Overview

This article delves into the effective mastery of electronic commutated motors (ECMs), a crucial topic for professionals in the field. It begins by examining the operation of ECMs, setting the stage for a comprehensive comparison with other motor types. By highlighting the unique advantages of ECMs, the article builds interest in their application.

ECMs stand out in enhancing energy efficiency and performance, particularly within HVAC systems. Their variable speed operation and advanced control features significantly reduce energy consumption and operational costs compared to traditional motors. This not only addresses the pressing need for energy-efficient solutions but also positions ECMs as a desirable choice for modern applications.

To further engage the reader, the article provides actionable guidance on the selection and programming of ECMs. By offering practical insights, it empowers professionals to make informed decisions that align with their operational goals. The structured approach ensures that each section logically flows into the next, reinforcing the article’s authority and credibility.

In conclusion, mastering ECMs is not just about understanding their mechanics; it’s about leveraging their capabilities to drive efficiency and performance in HVAC systems. This article serves as a valuable resource for those looking to enhance their expertise in this vital area.

Introduction

Electronic commutated motors (ECMs) are transforming HVAC technology, presenting a sophisticated alternative to traditional motor systems. By utilizing electronic controls for precise commutation, these motors significantly enhance energy efficiency and improve overall system performance. As a result, they are becoming increasingly essential in modern applications.

However, the promise of superior efficiency brings with it the challenge of selection and programming. This complexity raises an important question: how can one effectively navigate the intricacies of ECM technology to maximize its benefits while steering clear of potential pitfalls?

This article explores the operation, comparison, and optimal selection of ECMs, offering insights that empower both professionals and enthusiasts. By understanding these elements, readers can harness the full potential of this innovative technology.

Define Electronically Commutated Motors (ECMs)

Electronic commutated motors represent a significant advancement in electric devices, utilizing electronic controls to manage the commutation process—the switching of current in the windings. Unlike conventional engines that rely on mechanical brushes for commutation, an electronic commutated motor employs integrated circuits, which markedly enhance performance and efficiency. This innovative technology allows for precise regulation of speed and torque, making the electronic commutated motor ideal for applications requiring variable speed operation, such as HVAC systems.

