Overview

The article elucidates the significant advantages of PWM (Pulse Width Modulation) controlled fans for electronics engineers. It emphasizes key benefits such as:

- Energy efficiency

- Noise reduction

- Enhanced system stability

Notably, evidence demonstrates that PWM fans can dynamically adjust their speed in response to thermal conditions. This capability leads to substantial energy savings and quieter operation, which are essential in modern electronic applications. By leveraging these advantages, engineers can optimize their designs for improved performance and sustainability.

Introduction

In the rapidly evolving landscape of electronics, effective thermal management has emerged as a critical factor in ensuring optimal performance and reliability. Gagner-Toomey Associates stands at the forefront of this challenge, offering innovative Pulse Width Modulation (PWM) cooling solutions tailored to meet the diverse needs of modern electronic systems.

With a legacy dating back to 1981, this leading provider not only showcases cutting-edge PWM fan technology but also emphasizes the importance of energy efficiency and noise reduction.

As industries increasingly rely on advanced cooling strategies to support the expansion of technologies like 5G, understanding the advantages of PWM fans becomes essential for engineers striving to enhance system stability and longevity.

This article delves into the multifaceted benefits of PWM technology, exploring its role in improving performance across various applications and providing essential insights for engineers navigating the complexities of thermal management.

Gagner-Toomey Associates: Leading Provider of PWM Cooling Solutions

Gagner-Toomey Associates stands out as a leading provider of featuring , dedicated to advancing innovative temperature regulation technologies that markedly enhance performance and efficiency in electronic systems. With a robust history of serving Northern California’s technology markets since 1981, Gagner-Toomey presents an extensive portfolio of manufacturers, showcasing the latest innovations, including the . This enables engineers to deploy tailored to their unique requirements.

As is crucial to the success of expanding , Gagner-Toomey’s unwavering commitment to excellence, exceptional customer support, and consultative approach positions them as a reliable partner for electronics engineers. Furthermore, advancements in Delta’s illustrate the impact of PWM controlled fan technologies on performance and reliability, underscoring the importance of investing in optimal to ensure seamless connectivity and enhance user experiences. Gagner-Toomey serves a diverse array of sectors, including:

- Telecom

- Networking

- IT/Data Center

- Automotive

ensuring that engineers have access to the most efficient , such as the PWM controlled fan.

