Introduction

The evolution of fan technology presents a critical comparison between magnetic levitation fans and traditional models, each with unique advantages and drawbacks. Engineers are exploring the mechanics of these devices, revealing a landscape where efficiency, noise levels, and maintenance requirements are pivotal in decision-making.

On one side, magnetic levitation fans promise longer lifespans and reduced energy consumption; on the other, traditional fans offer cost-effectiveness and simplicity.

Which fan type truly reigns supreme in modern applications? This article delves into the intricacies of both technologies, providing insights that could shape the future of cooling solutions.

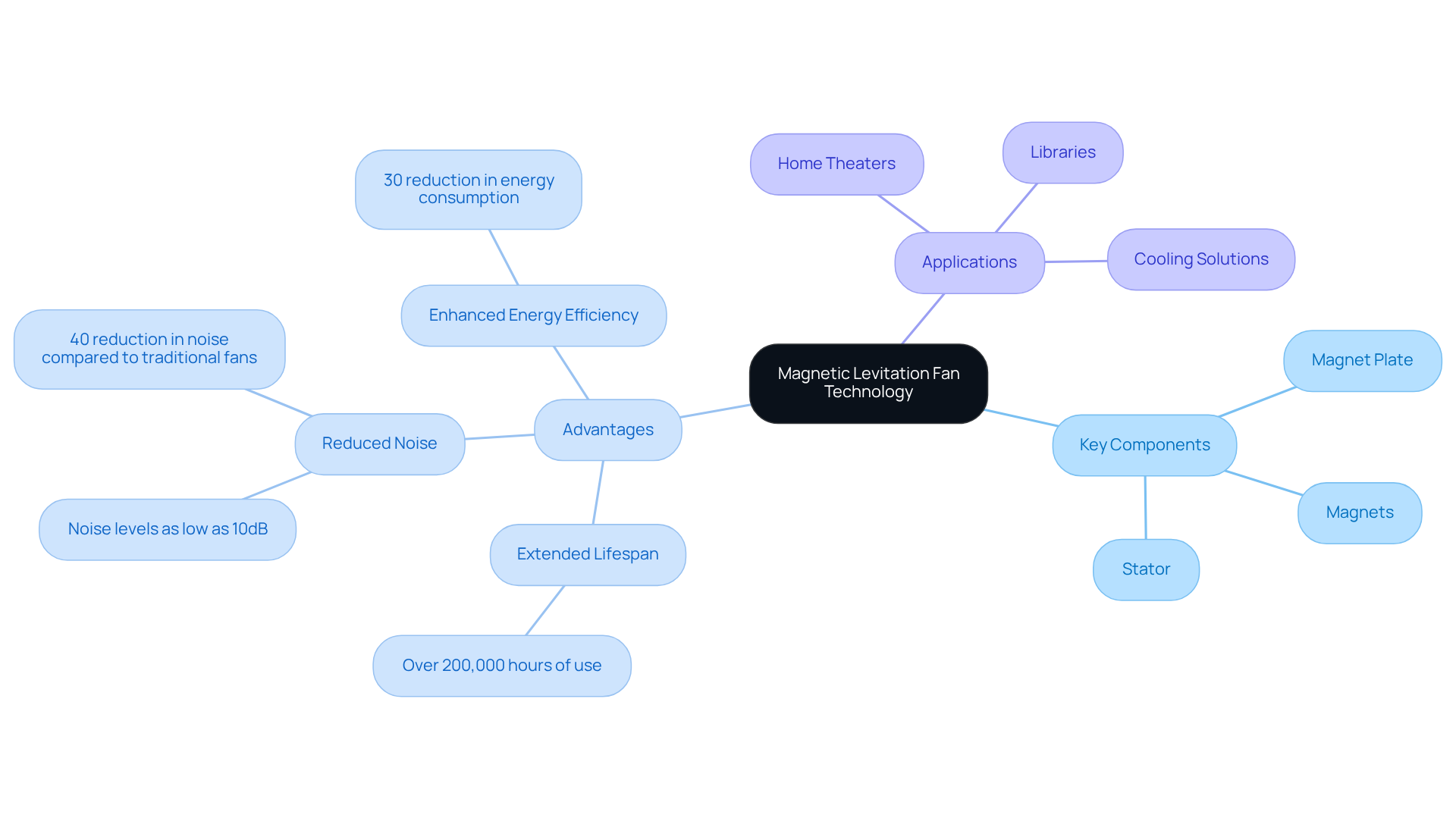

Understand Magnetic Levitation Fan Technology

Magnetic levitation (MagLev) devices represent a groundbreaking solution to the challenges posed by friction in conventional systems. By utilizing magnetic fields to suspend the rotor, these devices eliminate physical contact with bearings, significantly reducing friction. This innovative technology not only enhances efficiency but also extends operational lifespans, with MagLev devices achieving over 200,000 hours of use-far exceeding the typical 40,000 hours of traditional models.

Key components of a MagLev fan include:

- A magnet plate

- Magnets

- A stator

These components work together to create a frictionless environment. The absence of mechanical contact not only minimizes wear and tear but also reduces sound and vibration. This makes MagLev devices particularly suitable for applications requiring silent operation, such as home theaters and libraries. Engineers have noted that these devices operate at noise levels as low as 10dB, compared to 24dB for conventional models.

Moreover, the energy efficiency of MagLev technology is remarkable, demonstrating a 30% reduction in energy consumption. This effectiveness positions MagLev devices as a superior choice in the electronics sector, appealing to those who prioritize both performance and sustainability. In summary, the advantages of MagLev technology-extended lifespans, reduced noise, and enhanced energy efficiency-make it a compelling option for modern applications.

Explore Traditional Fan Mechanisms

Conventional devices typically operate using mechanical bearings, such as ball or sleeve bearings, which facilitate rotor rotation. These devices rely on electric motors to drive the blades, generating airflow through their spinning action. However, while they are efficient, conventional ventilators face significant drawbacks. Friction-related wear can lead to noise and reduced durability, with a typical lifespan of around 40,000 hours. Regular maintenance is essential to ensure optimal performance, as these devices often require routine upkeep.

