Introduction

The electronics industry is facing an escalating demand for effective cooling solutions, particularly in compact systems where space is limited. Engineers are tasked with the critical challenge of selecting the right components to ensure optimal thermal management without sacrificing performance. This article explores ten essential features of 3 inch computer fans, emphasizing their role in enhancing airflow, reducing noise, and boosting energy efficiency.

As technology continues to advance, how can engineers effectively navigate these specifications to secure the best cooling solutions for their projects?

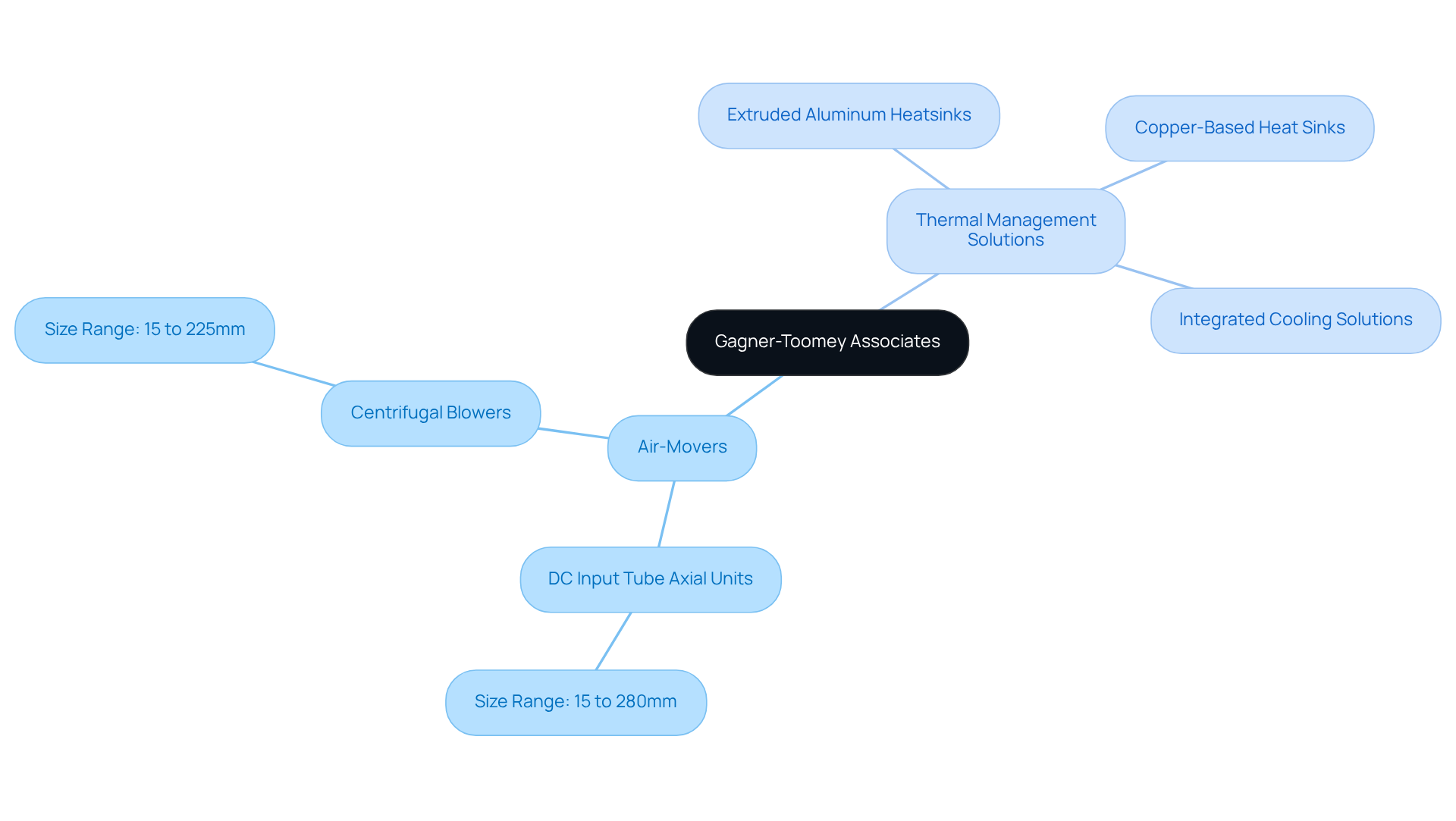

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics

Gagner-Toomey Associates stands at the forefront of advanced temperature control solutions specifically designed for the electronics industry. As the world’s largest manufacturer of both standard and custom air-movers, the company offers an extensive range of temperature regulation products. This includes:

- DC input tube axial units that span from 15 to 280mm

- Centrifugal blowers ranging from 15 to 225mm

These devices are engineered with a focus on enhancing performance, efficiency, and minimizing noise, making them essential for maintaining optimal temperatures in compact electronic systems. This reliability is crucial for performance-critical applications, ensuring durability and consistent operation.

Moreover, Gagner-Toomey’s comprehensive portfolio features innovative thermal management solutions, including:

- Extruded aluminum heatsinks

- Copper-based heat sinks

- Integrated cooling solutions

This diverse offering solidifies their position as a leading provider in the field, catering to the specific needs of the electronics sector.

