Introduction

Low energy fans are transforming the realm of electronic design, presenting a compelling solution to the increasing demand for energy efficiency. By leveraging advanced technologies, these fans not only minimize power consumption but also lead to substantial cost savings and a reduced carbon footprint. Yet, as engineers confront the intricacies of selecting and implementing these sophisticated cooling systems, they encounter pivotal questions:

- What factors must be prioritized to guarantee optimal performance?

- How can installation techniques enhance efficiency and reliability?

This article explores best practices for employing low energy fans, equipping designers with the essential insights to elevate their electronic applications while fostering sustainability.

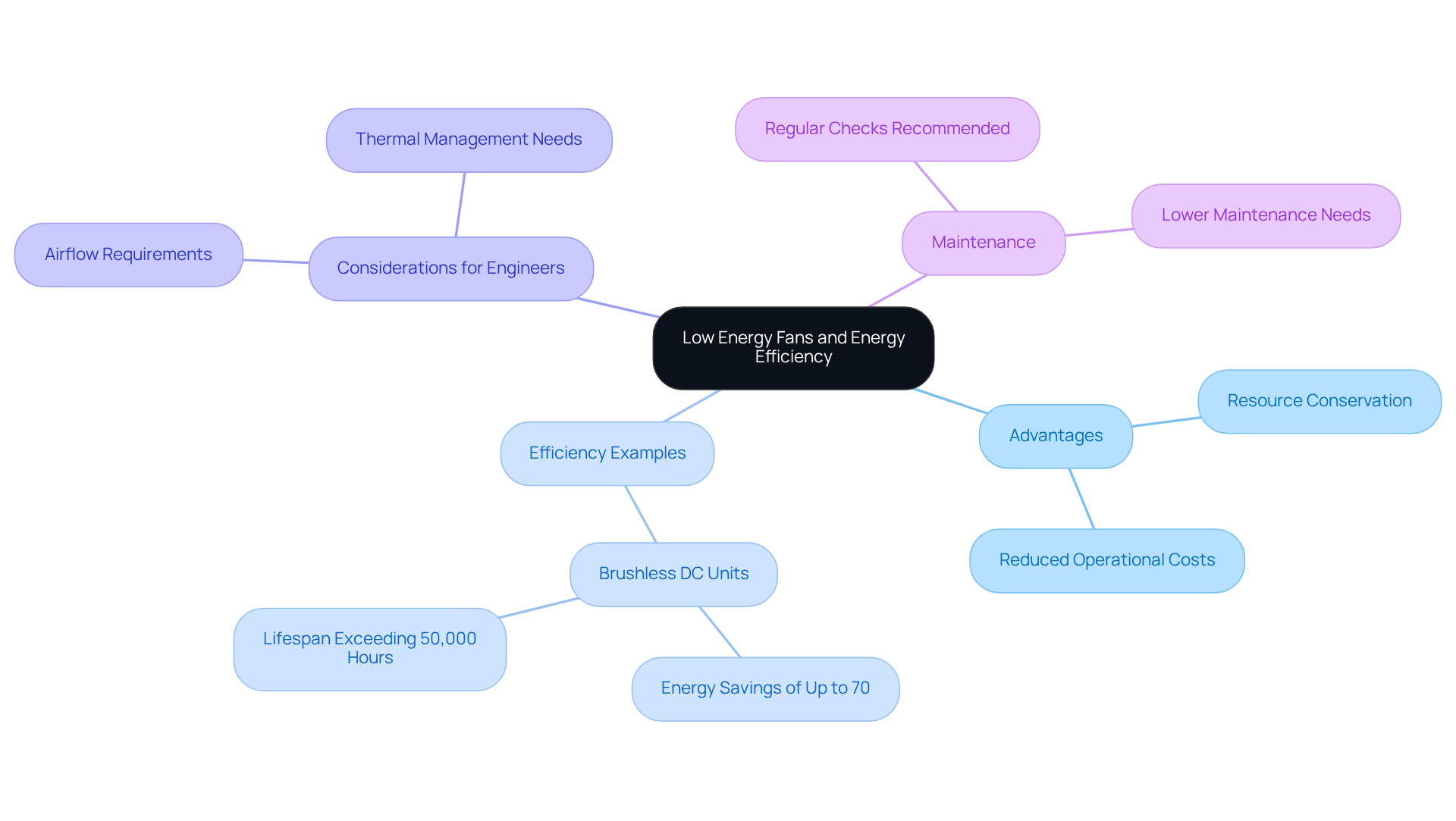

Understand the Role of Low Energy Fans in Energy Efficiency

Low power devices are essential for enhancing resource conservation in electronic designs. These devices leverage advanced motor technologies and optimized blade designs to significantly cut power consumption while ensuring effective cooling performance. For instance, brushless DC units stand out for their superior efficiency, consuming up to 70% less power compared to traditional AC models. This substantial reduction in energy usage not only decreases operational costs but also minimizes the carbon footprint, making them a prime choice for environmentally conscious designs.

