Introduction

Understanding the performance of axial fans is crucial for engineers aiming to optimize cooling solutions across various applications. These performance curves provide a comprehensive visualization of the interplay between airflow, static pressure, and fan speed. This knowledge empowers engineers to make informed decisions that enhance both efficiency and reliability.

However, numerous factors influence fan performance – from design and motor efficiency to environmental conditions. How can engineers effectively navigate these complexities to ensure optimal operation? This article delves into the intricacies of axial fan performance curves, offering key insights that can significantly enhance cooling strategies and extend system longevity.

Define Axial Fan Performance Curves

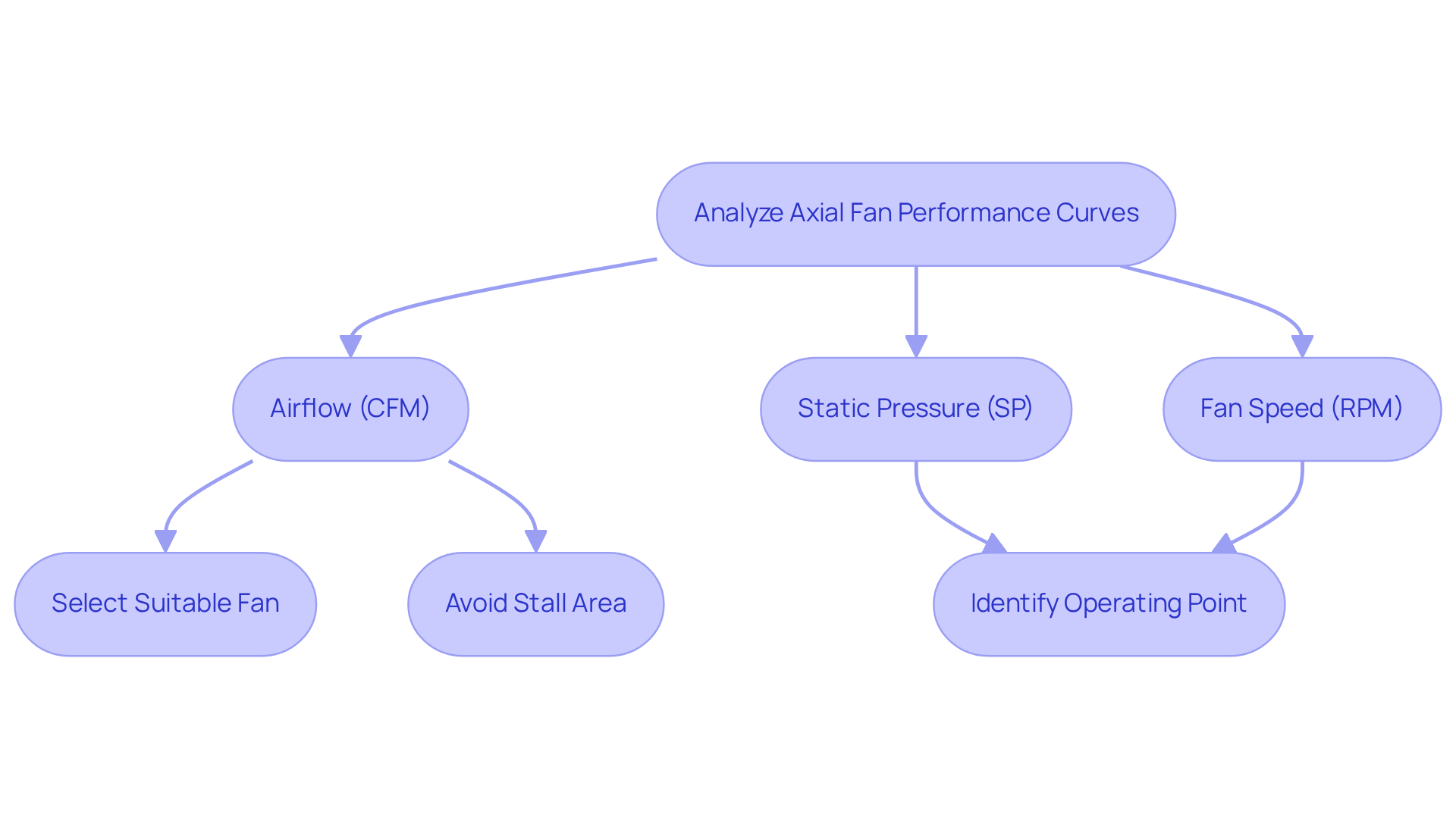

The axial fan performance curve serves as a crucial visual aid that illustrates the intricate relationship between airflow (CFM), static pressure (SP), and fan speed (RPM). These graphs empower engineers to understand the axial fan performance curve under varying conditions, which facilitates the selection of the most suitable fan for specific applications. Gagner-Toomey Associates offers an extensive range of DC input tube axial fans, spanning sizes from 15 to 280mm, optimized for efficiency and low noise. Each line on the graph typically represents different fan speeds, which together illustrate the axial fan performance curve and provide a comprehensive analysis across a variety of operational scenarios.

Understanding the axial fan performance curve is essential for enhancing cooling solutions in electronic systems, as it significantly influences thermal management and overall efficiency. By grasping the connection between airflow and static pressure, engineers can avoid operating in the stall area of the fan graph, a region that should be evaded to prevent instability and potential damage. Moreover, identifying the operating point on the axial fan performance curve is critical, as it signifies the stable equilibrium between the fan and the system.

Practical applications, such as the use of variable speed blowers in fixed systems, demonstrate how analyzing the axial fan performance curve can improve energy management and bolster system reliability. By leveraging these insights, engineers can ensure that their cooling setups, including Gagner-Toomey’s innovative cooling solutions, operate at peak efficiency, ultimately extending the lifespan of electronic components.

Explore Factors Affecting Fan Performance

Several factors significantly influence the performance of axial fans:

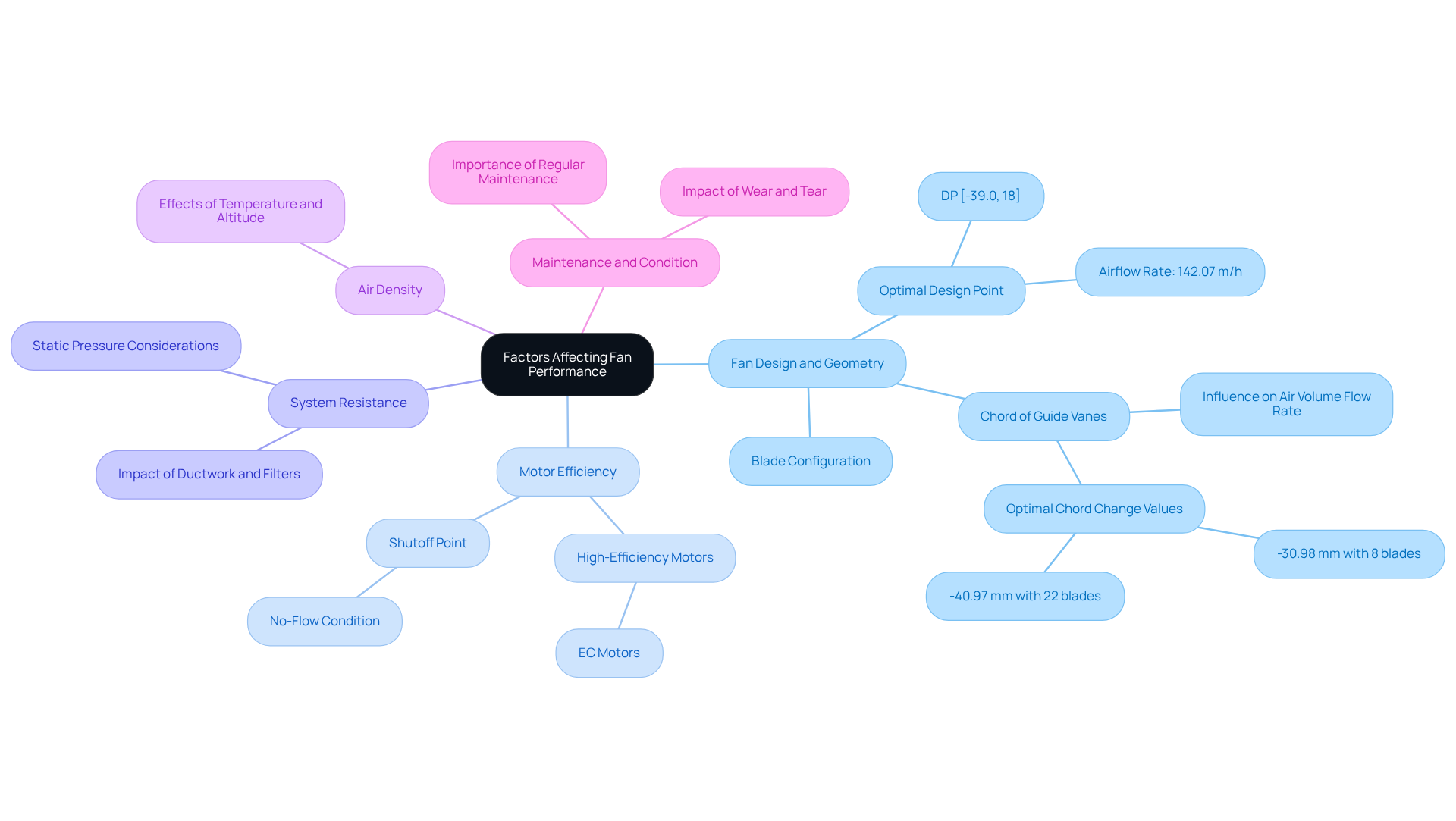

Fan Design and Geometry

The configuration of blades – encompassing their shape, number, and pitch angle – plays a crucial role in determining airflow and pressure characteristics. Enhancing these parameters can lead to improved efficiency and effectiveness. For instance, studies indicate that the chord of guide vanes is a primary factor affecting air volume flow rate, with specific configurations yielding optimal results. Notably, the optimal design point is identified as DP [-39.0, 18], corresponding to an airflow rate of 142.07 m/h at a rotation speed of 5000 r/min. Additionally, the highest airflow rates are achieved with chord change values of -30.98 mm with 8 blades and -40.97 mm with 22 blades.

Motor Efficiency

The effectiveness of the motor driving the fan directly influences overall functionality. High-efficiency motors, such as EC motors, enhance energy savings and reduce operational costs, making them a preferred choice in many applications. This is especially pertinent when examining the ‘shutoff point’ or ‘no-flow’ condition, where the fan creates force but cannot move air. This highlights the significance of motor selection in system design.

System Resistance

The static pressure that the fan must surpass – affected by ductwork, filters, and other elements – can significantly alter its effectiveness curve. Engineers must consider these resistances when choosing blowers to ensure they align with the axial fan performance curve for effective function within the system.

Air Density

Changes in air density, which can occur due to variations in temperature and altitude, affect the fan’s ability to move air. Understanding these dynamics is essential for precise outcome predictions.

Maintenance and Condition

Regular maintenance is vital for ensuring that fans operate at peak efficiency. Over time, wear and tear can diminish efficiency, underscoring the importance of regular inspections and maintenance. This aspect is crucial for maintaining optimal functionality and extending the lifespan of the equipment.

By thoroughly grasping these elements, engineers can refine fan selection and system design tailored for specific applications, ultimately enhancing efficacy and reliability.

