Introduction

The world of fan motor bearings is often overlooked, yet it plays a critical role in the efficiency and reliability of various applications, from automotive to medical technologies. Engineers face a multitude of options, each presenting unique advantages that can significantly influence performance and longevity. With so many choices available, how can they determine the best fit for their specific needs? This article explores ten essential insights on fan motor bearings, equipping engineers with the knowledge necessary to navigate this complex landscape and make informed decisions for their projects.

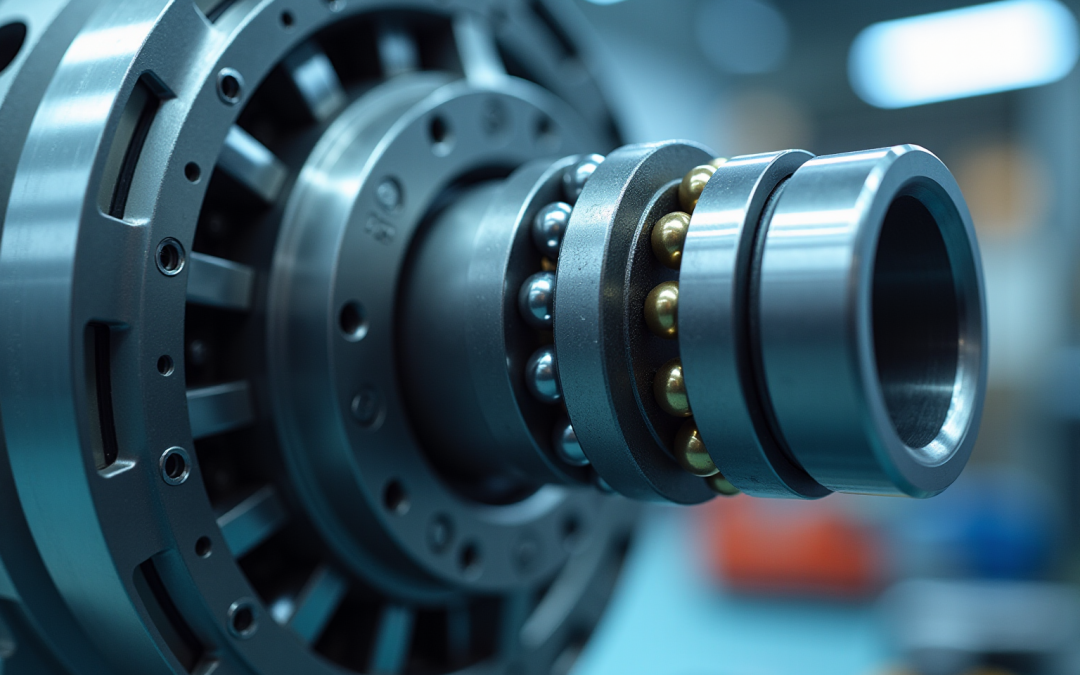

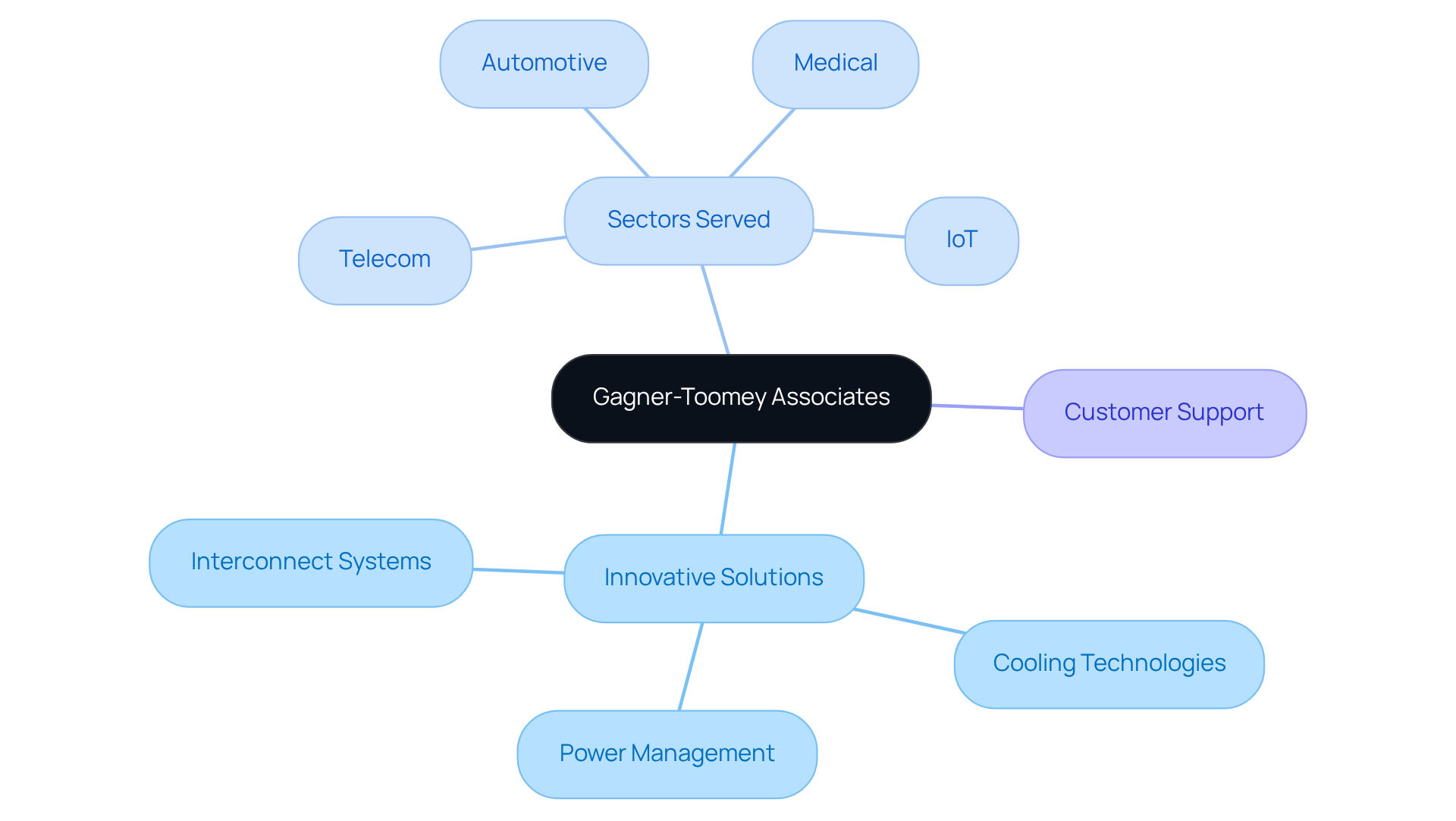

Gagner-Toomey Associates: Leading Solutions for Fan Motor Bearings

Gagner-Toomey Associates leads the way in delivering innovative solutions for fan motor bearing systems, leveraging a diverse portfolio of manufacturers. As the market for fan motors evolves, engineers face the challenge of accessing cutting-edge technologies in cooling, power management, and interconnect systems. Gagner-Toomey Associates addresses this need by providing the latest advancements in fan design, which not only enhance performance but also significantly improve reliability across various applications.

Their expertise ensures that engineers can rely on specialized solutions tailored to their specific requirements. With a commitment to exceptional customer support, Gagner-Toomey Associates empowers professionals in sectors such as:

- Telecom

- Automotive

- IoT

- Medical

to achieve optimal functionality and efficiency in their projects. By choosing Gagner-Toomey Associates, engineers can confidently navigate the complexities of fan motor bearing systems, knowing they have a trusted partner dedicated to their success.