As noted by Gagner-Toomey Associates, their brushless DC devices utilize 50-65% less energy than standard ceiling units, underscoring their efficiency and solidifying their reputation as a leader in innovative cooling solutions. Furthermore, these devices often boast a lifespan exceeding 50,000 hours, showcasing their long-term reliability and cost-effectiveness.

Engineers must consider the specific airflow requirements and thermal management needs of their applications when selecting the most suitable low energy fans. This ensures optimal functionality without unnecessary resource expenditure. Regular maintenance checks are also advisable to guarantee proper operation and maximize the advantages of these advanced cooling solutions provided by Gagner-Toomey Associates.

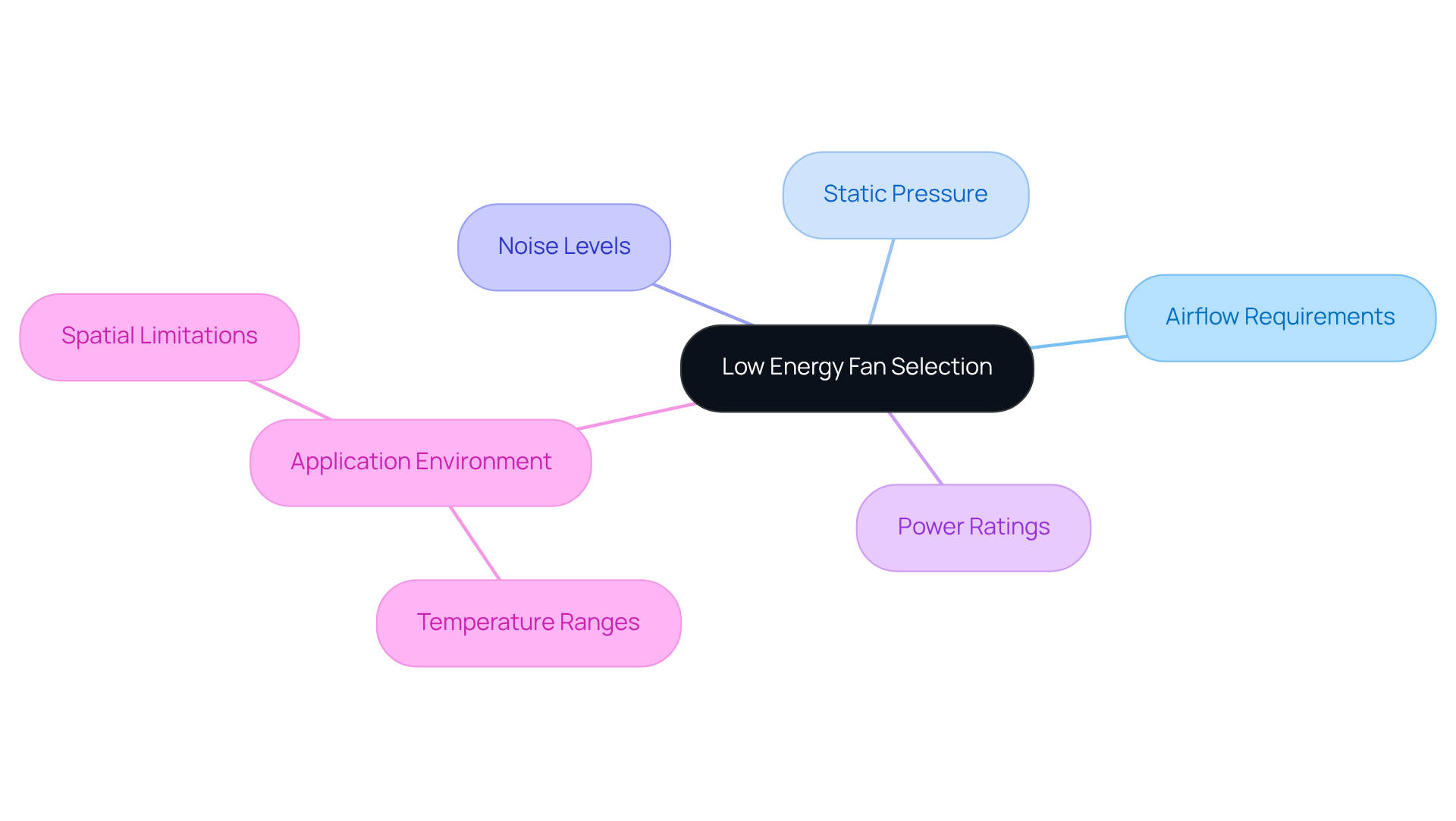

Select Appropriate Low Energy Fans for Your Design Needs

When selecting low energy fans for electronic designs, engineers face critical considerations including airflow requirements, static pressure, noise levels, and power ratings. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive range of DC input Tube Axial units and Centrifugal Blowers, all optimized for performance and efficiency.

For example, fans with a high Enthusiasm Index (FEI) are particularly desirable, as they indicate enhanced vitality results. Furthermore, engineers must assess the specific application environment – such as temperature ranges and spatial limitations – to ensure compatibility with their designs.

Utilizing fan selection software can significantly aid in comparing various models and their specifications, leading to more informed decisions. Practical applications, such as the deployment of Gagner-Toomey’s EC (Electronically Commutated) units in data centers, exemplify how thoughtful selection can yield substantial power savings and improved cooling performance.

In conclusion, by carefully considering these factors and leveraging available tools, engineers can optimize their ventilator choices, ensuring both efficiency and effectiveness in their electronic designs.