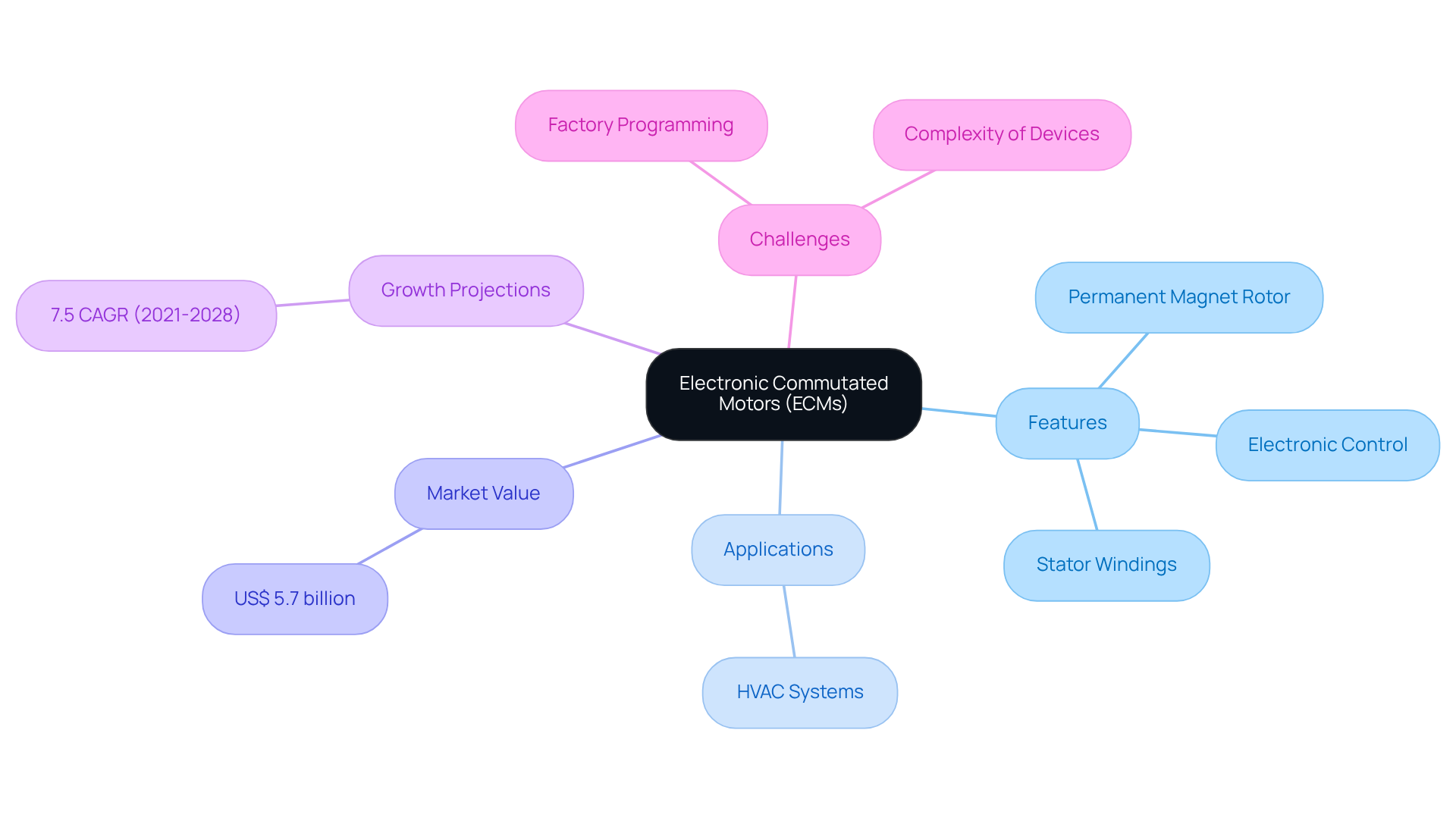

Typically, an electronic commutated motor features a permanent magnet rotor paired with a stator that has windings energized in a sequence dictated by the motor controller. This design results in smooth and efficient operation, a crucial factor in modern applications. As of 2023, the global market for electronic commutated motors (ECM) was valued at approximately US$ 5.7 billion, with the HVAC electronic commutated motor segment projected to grow at a compound annual growth rate (CAGR) of 7.5% from 2021 to 2028. Industry experts, including Christopher Mohalley, emphasize that electronic commutated motors not only enhance energy efficiency but also improve indoor air quality, making them a preferred choice in contemporary electronic applications.

However, it is essential to recognize that engine control modules are factory programmed and not easily adjustable in the field, which can impose operational constraints. Additionally, the complexity of ECM devices increases the likelihood of failures, necessitating complete replacement if any component malfunctions. Despite these challenges, the advantages of energy management systems in optimizing energy use, coupled with their growing significance in both residential and commercial settings, underscore their relevance in the shift toward sustainable technologies.