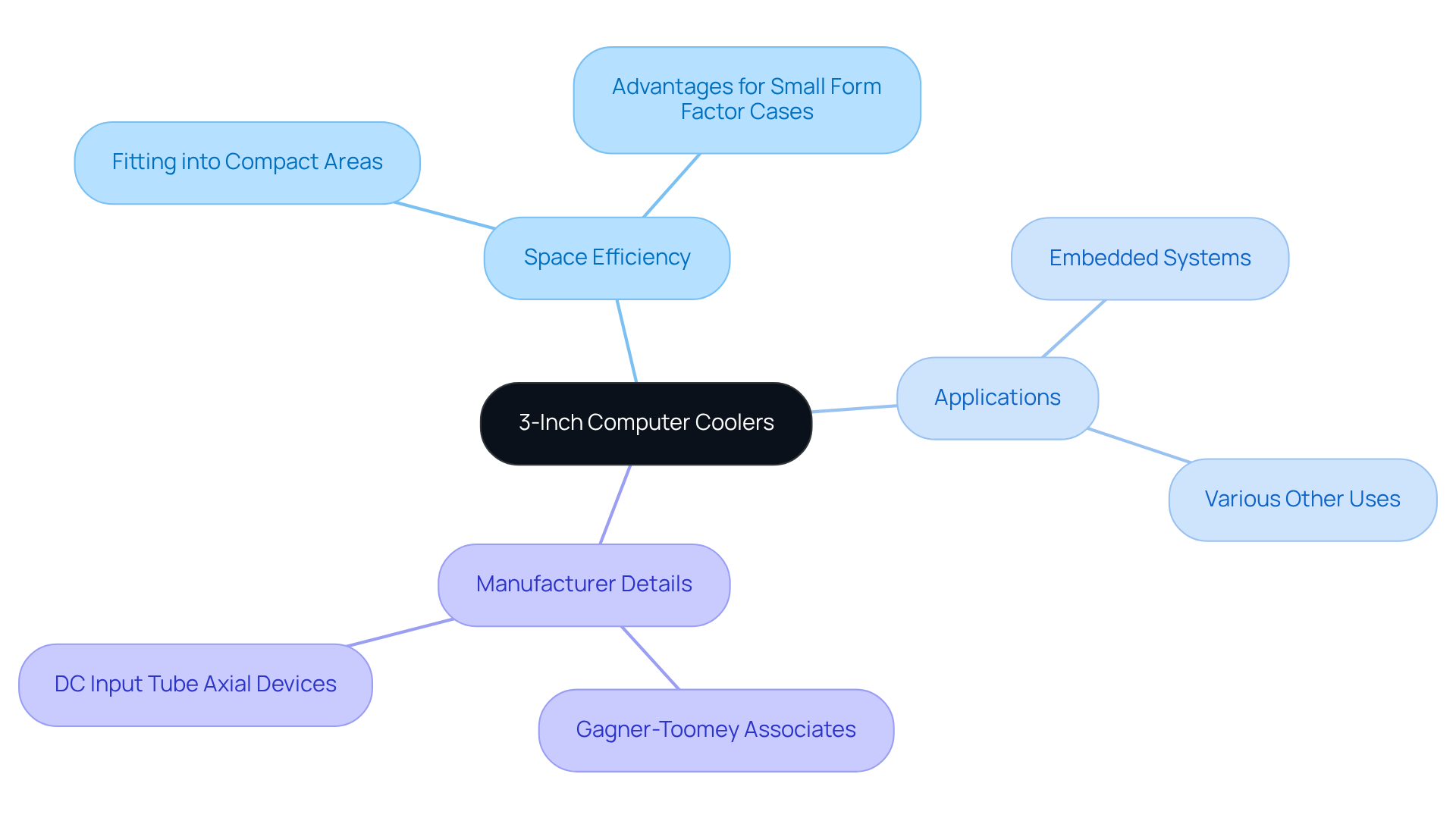

3-Inch Size: Ensuring Compatibility with Your System

Maximizing Space Efficiency with 3-Inch Computer Coolers

In the realm of computer cooling solutions, space constraints pose a significant challenge. The dimensions of a 3 inch computer fan, typically measuring 80mm, are specifically designed to fit into compact areas where larger models simply cannot. This compact size of a 3 inch computer fan is particularly advantageous for small form factor cases, embedded systems, and various applications where every inch counts.

Gagner-Toomey Associates stands as the world’s largest producer of both standard and custom air-movers, offering an extensive range of DC input Tube Axial devices that cater to this size requirement. Engineers must carefully consider the dimensions of their systems to ensure these devices can be installed without obstruction, thereby facilitating optimal airflow and effective temperature regulation.

With Gagner-Toomey’s commitment to optimized performance and low noise characteristics, these devices emerge as an exceptional choice for enhancing thermal management in electronics. By integrating these compact coolers, professionals can achieve superior cooling solutions that align with the demands of modern technology.