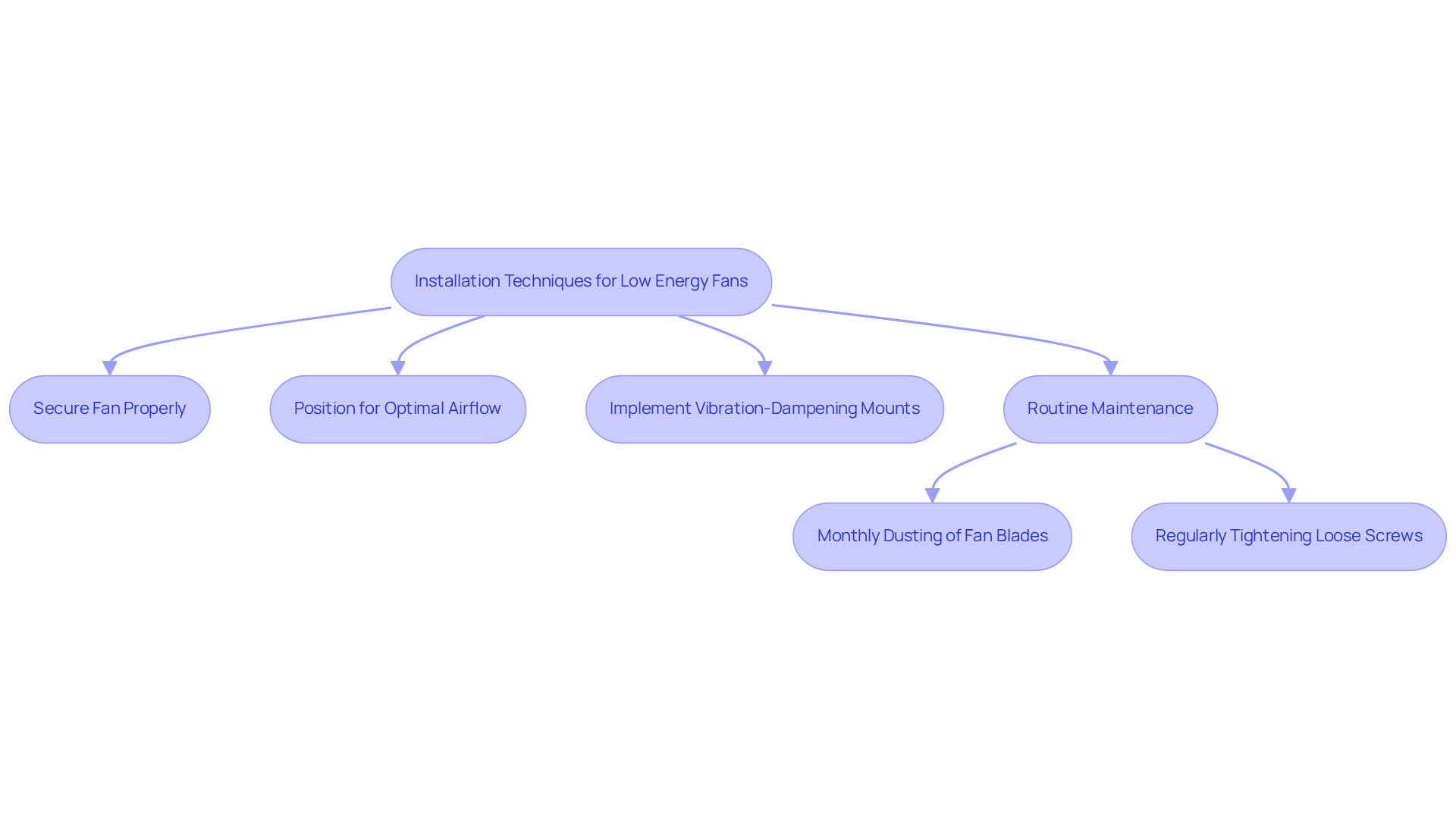

Implement Effective Installation Techniques for Low Energy Fans

To achieve optimal results from low energy fans, efficient installation methods are crucial. Properly securing the fan minimizes vibrations, which can lead to noise and decreased efficiency. Engineers must prioritize the orientation and positioning of the fan to maximize airflow and cooling effectiveness. For example, blowers should be positioned to allow unobstructed airflow, avoiding placement near walls or barriers that could hinder performance.

Statistics show that for rooms between 200 and 300 square feet, a recommended CFM range of 3,000 to 4,000 is ideal. Additionally, a blower capable of delivering at least 64 CFM is necessary for a control cabinet generating 400 Watts of heat. Implementing vibration-dampening mounts can further reduce noise levels and extend the fan’s operational lifespan.

Routine maintenance inspections are essential to keep ventilators clean and free from dust accumulation, which can obstruct airflow and overall functionality. This includes:

- Monthly dusting of fan blades

- Regularly tightening loose screws

By mastering these installation techniques, engineers can ensure that low energy fans operate at peak efficiency, significantly contributing to effective thermal management in electronic designs.