Analyze Components of the Performance Curve

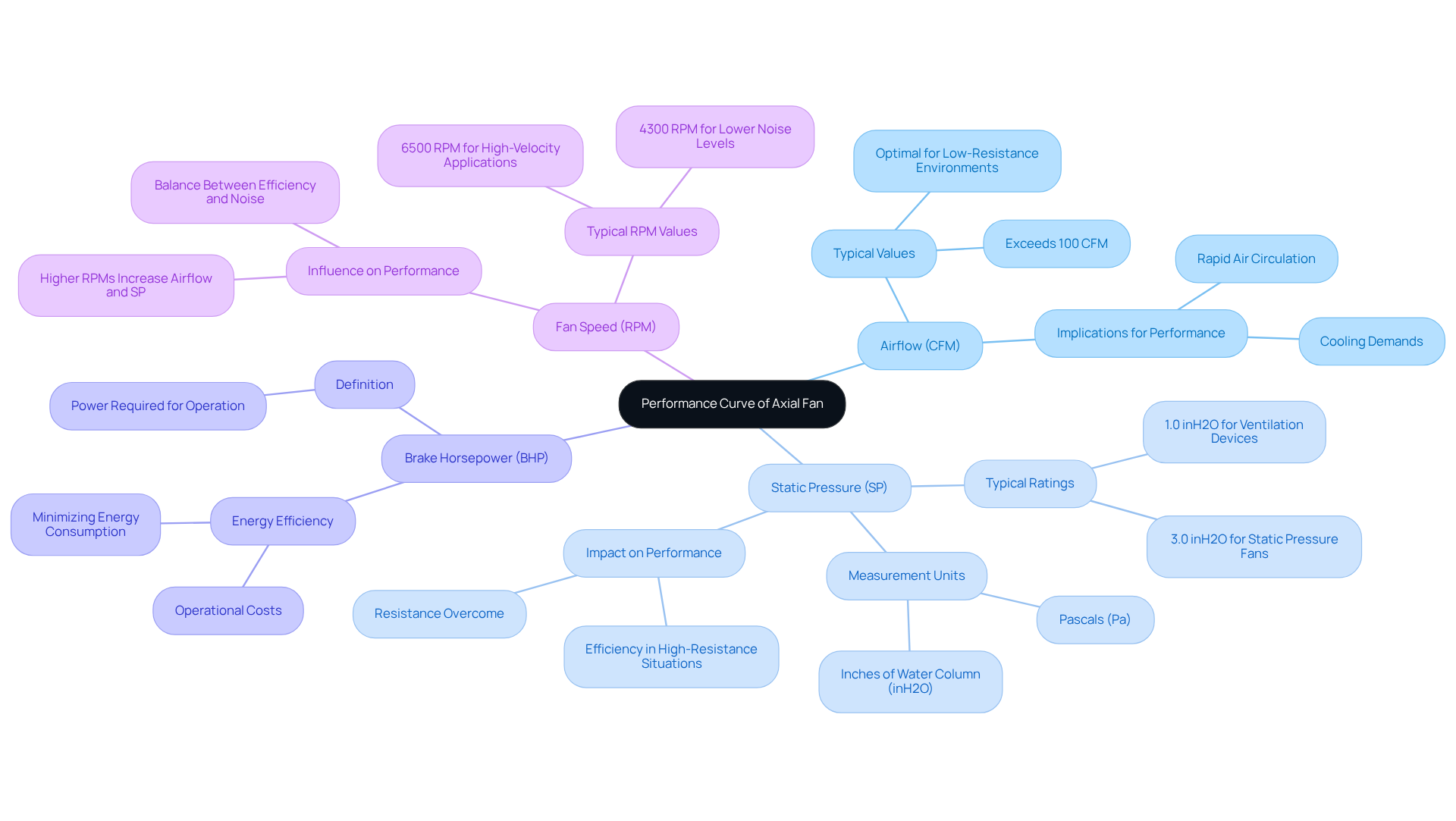

The performance curve of an axial fan includes several critical components essential for evaluating its effectiveness across various applications:

-

Airflow (CFM): This metric quantifies the volume of air the fan can move, typically expressed in cubic feet per minute (CFM). It is vital for assessing whether the fan can meet the cooling demands of a specific application. For instance, airflow fans often exceed 100 CFM, making them particularly effective in low-resistance environments.

-

Static Pressure (SP): Measured in inches of water gauge (in. ‘wg), static pressure represents the resistance the fan must overcome to facilitate air movement through the system. Understanding static pressure is crucial, as it directly affects the fan’s capacity to move air efficiently, especially in high-resistance situations where static pressure ratings are generally around 1.0 inH2O.

-

Brake Horsepower (BHP): This parameter signifies the power required to operate the fan at a specified airflow and static pressure. Evaluating BHP is essential for understanding energy efficiency and operational costs, as it aids in selecting fans that minimize energy consumption while meeting performance needs.