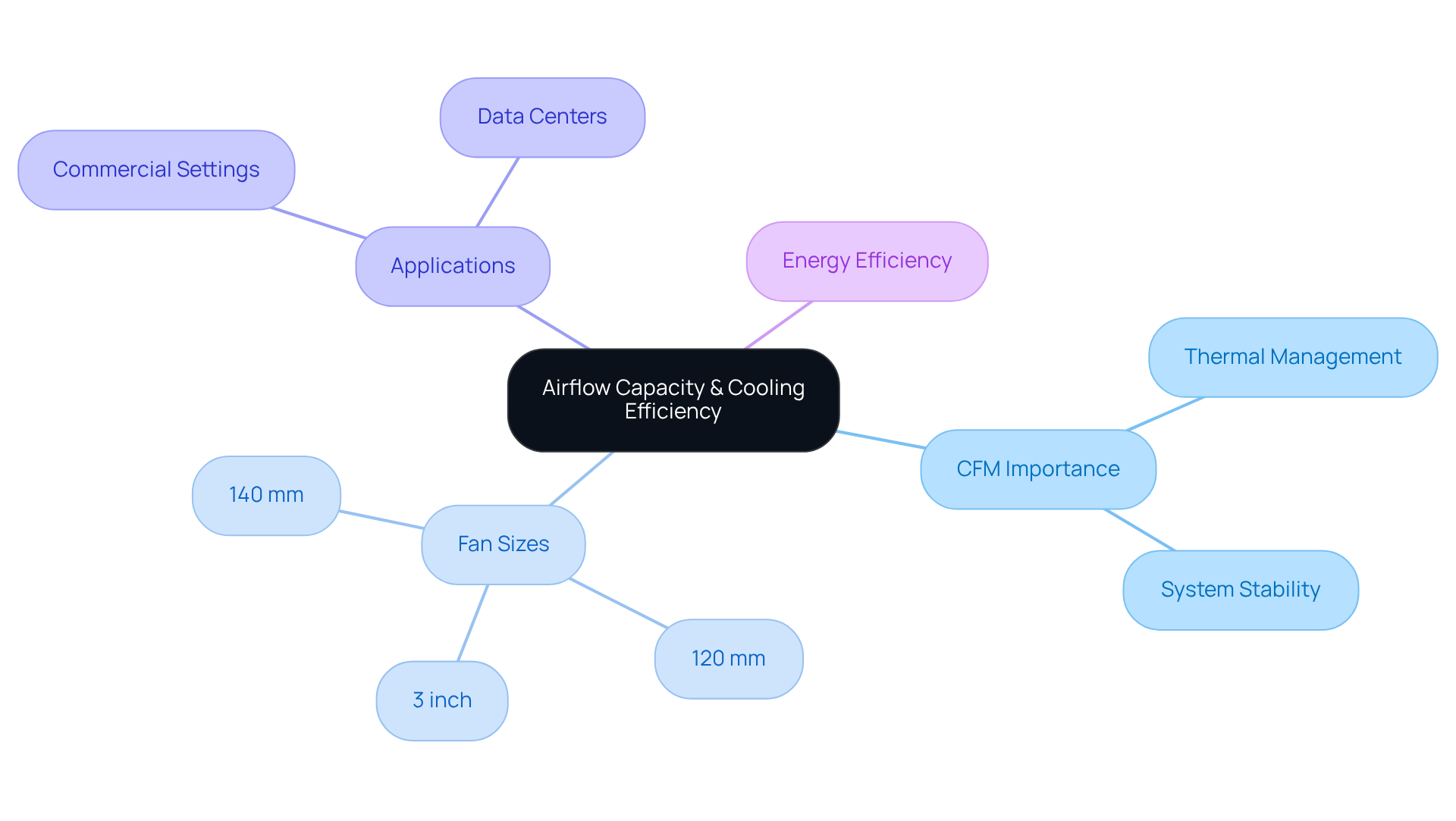

Airflow Capacity: Maximizing Cooling Efficiency

Airflow capacity, measured in cubic feet per minute (CFM), is a critical specification for a 3 inch computer fan. It directly impacts the thermal efficiency of high-performance components. Fans with higher CFM ratings facilitate greater airflow, which is essential for dissipating heat effectively and preventing overheating-key factors in maintaining system stability. In commercial settings, for example, blowers often require CFM ratings exceeding 10,000 to ensure adequate ventilation and comfort in expansive environments. This principle extends to electronics, where a 3 inch computer fan with a higher CFM can significantly enhance thermal management.

Thermal management specialists assert that understanding CFM is crucial for selecting the right 3 inch computer fan for specific applications. A notable case is the transition to larger, energy-efficient ventilators in a manufacturing plant, which resulted in a 20% decrease in energy usage. This underscores the profound effect of airflow capacity on temperature regulation. Furthermore, in data centers, approximately 55% of total energy is consumed in maintaining IT equipment temperature, highlighting the necessity for effective airflow management.

Practical examples further illustrate this concept: larger units, such as 140 mm types, deliver enhanced airflow compared to standard 120 mm models. They operate at lower RPMs while maintaining efficient temperature management. This efficiency is vital in high-performance systems where thermal management is paramount. Ultimately, engineers must prioritize airflow capacity when selecting blowers to improve temperature regulation and ensure the reliability of electronic systems.

