Introduction

In industrial environments where moisture and dust can wreak havoc, the demand for reliable cooling solutions has never been greater. Engineers seeking to optimize performance and ensure safety face a complex landscape of features in waterproof industrial fans. This article explores ten essential characteristics that not only enhance efficiency and durability but also address the unique challenges encountered in demanding settings. How can engineers ensure they select the right fan that balances performance, energy efficiency, and safety while meeting the specific needs of their projects?

Understanding these characteristics is crucial for making informed decisions. By delving into the intricacies of waterproof industrial fans, engineers can navigate the complexities of their requirements, ensuring that their choices lead to optimal outcomes. The following sections will provide actionable insights, guiding you through the essential features that define effective cooling solutions in challenging environments.

Gagner-Toomey Associates: Leading Provider of Waterproof Industrial Fan Solutions

Gagner-Toomey Associates stands out as a leading provider of innovative temperature control solutions, especially in advanced technologies for waterproof industrial fans tailored for the electronics sector. In an industry where moisture and dust pose significant challenges, the need for reliable cooling solutions is paramount. Gagner-Toomey prioritizes innovation and exceptional customer service, representing a diverse portfolio of manufacturers that equip engineers with cutting-edge cooling technologies.

The company’s extensive product line includes:

- DC input tube axial devices

- Centrifugal blowers

This ensures engineers have access to a comprehensive range of options designed to meet their specific needs. Recent statistics reveal that energy-saving devices can reduce energy consumption by up to 70% compared to traditional AC motors, underscoring the efficiency of these advanced solutions. Successful implementations of waterproof industrial fans across various engineering projects further demonstrate their reliability and operational efficiency.

As the industry continues to evolve, Gagner-Toomey Associates remains at the forefront, connecting engineers with local distribution partners. This collaboration ensures a stable supply of components and state-of-the-art technologies that align with the specific requirements of engineers. By addressing the complex challenges faced in demanding environments, Gagner-Toomey not only enhances operational performance but also empowers engineers to achieve their project goals with confidence.

IP Rating: Understanding Waterproof Standards for Industrial Fans

The Ingress Protection (IP) rating system serves as a crucial benchmark for evaluating the capabilities of a waterproof industrial fan in commercial blowers. An IP68 rating indicates that the waterproof industrial fan is entirely dust-tight and can endure continuous immersion in water beyond 1 meter, making it particularly suitable for demanding environments. Notably, around 70% of engineers are familiar with the IP68 rating, highlighting its importance in the industry.

Understanding the IP rating system is vital for selecting the appropriate fan for specific applications. The first digit of the rating signifies protection against solid particles, while the second digit indicates protection against liquids. This knowledge is essential for engineers and decision-makers alike.

Real-world applications of waterproof industrial fans are prevalent in sectors such as manufacturing and outdoor setups, where equipment faces harsh conditions. Familiarity with these ratings not only ensures compliance with safety standards, as outlined by the international standard IEC 60529, but also enhances the durability and reliability of the equipment used. Ultimately, this leads to improved operational performance.

In summary, recognizing the significance of the IP68 rating and the broader IP rating system is imperative for professionals in the field. By prioritizing these standards, you can ensure that your equipment meets the demands of challenging environments, thereby optimizing performance and safety.

Material Quality: Ensuring Durability in Waterproof Industrial Fans

Material quality is crucial for the performance and durability of waterproof machinery. Fans made from corrosion-resistant materials like stainless steel, aluminum, and advanced high-grade plastics are vital for withstanding harsh environmental conditions. Stainless steel, especially grades 304 and 316, provides exceptional corrosion resistance due to its chromium content, which forms a protective oxide layer that prevents rust. On the other hand, aluminum, while lightweight and cost-effective, may not offer the same durability in corrosive environments. High-grade plastics are also employed for their resistance to moisture and chemicals, making them suitable for various applications.

Engineers must prioritize the waterproof industrial fan and other devices constructed from these durable materials to ensure reliability and efficiency in temperature regulation applications. For instance, waterproof industrial fans, like IP55-rated blowers, are designed to withstand contact with dust and low-pressure water jets, making them ideal for manufacturing environments where moisture and impurities are prevalent. The choice of material significantly impacts not only the fan’s performance but also its maintenance requirements and overall lifespan. This makes material selection a critical factor in the design and selection process for cooling solutions.

