Introduction

High-speed blowers are transforming the field of electronics engineering, presenting a range of benefits that significantly boost both performance and sustainability. These advanced devices excel at delivering substantial airflow while minimizing energy consumption, effectively reducing costs and promoting eco-friendly practices that are increasingly essential in today’s industry. As engineers strive to balance efficiency with reliability and innovation, a critical question emerges: how can high-speed blowers be effectively utilized to tackle the diverse challenges posed by modern electronic applications?

Enhance Energy Efficiency with High-Speed Blowers

Gagner-Toomey Associates’ high speed blowers are notable for their optimal energy efficiency, providing substantial airflow while significantly reducing energy consumption. By leveraging advanced motor technologies and aerodynamic designs, these fans achieve energy savings of up to 40% compared to conventional systems. This impressive efficiency not only lowers electricity costs but also reduces the carbon footprint of engineering projects, aligning perfectly with the industry’s increasing focus on sustainability.

In practical applications, such as cooling systems, Gagner-Toomey Associates’ rapid fans maintain ideal temperatures, ensuring electronic components operate safely without excessive energy use. A notable example is the enhancement at the Kill Creek Water Resource Recovery Facility, where switching to rapid aerators has led to annual savings of $35,000. This underscores their role in boosting operational efficiency and promoting eco-friendly practices.

Moreover, Gagner-Toomey Associates offers a diverse product line, including:

- DC input Tube Axial fans ranging from 15 to 280mm

- Centrifugal Blowers from 15 to 225mm

These products are essential for tackling complex temperature regulation challenges in the electronics sector. Investing in high speed blowers proves financially sound, with a payback period expected to be under five years, reflecting the increasing demand for these devices amid the complexities of modern electronic equipment.

The EC fan market is projected to grow at a CAGR of 7.8% from 2024 to 2032, indicating a clear shift towards energy-efficient ventilation solutions. Gagner-Toomey Associates is recognized for its comprehensive range of thermal management solutions, including extruded aluminum heatsinks, copper-based heat sinks, and integrated cooling solutions, further demonstrating their commitment to innovative cooling technologies.