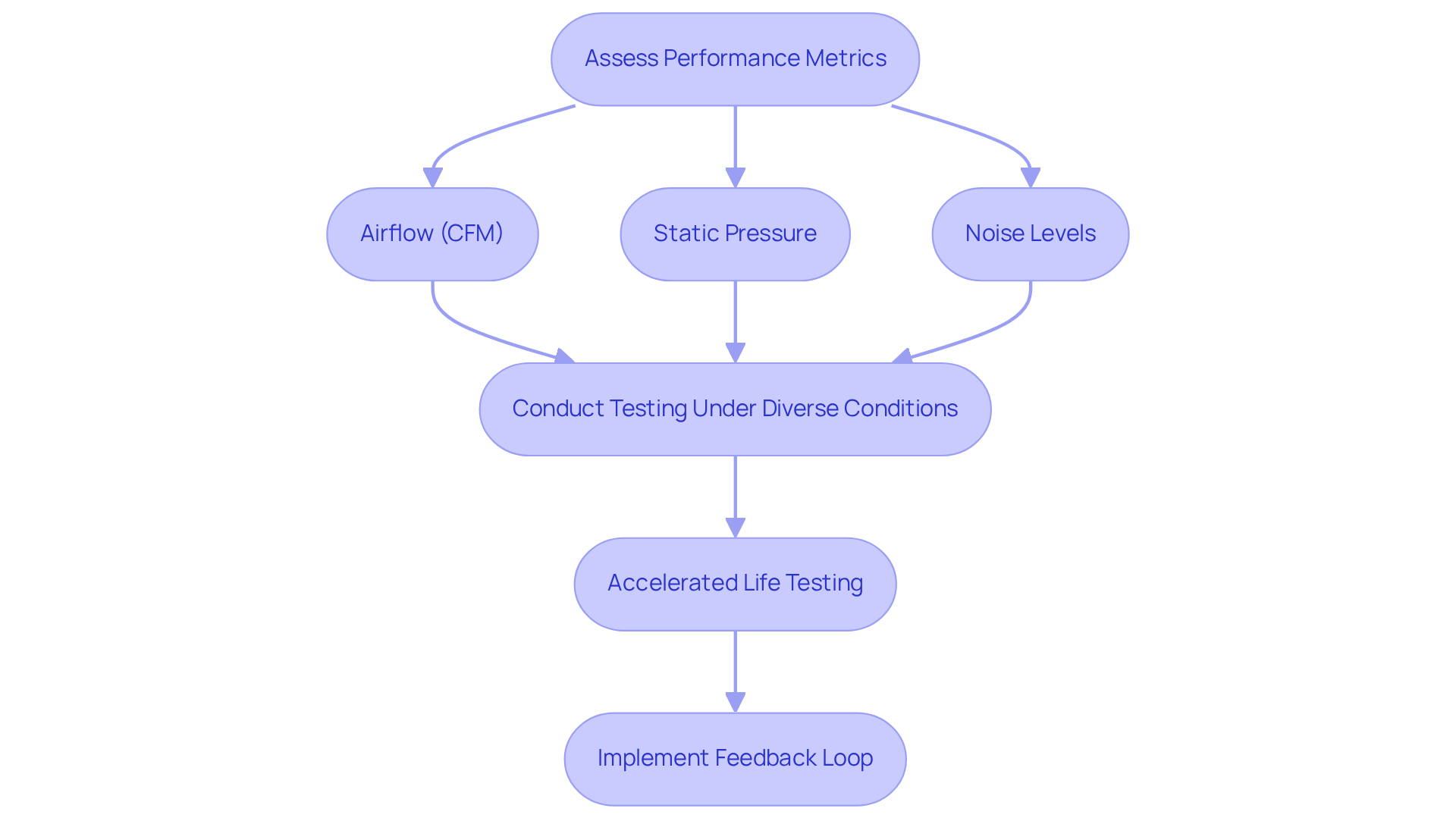

Evaluate Performance and Reliability of Integrated Fans

Assessing the efficiency and reliability of integrated low energy ventilators is crucial for ensuring optimal performance in various applications. Key metrics such as airflow (CFM), static pressure, and noise levels must be thoroughly evaluated. Engineers should employ advanced testing instruments to measure these parameters under diverse operating conditions, confirming that the devices can effectively manage the thermal loads anticipated in real-world scenarios.

Reliability testing, particularly accelerated life testing, plays a vital role in understanding the longevity and durability of ventilators. For instance, the capability to maintain static pressure is essential; devices designed for high resistance can sustain airflow even in challenging conditions, with some achieving static pressure ratings close to 1.0 inH2O.

Implementing a feedback loop to gather and analyze performance data is imperative for facilitating iterative improvements in fan selection and integration in future designs. Case studies from industries that have embraced rigorous testing protocols highlight the importance of these evaluations. They demonstrate that comprehensive testing not only boosts the cooling efficiency of low energy fans but also prolongs their lifespan, ultimately contributing to more reliable electronic designs.

Conclusion

Low energy fans are pivotal in boosting energy efficiency within electronic designs, delivering both cost savings and environmental advantages. By utilizing advanced technologies, these fans drastically cut power consumption while providing effective cooling performance. This makes them an indispensable component for engineers dedicated to sustainable design practices.

Understanding the selection, installation, and evaluation of low energy fans is crucial. Engineers must grasp airflow requirements, apply proper installation techniques, and rigorously test performance metrics. By selecting the right fans and ensuring effective installation, they can optimize designs for efficiency and reliability, ultimately enhancing thermal management and extending device lifespan.