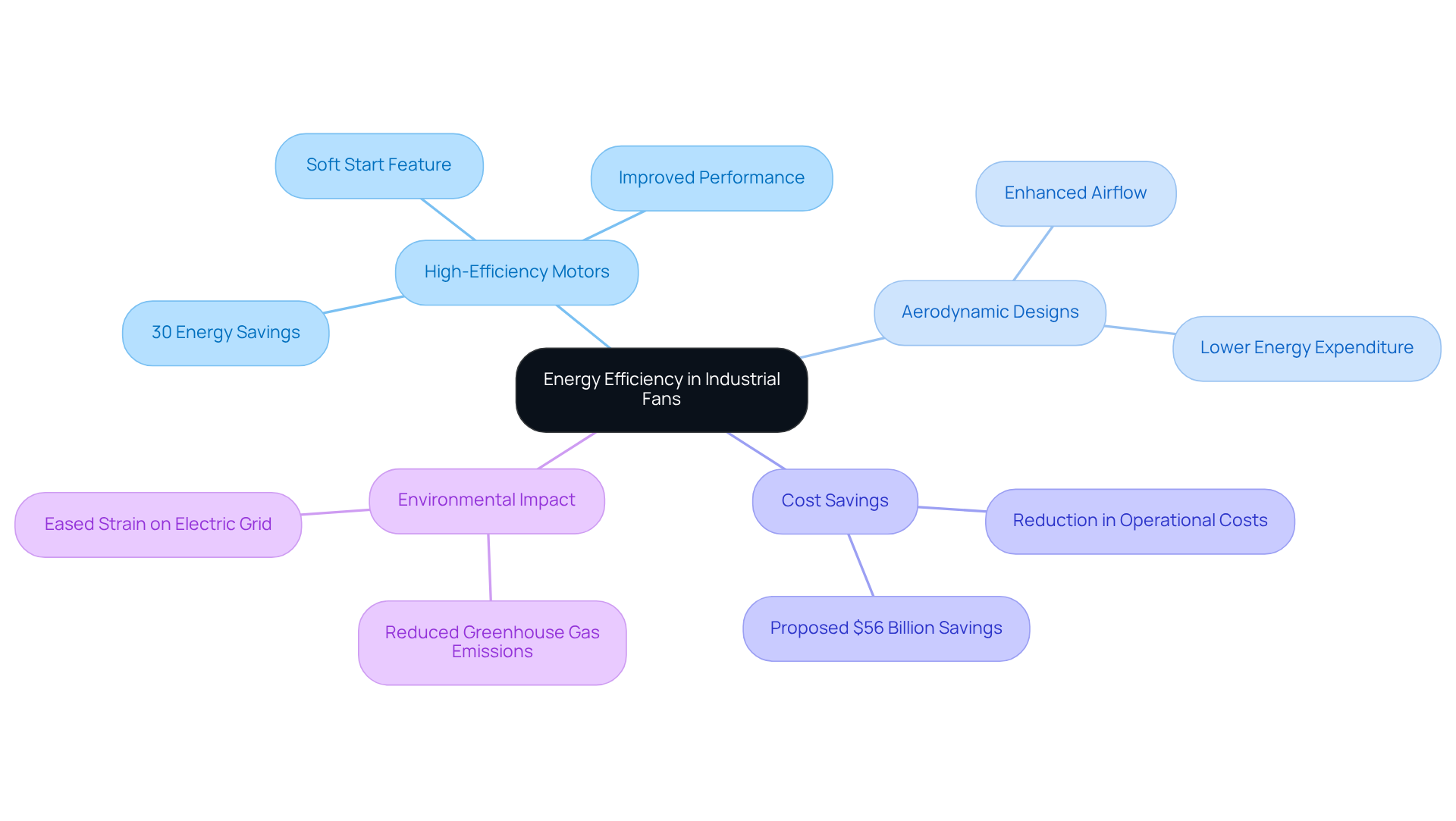

Energy Efficiency: Maximizing Performance While Minimizing Costs

Energy conservation in waterproof industrial fans is crucial for reducing operational costs and minimizing environmental impacts. Traditional motors can be inefficient, but fans equipped with high-efficiency motors can achieve average energy savings of up to 30%. This significant reduction in energy consumption does not compromise optimal airflow. Moreover, the integration of electronic commutation (EC) motors not only enhances energy efficiency but also improves fan performance through precise speed control. These motors feature a soft start that activates within five seconds of power on, extending the lifespan of both the fan and the equipment.

When selecting fans, engineers must prioritize energy ratings to ensure they meet cooling requirements while promoting sustainable practices. The implementation of aerodynamic blade designs further boosts performance, facilitating effective airflow with lower energy expenditure. According to proposed energy-saving standards, American companies could save nearly $56 billion on utility costs, underscoring the economic benefits of adopting energy-efficient solutions.

As Andrew deLaski, executive director of the Appliance Standards Awareness Project, points out, these measures not only reduce costs for businesses but also decrease greenhouse gas emissions. By incorporating high-efficiency motors and considering features like locked rotor protection—which endures for a minimum of 72 hours at rated voltage—organizations can realize substantial savings throughout their equipment’s lifespan. This highlights the critical importance of energy efficiency in refrigeration systems.