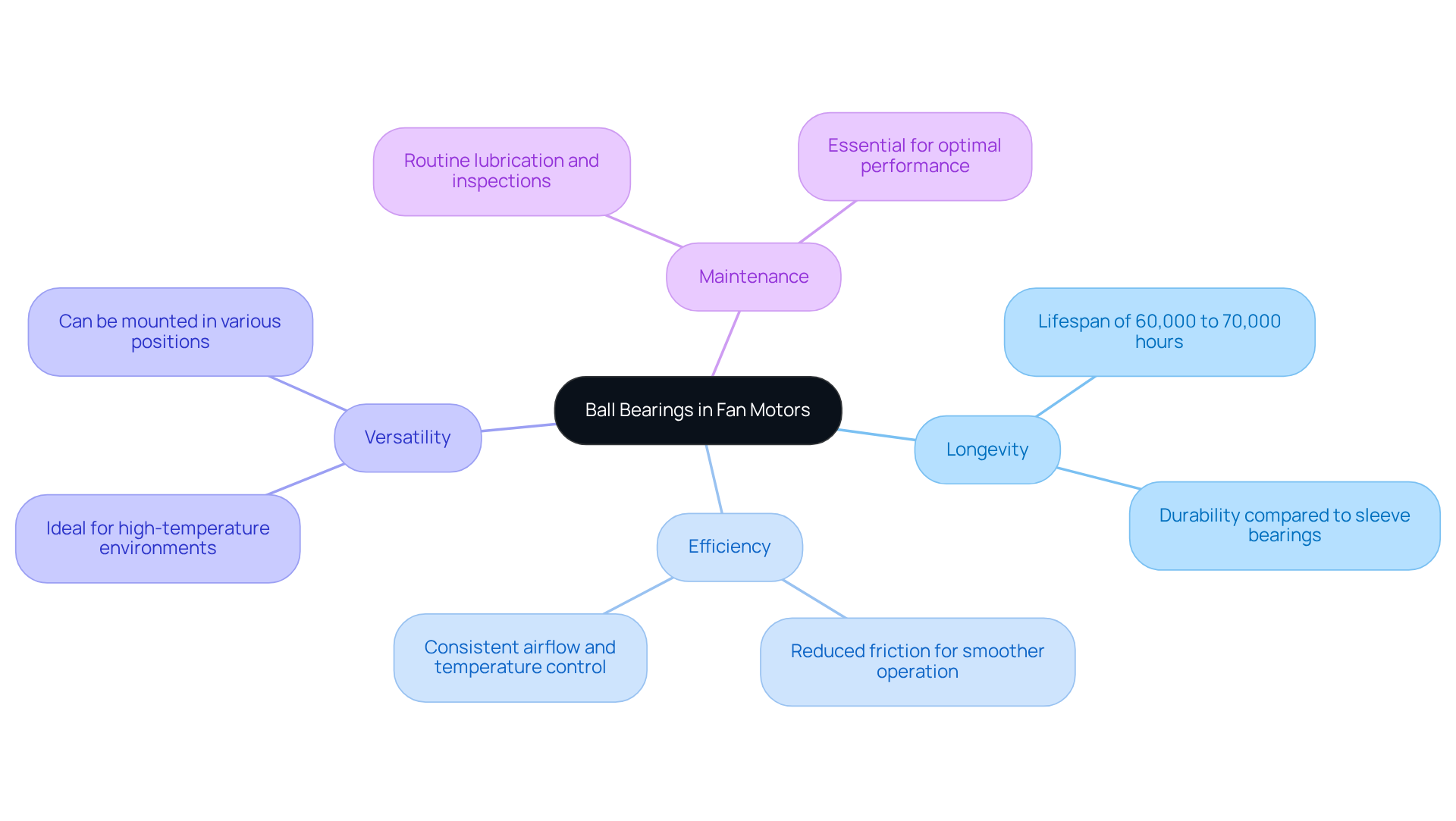

Ball Bearings: Advantages and Applications in Fan Motors

Ball components are recognized for their exceptional longevity and effectiveness, making them a preferred choice for high-speed fan applications, particularly in Gagner-Toomey Associates’ innovative cooling solutions that incorporate fan motor bearing technology. These components significantly reduce friction, enabling smoother operation and extending their lifespan, which typically ranges from 60,000 to 70,000 hours under normal conditions. Notably, ball rollers can last up to ten times longer than sleeve types, underscoring their durability compared to other varieties.

In the realm of electronics cooling, ball components are widely utilized in Gagner-Toomey’s computer cooling fans and HVAC systems, especially in the fan motor bearing, where reliability and performance are paramount. Engineers frequently highlight their efficiency in high-velocity scenarios, noting that ball components excel in maintaining consistent airflow and temperature control. Recent advancements have integrated these components into Gagner-Toomey’s cutting-edge cooling solutions, enhancing their effectiveness in managing heat dissipation.

Their versatility allows for mounting in various positions, making them ideal for high-temperature environments and outdoor settings where resistance to dust and moisture is crucial. To prolong the lifespan of ball components and ensure optimal performance in demanding applications, routine maintenance activities, including adequate lubrication and regular inspections of the fan motor bearing, are essential.

Overall, the strategic implementation of ball components in Gagner-Toomey’s electronics cooling systems underscores their critical role in achieving optimal performance and longevity.