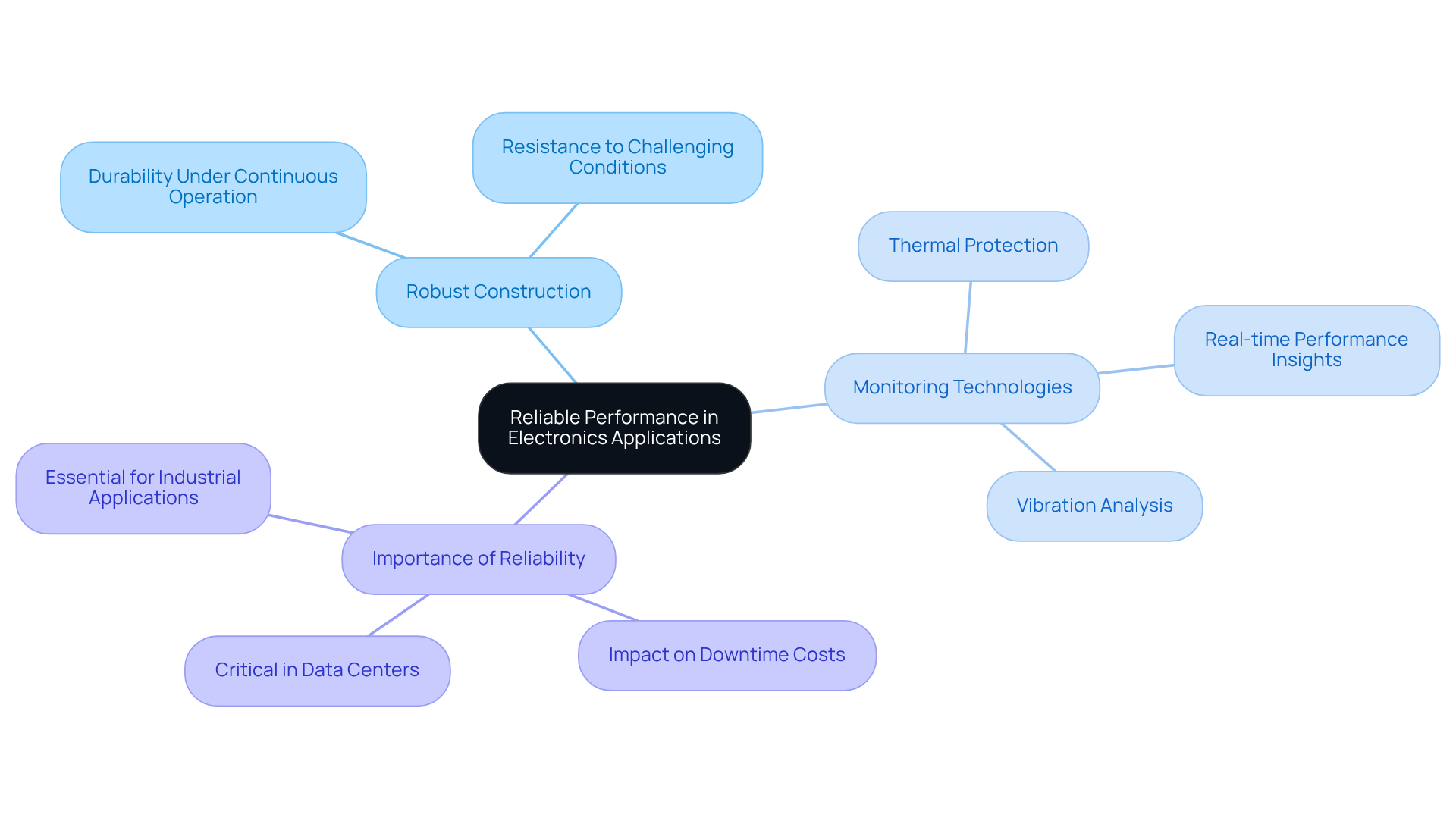

Achieve Reliable Performance in Electronics Applications

High-speed fans are engineered for exceptional reliability, boasting robust constructions that withstand the rigors of continuous operation. These systems often come equipped with cutting-edge monitoring technologies that deliver real-time performance insights, enabling proactive maintenance and significantly reducing the risk of unexpected failures. For instance, many rapid air movers integrate thermal protection and vibration analysis features, which are vital for maintaining consistent performance under challenging conditions.

This level of reliability is especially crucial in electronics applications, such as data centers and industrial settings, where even a moment of downtime can result in considerable financial repercussions. As the market evolves, the integration of advanced monitoring technologies is becoming increasingly essential to ensure that high speed blowers meet the stringent demands of modern industrial applications.

