Introduction

Designing efficient blowers for electronics presents a complex challenge, demanding a profound understanding of various design specifications and environmental factors. This article delves into four best practices engineers can adopt to enhance blower performance:

- Pinpointing essential design requirements

- Selecting optimal materials

- Implementing rigorous testing protocols

- Ensuring compliance with current standards

Yet, with the rapid pace of technological advancements and the growing emphasis on energy efficiency, how can engineers ensure their designs not only meet current standards but also anticipate future challenges? This inquiry sets the stage for a deeper exploration into innovative solutions that can drive the industry forward.

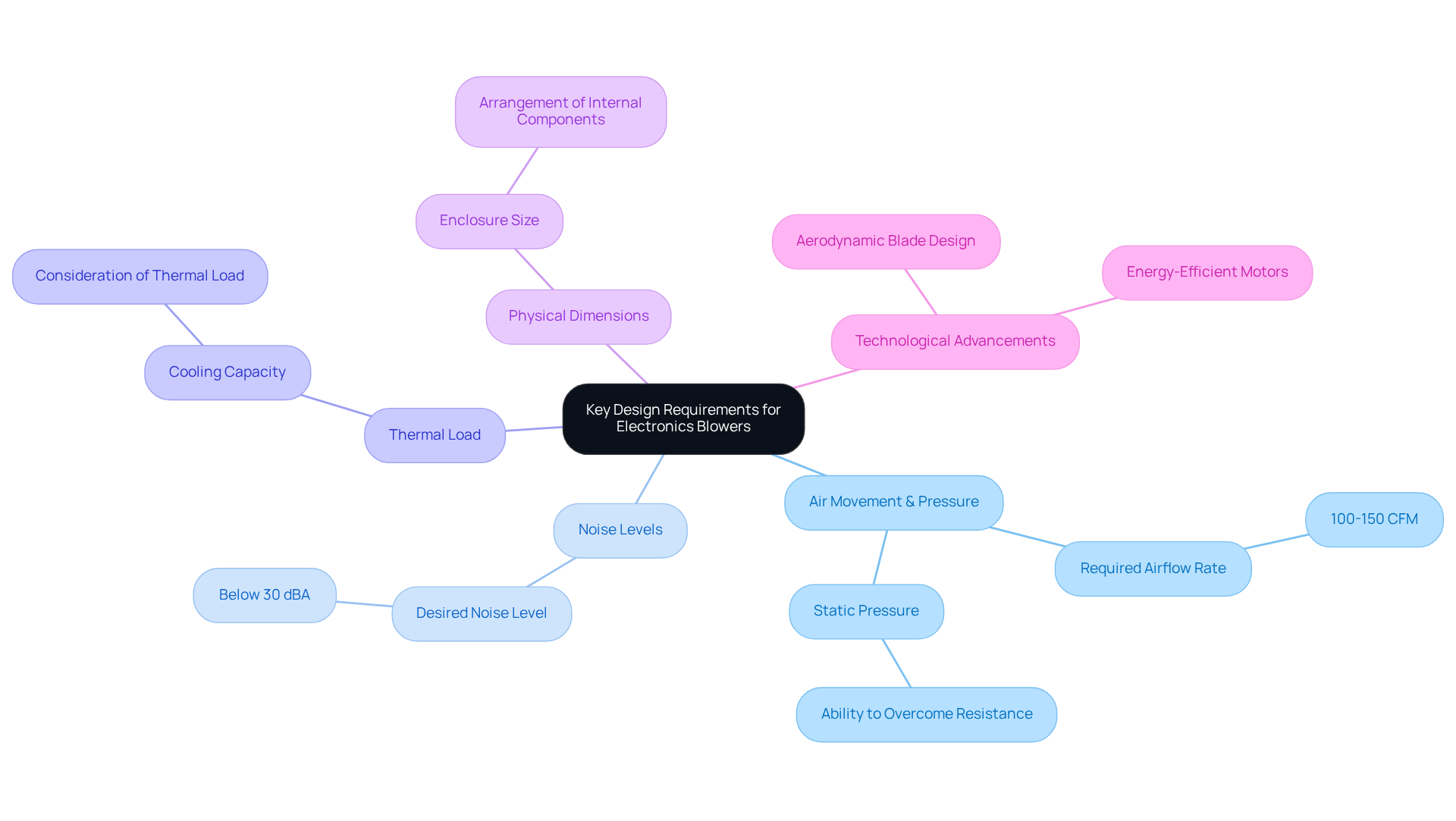

Identify Key Design Requirements for Electronics Blowers

Creating an efficient fan for electronics applications presents a significant challenge that demands a thorough understanding of essential design specifications. Engineers must first assess the specific air movement and pressure requirements dictated by the application. For instance, cooling high-performance CPUs typically necessitates fans that can deliver circulation rates averaging between 100 to 150 CFM, all while maintaining noise levels ideally below 30 dBA. Furthermore, the thermal load of the components being cooled plays a crucial role in determining the fan’s capacity and efficiency.