Explain How ECMs Operate in HVAC Systems

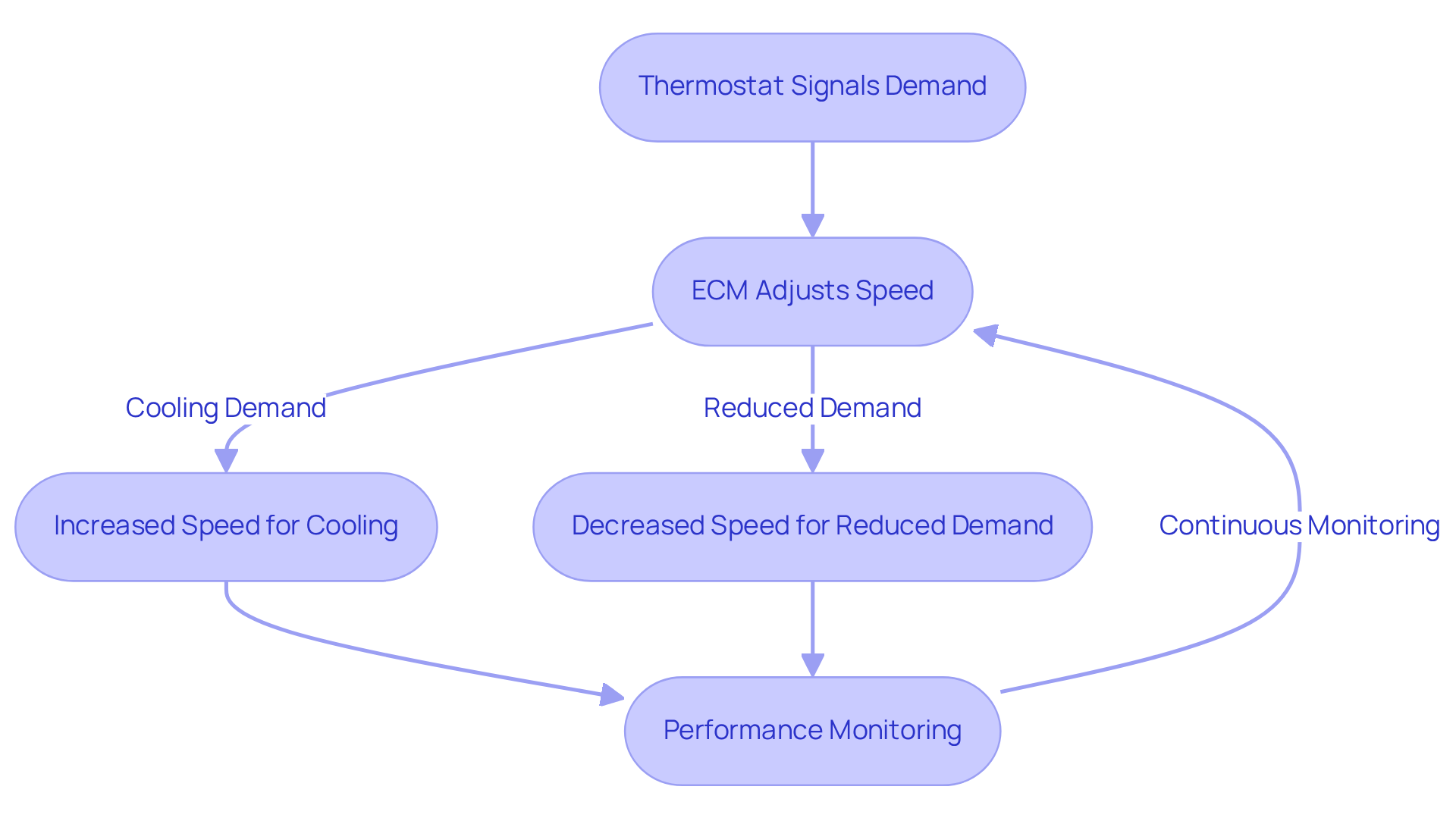

Electronic commutated motors represent a significant advancement in HVAC technology, addressing the critical need for energy efficiency in heating and cooling systems. These motors dynamically adjust their speed based on real-time heating or cooling demands, employing a sophisticated feedback loop that continuously monitors performance. For instance, when a thermostat signals a requirement for cooling, the ECM increases its speed to optimize air circulation. Conversely, during periods of reduced demand, the motor decreases its speed, leading to substantial energy savings.

This variable speed operation not only ensures consistent indoor temperatures, enhancing overall comfort, but also minimizes wear and tear on the system, thereby extending its lifespan. Recent research indicates that electromechanical systems can achieve energy performance ratings exceeding 80%, a remarkable improvement over conventional motors, which typically hover around 60%. HVAC professionals advocate for the integration of electronic commutated motors equipped with intelligent controls that adapt performance based on real-time occupancy and environmental conditions. This results in enhanced energy efficiency and operational effectiveness.

Moreover, electronic control modules come with built-in self-diagnostic systems that alert users to potential issues, further streamlining maintenance processes. While the initial investment for electronic commutated motors may be higher than that of traditional AC units, the long-term energy savings and reduced maintenance needs make them a wise investment for superior HVAC performance. By choosing ECMs, you not only enhance your system’s efficiency but also contribute to a more sustainable future.