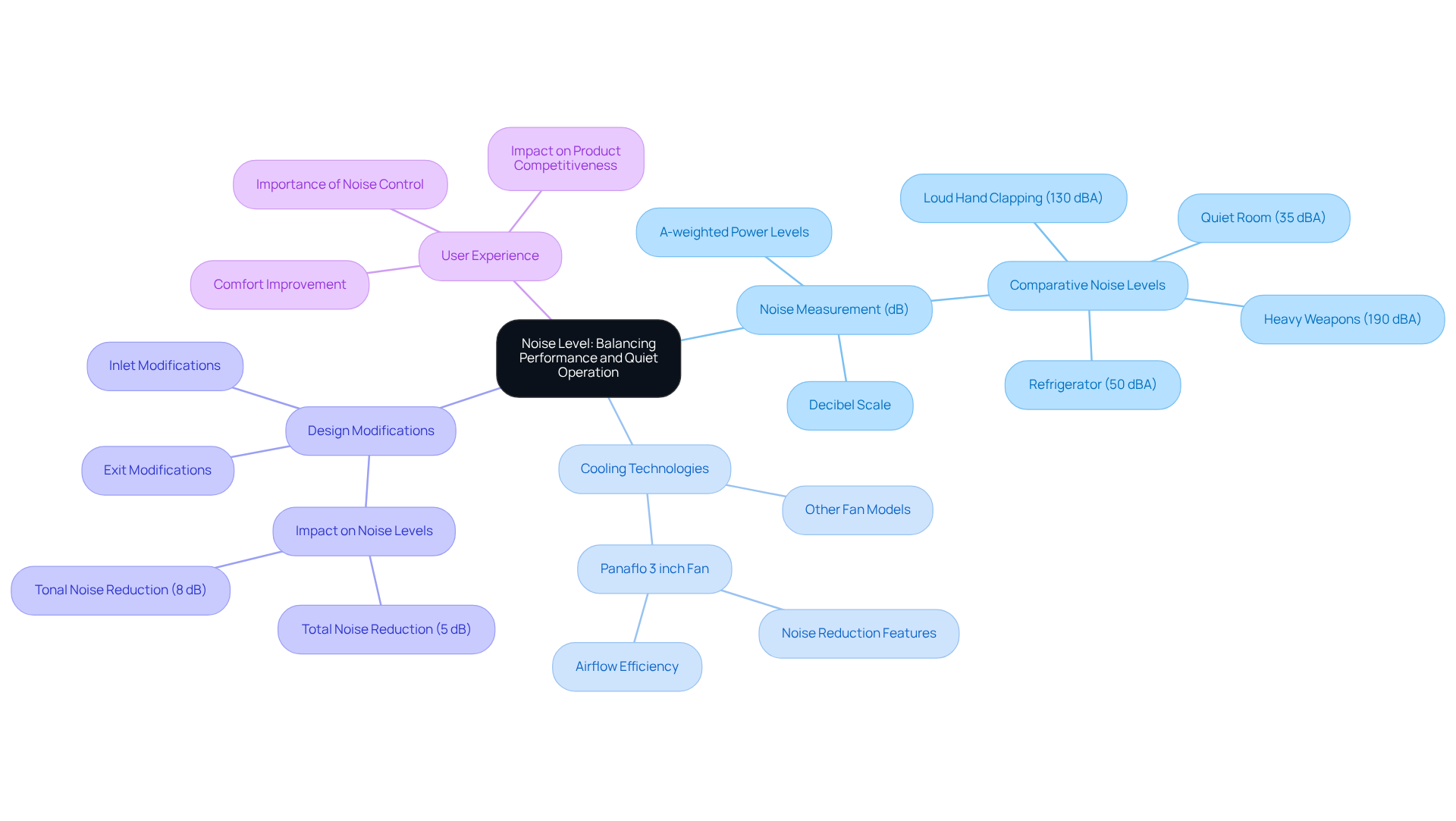

Noise Level: Balancing Performance and Quiet Operation

Noise levels in computer cooling systems are quantified in decibels (dB), a critical factor for engineers striving to balance airflow and noise, particularly in sensitive environments like home theaters or offices. Contemporary units, such as the Panaflo models evaluated, include a 3 inch computer fan that incorporates advanced noise-reduction technologies, enabling them to operate quietly while delivering efficient airflow.

For instance, as noted by Jinchun Huang, devices designed with inlet and exit modifications can achieve noise reductions of approximately 5 dB and tonal noise reductions of about 8 dB. This significantly enhances user experience without compromising airflow. Choosing devices like a 3 inch computer fan with lower dB ratings not only improves comfort but also aligns with the growing trend in 2025 towards quieter operation in cooling solutions.

As highlighted by acoustics specialists, controlling noise at its source is essential for enhancing both functionality and sound quality. Therefore, making informed fan selections is crucial for engineers in the electronics sector.