In addition to these factors, engineers should carefully consider the physical dimensions of the enclosure, the arrangement of internal components, and any potential obstacles that could hinder performance. Recent advancements in fan technology underscore the importance of aerodynamic blade design and energy-efficient motors, which are vital for achieving the desired air movement and static pressure in high-density electronic environments. As one engineer aptly noted, “Understanding the airflow and pressure needs is pivotal for optimizing cooling solutions across diverse applications.”

By prioritizing these critical factors, engineers can significantly enhance both the effectiveness and durability of their blower design, ensuring optimal performance in various applications.

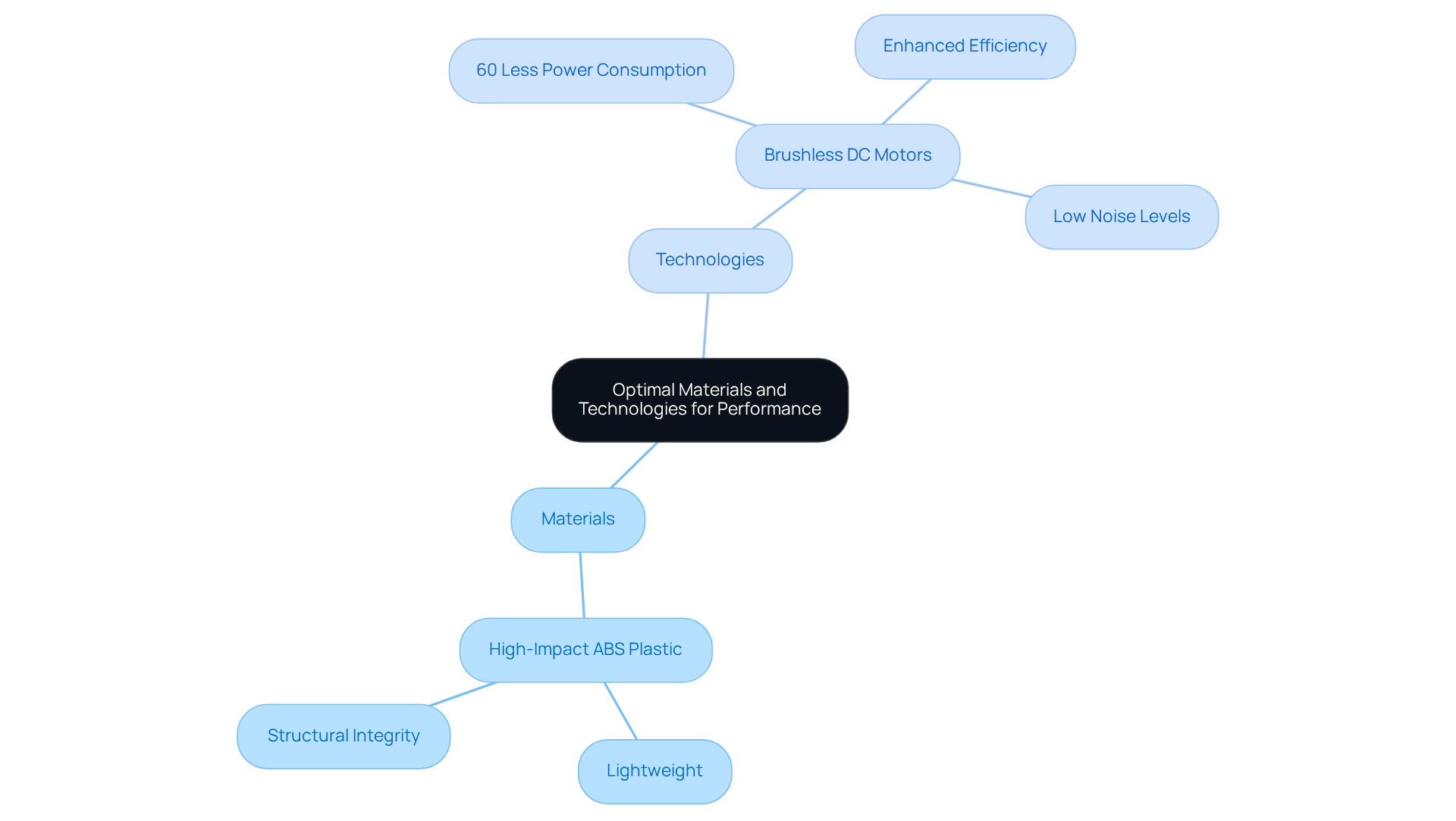

Select Optimal Materials and Technologies for Performance

In fan design, engineers face the critical challenge of selecting materials and technologies that ensure high thermal conductivity, lightweight characteristics, and resistance to environmental factors such as moisture and dust. High-impact ABS plastic stands out as an excellent choice for housing, effectively reducing weight while maintaining structural integrity.

Gagner-Toomey Associates provides a range of advanced motor technologies, with a particular focus on brushless DC motors. These motors significantly enhance efficiency and minimize noise levels, making them ideal for sensitive applications. Notably, brushless DC fans consume up to 60% less power than traditional AC units, leading to substantial operational savings. Their durability further ensures reliability and consistent performance over time.

To optimize blower design and airflow characteristics, engineers can leverage computational fluid dynamics (CFD) simulations. This approach guarantees that the selected materials and technologies work in harmony to achieve peak performance. Transitioning to brushless DC fans can result in a payback period of approximately 2-3 years, positioning them as a cost-effective solution for modern ventilation applications.