Compare ECMs with PSC Motors: Efficiency and Performance

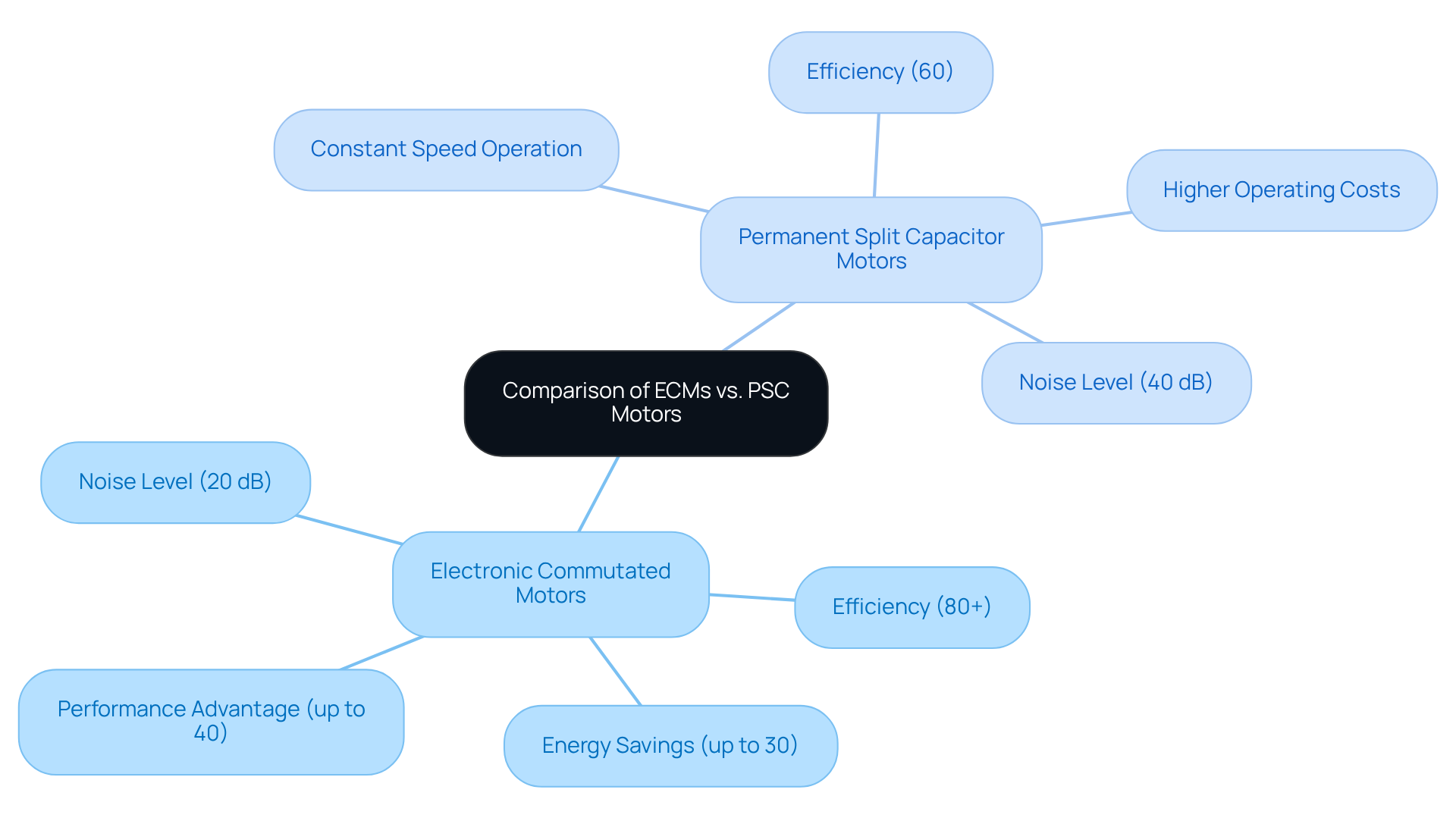

When comparing electronic commutated motors to Permanent Split Capacitor (PSC) devices, several critical distinctions emerge. Energy conversion machines typically achieve performance ratings exceeding 80%, particularly excelling at partial loads due to their ability to dynamically adjust speed based on real-time demand. This adaptability can lead to energy savings of up to 30% compared to conventional PSC devices, which generally operate at a constant speed, resulting in energy waste when full capacity isn’t needed. For instance, energy-efficient machines can cut approximately 25% off yearly operating expenses related to heating and cooling, while PSC devices often hover around 60% efficiency. Additionally, energy control systems can slash annual fan operating expenses by as much as 75% during constant fan requirements, underscoring their cost-saving potential.

In terms of performance, electronic control mechanisms provide smoother operation and quieter functioning, capable of ramping up and down without the jarring starts and stops typical of PSC units. This feature is particularly beneficial in environments where noise reduction is essential, as electronic commutated motors operate at about 20 dB, significantly quieter than PSC devices, which can reach 40 dB. Furthermore, electronic control modules enhance airflow and temperature regulation, making them ideal for modern HVAC applications that prioritize energy conservation and occupant comfort. Industry insights indicate that variable-speed electronic commutated motor devices can achieve up to 40% greater performance compared to traditional PSC models, highlighting their operational advantages. Data supports this, showing that variable-speed technology can reduce energy usage during partial load conditions by 35-45%.