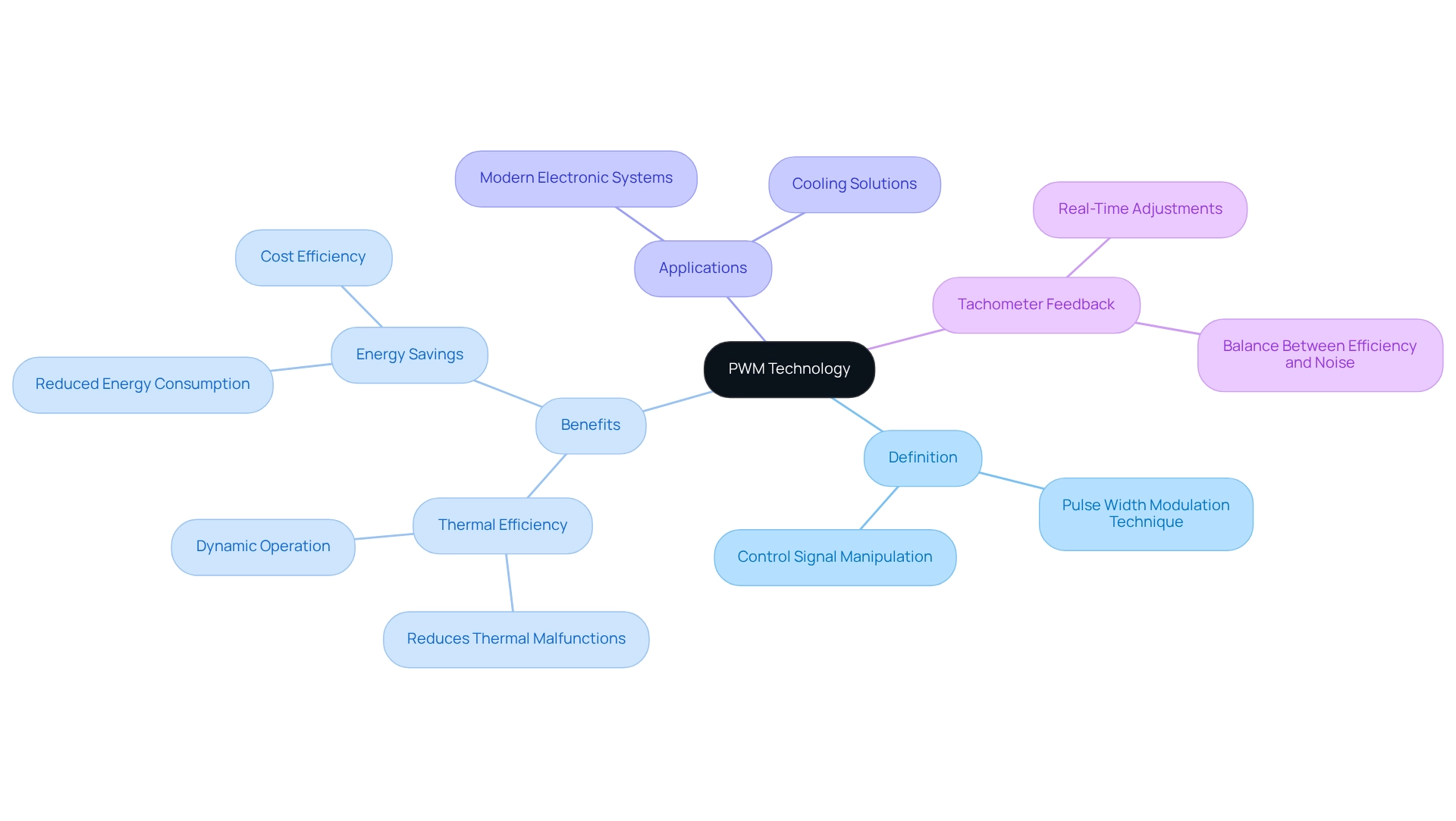

Understanding PWM Technology: The Backbone of Efficient Fan Control

Pulse Width Modulation (PWM) is a sophisticated technique used to regulate the speed of a by manipulating the pulse widths in a control signal. This method enables precise adjustments to fan speed, facilitating dynamic operation that aligns seamlessly with thermal requirements.

By varying the duty cycle of the PWM controlled fan, engineers can significantly while concurrently reducing . This capability is particularly vital in modern electronic systems, where effective is crucial.

Notably, the integration of a PWM controlled fan with tachometer feedback underscores its importance; this combination allows for , achieving an optimal balance between efficiency and noise reduction. Such advancements not only mitigate the risk of thermal malfunctions but also contribute to energy savings, making indispensable in the design of reliable and efficient temperature control solutions.

Gagner-Toomey Associates has successfully served over 400 clients, demonstrating their expertise in this domain. As Mondelez International articulates, ‘We have been working with MarkWide Research for a number of years now, and we have found their market research reports to be invaluable in helping us make strategic decisions for our business.’ This statement underscores the value of informed insights in optimizing PWM technology for enhanced performance.