Bearing Type: Enhancing Durability and Performance

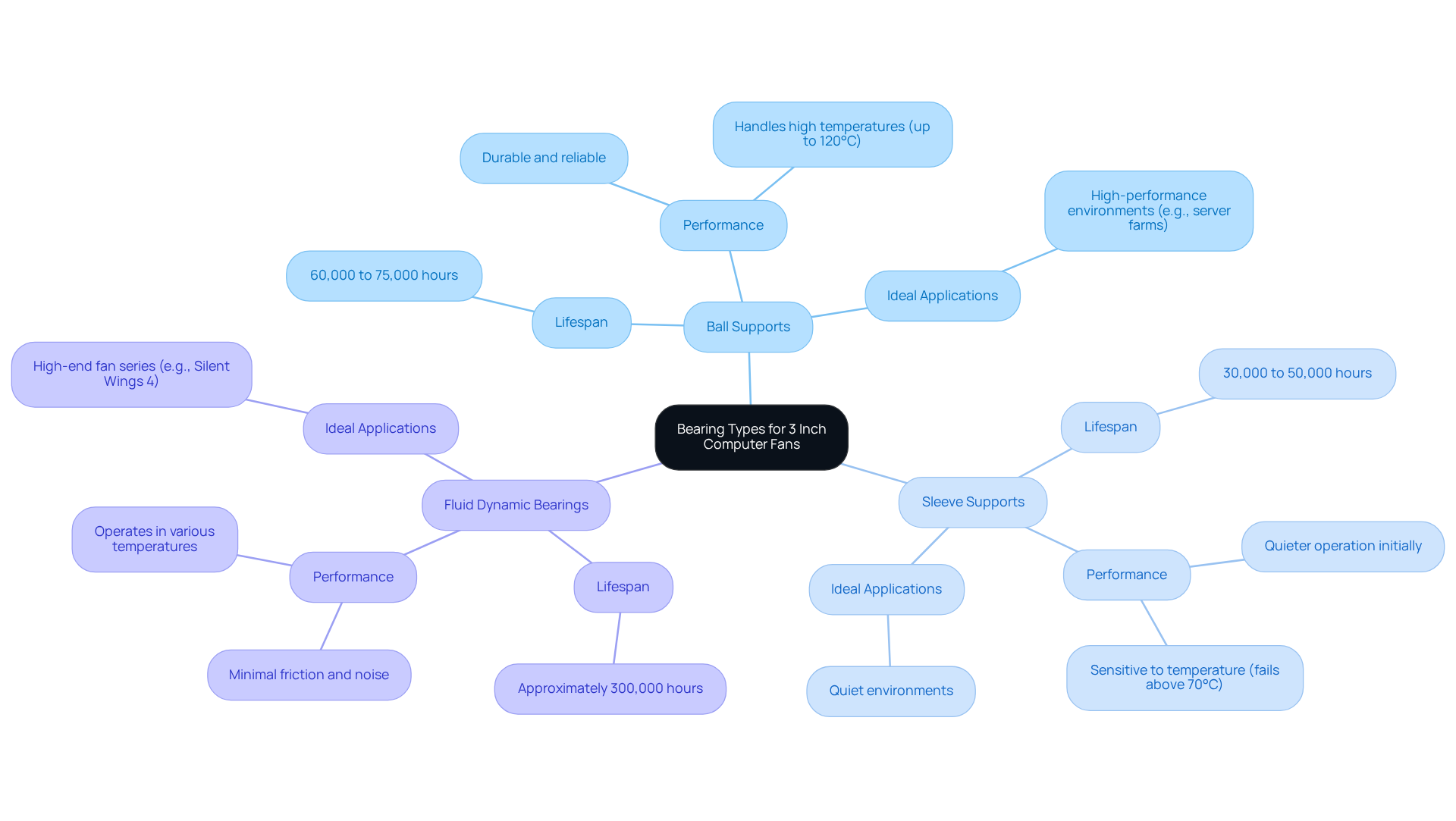

3 inch computer fans primarily feature various types of supports, including sleeve, ball, and fluid dynamic. Each type possesses distinct characteristics that significantly influence performance and longevity.

- Ball supports are particularly noted for their durability, often lasting between 60,000 to 75,000 hours under optimal conditions. This makes them ideal for high-performance applications, such as server farms, where reliability is paramount.

- Conversely, sleeve supports, while initially quieter and more cost-effective, generally have a lifespan of about 30,000 to 50,000 hours. Their longevity is heavily dependent on maintenance practices and operational conditions, and they may fail catastrophically under heavy use or elevated temperatures, especially when exceeding 70°C. A study from the University of Michigan underscores this disparity, revealing that ball supports can last up to ten times longer than sleeve supports in ideal conditions. This highlights the critical impact of support type on the performance of a 3 inch computer fan.

In practical applications, the preference for a 3 inch computer fan as a cooling device in server environments is evident. They excel in managing greater loads and temperatures, while sleeve-type cooling units are often utilized in quieter settings where noise levels are a priority. Recent advancements in bearing technology, particularly fluid dynamic bearings, have revolutionized the market. These bearings boast an impressive lifespan of approximately 300,000 hours and minimal friction, significantly enhancing energy efficiency.

Understanding these distinctions is crucial for engineers aiming to select devices that meet specific performance and durability standards. By choosing the right support type, professionals can ensure optimal functionality and longevity in their cooling solutions.

