Introduction

An explosion-proof fan motor plays a vital role in safeguarding environments where flammable gases, vapors, or dust may be present, effectively preventing catastrophic incidents. These specially designed motors not only meet stringent safety standards but also enhance operational efficiency across various industries, such as oil and gas, pharmaceuticals, and food processing. As industries evolve and the demand for safety intensifies, organizations face a pressing question: how can they balance the imperative for robust safety measures with the costs associated with implementing explosion-resistant technologies?

To address this challenge, it’s essential to recognize the critical importance of explosion-proof fan motors in maintaining safety and compliance. By investing in these technologies, companies can significantly reduce the risk of accidents, thereby protecting their workforce and assets. Moreover, the operational efficiency gained from these motors can lead to long-term cost savings, making them a worthwhile investment.

Ultimately, organizations must weigh the benefits of enhanced safety against the financial implications. By conducting thorough cost-benefit analyses and exploring innovative solutions, businesses can find a path that prioritizes safety without compromising their bottom line.

Define Explosion-Proof Fan Motor

An explosion proof fan motor is essential for safe operation in environments where combustible gases, vapors, or dust are present. These explosion proof fan motors are meticulously engineered to contain any internal explosions, effectively preventing the ignition of the surrounding atmosphere. The importance of blast-resistant technology, such as an explosion proof fan motor, lies in its ability to avert ignitions in hazardous settings, significantly reducing the risk of accidents.

Key characteristics include:

- Robust enclosures made from durable materials that withstand high temperatures and pressures, ensuring safety in critical locations such as chemical plants, oil refineries, and grain storage facilities, where an explosion proof fan motor is essential.

- Recent safety standards mandate rigorous testing and certification processes that protective equipment must undergo, guaranteeing these devices meet stringent criteria for dangerous environments.

- For example, devices classified under Class I, Division 1 are specifically designed to minimize ignition risks in areas with flammable gases, while Class II classifications address environments with combustible dust.

Practical applications underscore their significance; in the oil and gas industry, explosion proof fan motors are vital for maintaining operational integrity and protecting personnel. Furthermore, industry experts emphasize that the design of explosion proof fan motors must prioritize both safety and efficiency, reflecting the evolving criteria in hazardous area classifications. Additionally, upgrading existing equipment to meet explosion-resistant standards can be a cost-effective strategy, allowing companies to enhance security without the need for complete overhauls.