PWM Fans vs. Traditional Fans: Key Advantages for Electronics

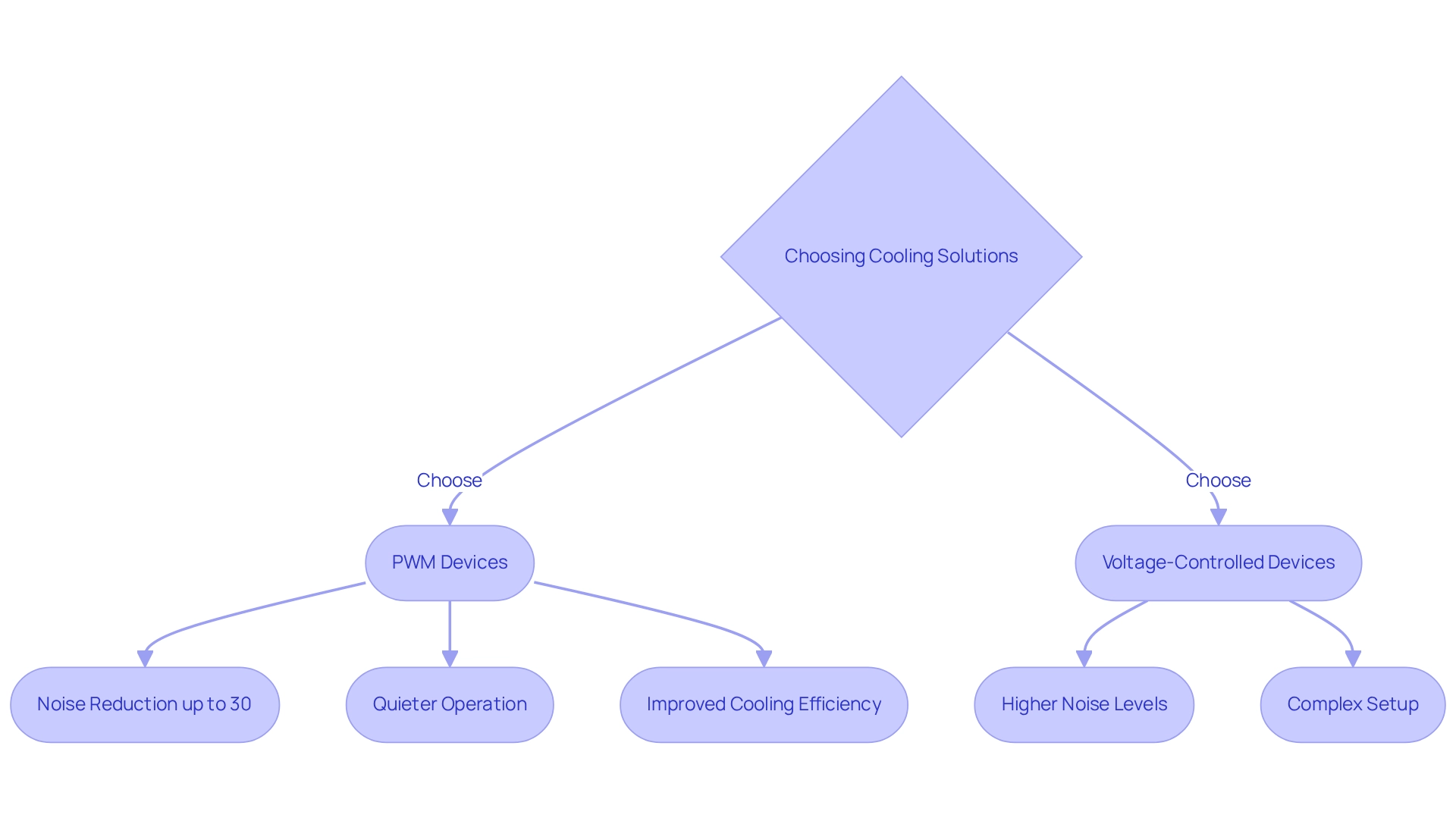

provide distinct advantages over traditional fans, establishing themselves as an essential choice for contemporary electronic applications.

Variable Speed Control: Unlike traditional fans that operate at a fixed speed, PWM fans dynamically adjust their speed based on real-time temperature readings. This capability ensures optimal temperature regulation tailored to specific needs with a .

: PWM units excel in energy conservation by functioning at lower speeds during times of decreased temperature regulation demand. This not only minimizes power consumption but also translates to lower operational costs, making a financially savvy choice for engineers. Common analog signals for voltage-controlled devices are typically 0-10 VDC or 6-20 mA, highlighting the efficiency of .

: Operating quietly at lower speeds, compared to conventional models, which often run at full speed regardless of the cooling requirements. This feature is particularly beneficial in environments where noise control is paramount.