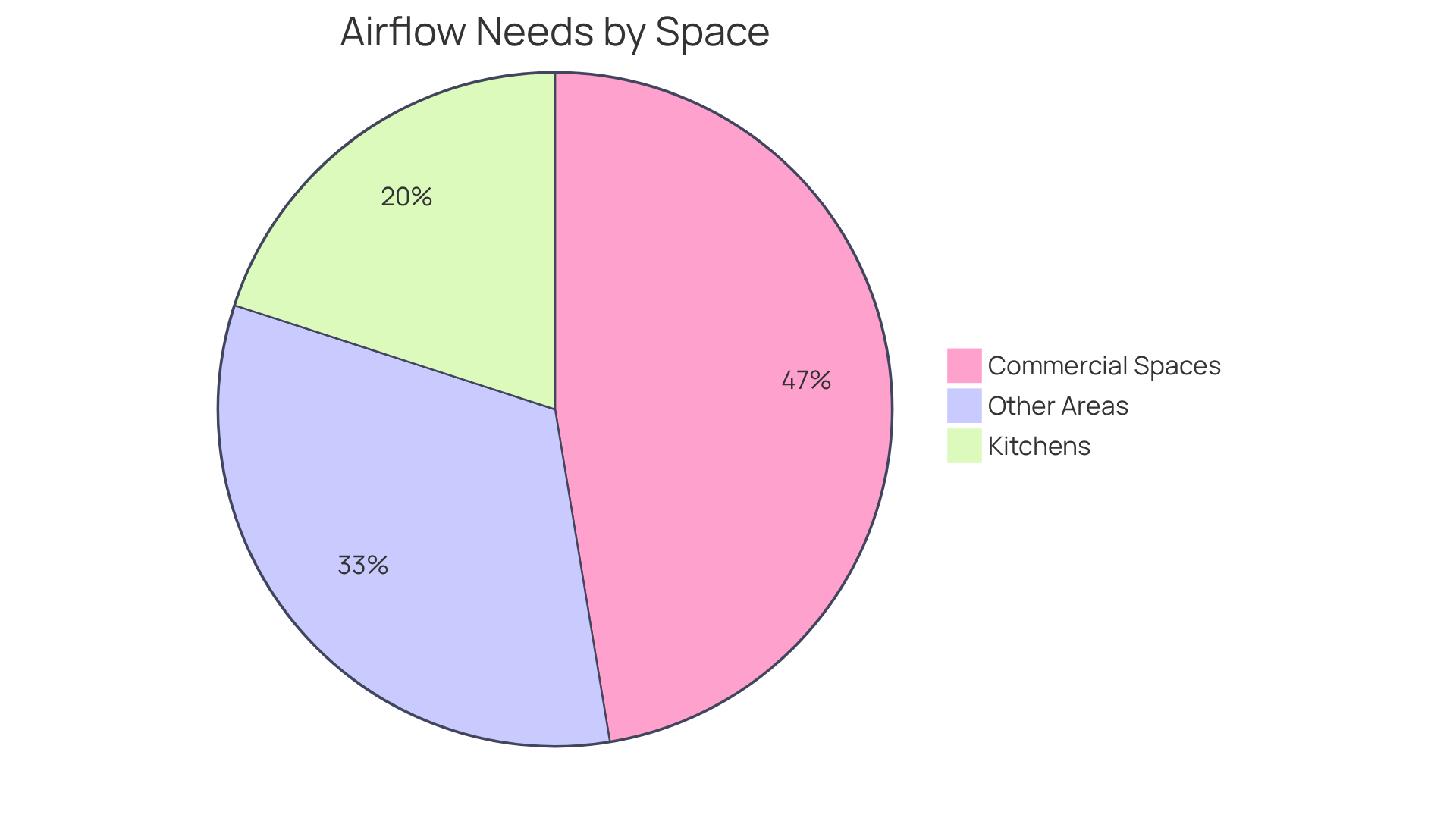

Airflow Capacity: Key to Effective Cooling Solutions

Airflow capacity, measured in cubic feet per minute (CFM), is a critical specification for waterproof industrial fans. Selecting a fan with sufficient airflow capacity is essential for effective temperature regulation in large or densely populated areas. For example, commercial spaces typically require airflow rates of 474 CFM for optimal ventilation, while kitchens may need as much as 200 CFM or more to satisfy their ventilation requirements.

Engineers must calculate the necessary CFM based on the dimensions of the space and the heat load generated by equipment. The formula to use is: CFM = Area (sq ft) × Velocity (FPM). Consider a room measuring 15 ft x 12 ft x 10 ft, which has a volume of 1,800 cubic feet. To achieve 10 air changes per hour (ACH), this room would necessitate a CFM of approximately 300.