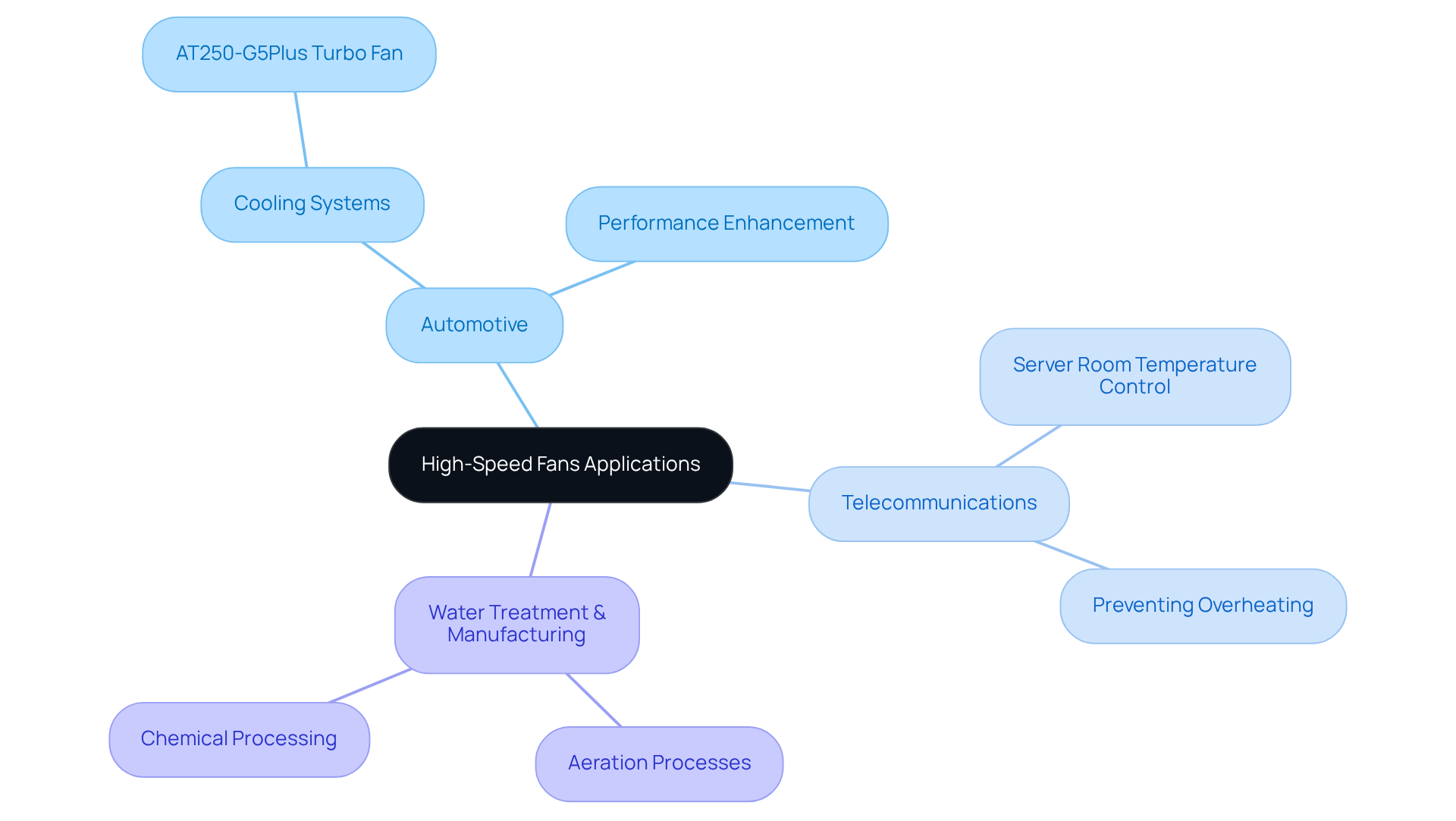

Utilize Versatile Solutions for Diverse Engineering Needs

High-speed fans are indispensable tools in a variety of applications, from cooling electronic components to ensuring proper ventilation in confined spaces. Their ability to deliver high airflow rates with adjustable speeds makes them suitable for both high-pressure and low-pressure environments.

In the automotive sector, high-speed fans are vital for cooling systems, effectively managing heat to enhance performance and reliability. Take the AT250-G5Plus turbo fan, for example; it supports differential pressures up to 900 mbar and delivers approximately 155 m³/min of airflow, showcasing the advanced capabilities of modern technology.

Similarly, in telecommunications, these fans are crucial for maintaining optimal temperatures in server rooms, preventing overheating and ensuring uninterrupted service. According to Grand View Research, high speed blowers, especially centrifugal and oil-free types, are being widely incorporated into processes such as water treatment and manufacturing. This versatility allows engineers to select the most appropriate fan for nearly any project requirement, whether related to automotive cooling or telecommunications infrastructure.

Moreover, the rapid fans market is projected to grow at a CAGR of 5.4% from 2025 to 2030, underscoring the increasing demand for these essential instruments across diverse engineering applications.