Real-world applications demonstrate that systems utilizing energy control mechanisms can significantly decrease energy consumption and operational costs, reinforcing their role as a vital component in achieving sustainability goals within the HVAC sector. Recent SEER2 and HSPF2 regulations mandate that systems support a minimum of 13.4 SEER ratings, further highlighting the importance of electronic commutated motors in meeting contemporary efficiency standards.

Guide to Selecting and Programming ECMs for Optimal Performance

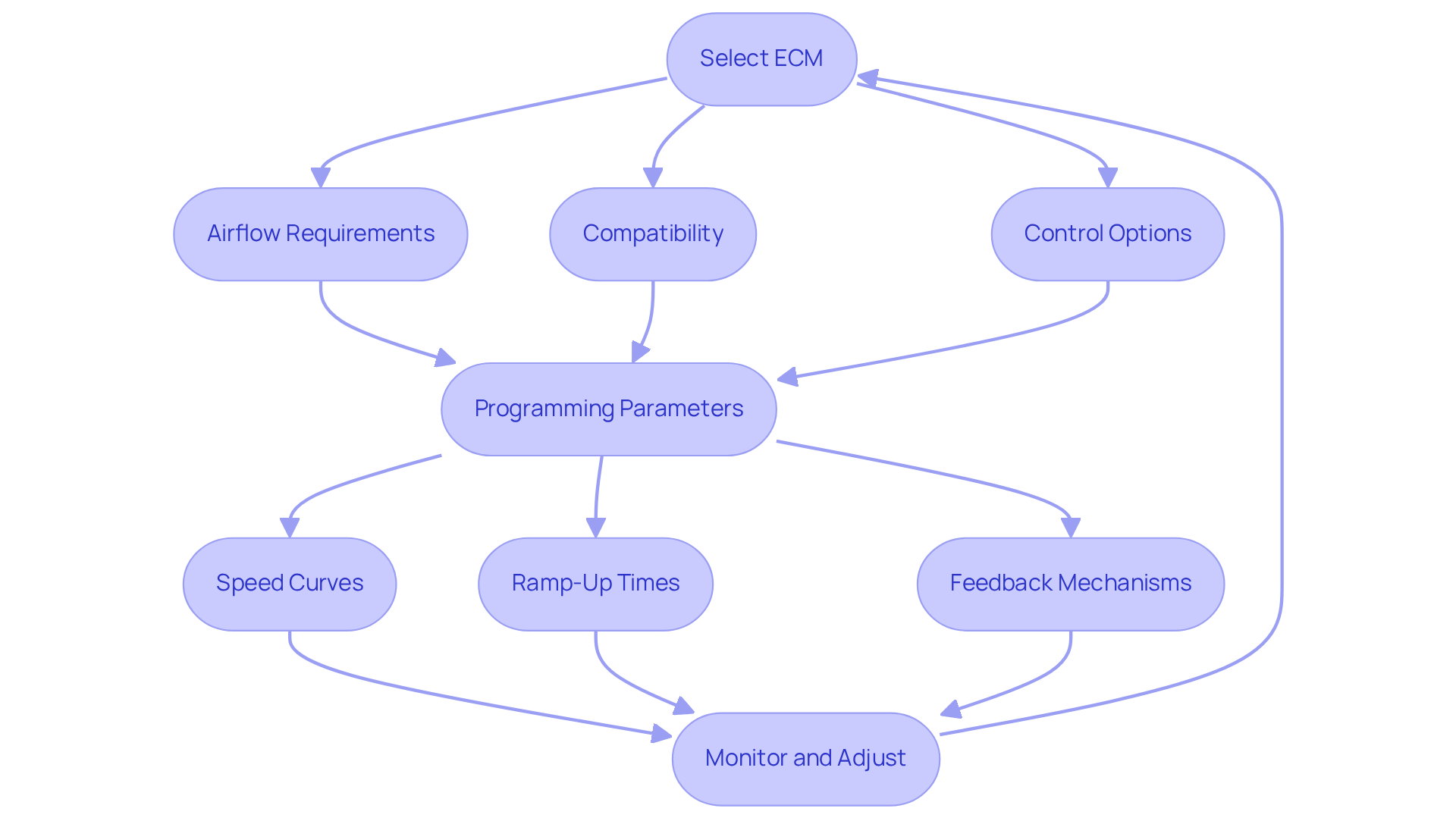

When selecting electronic commutated motors, it’s vital to consider key factors such as required airflow, compatibility with your existing setup, and available control options. Choosing a device that aligns with the specific needs of your HVAC system is essential for achieving optimal performance. Look for electronic commutated motors that offer adjustable speed settings and advanced control features, facilitating seamless integration with your current configurations.