By grasping airflow dynamics, engineers can select a waterproof industrial fan that not only enhances temperature regulation but also ensures comfortable working conditions. High-CFM units, capable of moving over 5,000 CFM, can effectively cool areas up to 300 square feet, particularly 4-speed models that provide versatile cooling options.

Understanding and calculating CFM is fundamental for optimizing HVAC performance and maintaining balanced airflow. This knowledge ultimately leads to improved energy efficiency and system longevity.

Noise Levels: Balancing Performance and Workplace Comfort

Noise levels are a critical factor in selecting waterproof industrial fans, especially in environments where comfort and communication are essential. Engineers must prioritize devices that feature advanced noise-reduction technologies, including sound-absorbing materials and aerodynamic blade designs, which effectively minimize operational noise.

For example, the implementation of HVLS units in manufacturing and agricultural settings has demonstrated that quieter environments significantly enhance worker communication and overall productivity. Maintaining acceptable noise levels, ideally between 70 dBA and 90 dBA at a distance of 10 feet, not only fosters a more comfortable workplace but also boosts productivity, making this a vital consideration in fan selection.

According to the Occupational Safety & Health Administration (OSHA), the permissible noise exposure limit is set at 90 dBA based on a time-weighted average over an 8-hour workday. In contrast, the National Institute for Occupational Safety & Health (NIOSH) recommends limiting exposure to below 85 dBA. As industries increasingly transition towards quieter solutions, the demand for innovative designs that effectively balance performance with reduced noise is more critical than ever.