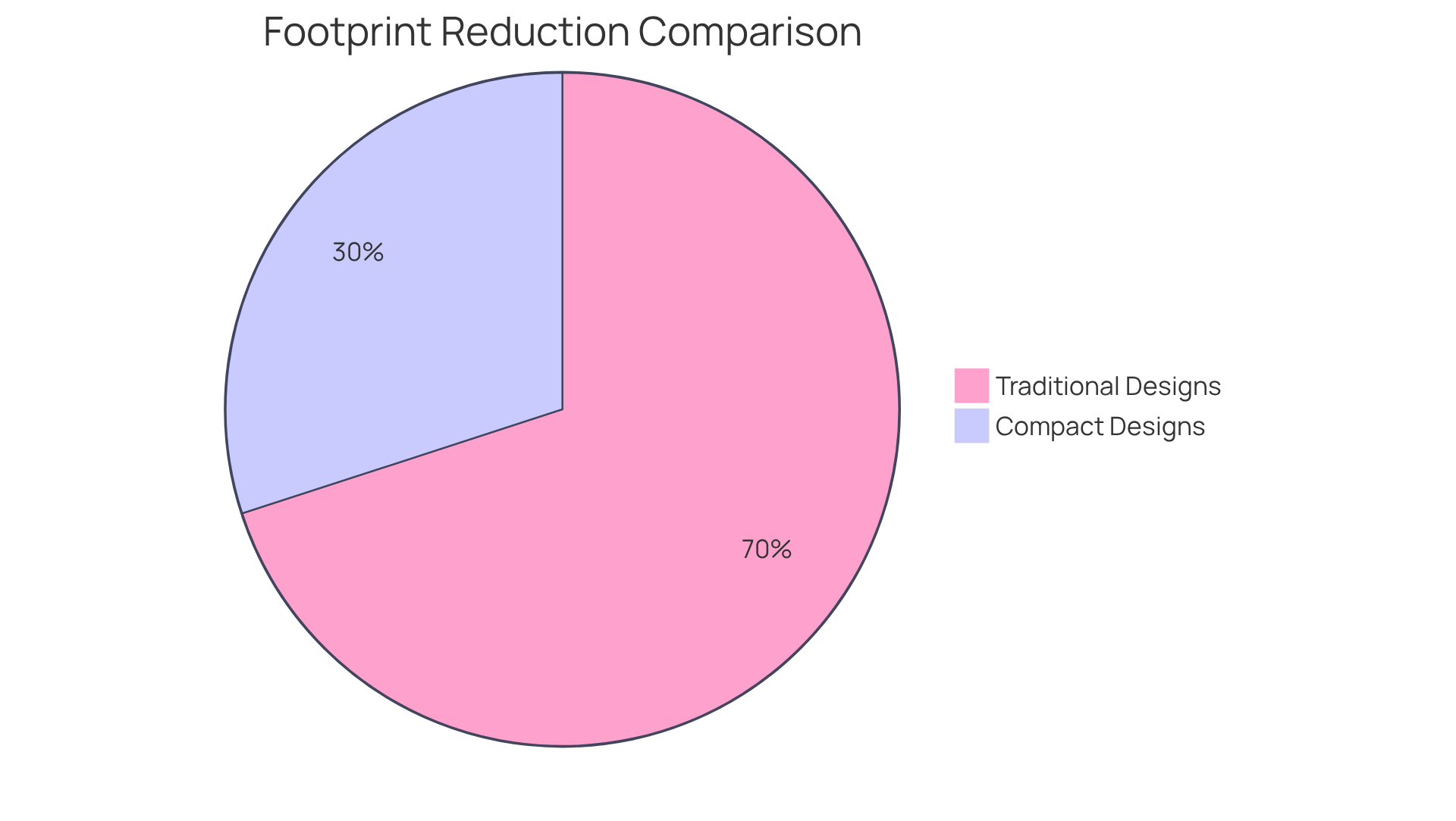

Maximize Space Efficiency with Compact Designs

High-speed fans prioritize compactness, allowing them to occupy minimal space without sacrificing performance. Their streamlined designs significantly reduce the overall footprint, making them ideal for applications where space is at a premium, such as portable electronics and densely packed server racks. For example, many modern high-speed fans leverage advanced materials and innovative engineering techniques to achieve a lightweight yet durable construction. This facilitates seamless integration into various designs, ultimately enhancing overall efficiency.

Statistics reveal that adopting space-efficient air-moving technologies can reduce equipment footprint by up to 30%. This reduction is crucial for engineers focused on optimizing their systems. User feedback consistently underscores the effectiveness of these compact devices in maintaining airflow and cooling performance, even in constrained environments.

As engineers increasingly prioritize space efficiency, the evolution of high-speed blowers continues to address these demands. Design innovations cater specifically to small areas, showcasing how these technologies can transform the landscape of compact engineering solutions.