Power Consumption: Ensuring Energy Efficiency

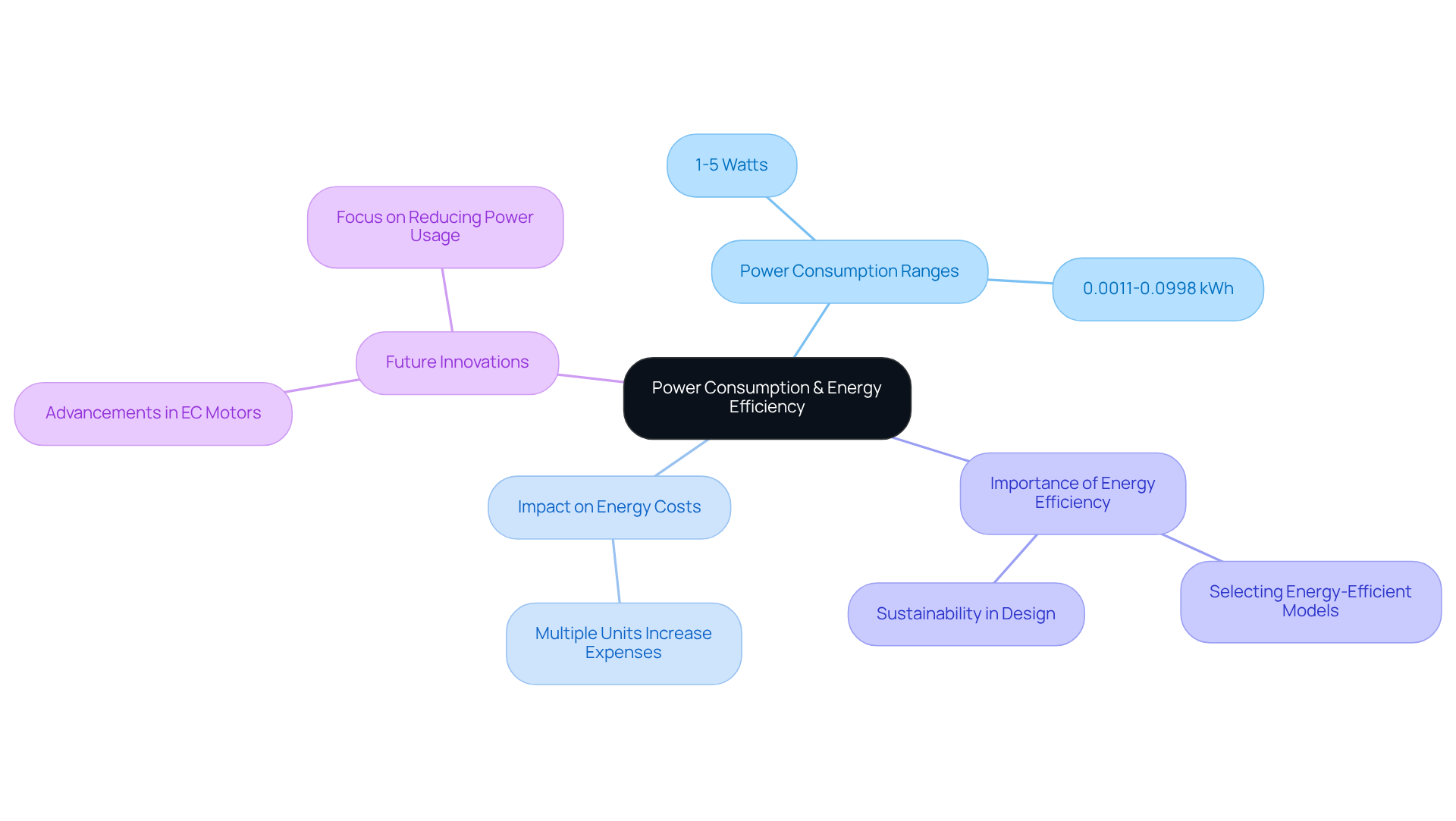

Power consumption in 3 inch computer fan units typically ranges from 1 to 5 watts, with most devices utilizing between 0.0011 kWh and 0.0998 kWh of electricity per hour. This seemingly minor consumption can lead to substantial savings, especially in larger systems or when multiple units are in operation. For instance, high-end systems equipped with several cooling devices can incur significant power usage from case coolers, ultimately resulting in elevated energy expenses.

Engineers must prioritize the power ratings of ventilation devices during system design. By selecting energy-efficient models, they can significantly reduce overall energy costs. This approach not only enhances the sustainability of designs but also aligns with the increasing emphasis on energy efficiency in electronics. Gagner-Toomey Associates, recognized as the globe’s largest producer of standard and custom air-movers, offers a comprehensive portfolio of DC input devices and blowers optimized for performance and efficiency. Their products are ideal for engineers focused on energy savings.

Looking ahead, innovations in 2025 are set to concentrate on further decreasing power usage in temperature control solutions, particularly through advancements in EC motors. These motors are acknowledged for their significant contributions to energy savings and efficiency across various sectors. As sustainability expert Cees Timmerman aptly noted, “12 V times 1.5 A is only 18 W,” underscoring the critical importance of considering power ratings in design.

