Introduction

Selecting the right 12V DC fan motor is not merely a technical decision; it’s a pivotal choice that can significantly influence efficiency, cost savings, and overall system performance. With a plethora of options available, it’s crucial for engineers and technicians to grasp the fundamental differences between brushed and brushless motors. Understanding these distinctions is essential for making informed decisions that align with both immediate cooling needs and long-term durability.

What challenges arise when trying to balance performance with durability? Engineers often face the dilemma of choosing a motor that not only meets current requirements but also withstands the test of time. By considering critical selection criteria, such as operational efficiency, maintenance needs, and environmental factors, one can ensure that the chosen motor delivers optimal performance over its lifespan.

In this context, it’s vital to delve deeper into the characteristics of both motor types. Brushed motors, while typically less expensive, may require more maintenance and have a shorter lifespan compared to their brushless counterparts. On the other hand, brushless motors offer enhanced efficiency and longevity, making them a compelling choice for demanding applications.

Ultimately, the decision-making process should involve a thorough evaluation of both immediate and future needs. By prioritizing these factors, engineers can select a motor that not only meets their current cooling demands but also provides reliable performance for years to come.

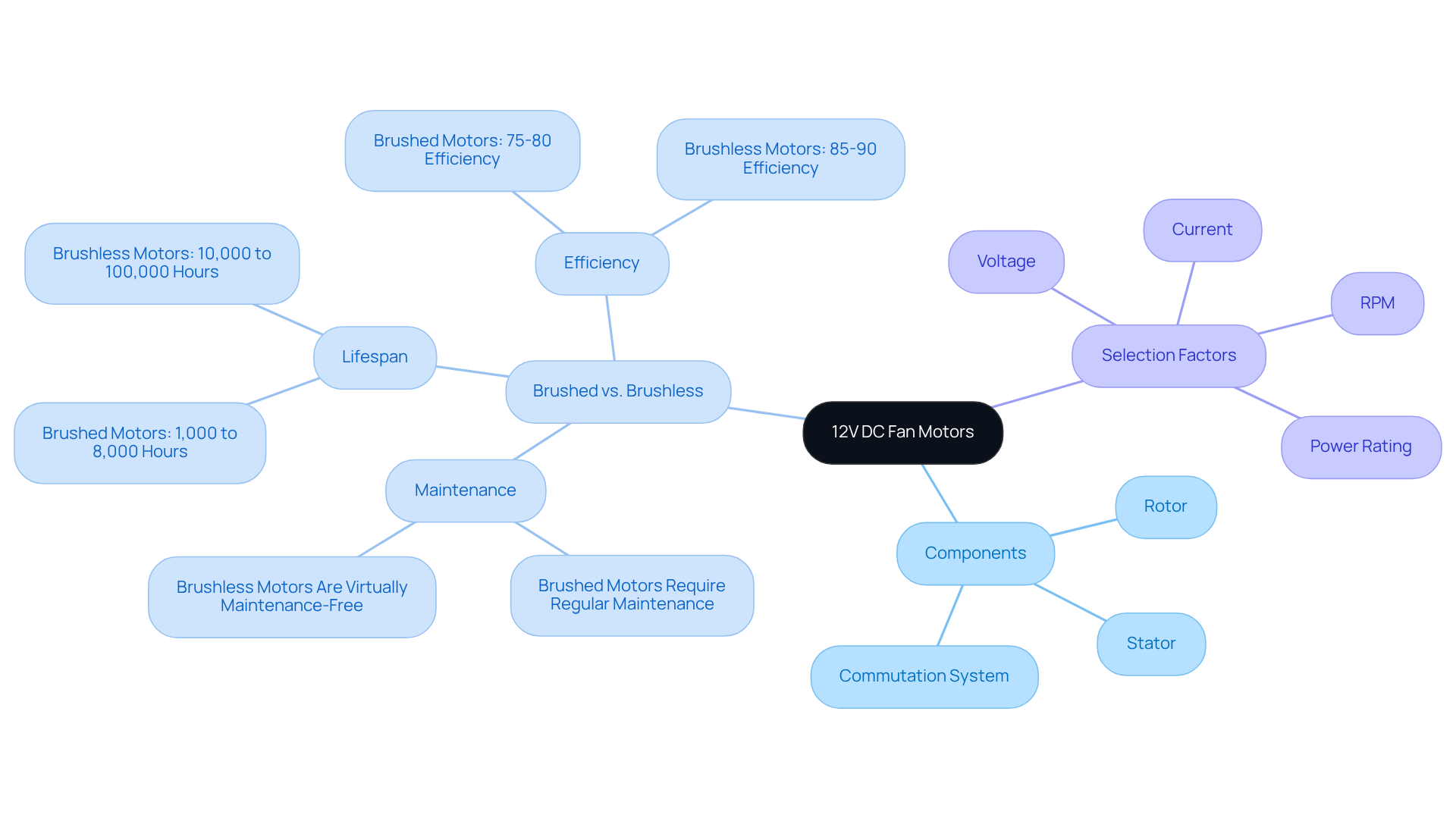

Understand the Fundamentals of 12V DC Fan Motors

The 12v dc fan motor plays a crucial role in converting electrical energy into mechanical energy, facilitating airflow for effective cooling and ventilation. These devices are composed of a rotor, stator, and a commutation system, with notable differences between brushed and brushless designs.

Brushed devices, while simpler and more cost-effective, necessitate regular maintenance due to wear on brushes and commutators. This wear leads to a shorter lifespan, typically ranging from 1,000 to 8,000 hours. In contrast, brushless devices stand out for their efficiency and longevity, operating between 10,000 and 100,000 hours with minimal maintenance. They achieve efficiencies exceeding 90%, which significantly reduces energy consumption and operational costs. For example, applications with annual operating costs exceeding $3,000 can realize substantial savings by choosing brushless technology.

When selecting a device like a 12v dc fan motor, it is essential to evaluate key factors such as:

- Voltage

- Current

- Power rating

- RPM

These elements directly influence functionality and suitability for specific cooling tasks. Understanding these fundamentals is vital for engineers aiming to choose the most effective device for their cooling needs, ensuring both reliability and efficiency in their applications.