-

Fan Speed (RPM): The rotational speed of the fan significantly influences both airflow and static pressure. Higher RPMs generally enhance airflow and static pressure, making them suitable for high-velocity cooling applications. However, increased speeds can also lead to higher noise levels and energy usage, necessitating a balance between efficiency and acoustics.

By thoroughly analyzing these components, engineers can identify the optimal operating point on the axial fan performance curve, ensuring efficient operation tailored to their specific application requirements.

Interpret Performance Curve Data for Application

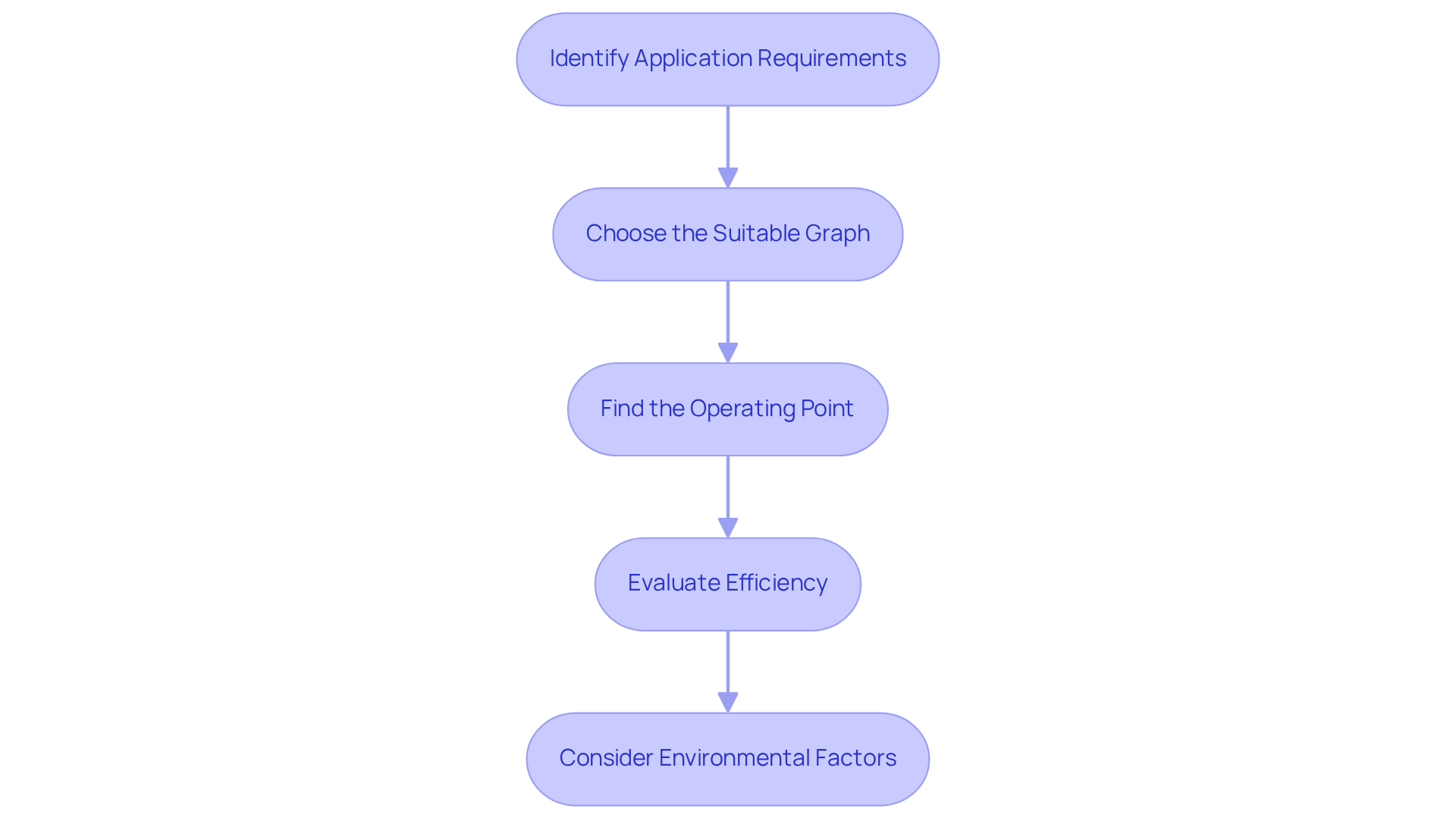

Analyzing the axial fan performance curve is crucial for effectively utilizing axial fans across various applications. Engineers must follow these key steps:

- Identify Application Requirements: Start by evaluating the essential airflow and static force needed for your application, taking into account heat load and system resistance.