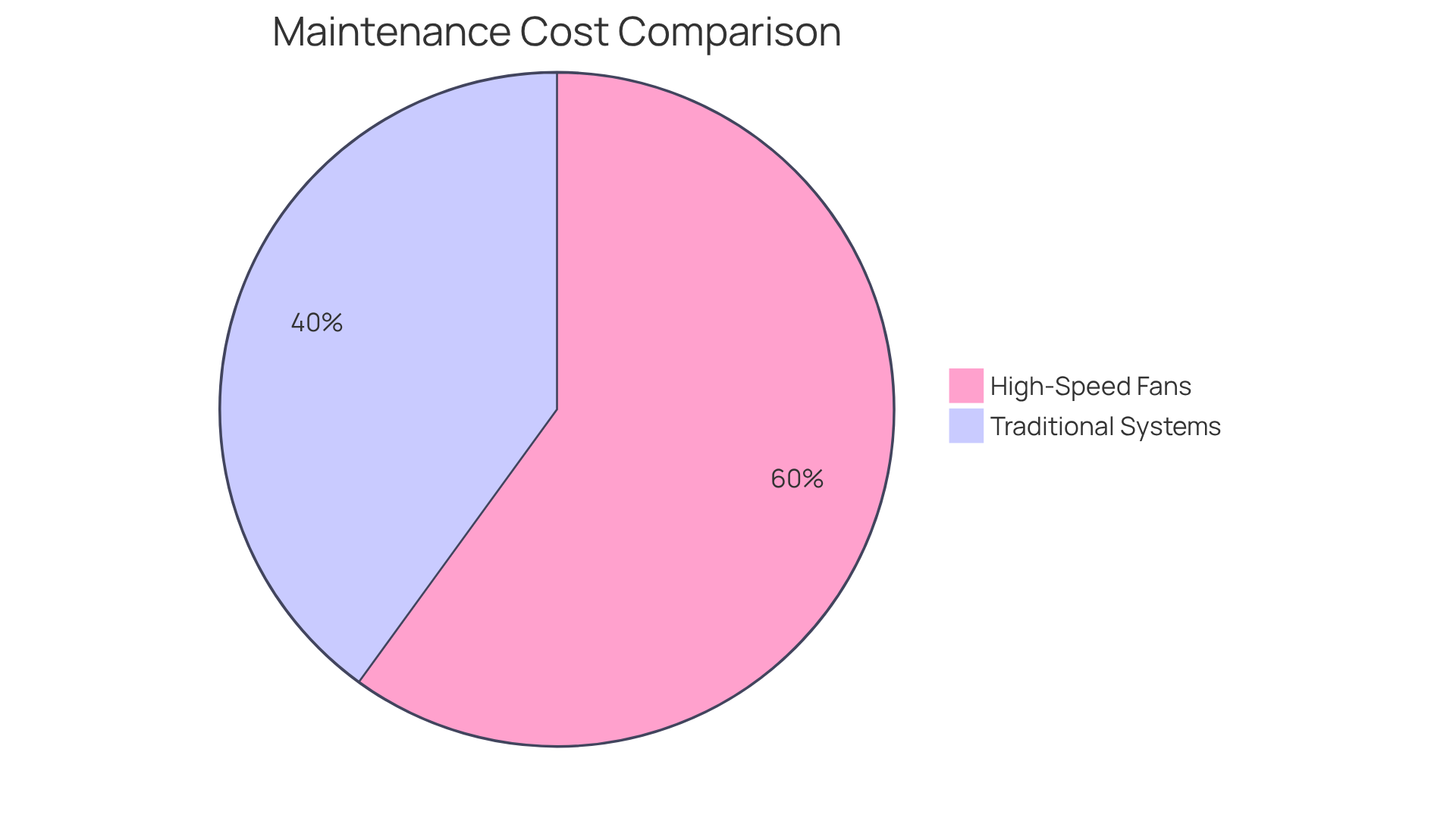

Reduce Maintenance Needs for Lower Operational Costs

High-speed fans present a compelling solution to the maintenance challenges posed by conventional systems. By incorporating advanced technologies like brushless motors and oil-free bearings, these fans significantly reduce wear and tear. This innovation eliminates the need for routine lubrication, thereby extending the lifespan of the fan and enhancing reliability.