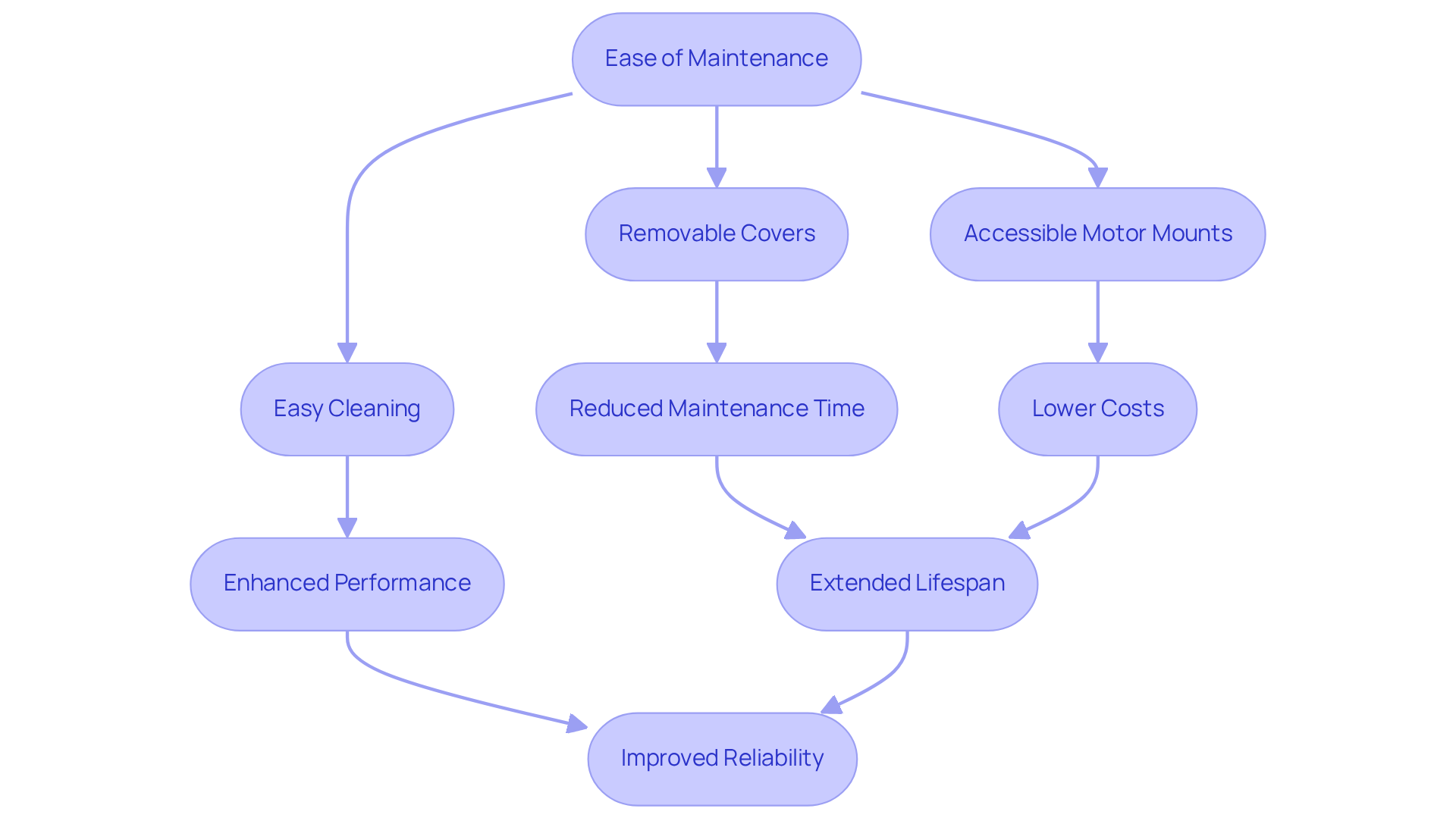

Ease of Maintenance: Ensuring Longevity and Reliability

The simplicity of upkeep is crucial for a waterproof industrial fan, as it directly impacts its lifespan and dependability. Fans designed with features like removable covers and accessible motor mounts significantly reduce maintenance time and associated costs. For instance, designs that facilitate easy cleaning, lubrication, and part replacement not only streamline maintenance but also enhance operational performance.

Routine maintenance tasks are essential for enhancing the performance and reliability of waterproof industrial fans, enabling engineers to concentrate on critical responsibilities instead of extended service periods. By prioritizing waterproof industrial fan models that emphasize ease of maintenance, organizations can ensure consistent performance and substantially extend the lifespan of their cooling solutions.

As David Long, Vice President of Sales, states, “Routine, proactive maintenance can extend the lifespan of your fan, enhance energy performance, and avert expensive failures.” This proactive approach not only protects investments but also improves workplace safety and efficiency.

In summary, investing in maintenance-friendly designs is not just a cost-saving measure; it’s a strategic decision that enhances overall operational effectiveness.