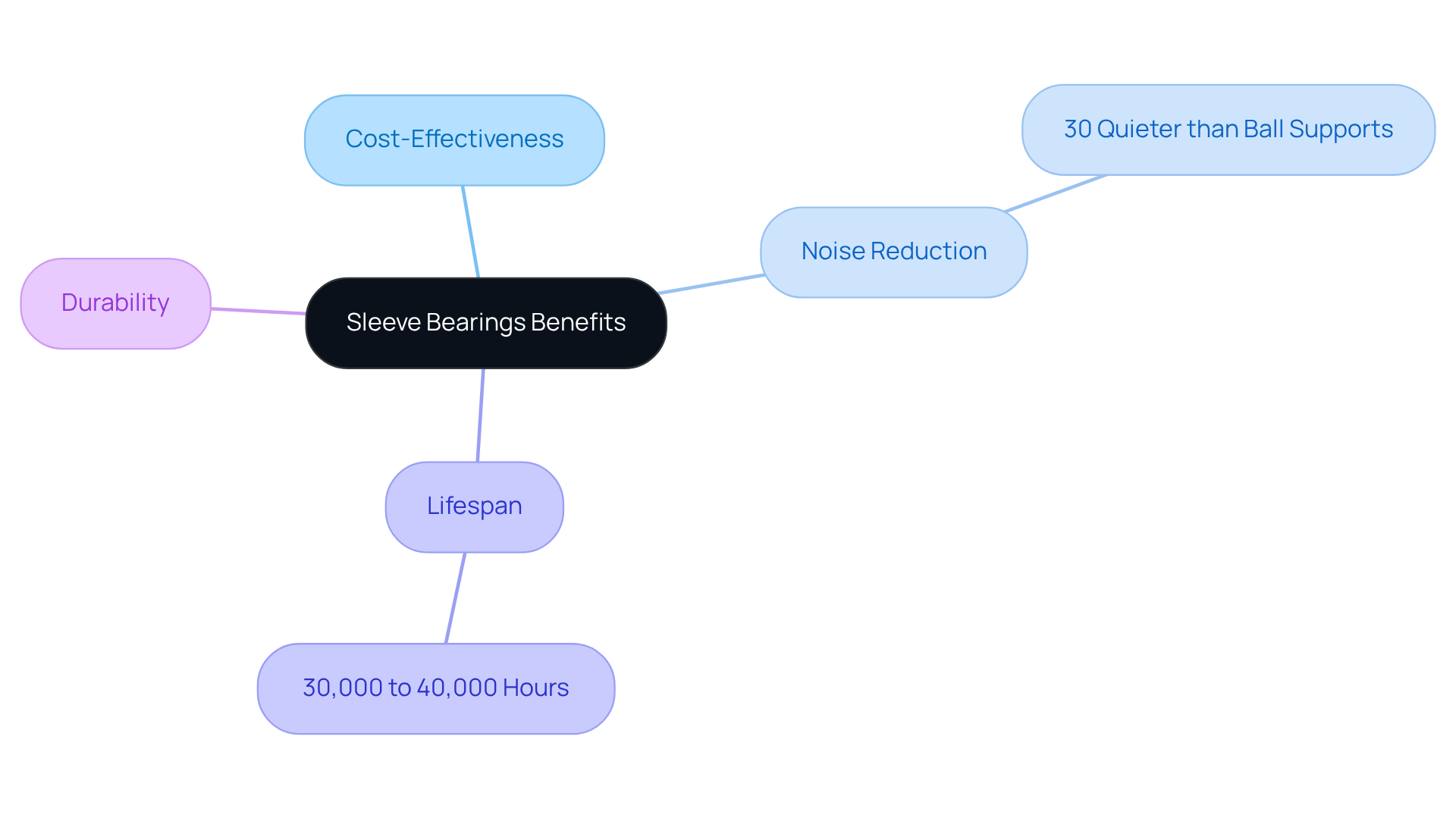

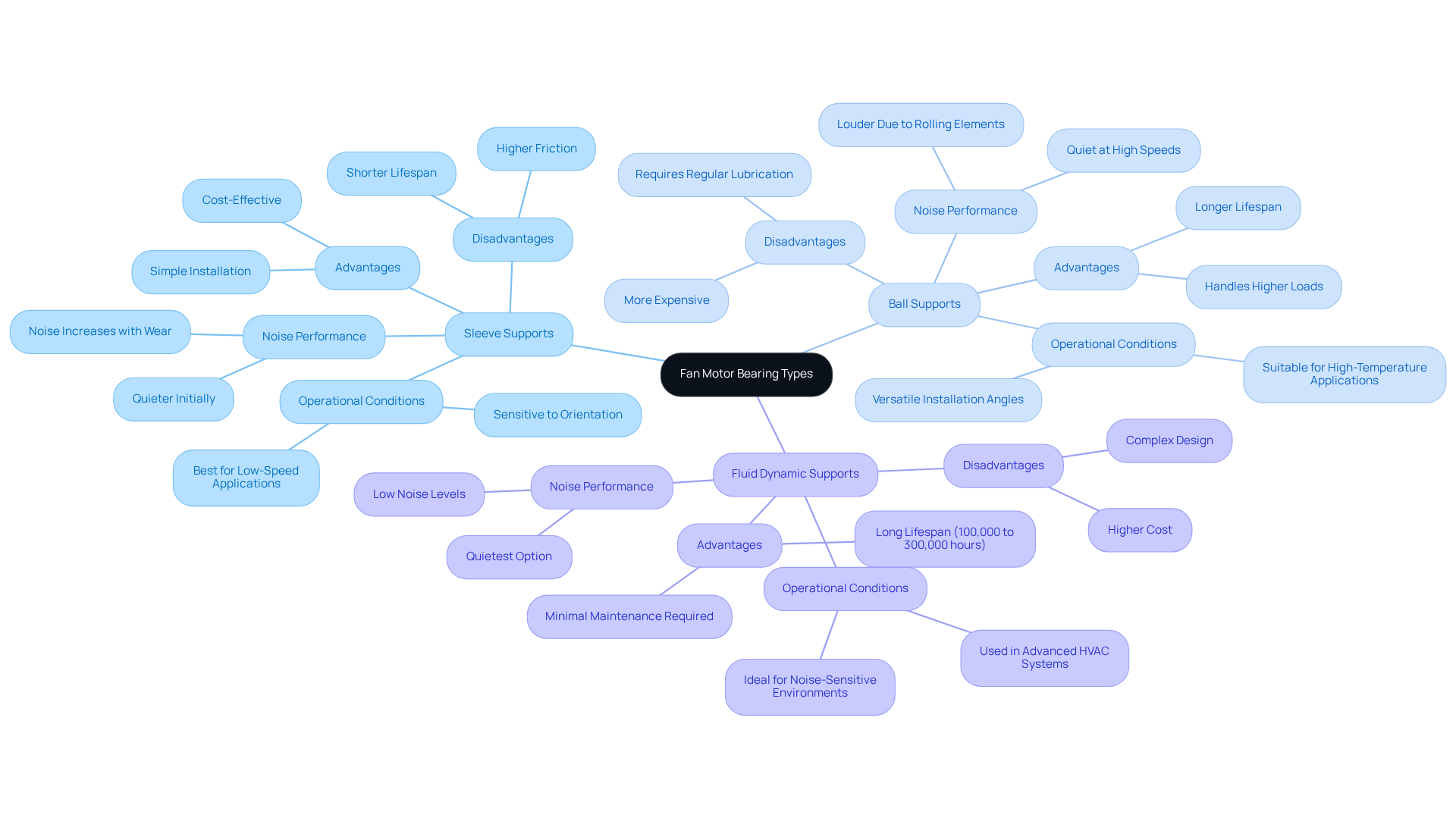

Sleeve Bearings: Key Benefits for Fan Motor Efficiency

Sleeve supports stand out due to their straightforward design and cost-effectiveness, particularly in household fan applications. Their ability to operate quietly makes them particularly advantageous in settings where noise reduction is crucial. Research indicates that sleeve supports can achieve noise levels approximately 30% lower than their ball support counterparts, significantly enhancing user comfort in residential environments. This characteristic makes them especially suitable for low-speed applications.

While sleeve supports typically have a shorter lifespan – averaging between 30,000 to 40,000 hours – compared to ball components, their robust design ensures reliable operation across various environments. This blend of affordability, durability, and noise reduction positions sleeve components with fan motor bearing as the preferred choice for engineers dedicated to developing efficient and quiet fan solutions.

As industry specialists note, “Another advantage of sleeve fan designs is that they typically generate less noise during operation, enabling extensive use in quiet environments such as offices.” This insight underscores the practical benefits of selecting sleeve supports, making them an essential consideration for professionals in the field.

Roller Bearings: Performance Insights for Fan Motor Applications

Roller supports are specifically engineered to handle heavier loads while providing enhanced stability compared to ball supports. This capability is particularly advantageous in applications that demand high radial load capacity, such as industrial fans. Their cylindrical design effectively minimizes friction and wear, which contributes to a longer service life and greater reliability in demanding environments.