Facilities that utilize high speed blowers, especially turbo models, report remarkable decreases in downtime and maintenance costs. In fact, companies can expect maintenance expenses to be 50-70% lower compared to traditional equipment. This reduction not only leads to improved operational efficiency but also facilitates a quicker return on investment, typically within 2-3 years, thanks to substantial energy and upkeep savings.

Moreover, the streamlined maintenance process of Inovair devices, which require only four simple components for servicing, further drives down operational costs and boosts productivity. This simplicity in maintenance underscores the advantages of high speed blowers, making them an appealing option for various applications.

In summary, the implementation of high speed blowers not only enhances reliability but also fosters long-term cost savings, making high speed blowers a strategic investment for facilities aiming to optimize their operations.

Lower Noise Levels for Improved Work Environments

High-speed fans are engineered for quiet operation, making them essential in environments where noise reduction is paramount. These fans often feature advanced motor technologies, such as electronically commutated (EC) motors, which operate at significantly lower decibel levels while maintaining efficiency. This capability is particularly beneficial in settings like laboratories and offices, where excessive noise can disrupt workflow and concentration.

Research underscores the detrimental effects of noise pollution on productivity, linking it to increased stress and diminished job satisfaction. Engineers emphasize that sustaining low noise levels is crucial for creating a conducive work environment, as it enhances focus and collaboration among team members.

The advantages of quiet operation extend beyond mere comfort; they also ensure compliance with regulatory standards for workplace noise levels. This compliance fosters a healthier and more productive atmosphere, ultimately benefiting both employees and organizations. By investing in high speed blowers, businesses can significantly improve their work environments, which leads to enhanced productivity and employee satisfaction.

Contribute to Sustainability with Eco-Friendly Solutions

High-speed fans are engineered with sustainability at their core, integrating energy-efficient methods that significantly reduce power usage and emissions. These fans leverage advanced materials and innovative designs to deliver exceptional performance while minimizing their environmental impact. Importantly, many models are compatible with renewable energy sources, further enhancing their eco-friendliness.

As industries increasingly strive to meet environmental standards and consumer expectations for greener products, this focus on sustainable engineering solutions becomes vital. For instance, the incorporation of magnetic bearing systems is projected to capture a 39.0% market share by 2025. This technology not only boosts operational efficiency but also extends equipment lifespan, thereby minimizing waste and reducing maintenance requirements.

With the rising demand for sustainable practices, high speed blowers are positioned as essential components in the transition towards more environmentally responsible engineering solutions. Their role in promoting sustainability cannot be overstated, making them a critical choice for industries committed to reducing their ecological footprint.

Leverage Advanced Technology for Superior Performance

High-speed fans utilize cutting-edge technologies, including variable frequency drives (VFDs) and smart control systems, to enhance performance. These innovations enable precise control over airflow and pressure, adapting seamlessly to the specific demands of various applications in real-time.

Consider the advantages of VFDs: they allow fans to operate at different speeds, significantly reducing energy consumption during periods of low demand while ensuring optimal performance when needed. This adaptability not only boosts efficiency but also prolongs the lifespan of the equipment, making it a smart investment for any operation.

Incorporating these advanced features into your systems can lead to substantial operational savings and improved reliability. By embracing high speed blowers that are equipped with VFDs and smart controls, you position your operations at the forefront of efficiency and sustainability.