In addition to these benefits, studies have demonstrated that as low as 20 dBA, in contrast to conventional units that may surpass 30 dBA under similar conditions. Moreover, the application of a PWM controlled fan has been associated with improved energy efficiency, with reports showing up to 30% reduced energy usage compared to traditional fan setups. As indicated by industry specialists, ‘Comprehending your apparatus’s capabilities and how they correspond with your will assist you in making a .’ Furthermore, investing in a PWM controlled fan is beneficial for accurate temperature regulation and noise reduction, even though it is pricier. The use of PCB Design and Analysis tools from Cadence, such as OrCAD software, can aid engineers in effectively implementing solutions for PWM controlled fans, demonstrating the practical applications of PWM technology in cooling systems. These factors collectively underscore the advantages of PWM devices in fulfilling the requirements of contemporary electronics.

Enhancing Energy Efficiency: The Role of PWM Controlled Fans

s significantly enhance by dynamically adjusting their speed based on real-time thermal conditions. This capability allows devices to operate at lower speeds when the unit is cool, resulting in reduced energy consumption. Research indicates that PWM devices can achieve of up to 30% compared to conventional systems, positioning them as not only environmentally friendly but also .

Furthermore, case studies have demonstrated that implementing in data centers leads to improved , effectively balancing energy savings with operational stability. For instance, one study proposed a that addresses while maintaining stable temperature control. Notably, the cold side temperature can be reduced to 1.56 °C when the hot side is cooled to 28.81 °C, showcasing the effectiveness of PWM technology in managing thermal conditions.

As J.-H.H., the designer of the energy-saving control scheme, stated, ‘The energy saving control scheme was designed to optimize performance while reducing consumption.’ Consequently, the incorporation of a PWM controlled fan represents a strategic action for aiming to enhance energy efficiency in their designs.

