivity gains associated with improving air quality through ventilation can reach approximately $6,500 per person per year.

By integrating , engineers can substantially , thereby improving overall air quality and creating a more efficient workspace. Additionally, centrifugal blowers are utilized across various industries, including mining, oilfield operations, food processing, and manufacturing, demonstrating their versatility and importance beyond merely indoor air quality.

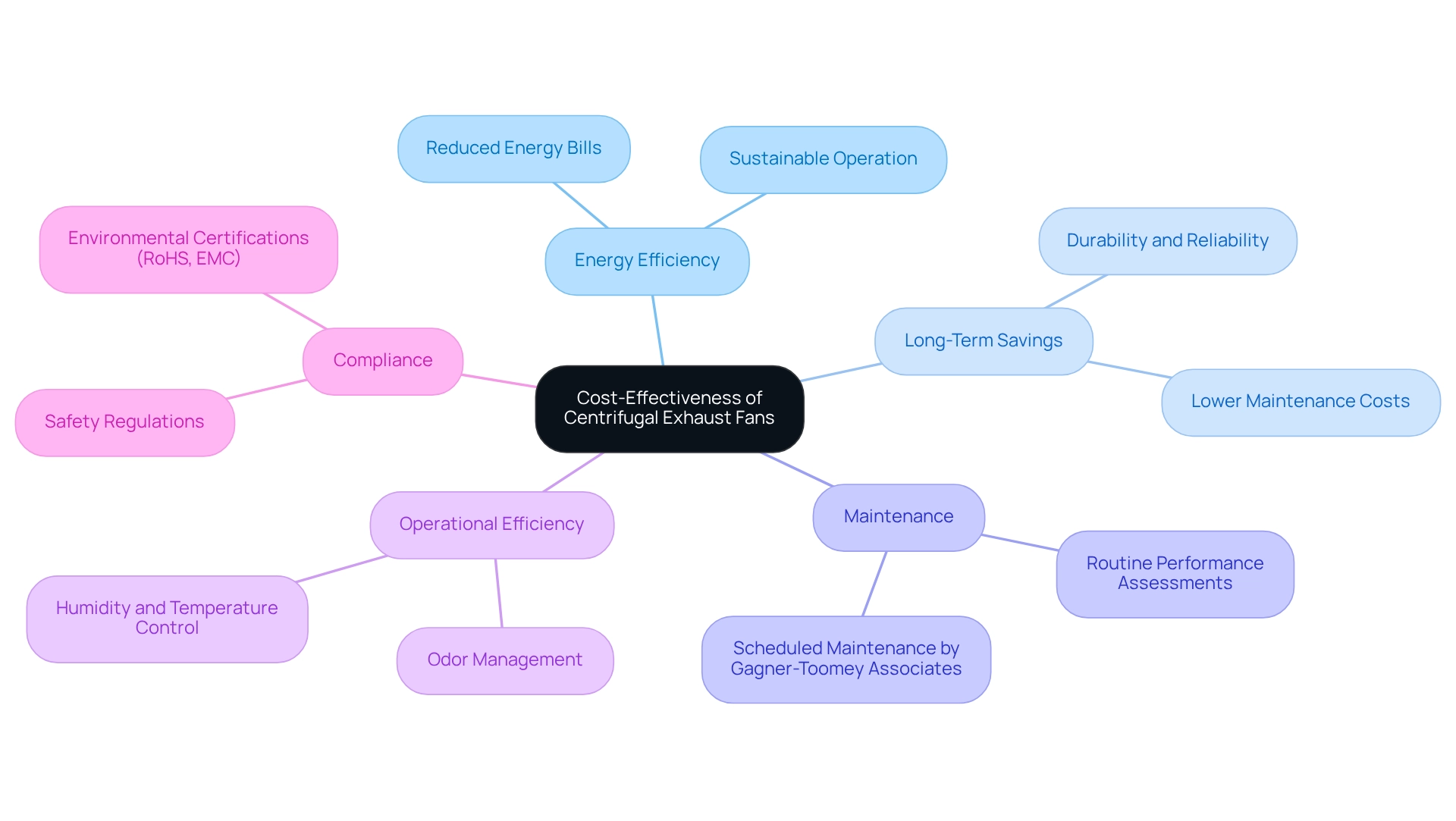

Cost-Effectiveness: Maximize Value with Centrifugal Exhaust Fans

stand out for their cost-effectiveness, largely attributed to their and robust durability. While the initial investment may surpass that of other fan types, the significant and reduced maintenance costs validate the expense.

For example, in the food and beverage sector, these devices proficiently manage odors, humidity, and temperature, thereby fostering and compliance with safety standards. Additionally, their reliability diminishes the likelihood of unexpected repair or replacement costs, allowing professionals to allocate resources more judiciously.