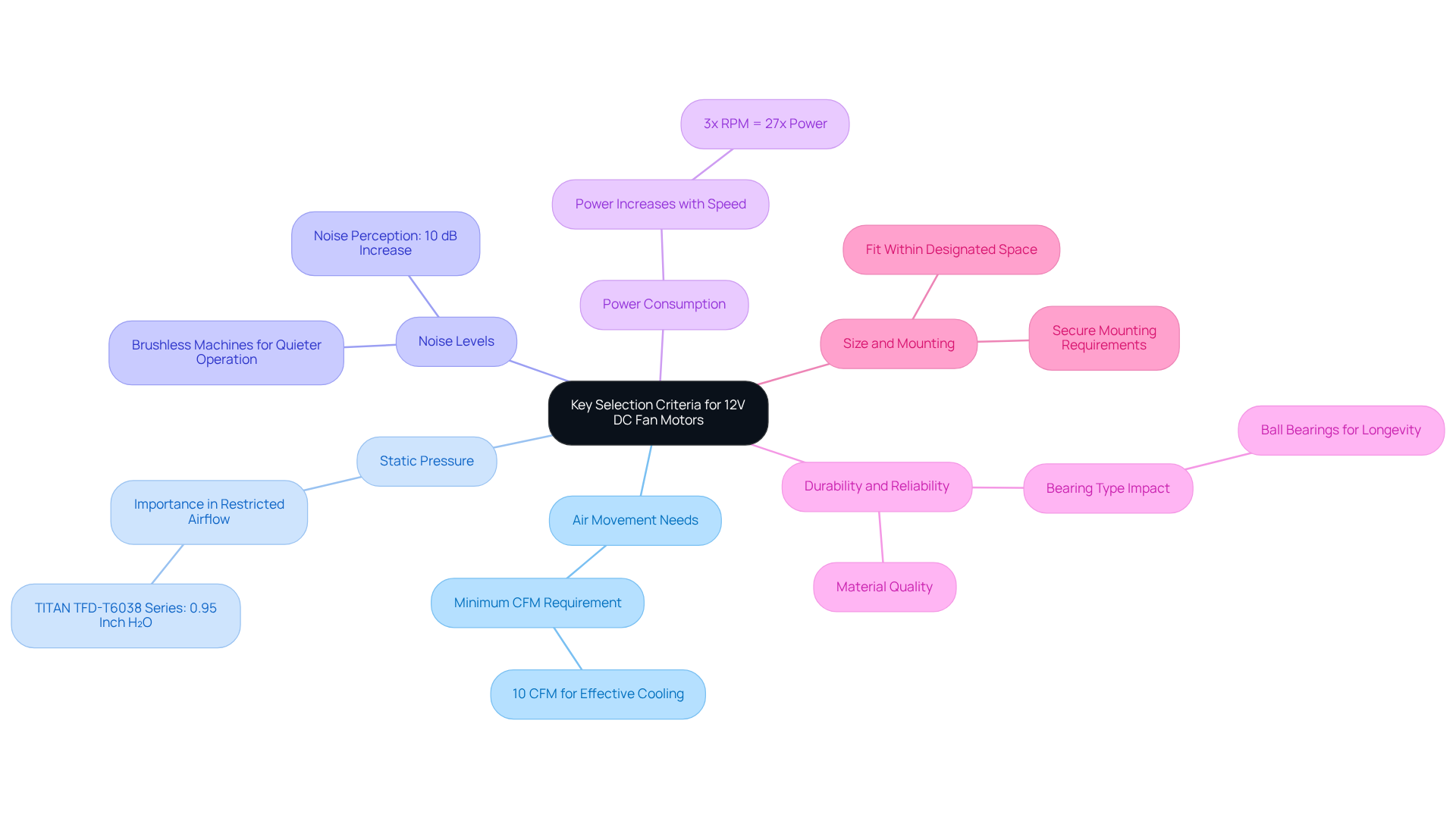

Evaluate Key Selection Criteria for 12V DC Fan Motors

When selecting a 12V DC fan motor, it’s crucial to evaluate several key criteria to ensure optimal performance:

-

Air Movement Needs: Start by accurately measuring the necessary air circulation, typically expressed in cubic feet per minute (CFM). Achieving effective cooling often requires a minimum volume of 10 CFM for sufficient heat dissipation.

-

Static Pressure: Next, assess the resistance the fan will encounter in its application. Higher static pressure ratings are essential for environments with restricted airflow, such as compact enclosures. For example, the TITAN TFD-T6038 Series can deliver up to 0.95 Inch H₂O static pressure, making it suitable for high-resistance scenarios.

-

Noise Levels: Evaluate the acceptable noise levels for your specific environment. Brushless machines are recognized for their quieter functioning, which is vital in noise-sensitive applications. Keep in mind that a 10 dB increase in noise is perceived as a doubling of the sound level.

-

Power Consumption: Ensure the device’s power rating aligns with your energy efficiency goals. The power required to operate a fan increases significantly with speed; for instance, tripling the RPM requires twenty-seven times the power.

-

Durability and Reliability: Choose devices made from premium materials to endure operational stresses and prolong lifespan. The choice of bearing type, such as ball bearings, can significantly impact durability.

-

Size and Mounting: Finally, confirm that the device fits within the designated space and can be securely mounted. Proper sizing is crucial for effective integration into your system.

By carefully assessing these criteria, engineers can select a fan unit, such as a 12V DC fan motor, that not only meets operational requirements but also aligns with functional needs, ensuring dependable cooling solutions across diverse applications.