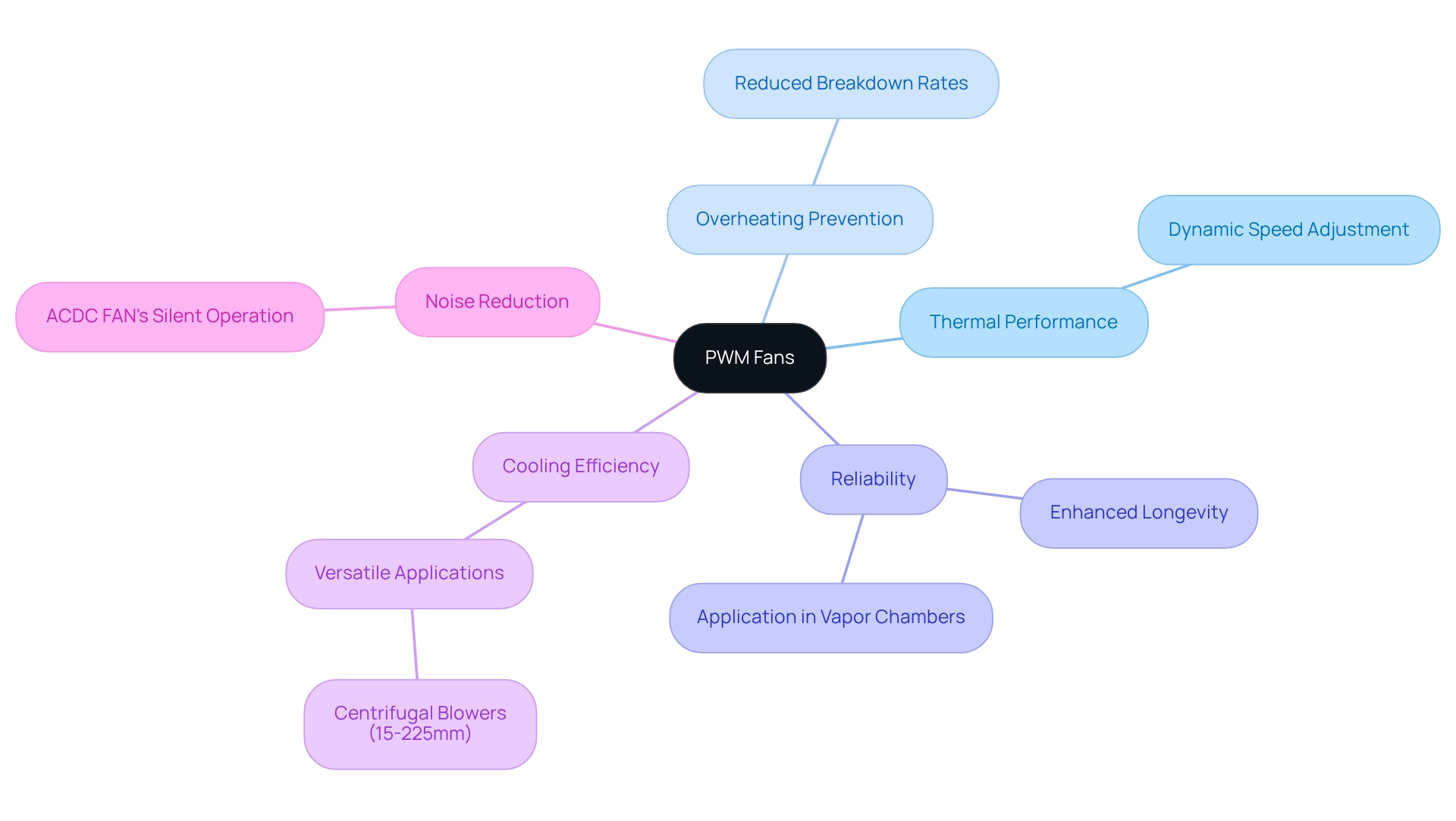

Noise Reduction Benefits: How PWM Fans Improve Acoustic Performance

are recognized for their remarkable capacity to operate quietly, a characteristic that significantly enhances . By intelligently adjusting the speed of the units in response to thermal requirements, these devices can reduce their operational pace during periods of low temperature regulation. This capability leads to a substantial decrease in noise levels, making [PWM devices](https://gagner-toomey.com/understanding-fan-pwm-meaning-definition-and-applications) particularly advantageous in noise-sensitive environments such as offices, residences, and data centers. Engineers can achieve without compromising , which is vital for maintaining optimal performance in high-performance setups.

Understanding system capabilities is essential for making between PWM and voltage-controlled devices. Statistics reveal that PWM devices can attain s of up to 30% compared to traditional voltage-controlled models, establishing them as a preferred choice for . Furthermore, case studies underscore the transformative impact of into cooling solutions, showcasing their ability to enhance cooling efficiency while prolonging the lifespan of electronic components. In one notable instance, the implementation of PWM devices resulted in a significant reduction in ambient noise levels, fostering improved workplace productivity and creating a more conducive working environment.

Moreover, voltage-controlled devices often necessitate additional hardware or software for effective management, complicating setup and integration. The benefits of PWM devices extend beyond mere noise reduction; they also contribute to more sustainable operations by minimizing power consumption. As the demand for quieter and more efficient temperature control solutions continues to rise, PWM devices emerge as critical components in the design of modern electronic systems. As one engineer remarked, “What a difference! Couldn’t even tell the SC936 is turned on!” This firsthand account underscores the substantial advantages of PWM devices in enhancing acoustic performance.

Improving System Stability: The Contribution of PWM Fans

are essential for . Their capability to dynamically adjust speed in response to temperature fluctuations ensures that critical components operate within safe limits. This proactive approach to is vital for and performance degradation.

Research indicates that systems equipped with significantly fewer breakdowns due to overheating, allowing engineers to develop more under varying loads. Moreover, the versatility of PWM devices not only .

For instance, ACDCFAN’s products operate silently at lower speeds without sacrificing performance. As noted by an expert, “This adaptability makes PWM devices superior to conventional ones in terms of both performance and efficiency.”

Additionally, Gagner-Toomey Associates provides ranging from 15 to 225mm, illustrating the diverse applications of PWM technology. Consequently, to enhance the reliability and longevity of their designs, effectively addressing challenges akin to those encountered in vapor chamber applications where reliability is paramount.

Versatile Applications: PWM Fans in Computers and Data Centers

PWM devices are indispensable across a spectrum of applications, particularly within computers and . In computing systems, they are crucial for regulating the temperatures of CPUs and GPUs, where maintaining optimal conditions is vital for achieving peak performance. Unlike DC fans, which exhibit limited speed control and struggle to adapt to rapidly changing temperature demands, can dynamically adjust their speeds based on real-time temperature readings. This adaptability significantly enhances their efficiency in managing thermal conditions, rendering them ideal for applications that necessitate precise .