Contextualize Importance in Electronics

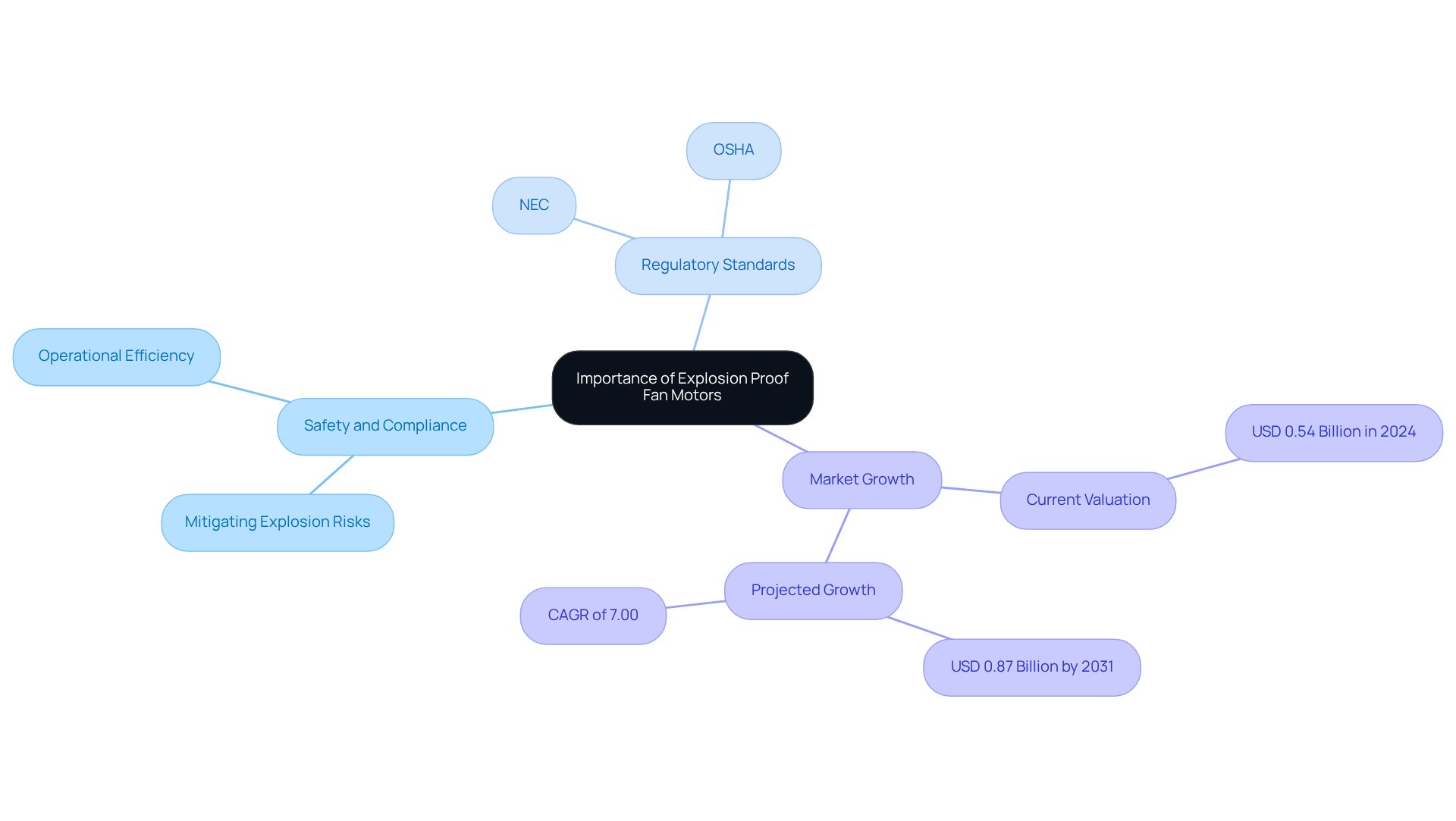

In the electronics sector, an explosion proof fan motor is essential, particularly in environments where volatile substances are present. Their design is critical for mitigating explosion risks, which can lead to catastrophic failures and loss of life. By employing these engines, organizations ensure compliance with stringent regulations, including the National Electrical Code (NEC) and Occupational Safety and Health Administration (OSHA) standards. These regulations mandate the use of explosion-resistant equipment in specific hazardous areas, safeguarding workers and preserving valuable equipment and infrastructure.

The blast-resistant motors market was valued at USD 0.54 billion in 2024 and is projected to grow at a CAGR of 7.00%, reaching USD 0.87 billion by 2031. This growth underscores the increasing demand for protection in sectors that handle flammable substances. Organizations that prioritize compliance with these regulations demonstrate a commitment to safety, which is vital for fostering a secure working environment and minimizing operational risks.

In conclusion, investing in explosion proof fan motors not only adheres to regulatory requirements but also enhances overall safety and operational efficiency.