Speed Control Options: Customizing Cooling Performance

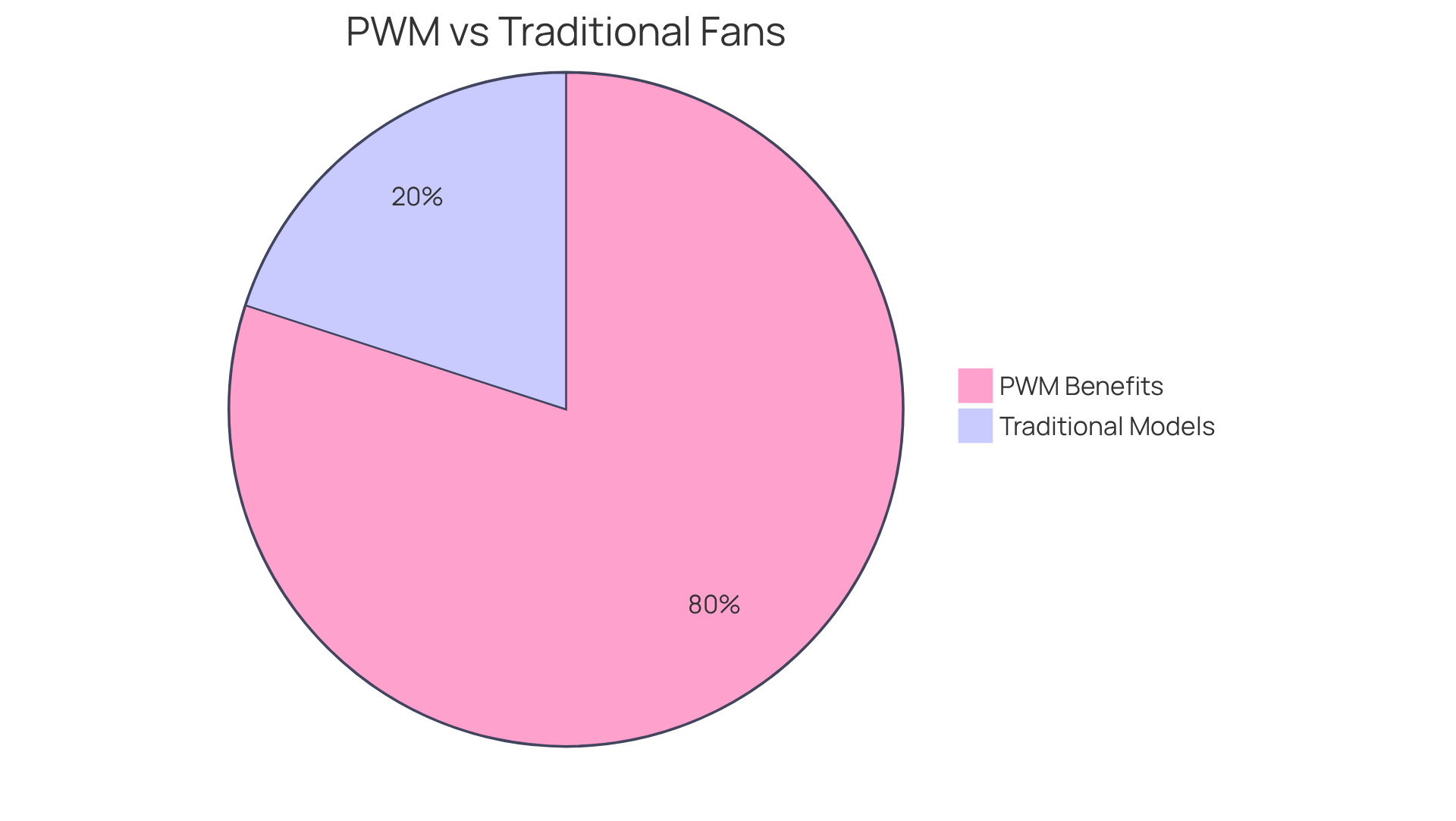

Many 3 inch computer fans now incorporate advanced speed control options, particularly PWM (Pulse Width Modulation) and voltage control. PWM technology enables precise adjustments in fan speed based on real-time temperature readings, significantly improving efficiency and reducing noise levels. This adaptability empowers engineers to customize fan operation to effectively address varying thermal loads.

For example, PWM devices can operate at as low as 10% of their peak speed during minimal thermal demand, in stark contrast to traditional models that typically run at a minimum of 50%. This capability not only boosts energy efficiency – potentially cutting power consumption by up to 30% compared to conventional models – but also extends the lifespan of electronic components by as much as 50%.

Engineers emphasize that the precision of PWM devices is vital for enhancing temperature management strategies, especially in high-performance environments. As one engineer remarked, “The flexibility of PWM devices renders them superior to conventional cooling systems in terms of both effectiveness and efficiency.” By integrating these controls into their designs, engineers can ensure that ventilators operate optimally, balancing airflow and noise reduction to enhance overall system efficiency.

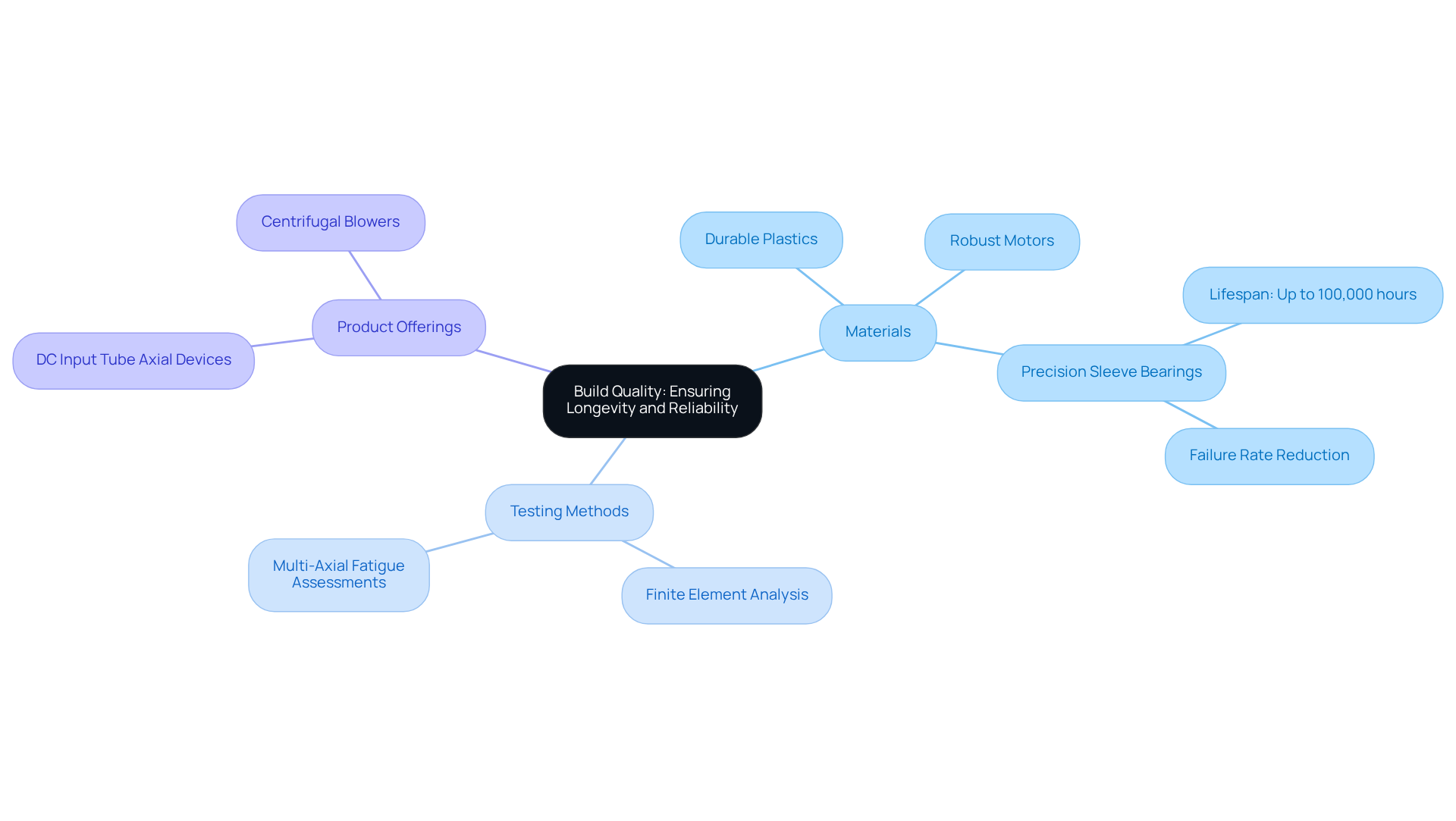

Build Quality: Ensuring Longevity and Reliability

The build quality of 3 inch computer fans is crucial for ensuring reliability and longevity in electronic applications. Gagner-Toomey Associates highlights the importance of using high-quality materials, such as durable plastics and robust motors, which significantly enhance a fan’s performance. For instance, devices designed with precision sleeve bearings typically exhibit reduced failure rates, boasting lifetimes of up to 100,000 hours, compared to standard sleeve bearings that average around 40,000 hours.