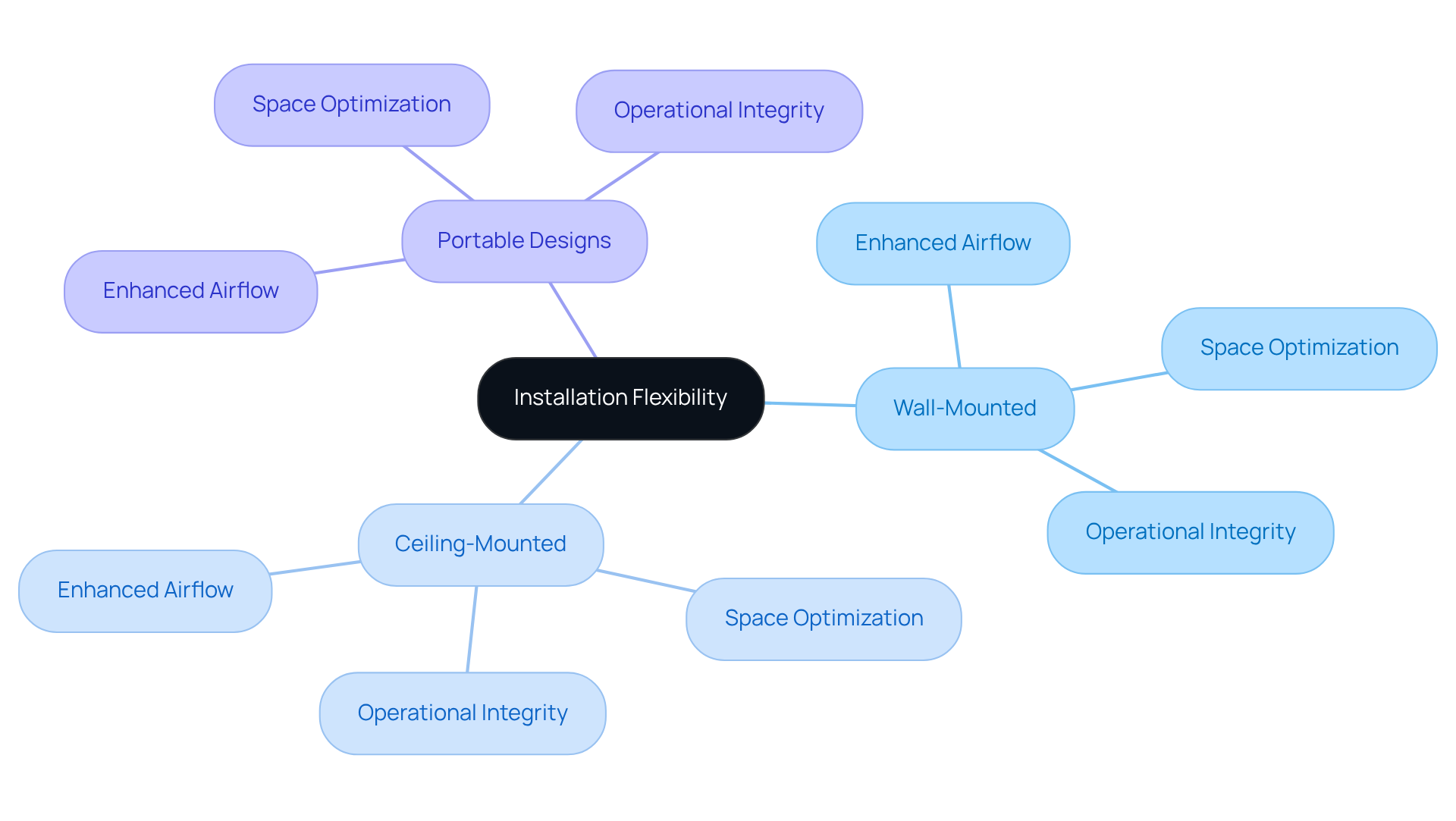

Installation Flexibility: Adapting to Diverse Industrial Environments

Installation flexibility is crucial for waterproof industrial fans, as different industrial environments demand tailored mounting solutions. Fans that offer multiple installation options—such as wall-mounted, ceiling-mounted, or portable designs—allow engineers to adapt to specific spatial constraints and airflow requirements. This versatility not only boosts cooling performance but also guarantees that equipment operates efficiently across diverse settings.

For example, a waterproof industrial fan can be strategically positioned in moisture-prone areas, safeguarding both the fan and surrounding equipment. With an average of five installation choices available for waterproof industrial fans, engineers can select the most suitable setup to enhance airflow and maintain operational integrity in challenging conditions.

By understanding the significance of installation flexibility, engineers can make informed decisions that optimize performance and reliability in their applications.