This is especially critical in data centers, where can lead to substantial reductions in . For instance, Digital Realty’s SIN10 facility in Singapore achieves remarkable efficiency, conserving 1.24 million liters of water monthly through . As Kyle Chien, Senior Director of Market Insights at Innovation Acceleration Group, Digital Realty, articulates, “Whether it’s AI, IoT, or HPC, our facilities are shell-ready and design-ready to meet the advanced computing temperature management needs of our customers.”

With the escalating demand for , the versatility of PWM fans positions them as the preferred solution across various electronic setups, from consumer devices to extensive industrial applications. Their superior flexibility and precision in speed modulation not only enhance temperature control but also contribute to the overall sustainability of data center operations, ultimately influencing .

Choosing the Right PWM Fan: Essential Considerations for Engineers

When selecting , engineers must meticulously evaluate several to ensure in their applications.

- Size: The fan must fit seamlessly within the designated space of the setup, which is essential for preserving airflow efficiency and overall system integrity.

- Airflow: Assessing the required airflow for is paramount, tailored to the specific application. For instance, centrifugal fans are often favored for lower airflow needs, rendering them ideal for compact electronic devices. This consideration is particularly pertinent in scenarios such as the studied in 1995, where was vital for ensuring adequate ventilation for a substantial number of hens.

- : This factor is crucial, especially in densely populated environments where airflow resistance can significantly affect performance. A fan’s ability to counteract this resistance is essential for providing sufficient ventilation. The findings from the poultry house case study underscore the importance of selecting units capable of delivering the necessary airflow despite potential static pressure challenges.

- Noise Level: Engineers should opt for devices that meet the acoustic demands of their application. Noise can be a decisive factor in environments where sound levels must be minimized, such as in consumer electronics or medical devices. Yanta highlights that inquiries arise regarding how different models can achieve efficiency while adhering to their specifications, reinforcing the need for a thorough evaluation of in conjunction with performance.

By rigorously analyzing these factors, when selecting a , ensuring it aligns with the specific thermal requirements of their projects. Furthermore, real-world assessments, including those conducted in agricultural contexts, emphasize the significance of airflow performance and static pressure in fan selection, thereby underscoring the necessity for careful consideration in engineering applications.