The rating life of roller components-defined as the lifespan calculated for 90% reliability-serves as a crucial consideration for engineers, especially in high-load applications. Performance metrics demonstrate that roller components can endure high-stress conditions, adeptly managing heat generation and reducing friction, thereby enhancing operational efficiency. To sustain the longevity and functionality of these components, proper lubrication is essential.

Expert insights reveal that the load capacity of roller components significantly surpasses that of ball components, particularly in scenarios involving heavy loads and continuous operation. This makes roller supports a superior choice for engineers seeking to improve performance and durability in fan motor bearing designs. By opting for roller supports, engineers can ensure a more reliable and efficient operation in their applications.

Fluid Dynamic Bearings: Innovations in Fan Motor Technology

Fluid dynamic supports address a critical challenge in mechanical systems: the friction and wear associated with rotating shafts. By utilizing a thin film of lubricant, these supports significantly reduce friction, thereby enhancing the longevity of components. This advanced technology not only extends the lifespan of the system but also promotes quieter operation, making it particularly advantageous for high-performance applications like computer cooling systems and high-speed fans.

Research shows that fluid dynamic supports can achieve an impressive lifespan of approximately 300,000 hours, far surpassing traditional support types. Their innovative design allows for quieter operation, reducing noise levels by as much as 10 decibels compared to sleeve supports. This reduction is crucial in environments where noise control is paramount.

As innovations in fluid dynamic support technology continue to evolve, their efficiency and reliability in cooling systems are further enhanced. The fan motor bearing and other components are increasingly favored in modern fan designs, offering superior performance while maintaining low vibration levels. This ensures optimal cooling without compromising user comfort, making fluid dynamic supports a preferred choice in today’s high-performance applications.

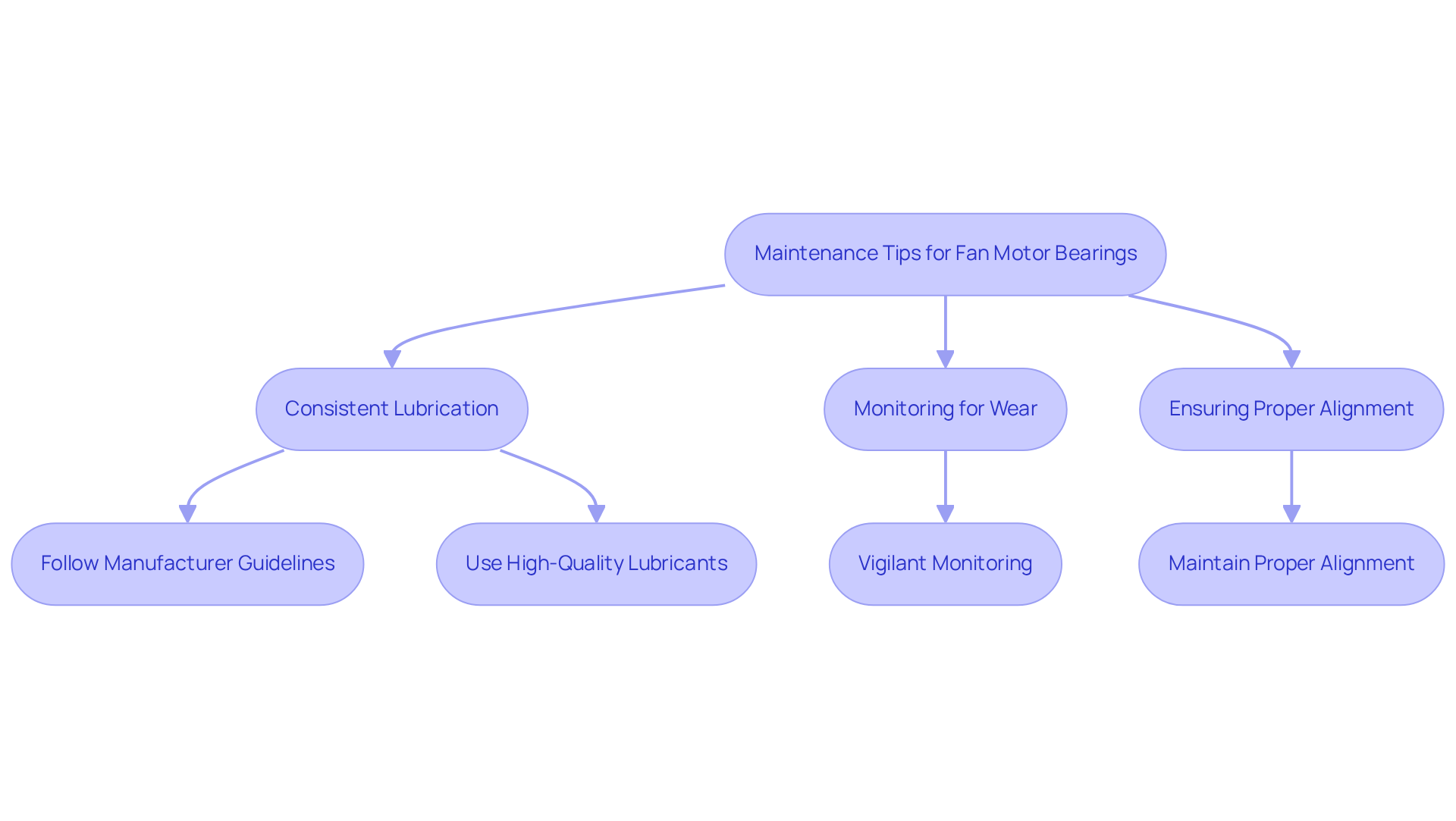

Maintenance Tips: Ensuring Longevity of Fan Motor Bearings

To extend the lifespan of the fan motor bearing, regular upkeep is not just beneficial; it’s essential. This maintenance involves:

- Consistent lubrication

- Vigilant monitoring for wear

- Ensuring proper alignment

Following manufacturer guidelines for maintenance schedules is crucial, with recommendations suggesting lubrication intervals based on operational conditions. For instance, in high-intensity settings, components may require lubrication as frequently as twice a week. Proper lubrication of the fan motor bearing minimizes friction and helps dissipate heat, thereby preventing overheating that can significantly reduce the lifespan of the motor-an increase of just 10°C in operating temperature can halve the lifespan of the fan motor bearing. Overheating particularly affects winding insulation and the lubrication of the fan motor bearing, making it vital to maintain optimal operating temperatures.

Utilizing high-quality lubricants, such as NLGI #2 lithium-based grease, enhances performance and protects against corrosion. Additionally, synthetic lubricants are recommended for high-temperature environments due to their thermal stability and resistance to degradation. Real-world applications, such as infrared thermography for early detection of overheating issues, demonstrate the effectiveness of proactive maintenance strategies. Routine examinations of the fan unit and the fan motor bearing for indications of wear, overheating, or unusual sounds are essential to avert failure.

Furthermore, maintaining detailed records of maintenance activities empowers operators and engineers to predict problems before they occur. By applying these methods, engineers can guarantee optimal performance and durability of fan components.

Noise Levels: Comparing Fan Motor Bearing Types

In the realm of fan motor components, the fan motor bearing’s noise performance emerges as a pivotal concern. Sleeve supports are generally quieter than ball supports, particularly at reduced speeds, making them a preferred choice in applications where noise reduction is paramount. However, as lubrication deteriorates over time, sleeve supports may become noisier, potentially impacting their suitability for long-term use. Conversely, ball elements exhibit a more consistent noise profile throughout their lifespan, ensuring reliable performance even under varying operational conditions.

Fluid dynamic supports distinguish themselves as the quietest option available, employing a thin layer of lubricating fluid to minimize friction and wear. This innovative design enables them to operate at exceptionally low noise levels, rendering them ideal for noise-sensitive environments such as telecom cabinets and advanced HVAC systems. For instance, fluid dynamic supports can achieve lifespans ranging from 100,000 to 300,000 hours while maintaining their quiet operation, significantly reducing the need for maintenance and replacements.

Decibel levels further illustrate these distinctions: sleeve supports typically operate at lower decibels initially, but their noise levels can escalate as they wear down. Although ball rollers are inherently louder due to their rolling components, they can function quietly at higher speeds, often matching the noise levels of sleeve supports under specific conditions. Ultimately, the choice between these support types should consider not only noise performance but also the specific operational requirements, environmental factors of the application, and the role of the fan motor bearing.

Cost Analysis: Evaluating Fan Motor Bearing Options

Cost analysis reveals that sleeve supports are often the most economical choice, primarily due to their lower initial costs. However, ball components, despite their higher price, offer enhanced performance and durability, making them a preferred option for high-demand applications.

Fluid dynamic supports (FDs) present a compelling case; although they require a greater initial investment, their long-term benefits are significant. With lifespans frequently exceeding 100,000 hours and reduced friction leading to lower maintenance and replacement costs, FDBs can result in substantial savings over time. For instance, transitioning to rolling element supports in industrial settings has shown a decrease in energy losses from 30 kW to 12 kW per expander, translating to over 100,000 kWh of additional electrical energy output annually. This shift not only enhances operational efficiency but also fosters a more favorable economic outlook for companies investing in high-quality support solutions.

Expert insights underscore that while the upfront costs of fluid dynamic supports may deter some, the cumulative savings in maintenance and energy efficiency can far exceed these initial expenses. This makes them a wise investment for the future.