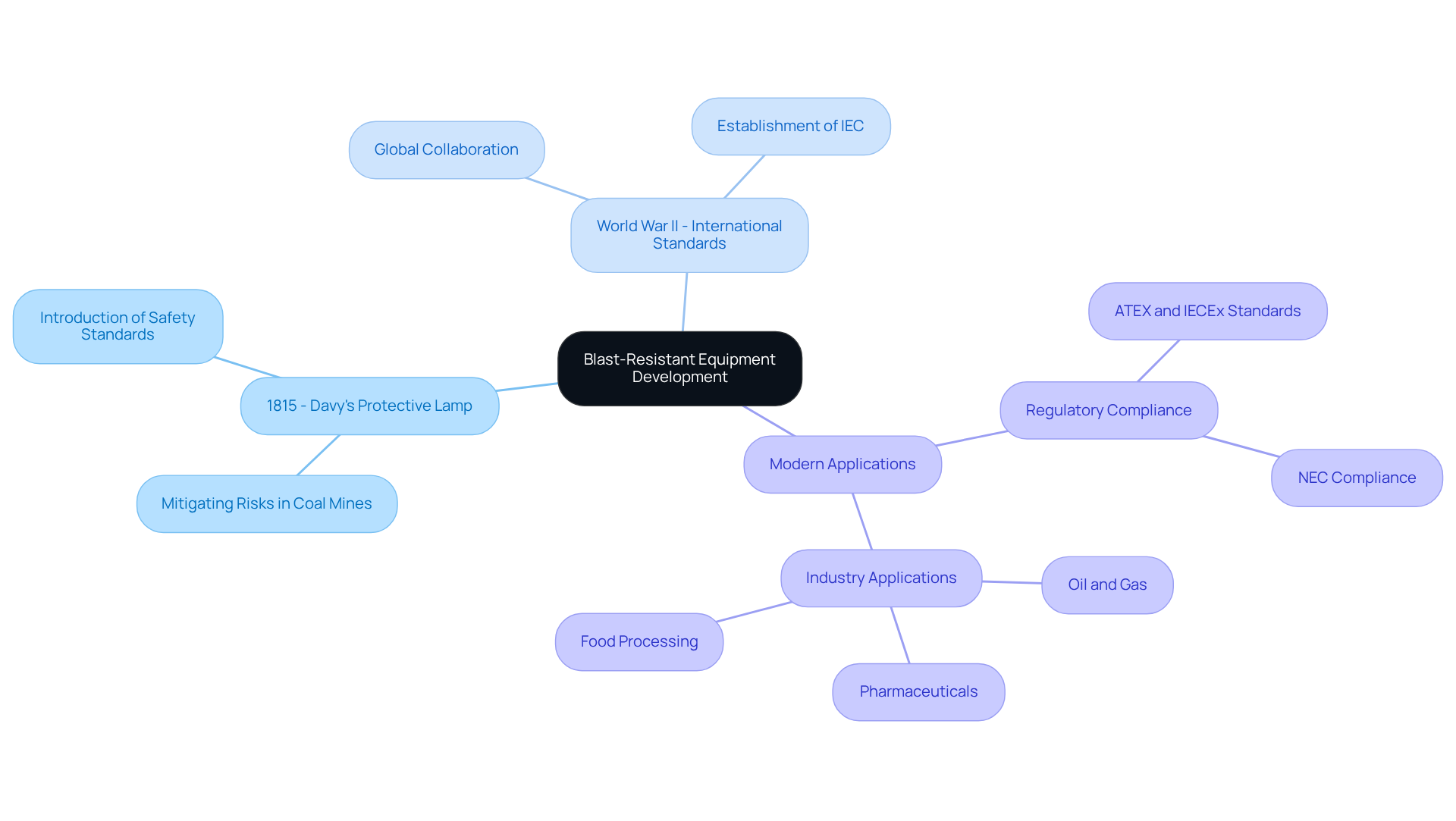

Trace Historical Development and Applications

The origins of blast-resistant equipment date back to the early 19th century, notably with Sir Humphry Davy’s invention of the protective lamp in 1815. This groundbreaking device aimed to mitigate the risks of blasts in coal mines, marking a significant advancement in industrial safety. It specifically addressed the dangers posed by grisou gas, primarily methane, which could accumulate in mine tunnels. The impact of World War II accelerated the establishment of international standards for blast-resistant equipment, underscoring the necessity for global collaboration in enhancing safety regulations.

As industries expanded and the use of combustible materials became more prevalent, the demand for sophisticated blast-resistant technologies surged. Over the years, the development of explosion proof fan motors has proven essential across various sectors, including oil and gas, pharmaceuticals, and food processing. These machines are engineered to operate safely in hazardous environments, preventing sparks and high temperatures that could ignite surrounding atmospheres. For instance, in the oil and gas industry, blast-resistant motors are vital for the operation of compressors and pumps, ensuring safe practices in environments with persistent explosive risks.

The increasing adoption of hazard-resistant equipment reflects a growing awareness of safety standards and regulatory compliance. Industries are now more inclined to implement blast-resistant solutions, driven by stringent regulations such as ATEX and IECEx, which mandate that equipment adheres to rigorous standards. This shift not only enhances operational safety but also protects personnel and assets from potential threats.

Insights from industry experts, such as Andrea Battauz, emphasize the critical role of blast-resistant technology in maintaining quality standards. Additionally, specific case studies from the pharmaceutical and food processing sectors illustrate the tangible benefits of blast-resistant technologies, highlighting their indispensable role in safeguarding operations.