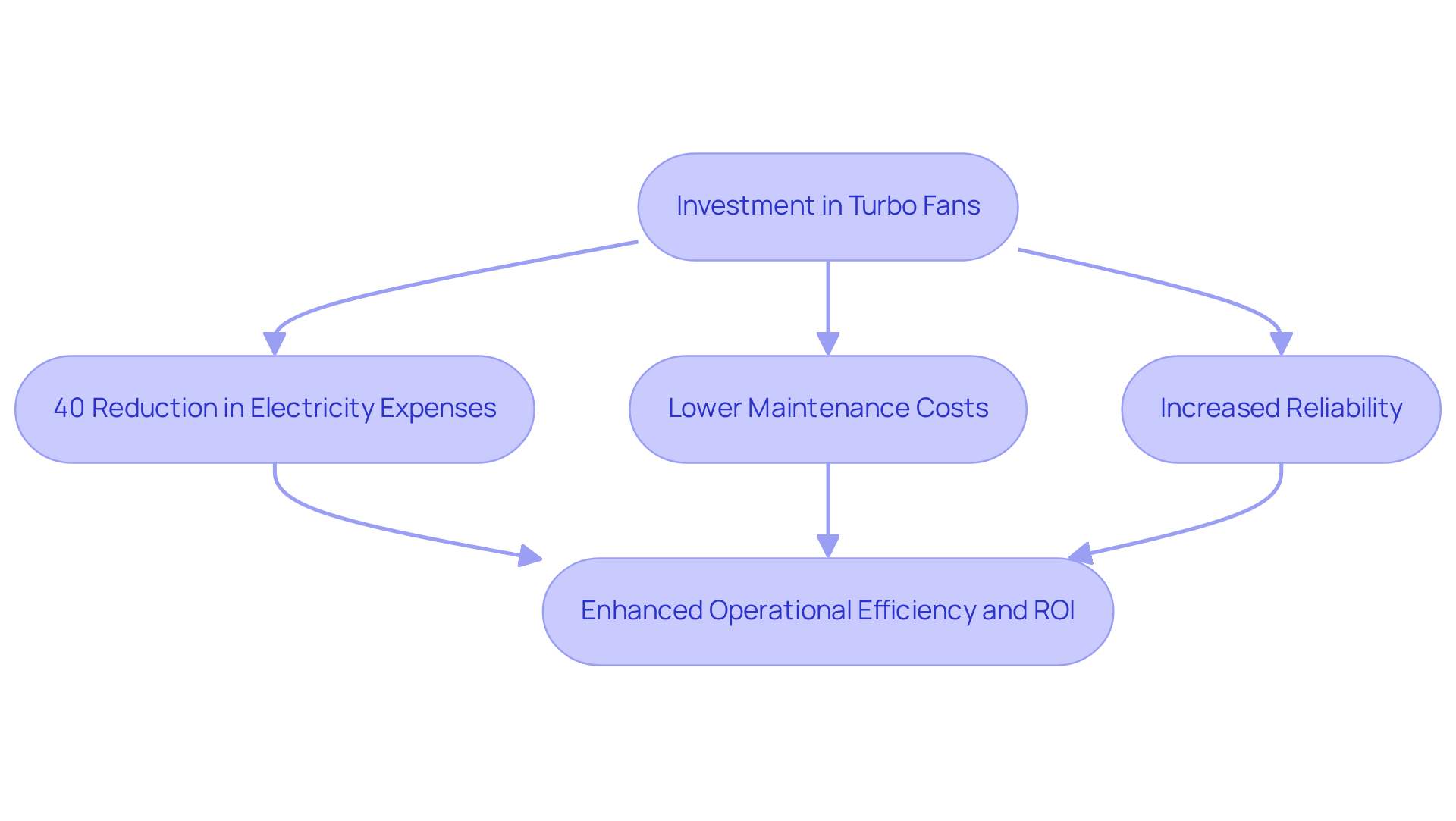

Achieve Cost-Effectiveness in Engineering Solutions

Investing in fast turbo fans presents a compelling opportunity for significant cost reductions over time. These fans, designed with energy efficiency in mind, can lower electricity expenses by as much as 40%. This impressive figure stems from the fact that rapid turbo devices are 40% more effective than their traditional counterparts. Furthermore, their lower maintenance requirements contribute to decreased operational costs, enhancing overall savings.

The reliability of rapid fans minimizes downtime, enabling continuous operations and boosting productivity. Facilities that have adopted these advanced air movers often report realizing a return on investment within just a few years. This is particularly noteworthy given the market’s anticipated growth, projected to expand from USD 825.6 million in 2025 to over USD 1.22 billion by 2035.

In light of these factors, rapid fans emerge not only as a performance-driven choice but also as a cost-effective alternative for engineering projects. Their combination of efficiency, reliability, and economic benefits makes them an intelligent investment for any facility aiming to optimize operations.