Engineers have observed that conventional devices can produce considerable noise, particularly at higher speeds, with levels exceeding 90 dB. This can pose challenges in noise-sensitive environments. Furthermore, the dependence on AC induction motors can lead to additional conversion losses, negatively affecting overall efficiency. To extend the lifespan of these devices, routine maintenance, including cleaning and oiling, is crucial, especially in environments where dust and humidity can accelerate deterioration.

In contrast, modern solutions, such as electronically commutated (EC) devices, offer enhanced performance and reduced maintenance needs. These advancements make them an appealing choice for a variety of applications, providing a compelling alternative to traditional ventilators.

Compare Advantages and Disadvantages of Each Fan Type

Comparing Magnetic Levitation Fans to Traditional Fans

When evaluating the performance of magnetic levitation fans against traditional fans, several key advantages and disadvantages come to light.

Magnetic Levitation Fans

Advantages:

- Longevity: These fans boast lifespans exceeding 200,000 hours, significantly outlasting traditional models, which typically last around 5,000 to 10,000 hours. This remarkable longevity stems from reduced friction and wear, allowing magnetic levitation devices to last 3 to 5 times longer than clip-on models.

- Noise Reduction: Operating at noise levels as low as 18-22 decibels, the magnetic levitation fan is ideal for sensitive environments where quiet operation is crucial. Dr. Lena Torres, an Acoustic Environmental Researcher, emphasizes that even a 10-decibel reduction can make a space feel twice as quiet, offering measurable psychological benefits.

- Energy Efficiency: A magnetic levitation fan consumes only 2-5 watts of power, achieving energy savings of up to 60% compared to conventional models, which typically draw 6-12 watts. Furthermore, they can consume 30-50% less energy than traditional blowers, underscoring their efficiency.

- Maintenance-Free: Their innovative design minimizes wear and tear, resulting in lower maintenance requirements and operational costs over time. The overall expense of ownership for a magnetic levitation fan can be less than that of several clip-on units when considering lifespan and energy savings.

Disadvantages:

- Cost: The initial investment for magnetic levitation fans ranges from $70 to $120, making them pricier than traditional fans, which usually cost between $15 and $35.

- Complexity: The advanced technology may require specialized knowledge for installation and troubleshooting, potentially complicating the user experience.