Adopting these best practices not only drives the success of individual projects but also aligns with the broader objectives of energy conservation and sustainability in the electronics sector. As the demand for energy-efficient solutions escalates, integrating low energy fans represents a critical step toward achieving more environmentally responsible electronic designs.

Frequently Asked Questions

What is the role of low energy fans in energy efficiency?

Low energy fans are essential for enhancing resource conservation in electronic designs by utilizing advanced motor technologies and optimized blade designs to significantly reduce power consumption while ensuring effective cooling performance.

How much power do brushless DC fans consume compared to traditional AC models?

Brushless DC fans consume up to 70% less power compared to traditional AC models, making them highly efficient.

What are the environmental benefits of using low energy fans?

The substantial reduction in energy usage from low energy fans decreases operational costs and minimizes the carbon footprint, making them a prime choice for environmentally conscious designs.

How much energy do brushless DC devices save compared to standard ceiling units?

Brushless DC devices utilize 50-65% less energy than standard ceiling units, highlighting their efficiency.

What is the lifespan of low energy fans like those from Gagner-Toomey Associates?

These low energy fans often boast a lifespan exceeding 50,000 hours, showcasing their long-term reliability and cost-effectiveness.

What should engineers consider when selecting low energy fans?

Engineers must consider the specific airflow requirements and thermal management needs of their applications to ensure optimal functionality without unnecessary resource expenditure.

Is regular maintenance important for low energy fans?

Yes, regular maintenance checks are advisable to guarantee proper operation and maximize the advantages of these advanced cooling solutions.