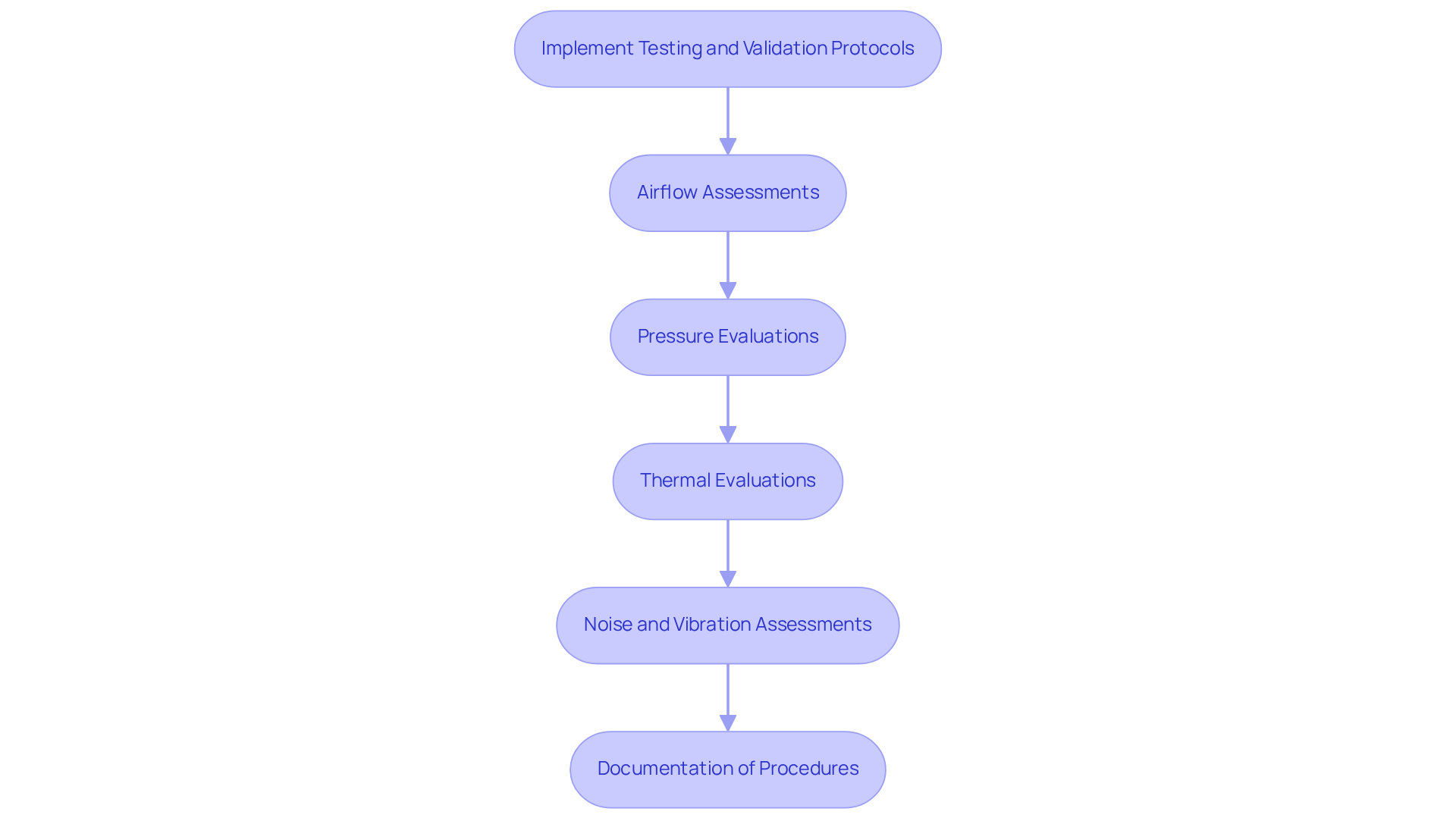

Implement Rigorous Testing and Validation Protocols

To guarantee the reliability and efficiency of fans, engineers must implement comprehensive evaluation and validation procedures. This begins with airflow assessments that measure the fan’s performance against established specifications. Pressure evaluations are equally critical, as they determine the fan’s capability to maintain optimal airflow under varying conditions. Additionally, thermal evaluations play a vital role in assessing the fan’s efficiency in managing heat dissipation, which is essential in electronics applications.

Moreover, evaluating noise levels and vibrations is crucial for ensuring that the fan operates quietly while maintaining structural integrity. Documenting all evaluation procedures and results is imperative for fostering continuous improvement and ensuring compliance with industry standards. Utilizing external evaluation centers can provide unbiased confirmation of efficiency metrics, thereby enhancing the trustworthiness of the device’s operational claims.

For instance, Hartzell Air Movement employs stringent examination methods in AMCA-accredited labs to verify airflow rates, static pressure, and power consumption. This rigorous testing ensures that their industrial fans meet high performance and reliability standards. Furthermore, the preparation of the foundation for fan installation is critical, as it supports the device and absorbs vibrations during operation. Such practices not only enhance product quality but also reinforce customer confidence in the solutions provided.

Hartzell further solidifies trust in their testing and validation processes by backing their products with the industry’s only 5-year warranty. This commitment to quality assurance not only elevates their reputation but also assures customers of the reliability and effectiveness of their fans.