In conclusion, the evolution of explosion proof fan motors signifies remarkable progress in industrial safety technology. Their applications range from ventilating hazardous areas to cooling sensitive electronic devices. As industries continue to innovate, the importance of blast-resistant solutions remains paramount in protecting operations from explosive hazards.

Identify Key Characteristics and Features

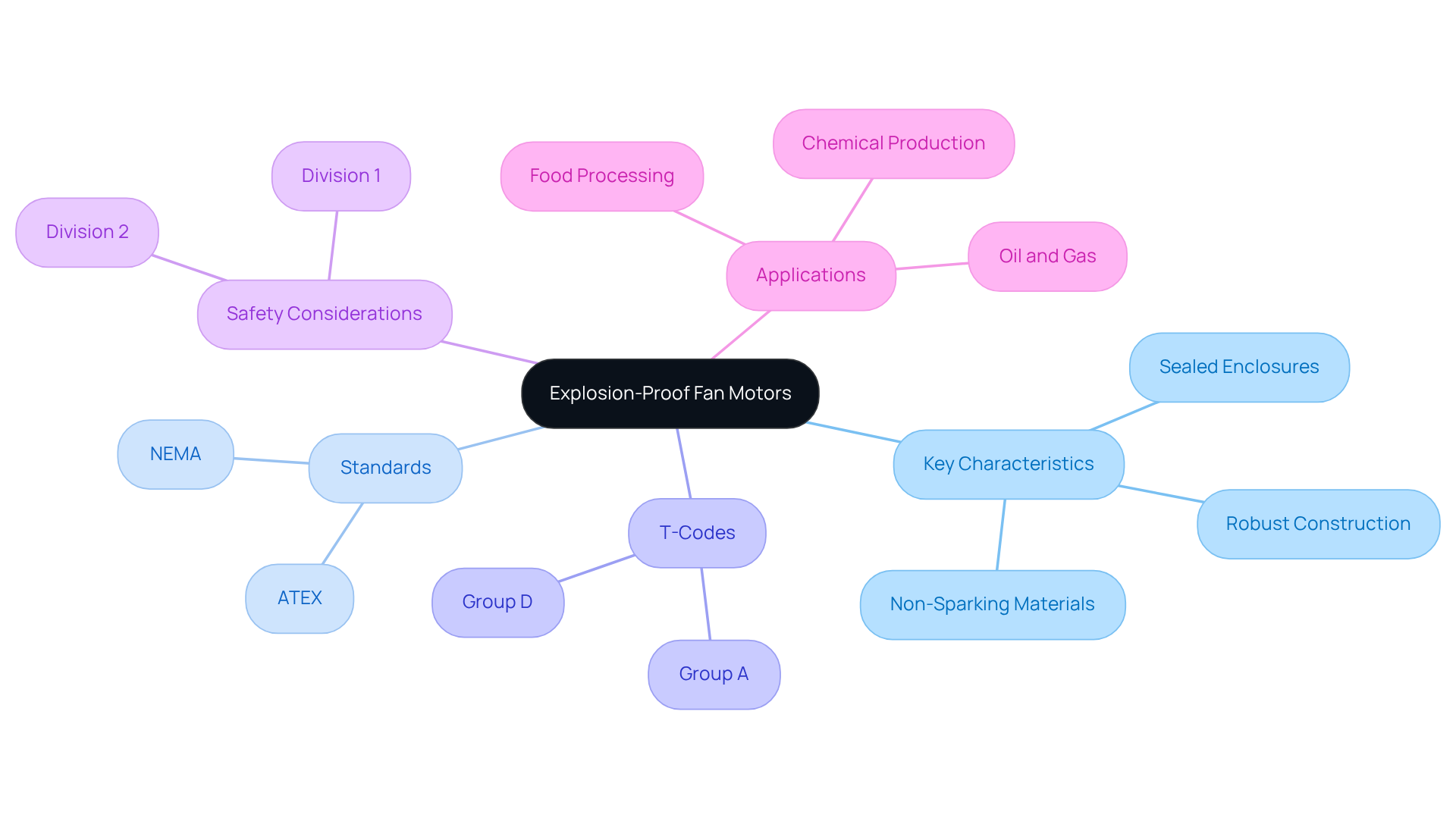

The use of an explosion proof fan motor is critical in ensuring safety in hazardous environments. Key characteristics of these engines include:

- Robust construction

- Sealed enclosures

- Use of non-sparking materials

Designed to withstand elevated temperatures and pressures, they incorporate features like flame paths that cool escaping gases and prevent ignition.