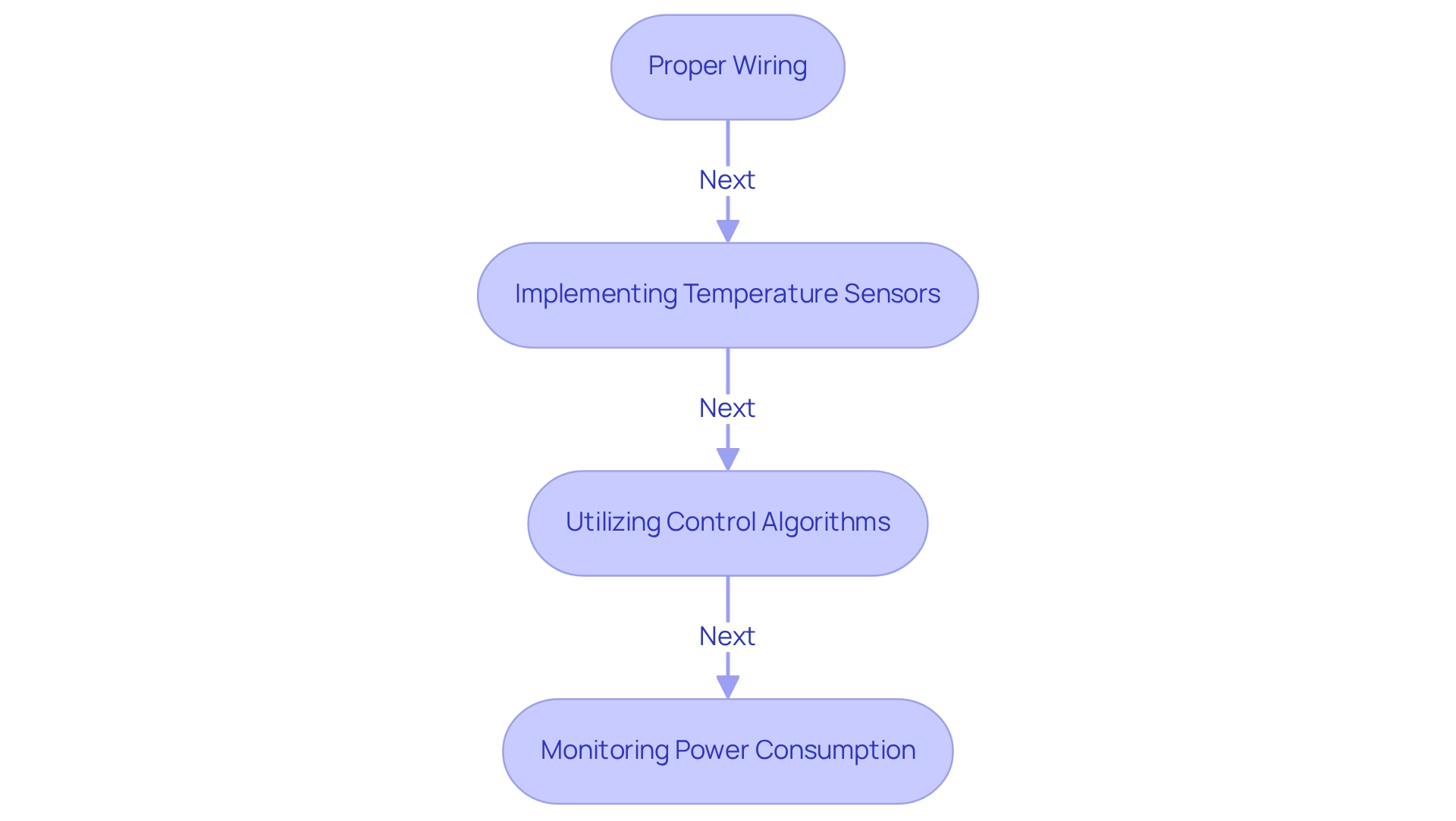

Integrating PWM Technology: Best Practices for Cooling Systems

To effectively integrate a into cooling systems, engineers must adhere to several that ensure .

- Proper Wiring: Accurate wiring of the PWM controlled fan to the control system is crucial for enabling . This ensures that the PWM controlled fan responds correctly to control signals, thereby optimizing its performance. Notably, the PWM controlled fan’s internal tach signal-generation circuitry is inactive during the off phase of low-frequency PWM, emphasizing the critical nature of proper wiring for effective control.

- Additionally, implementing is essential for providing , allowing for optimal adjustments in based on current thermal conditions. Research indicates that efficient temperature tracking can significantly enhance the responsiveness of refrigeration mechanisms, especially when using a PWM controlled fan, as it utilizes advanced control algorithms to facilitate dynamic adjustments of fan speeds in response to varying thermal conditions. This adaptability not only improves the of a PWM controlled fan but also contributes to energy savings. The control flowchart illustrates how these algorithms manage fan speed based on temperature readings from the thermoelectric element.

Morris Saypanya from SANYO DENKI emphasizes that ‘SANYO DENKI can provide customized solutions that improve efficiency, simplify integration, and lessen the load on your hardware and software.’

- A case study on and fan speed underscores the importance of these practices, revealing a parabolic relationship between fan speed and power consumption. Specifically, a linear decrease in fan speed results in a 60% reduction in power usage, highlighting the non-linear dynamics of power consumption and reinforcing the necessity for precise control mechanisms in temperature regulation.

By adhering to these best practices, engineers can significantly enhance the performance and efficiency of their refrigeration units, leading to more reliable and effective .

The Essential Role of PWM Controlled Fans in Modern Electronics

In modern electronics, the indispensable delivers efficient, reliable, and silent temperature regulation solutions. Their ability to dynamically adjust speeds in response to thermal demands significantly enhances , particularly through the use of , while also improving system stability and longevity. As electronic devices become increasingly powerful, the necessity for effective using a PWM controlled fan is paramount.