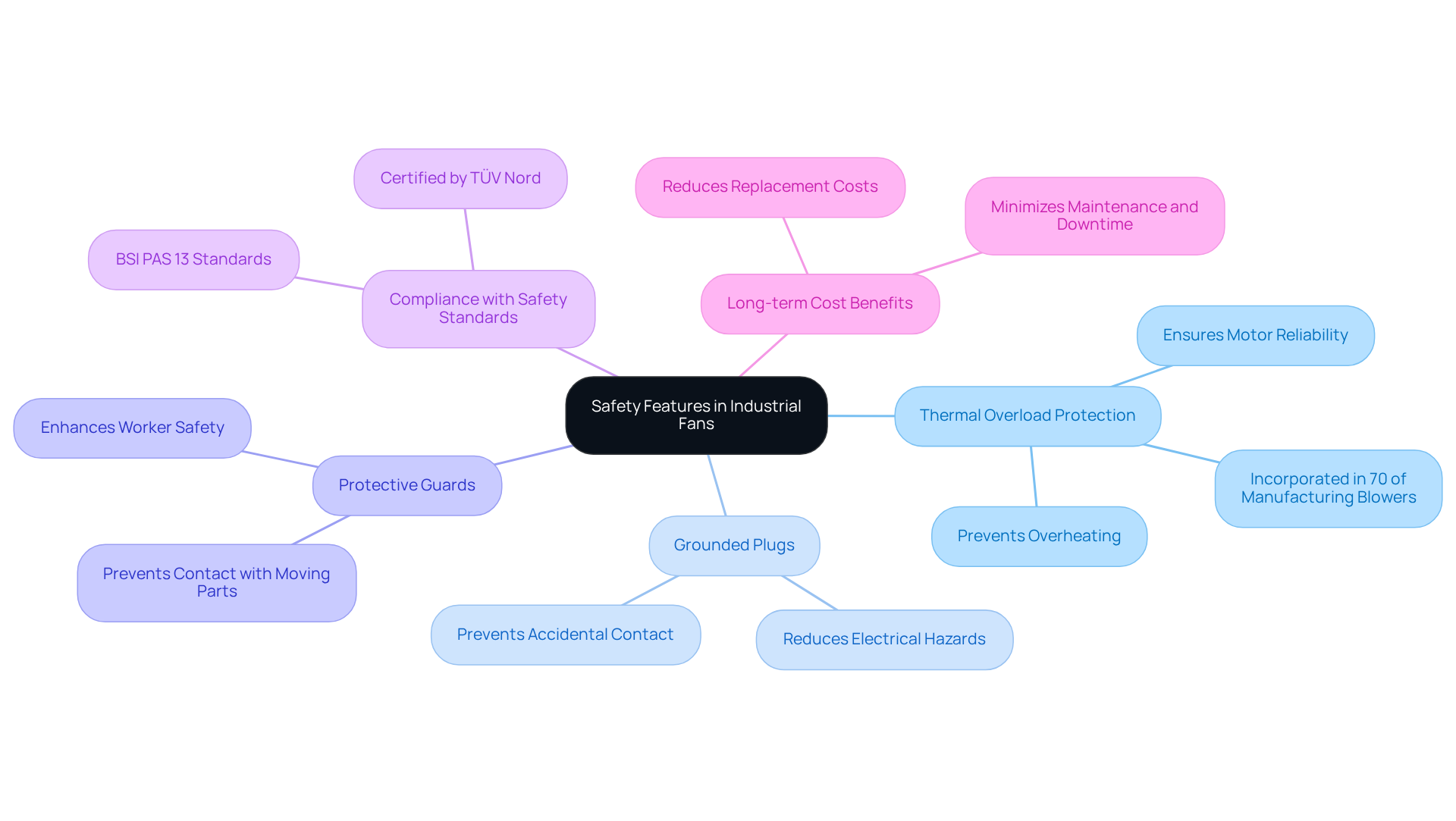

Safety Features: Protecting Workers and Equipment

Safety attributes in a waterproof industrial fan are crucial for safeguarding both personnel and equipment. The problem is clear: without effective safety measures, the risk of accidents increases significantly. Key safety features, such as thermal overload protection, are vital; approximately 70% of manufacturing blowers incorporate this feature, ensuring motors do not overheat and malfunction during operation. Additionally, grounded plugs and protective guards play a critical role in preventing accidental contact with moving parts, thereby reducing the risk of electrical hazards.

In 2023, the fatality rate stood at 3.5 fatalities per 100,000 full-time equivalent workers, highlighting the urgent need for robust safety measures in industrial environments. Engineers must prioritize devices that comply with established safety standards, such as those set by BSI PAS 13. Notably, A-SAFE products undergo rigorous testing according to these standards and are certified by TÜV Nord, ensuring their reliability.

By utilizing devices equipped with strong safety features, organizations not only protect their personnel but also significantly mitigate the risk of equipment damage. This dual benefit fosters a safer and more efficient working environment. As A-SAFE aptly states, “The initial costs of installing A-SAFE protections have more than compensated for the savings we have made on replacing damaged parts and regular painting and maintenance.” This statement underscores the long-term value of investing in safety.