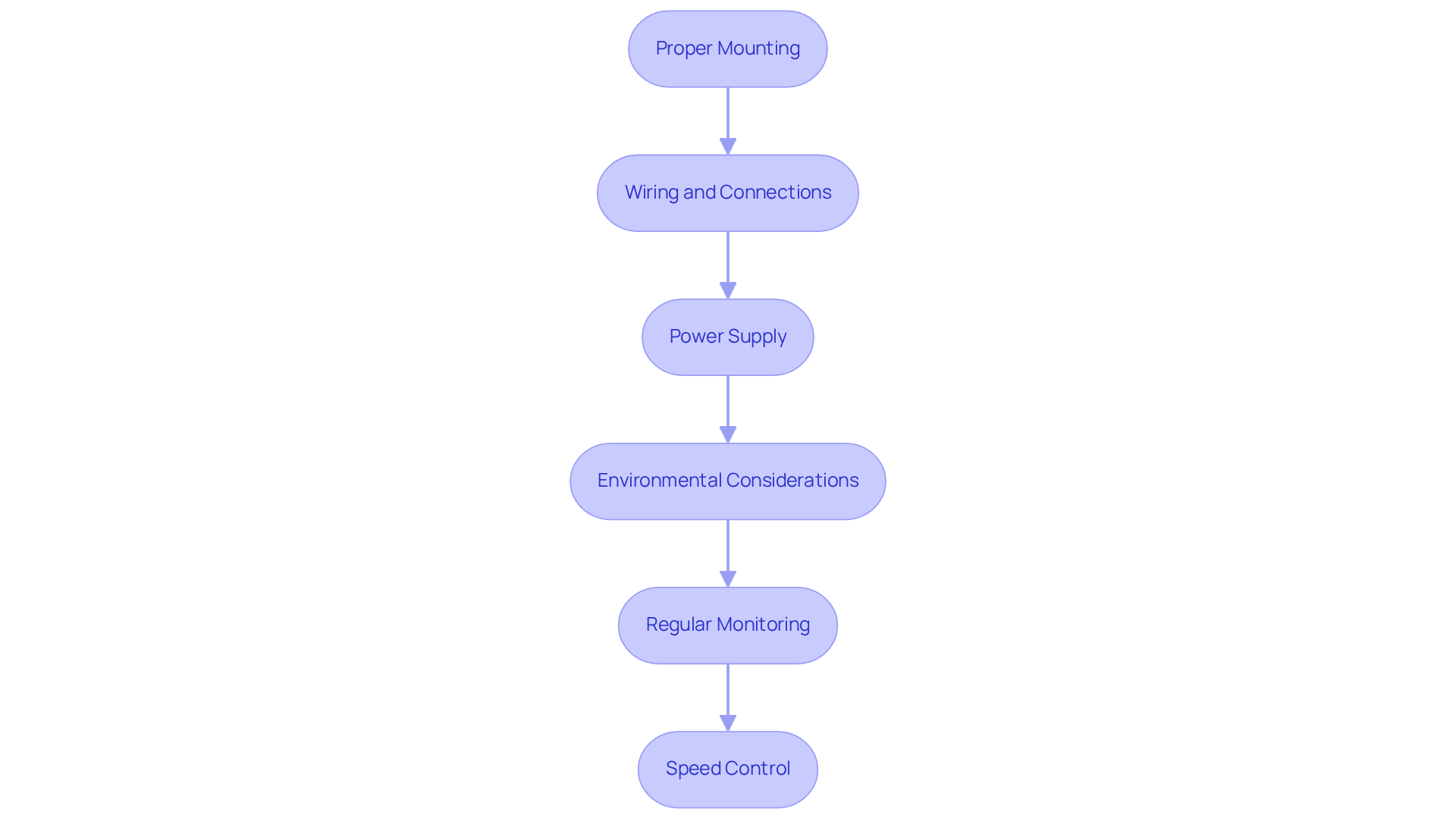

Implement Best Practices for Installation and Usage

To achieve optimal performance from your devices, it’s crucial to adhere to specific best practices during the installation and usage of the 12v dc fan motor.

- Proper Mounting: Securely mount the fan to minimize vibrations and noise. If necessary, utilize vibration-dampening materials to enhance stability.

- Wiring and Connections: Ensure that all electrical connections are secure and insulated to prevent shorts. Employ suitable gauge wires to effectively manage the device’s current.