- Choose the Suitable Graph: Select the efficiency graph that aligns with the desired fan speed, as each graph presents unique airflow and pressure characteristics.

- Find the Operating Point: Determine where the system resistance curve intersects with the fan efficiency curve. This intersection reveals the actual operating conditions of the fan within the system.

- Evaluate Efficiency: Analyze the brake horsepower at the operating point to assess energy consumption and efficiency. Aim for an optimal balance between airflow and power usage to enhance efficiency. Recent analyses show that selecting efficient fans can significantly lower power consumption, a critical consideration for engineers.

- Consider Environmental Factors: Account for how variations in temperature, altitude, and humidity can impact fan efficiency, adjusting your selection accordingly. The emerging trend towards biodegradable fan blades reflects the industry’s shift towards sustainability, resonating with engineers concerned about environmental impacts.

By adhering to these steps, engineers can leverage the axial fan performance curve data to ensure optimal fan selection and system design, ultimately enhancing cooling efficiency in electronic applications. This approach is particularly vital in high-density environments like data centers, where efficient cooling solutions are paramount. With the axial flow cooling fans market projected to grow significantly by 2026, understanding these principles becomes increasingly important for engineers aiming to meet the rising demand for effective cooling solutions.

Conclusion

Understanding axial fan performance curves is crucial for engineers who seek to optimize cooling solutions across various applications. These curves reveal the intricate relationship between airflow, static pressure, and fan speed, empowering engineers to make informed decisions that enhance system efficiency and reliability. By mastering these performance curves, engineers can select the most appropriate fans for their specific requirements, ultimately improving thermal management and extending the lifespan of electronic components.

Several key factors influencing axial fan performance have been highlighted throughout this article:

- The design and geometry of fan blades

- Motor efficiency

- System resistance

- Air density

- Maintenance practices

These factors significantly impact a fan’s effectiveness. Moreover, grasping the components of the performance curve-such as airflow (CFM), static pressure (SP), brake horsepower (BHP), and fan speed (RPM)-is essential for engineers to identify optimal operating conditions. By systematically analyzing performance curve data, engineers can ensure their cooling systems operate at peak efficiency.

In today’s rapidly evolving technological landscape, the significance of mastering axial fan performance curves cannot be overstated. As the demand for efficient cooling solutions escalates, particularly in high-density environments like data centers, engineers must leverage these insights for sustainable and effective designs. By prioritizing the analysis of axial fan performance curves, engineers can not only address current challenges but also anticipate future needs, thereby contributing to the advancement of reliable and efficient cooling technologies.

Frequently Asked Questions

What is an axial fan performance curve?

The axial fan performance curve is a visual representation that illustrates the relationship between airflow (CFM), static pressure (SP), and fan speed (RPM) for an axial fan.

Why are axial fan performance curves important for engineers?

These curves help engineers understand axial fan performance under varying conditions, allowing them to select the most suitable fan for specific applications and enhance cooling solutions in electronic systems.

What does each line on the axial fan performance curve represent?

Each line on the graph typically represents different fan speeds, providing a comprehensive analysis of the fan’s performance across various operational scenarios.

How does understanding the axial fan performance curve influence thermal management?

Understanding the curve helps engineers grasp the connection between airflow and static pressure, which is crucial for avoiding the stall area of the fan graph and ensuring stable operation.

What is the significance of identifying the operating point on the axial fan performance curve?

The operating point signifies the stable equilibrium between the fan and the system, which is critical for optimal performance and reliability.

How can analyzing the axial fan performance curve improve energy management?

Practical applications, such as using variable speed blowers in fixed systems, demonstrate that analyzing the performance curve can enhance energy management and bolster system reliability.

What types of axial fans does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a wide range of DC input tube axial fans, with sizes ranging from 15 to 280mm, optimized for efficiency and low noise.