For example, the be quiet! Pure Wings 2 120mm PWM Cooling Fan exemplifies this necessity, offering that cater to users who prioritize a . This fan has achieved a perfect rating of 5.0 out of 5 stars, underscoring its quiet operation and effective airflow, making it a top choice for engineers focused on .

Moreover, the adaptability of PWM controlled fans positions them as , highlighting their growing prevalence in electronic device design. By staying informed about advancements in cooling solutions, engineers can create both functional and aesthetically pleasing builds, reinforcing the significance of the PWM controlled fan in the contemporary electronics market.

As noted by Hongyuan Shi, ‘The geometry and distribution of these microchannels directly influence thermal efficiency and the system’s overall hydraulic performance,’ emphasizing the critical role of design in thermal management. Additionally, ACDC FAN’s solutions operate quietly at lower speeds without sacrificing performance, further illustrating the advantages of the PWM controlled fan.

Conclusion

Effective thermal management is paramount in the rapidly evolving landscape of electronics, with PWM technology emerging as a pivotal element in achieving this objective. Gagner-Toomey Associates spearheads this initiative by offering innovative PWM cooling solutions that significantly enhance both the performance and reliability of electronic systems, while also meeting the increasing demands for energy efficiency and noise reduction. By leveraging the advantages of PWM fans—such as variable speed control, energy savings, and substantial noise reduction—engineers can ensure optimal cooling tailored to the specific requirements of their applications.

This article elucidates the multifaceted benefits of PWM technology, underscoring its vital role in enhancing system stability and longevity across diverse industries, including telecommunications, data centers, and automotive applications. As engineers grapple with the complexities of thermal management, a comprehensive understanding of PWM technology becomes essential. The capability to dynamically adjust fan speeds in response to real-time thermal conditions facilitates more efficient cooling, ultimately resulting in reduced operational costs and improved user experiences.

In conclusion, the integration of PWM cooling solutions represents a transformative advancement in electronic design, paving the way for more reliable, quieter, and energy-efficient systems. As the demand for sophisticated cooling strategies continues to escalate, the insights presented in this article serve as an invaluable resource for engineers aiming to optimize their designs. Embracing PWM technology not only enhances performance but also contributes to a more sustainable future in electronics, establishing it as an indispensable tool for the challenges that lie ahead.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leading provider of thermal management solutions, particularly featuring PWM controlled fans, aimed at enhancing performance and efficiency in electronic systems.

Since when has Gagner-Toomey been serving the technology markets in Northern California?

Gagner-Toomey has been serving the technology markets in Northern California since 1981.

What technology does Gagner-Toomey Associates specialize in?

Gagner-Toomey specializes in PWM controlled fan technology, which allows for advanced temperature regulation in electronic systems.

Why is effective thermal management important for 5G networks?

Effective thermal management is crucial for the success of expanding 5G networks as it ensures optimal performance and reliability of electronic systems.

What sectors does Gagner-Toomey serve?

Gagner-Toomey serves various sectors, including Telecom, Networking, IT/Data Center, and Automotive.

How does Pulse Width Modulation (PWM) work in controlled fans?

PWM regulates the speed of a fan by manipulating the pulse widths in a control signal, allowing for precise adjustments to fan speed based on thermal requirements.

What are the benefits of using PWM controlled fans?

PWM controlled fans provide variable speed control, energy efficiency, and noise reduction, making them superior to traditional fans.

How do PWM fans enhance energy efficiency?

PWM fans operate at lower speeds during times of reduced cooling demand, minimizing power consumption and lowering operational costs.

What noise levels can PWM fans achieve compared to traditional fans?

PWM fans can achieve noise levels as low as 20 dBA, whereas traditional fans may exceed 30 dBA under similar conditions.

What is the impact of integrating tachometer feedback with PWM controlled fans?

The integration of tachometer feedback allows for real-time modifications based on actual fan speed, optimizing efficiency and reducing noise.

How has Gagner-Toomey demonstrated its expertise in the field?

Gagner-Toomey has successfully served over 400 clients, showcasing their extensive experience and knowledge in thermal management solutions.

What tools can assist engineers in implementing PWM controlled fan solutions?

Engineers can use PCB Design and Analysis tools from Cadence, such as OrCAD software, to effectively implement PWM controlled fan solutions.