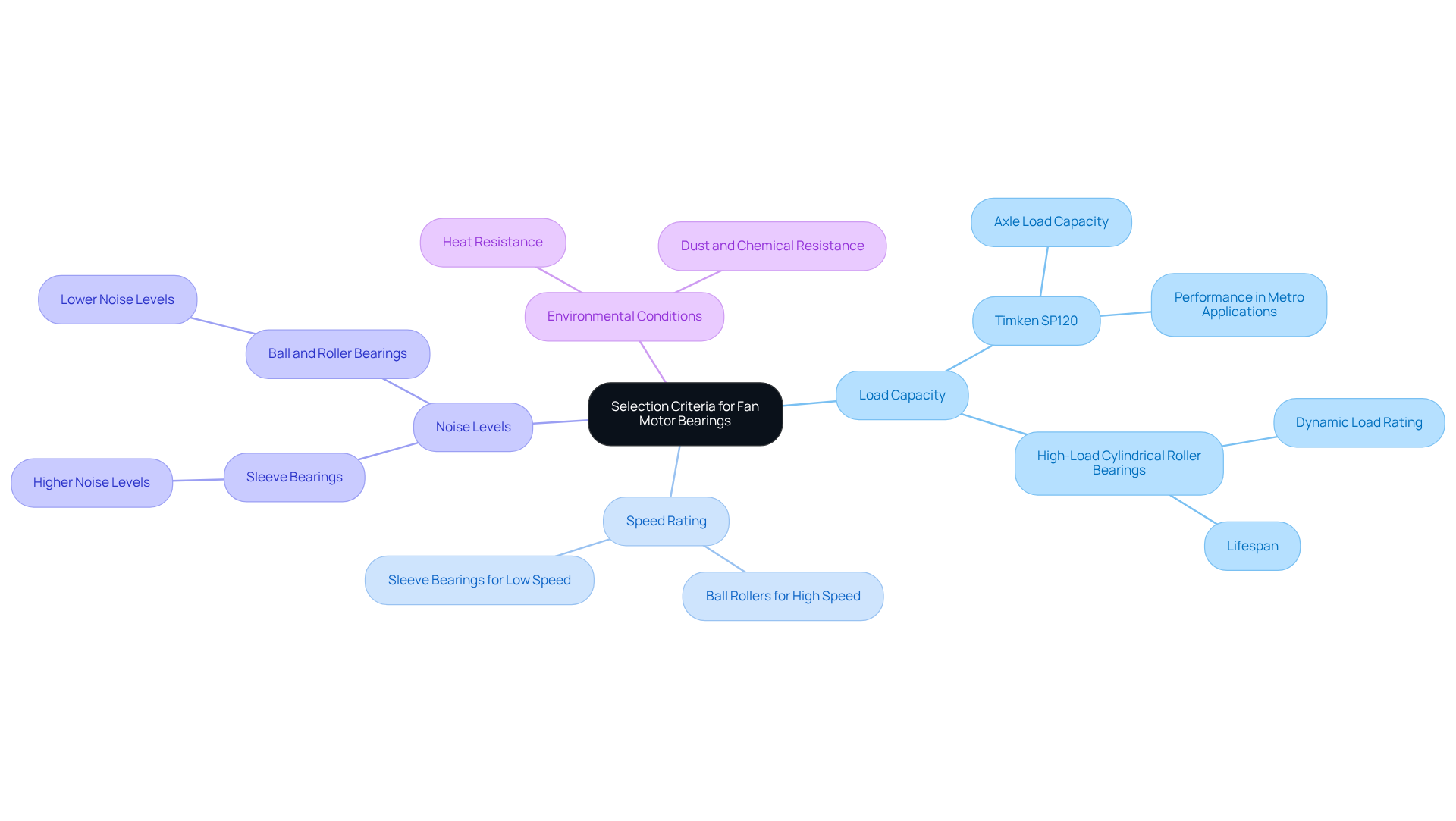

Selection Criteria: Choosing the Right Fan Motor Bearing

Choosing the right fan motor bearing is crucial for ensuring optimal performance and durability. Engineers must prioritize several key factors:

- Load capacity

- Speed rating

- Noise levels

- Environmental conditions

For instance, ball rollers are often recommended for high-speed applications due to their low friction and durability. In contrast, sleeve supports, while more economical, may wear out faster and generate more noise, making them less suitable for noise-sensitive environments.

Understanding load capacity is particularly vital for larger motors that face significant operational demands. Take the Timken SP120 components, for example; they can handle axle loads of up to 16 tons for Type A applications, making them ideal for heavy-duty tasks. Furthermore, C-Series bearings offer 40% less dust ingress and 30% lower friction than the industry average, enhancing their performance and reliability.

Compatibility with the fan motor bearing design and specific application requirements is another critical consideration. By thoroughly evaluating these criteria, engineers can significantly improve the efficiency and reliability of fan devices, ultimately leading to superior operational outcomes.