Programming the ECM involves setting parameters like speed curves, ramp-up times, and feedback mechanisms to customize the motor’s operation according to your system’s requirements. Many modern electronic content management systems come equipped with user-friendly interfaces or software that streamline this programming process. Regularly reviewing and adjusting these configurations can significantly enhance productivity and functionality, ensuring that your system operates efficiently under varying conditions.

For instance, a study revealed that properly programmed electronic commutated motors can boost HVAC performance by as much as 30%, underscoring the importance of meticulous programming. Engineers emphasize that prioritizing simplicity and clarity in programming leads to more reliable and manageable systems. As Robert C. Martin aptly stated, “Clean code always looks like it was written by someone who cares,” highlighting the necessity of thoughtful programming practices. By adhering to best practices in programming for electronic commutated motors—such as continuous monitoring and iterative adjustments—you can ensure that your HVAC equipment remains responsive and efficient over time.

A pertinent case study illustrates this point: a junior developer at a manufacturing firm automated spreadsheet reporting, saving her team 12 hours each week. This example highlights the significant impact that effective programming can have on operational efficiency. By incorporating such practices into the programming of electronic commutated motors, engineers can realize substantial improvements in system performance.

Conclusion

Electronic commutated motors (ECMs) signify a pivotal advancement in HVAC technology, markedly enhancing energy efficiency and operational performance through advanced electronic controls. By employing integrated circuits in place of mechanical brushes, ECMs provide precise speed and torque regulation, making them exceptionally suited for variable speed applications. This innovative methodology not only optimizes energy consumption but also fosters improved indoor air quality, highlighting the critical role of ECMs in contemporary electronic systems.

The article underscores several key benefits of ECMs, particularly their capacity to dynamically adjust speed according to real-time demands. This adaptability results in substantial energy savings and diminished wear on HVAC systems. When compared to traditional Permanent Split Capacitor (PSC) motors, ECMs demonstrate performance ratings that exceed 80%, whereas PSC motors typically operate at around 60% efficiency. Additionally, the quieter operation and superior airflow regulation of ECMs render them the preferred option for environments where comfort and noise reduction are paramount.

Given these insights, it is evident that the integration of electronic commutated motors is not just a passing trend but an essential stride toward achieving sustainability in HVAC systems. As the market for ECMs continues to expand, it becomes imperative for professionals to prioritize the careful selection and programming of these motors to fully leverage their potential advantages. Embracing ECM technology not only facilitates significant cost savings and enhanced system performance but also champions a more energy-efficient future.

Frequently Asked Questions

What are electronically commutated motors (ECMs)?

Electronically commutated motors (ECMs) are advanced electric devices that use electronic controls to manage the commutation process, which is the switching of current in the motor windings. Unlike traditional motors that use mechanical brushes, ECMs utilize integrated circuits for improved performance and efficiency.

How do ECMs differ from conventional motors?

ECMs differ from conventional motors in that they do not rely on mechanical brushes for commutation. Instead, they employ electronic controls that allow for precise regulation of speed and torque, making them suitable for applications that require variable speed operation, such as HVAC systems.

What is the typical design of an ECM?

A typical electronic commutated motor features a permanent magnet rotor and a stator with windings that are energized in a specific sequence dictated by the motor controller. This design contributes to smooth and efficient operation.

What is the market value of ECMs as of 2023?

As of 2023, the global market for electronically commutated motors was valued at approximately US$ 5.7 billion.

What is the projected growth rate for the HVAC ECM segment?

The HVAC segment of electronically commutated motors is projected to grow at a compound annual growth rate (CAGR) of 7.5% from 2021 to 2028.

What benefits do ECMs provide in contemporary applications?

ECMs enhance energy efficiency and improve indoor air quality, making them a preferred choice in modern electronic applications, particularly in HVAC systems.

Are ECMs easily adjustable in the field?

No, engine control modules for ECMs are factory programmed and not easily adjustable in the field, which can create operational constraints.

What challenges are associated with ECMs?

The complexity of ECM devices can lead to a higher likelihood of failures, requiring complete replacement if any component malfunctions.

Why are ECMs significant in the context of sustainable technologies?

ECMs play a crucial role in optimizing energy use through energy management systems, highlighting their growing importance in both residential and commercial settings as part of the shift toward sustainable technologies.