Traditional Fans

Advantages:

- Cost-Effective: Their lower purchase price makes traditional fans accessible for a wide range of applications, particularly in budget-sensitive environments.

- Simplicity: The straightforward design allows for easier installation and maintenance, appealing to users who prefer less complexity.

Disadvantages:

- Shorter Lifespan: Traditional fans typically last around 5,000 to 10,000 hours, necessitating more frequent replacements and increasing long-term costs.

- Sound: Operating at typical sound levels of 35-50 decibels, they can be disruptive, especially in tranquil environments.

- Maintenance Needs: Regular maintenance is essential to ensure optimal performance, adding to the overall cost of ownership.

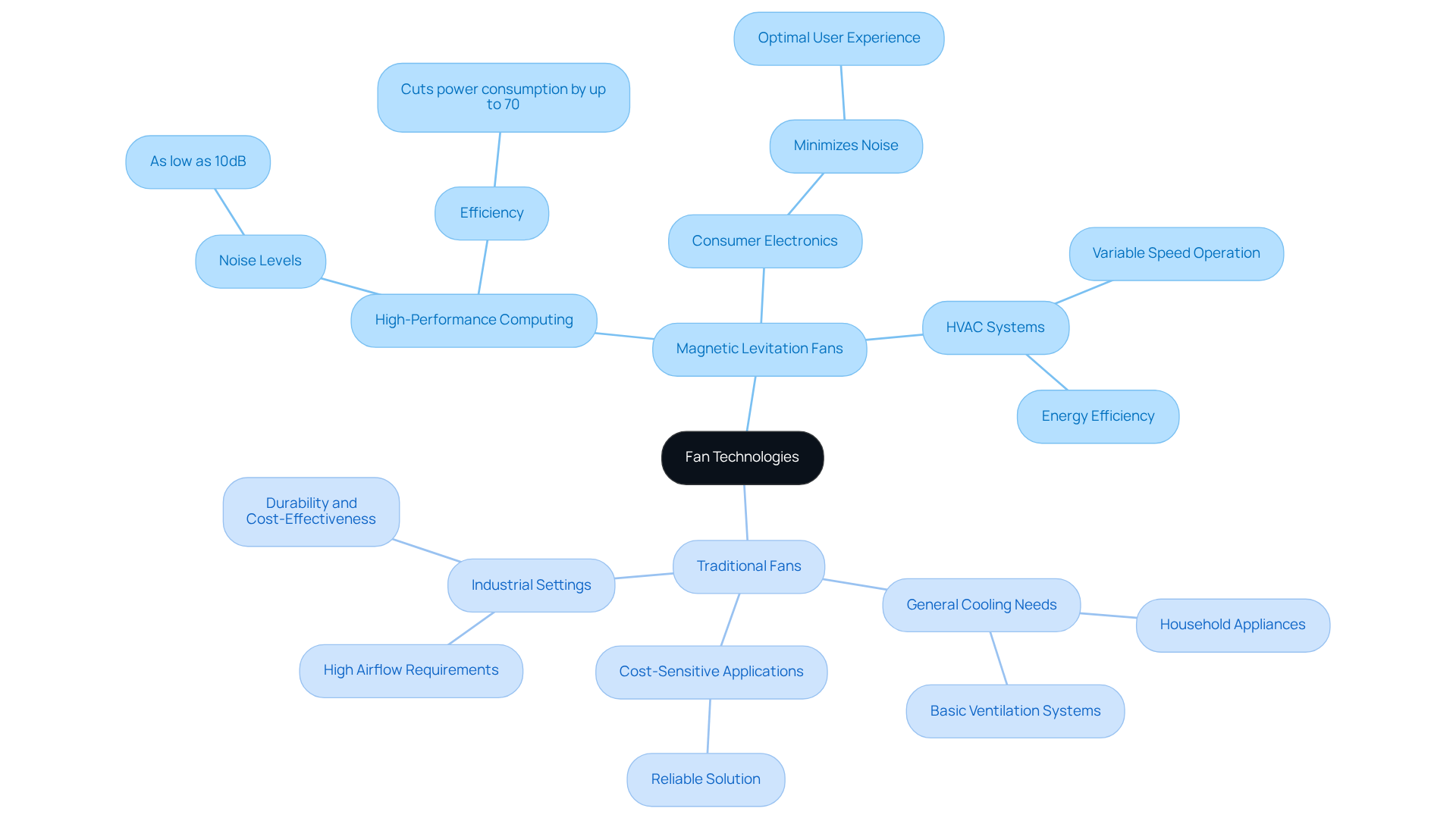

Identify Ideal Applications for Magnetic Levitation and Traditional Fans

The ideal applications for magnetic levitation fans are numerous and impactful:

- High-Performance Computing: With noise levels as low as 10dB and an impressive efficiency that can cut power consumption by up to 70% compared to traditional AC fans, these fans are perfect for data centers and server rooms.

- Consumer Electronics: They shine in high-end gaming PCs and audio equipment, where a magnetic levitation fan plays a crucial role in minimizing noise for an optimal user experience.

- HVAC Systems: These systems are particularly suited for applications that demand variable speed operation and energy efficiency, especially when using a magnetic levitation fan, which significantly enhances overall performance.

Conversely, traditional fans excel in various scenarios:

- General Cooling Needs: They are effective in household appliances and basic ventilation systems, delivering adequate airflow at a lower cost.

- Cost-Sensitive Applications: In situations where budget constraints are paramount, conventional air circulators offer a reliable solution without sacrificing functionality.

- Industrial Settings: These fans are ideal for environments that require high airflow, such as manufacturing facilities, where noise levels are less critical. Their durability and cost-effectiveness make them a staple in many industrial applications, especially in high-heat environments. As noted by Gordon Lindsay Glegg, engineers continually discover new uses for materials, and traditional fans exemplify this principle by effectively meeting the demands of diverse applications.

Conclusion

The comparison between magnetic levitation fans and traditional fans underscores a pivotal evolution in technology and performance. Magnetic levitation fans, with their cutting-edge design, present significant advantages, including extended lifespans, reduced noise levels, and enhanced energy efficiency. These benefits render them particularly attractive for modern applications that prioritize high performance and sustainability, distinguishing them from traditional models.

Key insights reveal that magnetic levitation fans can last over 200,000 hours, far surpassing the 40,000 hours typical of traditional fans. Furthermore, the remarkable noise reduction and energy savings associated with MagLev technology position it as the superior choice for sensitive environments, such as home theaters and data centers. Conversely, traditional fans maintain their appeal due to their cost-effectiveness and ease of maintenance, making them suitable for general cooling needs and budget-conscious applications.

Ultimately, the decision between magnetic levitation and traditional fans depends on specific application requirements and priorities. As technology advances, the benefits of magnetic levitation fans are likely to increasingly dominate the market, presenting engineers and consumers with a compelling case for transitioning to more efficient and sustainable solutions. Embracing these innovations not only enhances performance but also fosters a more environmentally conscious approach to cooling and ventilation.

Frequently Asked Questions

What is magnetic levitation (MagLev) fan technology?

Magnetic levitation (MagLev) fan technology uses magnetic fields to suspend the rotor, eliminating physical contact with bearings and significantly reducing friction.

What are the main advantages of MagLev technology?

The main advantages of MagLev technology include extended operational lifespans (over 200,000 hours), reduced noise levels (as low as 10dB), and enhanced energy efficiency (30% reduction in energy consumption).

How does MagLev technology compare to traditional fan models in terms of lifespan?

MagLev devices can achieve over 200,000 hours of use, which far exceeds the typical 40,000 hours of traditional fan models.

What components are essential for a MagLev fan?

Key components of a MagLev fan include a magnet plate, magnets, and a stator, which work together to create a frictionless environment.

Why is MagLev technology particularly suitable for silent operation?

The absence of mechanical contact in MagLev devices minimizes wear and tear, reducing sound and vibration, making them ideal for applications such as home theaters and libraries.

What noise levels do MagLev fans operate at compared to conventional models?

MagLev fans operate at noise levels as low as 10dB, while conventional models typically operate at around 24dB.

How does MagLev technology contribute to energy efficiency?

MagLev technology demonstrates a 30% reduction in energy consumption, making it a more energy-efficient option compared to traditional fans.