Engineers must prioritize devices that incorporate superior materials and have undergone rigorous testing protocols to validate their durability. Testing methods, including finite element analysis and multi-axial fatigue assessments, are essential for confirming that devices can withstand the operational stresses they will encounter in practical applications.

As we approach 2025, adherence to stringent standards for materials used in the construction of a 3 inch computer fan becomes critical, given that advancements in technology demand higher performance and reliability. Experts in product reliability assert that the choice of materials directly impacts a device’s operational efficiency and lifespan. This reinforces the necessity for engineers to select well-constructed units from Gagner-Toomey, minimizing the likelihood of failures and maintenance issues.

Gagner-Toomey offers a diverse range of products, including DC input Tube Axial devices and Centrifugal Blowers, ensuring that engineers have access to the right solutions for various applications.

Design Features: Aesthetic and Functional Considerations

3 inch computer fans are available in a variety of designs that meet both aesthetic and functional needs. Features such as LED lighting, customizable colors, and sleek finishes significantly enhance the visual appeal of a system. Moreover, design elements like blade shape and housing play a crucial role in determining airflow efficiency and noise levels. Engineers must carefully consider these factors when selecting blowers to ensure they fulfill both functional and aesthetic criteria. By prioritizing these design aspects, professionals can create systems that not only perform optimally but also resonate with users on a visual level.

Warranty and Support: Ensuring Peace of Mind

When selecting 3 inch computer fans as cooling devices, engineers must prioritize the warranty and support provided by manufacturers. A robust warranty not only delivers peace of mind but also guarantees that any defects or issues are addressed without incurring extra costs.

For instance, Gagner-Toomey Associates exemplifies exceptional customer support, which is crucial for troubleshooting and optimizing fan performance. This level of support can significantly impact project outcomes, enhancing the functionality and reliability of blowers within systems.

By opting for a 3 inch computer fan from reputable manufacturers known for their strong warranties and outstanding support, engineers can substantially improve the overall success of their projects.

Conclusion

The significance of 3 inch computer fans in modern electronics is paramount. These compact cooling solutions are essential for maintaining optimal temperatures within confined spaces, ensuring that high-performance components operate effectively and reliably. By grasping the unique features and specifications of these fans, engineers can make informed decisions that significantly enhance the overall performance of their systems.

Key aspects such as:

- Airflow capacity

- Noise levels

- Bearing types

- Power consumption

- Speed control options

- Build quality

- Design features

- Warranty support

are crucial. Each of these elements contributes to the efficiency and longevity of cooling solutions, highlighting the importance of selecting the right fan for specific applications. Gagner-Toomey Associates stands out as a leader in providing innovative cooling technologies tailored to meet the diverse needs of the electronics industry.

As technology evolves, the demand for efficient and reliable cooling solutions will only increase. Engineers must prioritize these critical factors when designing systems, ensuring they not only meet performance standards but also align with sustainability goals. By leveraging advancements in 3 inch computer fan technology, professionals can create systems that excel in performance while contributing to a more energy-efficient future.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in advanced temperature control solutions for the electronics industry, offering a wide range of both standard and custom air-movers.

What types of cooling devices does Gagner-Toomey Associates provide?

The company provides DC input tube axial units ranging from 15 to 280mm and centrifugal blowers ranging from 15 to 225mm.

Why are Gagner-Toomey’s cooling solutions important for electronics?

Their cooling solutions enhance performance, efficiency, and minimize noise, which is crucial for maintaining optimal temperatures in compact electronic systems, ensuring durability and consistent operation.

What additional thermal management solutions does Gagner-Toomey offer?

Gagner-Toomey offers a variety of thermal management solutions, including extruded aluminum heatsinks, copper-based heat sinks, and integrated cooling solutions.

What is the significance of a 3-inch computer fan in cooling solutions?

A 3-inch computer fan, typically measuring 80mm, is designed to fit into compact areas, making it ideal for small form factor cases and embedded systems where space is limited.

How does airflow capacity affect cooling efficiency?

Airflow capacity, measured in cubic feet per minute (CFM), directly impacts thermal efficiency. Higher CFM ratings facilitate greater airflow, essential for dissipating heat effectively and preventing overheating.

Why is understanding CFM important when selecting a computer fan?

Understanding CFM is crucial because it helps in choosing the right fan for specific applications, ensuring adequate ventilation and effective temperature regulation.

What example illustrates the impact of airflow capacity in a commercial setting?

In a manufacturing plant, transitioning to larger, energy-efficient ventilators resulted in a 20% decrease in energy usage, demonstrating the significant effect of airflow capacity on temperature regulation.

How does airflow management relate to energy consumption in data centers?

Approximately 55% of total energy in data centers is consumed for maintaining IT equipment temperature, highlighting the necessity for effective airflow management to optimize energy usage.

What should engineers prioritize when selecting blowers for electronics?

Engineers should prioritize airflow capacity to improve temperature regulation and ensure the reliability of electronic systems.