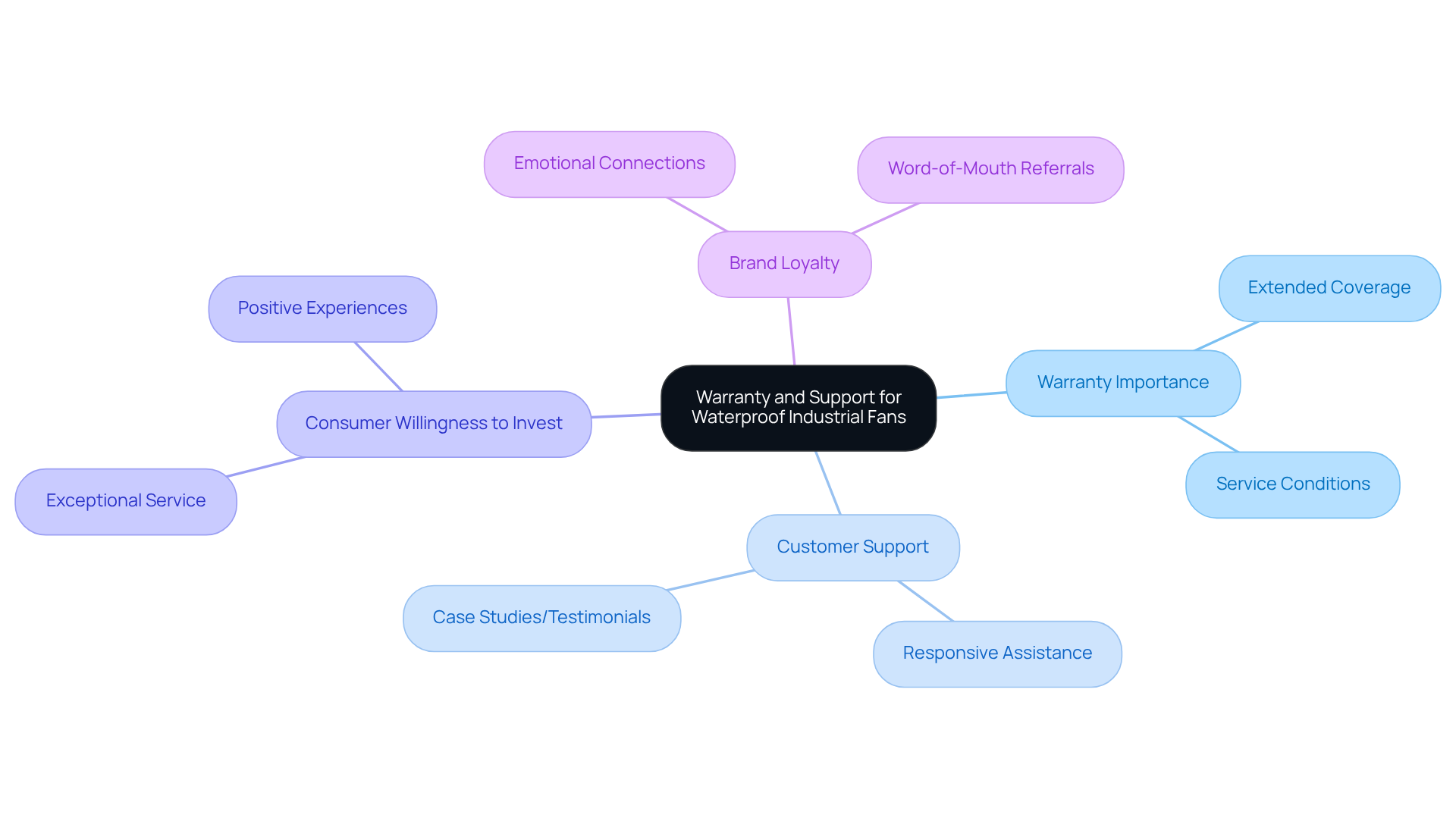

Warranty and Support: Ensuring Peace of Mind for Users

When selecting a waterproof industrial fan, warranty and customer assistance are paramount. A robust warranty not only reflects the manufacturer’s confidence in their product but also provides users with peace of mind regarding potential repairs or replacements. Engineers should prioritize devices that come with strong warranty terms, including extended coverage durations and clear service conditions, alongside responsive customer support.

Research shows that over 70% of consumers are willing to invest more in companies that deliver exceptional service. This statistic underscores the vital role of customer support in building brand loyalty. Positive customer experiences can lead to powerful brand advocacy. As Shep Hyken notes, creating raving fans is essential for business success. Therefore, manufacturers must cultivate strong relationships with their clients.

For instance, engineers should seek out manufacturers that offer detailed case studies or testimonials that highlight their customer support effectiveness. Ultimately, effective customer support transcends mere service; it represents a commitment to the reliability of the waterproof industrial fan, reinforcing the value of the selected cooling solutions.

Conclusion

Understanding the essential features of waterproof industrial fans is crucial for engineers selecting optimal cooling solutions in challenging environments. These fans not only enhance operational performance but also ensure safety and reliability across various applications. By prioritizing features such as:

- IP ratings

- Material quality

- Energy efficiency

- Airflow capacity

- Noise levels

- Ease of maintenance

- Installation flexibility

- Safety attributes

- Robust warranty support

engineers can make informed decisions that align with their specific project requirements.

Key insights highlighted throughout this article include the importance of the IP68 rating for durability, the role of high-efficiency motors in energy conservation, and the necessity of selecting materials that withstand harsh conditions. Additionally, understanding airflow dynamics and noise management is vital for creating comfortable and productive workspaces. Emphasizing ease of maintenance and installation flexibility further ensures that the chosen solutions remain effective and reliable over time.

Ultimately, selecting waterproof industrial fans transcends a mere technical decision; it is a strategic choice that impacts operational efficiency, safety, and cost-effectiveness. Engineers are encouraged to leverage the insights provided to enhance their projects, ensuring they choose solutions that meet the rigorous demands of their environments. By doing so, they not only protect their investments but also contribute to a safer and more efficient workplace, driving innovation and progress in their respective fields.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is a leading provider of innovative temperature control solutions, particularly specializing in waterproof industrial fans for the electronics sector.

What types of products does Gagner-Toomey offer?

Gagner-Toomey offers a diverse product line that includes DC input tube axial devices and centrifugal blowers, providing engineers with a comprehensive range of cooling solutions.

How do energy-saving devices from Gagner-Toomey compare to traditional AC motors?

Energy-saving devices can reduce energy consumption by up to 70% compared to traditional AC motors, highlighting their efficiency.

What is the significance of the IP68 rating for waterproof industrial fans?

An IP68 rating indicates that a waterproof industrial fan is entirely dust-tight and can withstand continuous immersion in water beyond 1 meter, making it suitable for demanding environments.

Why is understanding the IP rating system important for engineers?

Understanding the IP rating system is crucial for selecting appropriate fans for specific applications, as it indicates protection against solid particles and liquids.

In which sectors are waterproof industrial fans commonly used?

Waterproof industrial fans are commonly used in sectors such as manufacturing and outdoor setups, where equipment is exposed to harsh conditions.

What materials are recommended for the construction of waterproof industrial fans?

Recommended materials for waterproof industrial fans include corrosion-resistant stainless steel, aluminum, and advanced high-grade plastics, which help withstand harsh environmental conditions.

How does material quality affect the performance of waterproof industrial fans?

Material quality significantly impacts the performance, reliability, and lifespan of waterproof industrial fans, influencing their maintenance requirements and overall efficiency in temperature regulation applications.