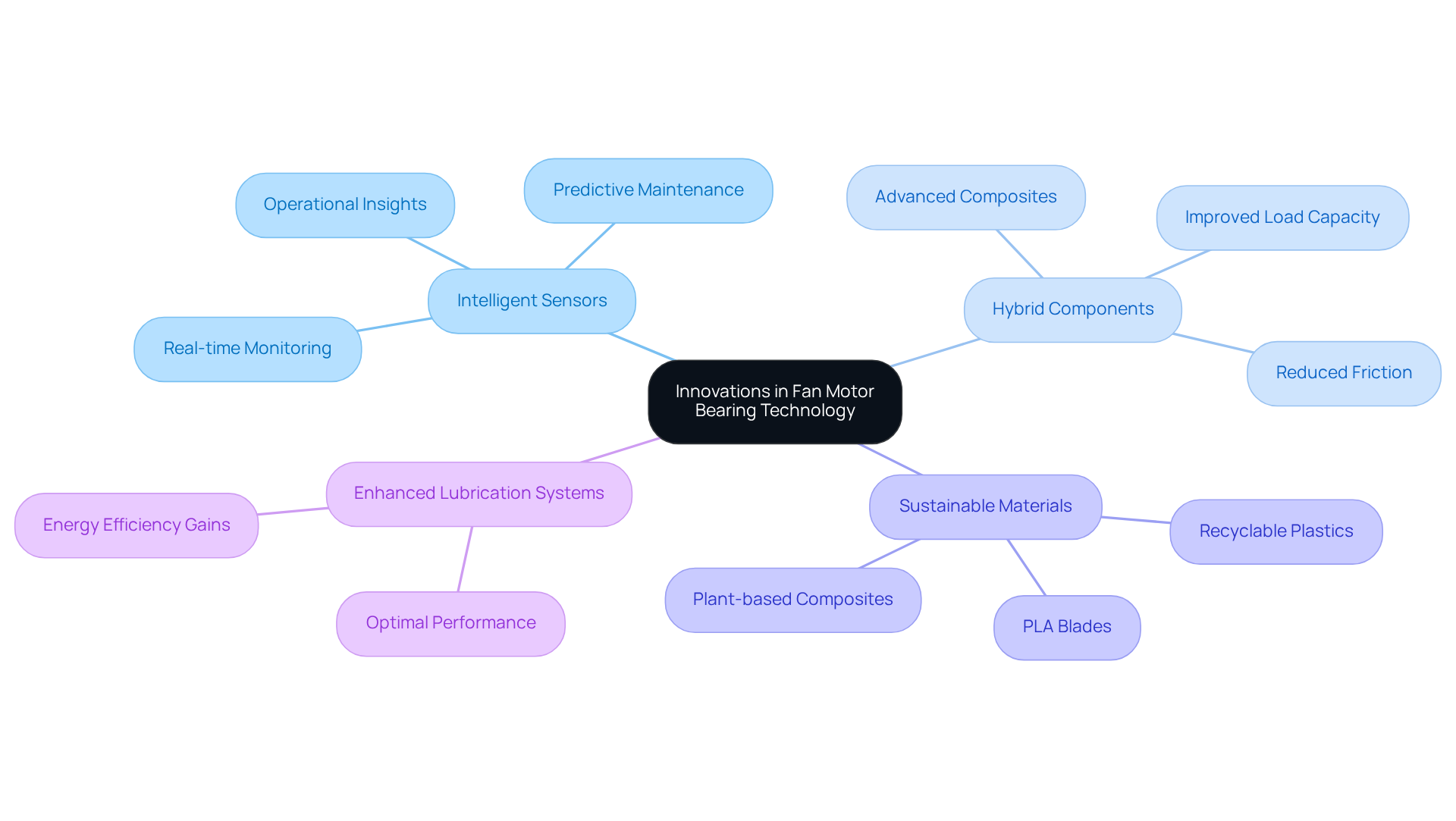

Future Trends: Innovations in Fan Motor Bearing Technology

The future of fan component technology is set for remarkable advancements, particularly through the integration of intelligent sensors that enable real-time monitoring and predictive maintenance. These sensors significantly enhance performance by providing critical insights into operational conditions, allowing for timely interventions that prevent failures and extend the lifespan of machinery. Industry leaders assert that the adoption of smart sensors not only boosts efficiency but also cuts operational costs by reducing downtime and maintenance requirements.

Real-world applications of intelligent sensors in fan engine supports are already demonstrating their potential. Manufacturers are increasingly embracing hybrid components that merge traditional materials with advanced composites, yielding improved load capacity and decreased friction. This transition towards sustainable materials, such as PLA blades crafted from corn starch, underscores the industry’s dedication to minimizing environmental impact while enhancing performance. Additionally, enhanced lubrication systems are being developed to work alongside smart sensors, ensuring optimal performance across varying conditions and leading to substantial energy efficiency gains.

The adoption of smart sensors in fan motor bearings is on the rise, driven by the growing demand for energy-efficient solutions within the electronics sector. Recent reports indicate that around 75% of automotive suppliers are prioritizing the integration of these technologies to meet new regulations, including the Euro 7 emissions standards, and to enhance their product offerings. As the industry evolves, the emphasis on smart sensor technology will be pivotal in shaping the future of fan motor bearing performance and reliability.

Conclusion

Selecting the right fan motor bearing is essential for engineers who want to optimize both performance and longevity in their designs. Understanding the various types of bearings – ball, sleeve, roller, and fluid dynamic – is crucial, as each type offers distinct advantages tailored to specific applications. By collaborating with experts like Gagner-Toomey Associates, engineers can access innovative solutions that enhance reliability and efficiency across diverse sectors.

The article emphasizes the unique characteristics and benefits of each bearing type.

- Ball bearings are ideal for high-speed applications.

- Sleeve bearings provide cost-effective and quiet operation.

- Roller bearings are designed to handle heavy loads with stability.

- Fluid dynamic bearings excel in longevity and noise reduction.

Furthermore, implementing routine maintenance practices is vital for prolonging the lifespan of these components, ensuring optimal performance in demanding environments.

In light of these insights, engineers are urged to stay abreast of emerging technologies and trends in fan motor bearing systems. The integration of intelligent sensors and sustainable materials is set to revolutionize the industry, enhancing both performance and environmental impact. By prioritizing the right selection criteria and maintenance practices, professionals can significantly boost the operational efficiency and reliability of their fan motor applications.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for delivering innovative solutions for fan motor bearing systems, leveraging a diverse portfolio of manufacturers to enhance performance and reliability in various applications.

What industries does Gagner-Toomey Associates support?

Gagner-Toomey Associates supports several industries, including Telecom, Automotive, IoT, and Medical, helping professionals achieve optimal functionality and efficiency in their projects.

What are the advantages of ball bearings in fan motors?

Ball bearings are known for their exceptional longevity and effectiveness, reducing friction for smoother operation and typically lasting between 60,000 to 70,000 hours. They excel in high-speed applications and are widely used in electronics cooling solutions.

How do ball bearings compare to sleeve bearings in terms of lifespan?

Ball bearings can last up to ten times longer than sleeve bearings, which typically have a lifespan of 30,000 to 40,000 hours, making ball bearings a more durable option.

What are the benefits of sleeve bearings in fan motors?

Sleeve bearings are cost-effective, operate quietly (approximately 30% quieter than ball bearings), and are ideal for low-speed applications, making them suitable for residential environments where noise reduction is important.

What maintenance is recommended for ball components in fan motors?

Routine maintenance activities, including adequate lubrication and regular inspections of the fan motor bearing, are essential to prolong the lifespan and ensure optimal performance of ball components.

In what environments are sleeve bearings particularly advantageous?

Sleeve bearings are advantageous in quiet environments, such as offices and residential settings, due to their lower noise levels during operation.