Gagner-Toomey Associates offers , which are vital for and ensuring these devices function effectively over time. It is advisable for professionals to routinely assess fan performance and make necessary adjustments to achieve optimal airflow and cooling.

Furthermore, selecting certified devices is imperative for , particularly in critical sectors such as pharmaceuticals and manufacturing. By choosing centrifugal exhaust fans that meet both performance requirements and budgetary constraints, professionals can ensure optimal functionality while enhancing value over time.

Regulatory Compliance: Meet Standards with Centrifugal Exhaust Fans

are meticulously engineered to comply with stringent regulatory standards, ensuring they meet . This adherence is particularly critical in the , where compliance with guidelines is a prerequisite for project approval and operational integrity. By selecting devices that fulfill these standards, professionals can guarantee the safe and efficient operation of their systems.

The shifting landscape of fan efficiency metrics, exemplified by the , highlights the necessity for continuous education and adaptation within the industry. A recent case study, ‘What is in 2023,’ illustrates how are transforming the marketplace, underscoring the significance of comprehending these developments.

Furthermore, as Michael Ivanovich notes, ‘, updates, and links related to the DOE regulation and AMCA 205 are in the Codes and Standards section,’ further emphasizing the regulatory framework that professionals must navigate. Grasping these regulations empowers when integrating centrifugal exhaust fans into their designs, ultimately enhancing system reliability and performance.

Additionally, statistics from GF Building Flow Solutions reveal that have successfully reduced production and facility waste by 36%, demonstrating the concrete advantages of .

Conclusion

Centrifugal exhaust fans play a crucial role in enhancing operational efficiency, ensuring durability, and improving air quality across diverse applications. Companies like Gagner-Toomey Associates exemplify innovation by providing solutions that empower engineers to implement cutting-edge ventilation systems tailored to the unique demands of industrial and commercial environments. The advantages of these fans extend beyond mere functionality; they facilitate significant energy savings, reduce operational costs, and contribute to healthier indoor environments.

The versatility and adaptability of centrifugal exhaust fans render them suitable for a broad spectrum of applications, from HVAC systems to fume extraction, equipping engineers with the flexibility necessary to optimize performance in varied settings. Moreover, the durability and ease of installation of these fans ensure long-lasting performance, minimizing maintenance efforts and associated costs. As the industry evolves, the integration of advanced technologies, such as smart fan solutions, will further enhance energy efficiency and air quality.

In conclusion, the increasing focus on regulatory compliance and sustainability highlights the necessity of selecting high-quality centrifugal exhaust fans. By prioritizing these systems, engineers can not only meet stringent performance standards but also cultivate healthier, more productive workplaces. The ongoing advancements in fan technology signal a future where optimal airflow, energy efficiency, and enhanced indoor air quality are attainable, reinforcing the vital role of centrifugal exhaust fans in contemporary engineering projects.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in providing cutting-edge solutions for centrifugal exhaust fans, focusing on optimizing performance and efficiency in cooling, power management, and ventilation systems.

How does Gagner-Toomey Associates support professionals in the electronics industry?

They offer specialized support and innovative solutions through a consultative approach, leveraging a sales team with over 150 years of combined industry experience to address unique challenges across various sectors.

What are the energy efficiency benefits of centrifugal exhaust fans from Gagner-Toomey Associates?

Centrifugal exhaust fans engineered by Gagner-Toomey Associates can achieve static efficiencies of up to 84%, significantly lowering operational costs and energy expenditures for facilities.

What trends are influencing the design of centrifugal exhaust fans?

There is an increasing focus on energy-efficient designs and the rise of smart fan technology in commercial applications, which can lead to substantial energy savings in workplace environments.

What are the projected energy savings from using centrifugal exhaust fans by 2025?

By 2025, typical energy savings from centrifugal exhaust fans are projected to reach approximately 30%, contributing to reduced electricity expenses and broader sustainability goals.

How do centrifugal exhaust fans improve indoor air quality?

They effectively remove contaminants, humidity, and odors, enhancing ventilation and facilitating the introduction of fresh air, which is vital for maintaining worker health and productivity in industrial settings.

What is the significance of addressing indoor air quality in workplaces?

Studies indicate that indoor air pollution levels can be significantly higher than outdoor levels, making it crucial to implement robust ventilation solutions like centrifugal exhaust fans to promote healthier work environments.

Why should engineers consider integrating centrifugal exhaust fans into their projects?

Integrating these fans can lead to significant improvements in indoor air quality, enhanced worker performance, and reduced health risks, making them essential for ensuring optimal air quality and safety in industrial environments.