These devices are often rated according to specific standards, such as NEMA and ATEX, which classify their suitability for various hazardous environments. Understanding T-codes, which indicate the highest surface temperature of explosion-proof devices, is essential for guaranteeing safe operation in dangerous conditions. For instance:

- Group A includes highly volatile materials like acetylene

- Group D encompasses substances such as gasoline, acetone, and alcohol

Engineers and protection specialists must grasp these characteristics when selecting the appropriate engine for their applications.

Moreover, efficient ventilation systems are vital in dangerous settings to maintain air quality and security, particularly in sectors like oil and gas, chemicals, and food processing. Real-world examples underscore the importance of adhering to these standards; for example, in chemical production facilities, choosing a device that meets ATEX certification can significantly reduce the risk of ignition in areas with flammable vapors.

Engineers emphasize the necessity of selecting engines that conform to both NEMA and ATEX standards to ensure operational security and compliance with regulatory requirements. As one engineer noted, “Choosing the appropriate hazardous-duty engine is not solely about adherence; it’s about guaranteeing the safety of our operations.”

While explosion proof fan motors may entail higher initial costs, they provide lower long-term maintenance expenses, making them a cost-efficient investment. By prioritizing safety and compliance, organizations can protect their operations and personnel effectively.

Conclusion

The significance of explosion proof fan motors is paramount, especially in environments where flammable gases, vapors, or dust present serious risks. These specialized motors are engineered to contain internal explosions, thereby protecting personnel and equipment in hazardous settings. By utilizing robust materials and adhering to stringent safety standards, explosion proof fan motors are essential in preventing ignition and ensuring safe operations across various industries.

Key characteristics of explosion proof fan motors include their durable construction and compliance with safety regulations. The historical context illustrates the evolution of blast-resistant technology, highlighting its growing importance in sectors such as oil and gas, pharmaceuticals, and food processing. Moreover, the economic advantages of investing in these motors, despite their higher initial costs, underscore their long-term value in enhancing safety and operational efficiency.

Ultimately, adopting explosion proof fan motors transcends mere compliance; it represents a commitment to safety and operational integrity. Organizations must acknowledge the critical role these devices play in mitigating risks associated with volatile environments. By prioritizing the implementation of explosion-resistant technologies, industries can cultivate a safer working atmosphere, safeguarding both personnel and assets from potential hazards.

Frequently Asked Questions

What is an explosion-proof fan motor?

An explosion-proof fan motor is designed for safe operation in environments with combustible gases, vapors, or dust. It is engineered to contain any internal explosions, preventing the ignition of the surrounding atmosphere.

Why is blast-resistant technology important?

Blast-resistant technology, such as explosion-proof fan motors, is crucial for preventing ignitions in hazardous settings, which significantly reduces the risk of accidents.

What are the key characteristics of explosion-proof fan motors?

Key characteristics include robust enclosures made from durable materials that can withstand high temperatures and pressures, ensuring safety in critical locations like chemical plants, oil refineries, and grain storage facilities.

What safety standards apply to explosion-proof fan motors?

Recent safety standards require rigorous testing and certification processes for protective equipment, ensuring they meet stringent criteria for dangerous environments. For instance, devices classified under Class I, Division 1 are designed for areas with flammable gases, while Class II classifications are for environments with combustible dust.

What are some practical applications of explosion-proof fan motors?

Explosion-proof fan motors are vital in the oil and gas industry for maintaining operational integrity and protecting personnel in hazardous environments.

How should explosion-proof fan motors be designed?

The design of explosion-proof fan motors must prioritize both safety and efficiency, reflecting the evolving criteria in hazardous area classifications.

Is it cost-effective to upgrade existing equipment to meet explosion-resistant standards?

Yes, upgrading existing equipment to meet explosion-resistant standards can be a cost-effective strategy for enhancing security without the need for complete overhauls.