Explore Innovative Solutions with Gagner-Toomey Associates

Gagner-Toomey Associates stands at the forefront of innovations in high speed blowers, dedicated to equipping engineers with the latest advancements in the field. By representing a diverse range of manufacturers and leveraging a robust network of local distributors, the company guarantees that engineers have access to products tailored to address their unique challenges.

From optimizing cooling systems to enhancing airflow in electronic applications, Gagner-Toomey Associates delivers customized solutions that drive innovation and operational efficiency. Their extensive expertise in the electronics sector, combined with strong relationships across various industries, positions them as an indispensable partner for engineers seeking to integrate cutting-edge technologies into their projects.

As the market for high speed blowers is projected to grow significantly, reaching USD 1.6 billion by 2035 at a CAGR of 5.6%, Gagner-Toomey is leading this evolution. They support engineers in navigating the complexities of modern design and implementation. Notably, water and wastewater treatment applications are expected to capture a 31.5% share of the market, while airfoil bearing systems are projected to command 61.0% of the market by 2025. This underscores the relevance of Gagner-Toomey’s offerings in meeting industry needs.

Conclusion

High-speed blowers stand as a significant advancement in electronics engineering, delivering numerous benefits that enhance performance and efficiency. These devices not only boost energy efficiency by lowering power consumption but also play a crucial role in sustainability efforts, making them an essential choice for contemporary engineering projects. The incorporation of cutting-edge technologies further enhances their reliability and versatility, enabling engineers to customize solutions for specific application needs.

Key advantages of high-speed blowers include:

- Their capacity for substantial energy savings

- Reduced maintenance demands

- Quiet operation across diverse environments

Their compact designs ensure seamless integration into space-constrained applications, while robust performance capabilities render them indispensable across various sectors, from telecommunications to automotive cooling systems. Moreover, the anticipated growth of the market highlights the increasing dependence on these efficient solutions in engineering.

Embracing high-speed blowers transcends mere functionality; it represents a strategic decision that aligns with broader sustainability and operational efficiency goals. By investing in these advanced technologies, engineers can significantly cut costs, enhance system reliability, and contribute to a greener future. The ongoing evolution of high-speed blowers, particularly through collaborations with innovative firms like Gagner-Toomey Associates, equips engineers to adeptly navigate the complexities of modern design and implementation.

Frequently Asked Questions

What are the key benefits of Gagner-Toomey Associates’ high-speed blowers?

Gagner-Toomey Associates’ high-speed blowers provide optimal energy efficiency, substantial airflow, and energy savings of up to 40% compared to conventional systems. This results in lower electricity costs and a reduced carbon footprint, aligning with sustainability goals.

How do high-speed blowers enhance operational efficiency in practical applications?

In applications like cooling systems, high-speed blowers maintain ideal temperatures for electronic components, ensuring safe operation without excessive energy use. For example, at the Kill Creek Water Resource Recovery Facility, switching to rapid aerators led to annual savings of $35,000.

What types of products does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a diverse product line, including DC input Tube Axial fans ranging from 15 to 280mm and Centrifugal Blowers from 15 to 225mm, which are essential for temperature regulation challenges in the electronics sector.

What is the expected payback period for investing in high-speed blowers?

The expected payback period for investing in high-speed blowers is under five years, reflecting their financial viability amid the increasing demand for these devices due to the complexities of modern electronic equipment.

What is the projected growth rate of the EC fan market?

The EC fan market is projected to grow at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2032, indicating a shift towards energy-efficient ventilation solutions.

How do high-speed fans ensure reliable performance in electronics applications?

High-speed fans are designed for exceptional reliability, featuring robust constructions and advanced monitoring technologies that provide real-time performance insights, enabling proactive maintenance and reducing the risk of unexpected failures.

Why is reliability important in electronics applications?

Reliability is crucial in electronics applications, such as data centers and industrial settings, because even a moment of downtime can lead to significant financial losses.

In what applications are high-speed fans used?

High-speed fans are used in various applications, including cooling electronic components, ensuring proper ventilation in confined spaces, automotive cooling systems, and maintaining optimal temperatures in telecommunications server rooms.

What is the projected growth rate of the rapid fans market?

The rapid fans market is projected to grow at a CAGR of 5.4% from 2025 to 2030, highlighting the increasing demand for these essential tools across diverse engineering applications.