- Power Supply: Confirm that the power supply delivers stable voltage and current in accordance with the engine’s specifications.

- Environmental Considerations: Install the fan in a clean, dry environment to avoid dust accumulation and moisture damage.

- Regular Monitoring: Periodically check the fan’s performance, including airflow and noise levels, to identify potential issues early on.

- Speed Control: If applicable, implement PWM (Pulse Width Modulation) for efficient speed control, which can enhance energy savings and reduce noise.

By following these practices, you can significantly improve the reliability and efficiency of your 12v dc fan motors.

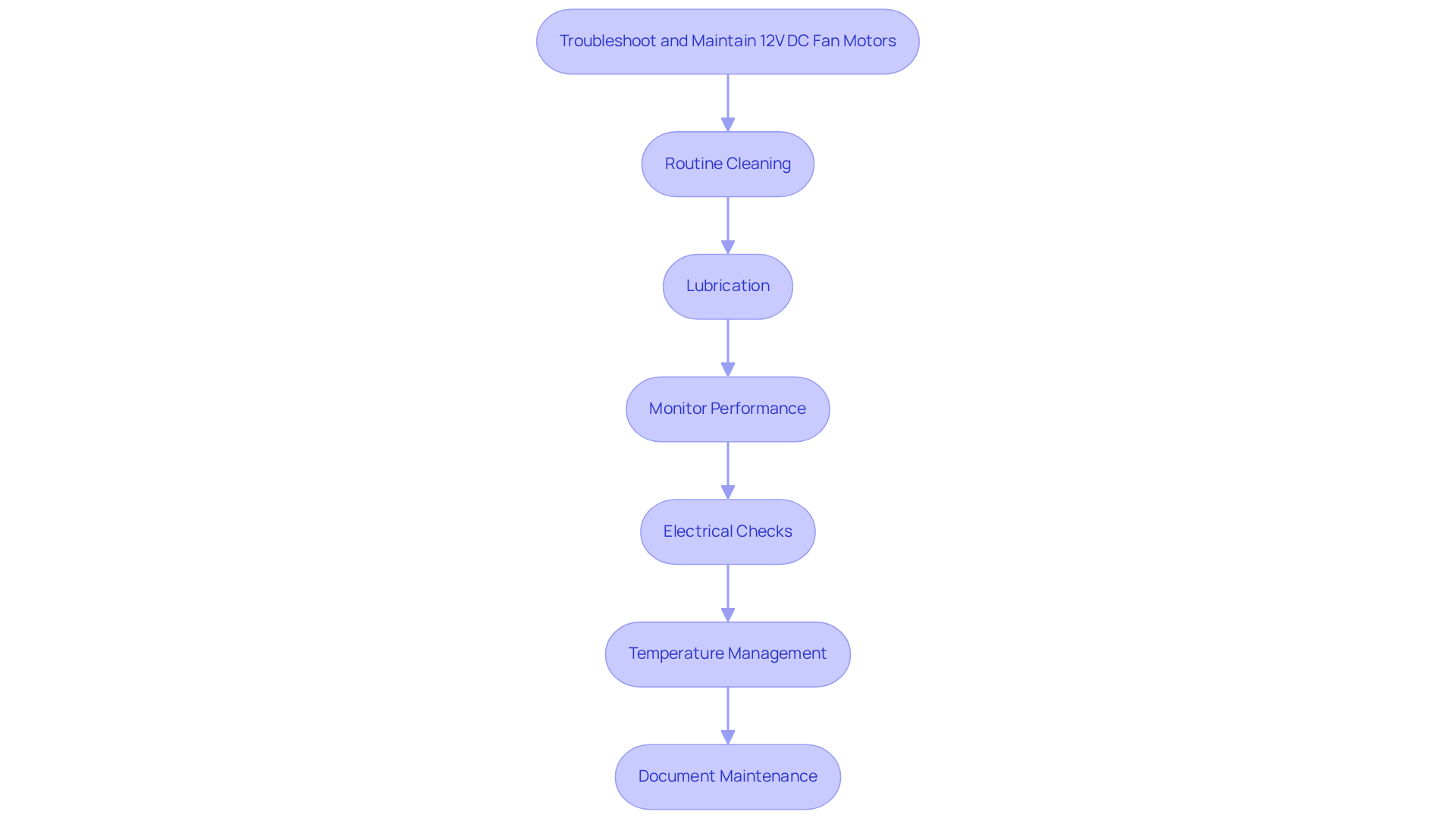

Troubleshoot and Maintain 12V DC Fan Motors Effectively

To effectively maintain and troubleshoot the 12v dc fan motor devices, it’s crucial to adopt a systematic approach. Here are key strategies to consider:

-

Routine Cleaning: Dust and debris can obstruct circulation, leading to overheating. Regularly clean the fan and engine to ensure optimal airflow.

-

Lubrication: To minimize friction and wear, apply the appropriate lubricants to bearings as recommended by the manufacturer. This simple step can significantly enhance performance.

-

Monitor Performance: Keep an eye out for abnormal noises, vibrations, or reduced airflow. These signs may indicate underlying mechanical issues that require immediate attention.

-

Electrical Checks: Regularly inspect wiring and connections for wear or corrosion. Confirm that the device is receiving the correct voltage and current to function properly.

-

Temperature Management: Excessive heat can lead to premature failure. Monitor the operating temperature and implement cooling solutions if necessary to maintain efficiency.

-

Document Maintenance: Keeping a record of maintenance activities and efficiency metrics allows you to identify trends and potential issues over time.

By following these maintenance and troubleshooting practices, you can extend the lifespan of your 12v dc fan motor and ensure consistent performance.

Conclusion

Choosing and maintaining a 12V DC fan motor is crucial for effective cooling and ventilation across various applications. Understanding the distinctions between brushed and brushless motors, evaluating key selection criteria, and implementing best practices for installation and maintenance are essential steps to achieve optimal performance and longevity.

Key considerations include:

- Assessing air movement needs

- Evaluating static pressure

- Monitoring noise levels

- Analyzing power consumption

- Ensuring durability

- Proper sizing of the motor

Regular maintenance practices, such as routine cleaning, lubrication, and performance monitoring, are vital for identifying potential issues before they escalate. Additionally, securing electrical connections and managing environmental factors can significantly enhance the reliability of these devices.

Ultimately, prioritizing informed selection and diligent maintenance of 12V DC fan motors not only improves operational efficiency but also contributes to energy savings and reduced operational costs. By adopting these best practices, engineers and technicians can ensure that their cooling solutions remain effective and dependable, fostering a more sustainable approach to system design and functionality.

Frequently Asked Questions

What is the primary function of a 12V DC fan motor?

The primary function of a 12V DC fan motor is to convert electrical energy into mechanical energy, facilitating airflow for effective cooling and ventilation.

What are the main components of a 12V DC fan motor?

A 12V DC fan motor is composed of a rotor, stator, and a commutation system.

What are the differences between brushed and brushless DC fan motors?

Brushed DC fan motors are simpler and more cost-effective but require regular maintenance due to wear on brushes and commutators, leading to a shorter lifespan of 1,000 to 8,000 hours. Brushless DC fan motors are more efficient and have a longer lifespan of 10,000 to 100,000 hours with minimal maintenance, achieving efficiencies exceeding 90%.

What are the advantages of using brushless DC fan motors?

Brushless DC fan motors offer higher efficiency, longer lifespan, and reduced energy consumption, which can lead to substantial operational cost savings, especially in applications with high annual operating costs.

What key factors should be considered when selecting a 12V DC fan motor?

Key factors to consider when selecting a 12V DC fan motor include voltage, current, power rating, and RPM, as these elements directly influence the motor’s functionality and suitability for specific cooling tasks.

Why is it important to understand the fundamentals of 12V DC fan motors?

Understanding the fundamentals is vital for engineers to choose the most effective device for their cooling needs, ensuring both reliability and efficiency in their applications.