Incorporate Innovative Design Techniques for Enhanced Efficiency

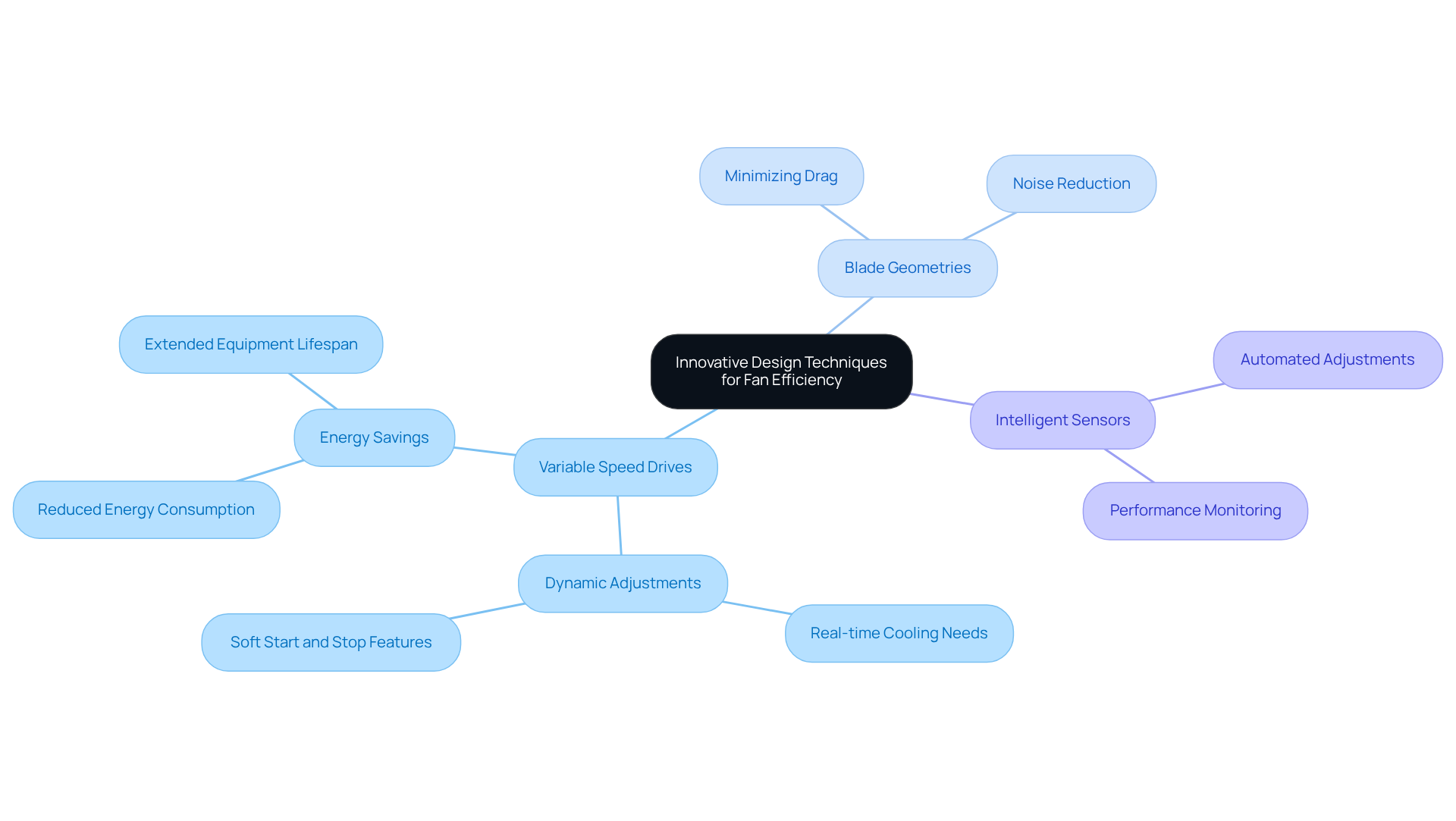

To enhance fan designs, engineers must incorporate innovative methods such as variable speed drives (VSD) and advanced blade geometries. The challenge lies in optimizing performance while ensuring energy efficiency. VSDs enable dynamic adjustments to fan speed based on real-time cooling needs, leading to significant energy savings. For example, variable frequency drives (VFDs) can drastically reduce energy consumption by aligning motor speed with specific load requirements. As noted by Willis Electrical, “With a VFD, you can adjust motor speed to match the specific load requirement at any given time, significantly reducing energy consumption.”

Moreover, optimizing blade shapes to minimize drag enhances fluid movement efficiency and reduces noise levels – critical factors in sensitive environments. The integration of intelligent sensors that monitor temperature and airflow facilitates automated adjustments, ensuring fans operate at peak performance. A compelling case study from Willis Electrical illustrates a successful partnership with a client in the oil and gas sector, where custom VFD control panels not only improved operational flexibility but also extended equipment lifespan.

By adopting these advanced design strategies, engineers can create blowers that not only meet but exceed performance expectations, ultimately bolstering system reliability and efficiency.

Conclusion

Creating effective blowers for electronics applications is not just a task; it’s a necessity that demands a multifaceted approach. Engineers must prioritize design requirements, material selection, rigorous testing, and innovative techniques. By grasping the unique demands of each application, they can optimize airflow and pressure, all while ensuring minimal noise and maximum efficiency.

Key elements come into play here. Selecting suitable materials, such as high-impact ABS plastic, and utilizing advanced motor technologies like brushless DC motors are crucial. Implementing comprehensive testing protocols further solidifies reliable performance. Moreover, incorporating innovative design strategies – think variable speed drives and optimized blade geometries – enhances energy efficiency and operational flexibility.

The significance of these best practices is paramount. As electronic devices evolve, the demand for efficient cooling solutions will only escalate. By adopting these strategies, engineers not only enhance the performance and durability of blowers but also contribute to a more sustainable and efficient future in electronics design. Embracing these practices ensures that cooling systems are not merely functional; they are optimized to meet the challenges posed by modern technology.

Frequently Asked Questions

What are the main design requirements for electronics blowers?

The main design requirements include assessing air movement and pressure needs, maintaining low noise levels, and considering thermal load, physical dimensions of the enclosure, and arrangement of internal components.

What air circulation rates are typically needed for cooling high-performance CPUs?

Cooling high-performance CPUs typically requires fans that can deliver circulation rates averaging between 100 to 150 CFM.

What is the ideal noise level for fans used in electronics applications?

The ideal noise level for fans used in electronics applications is below 30 dBA.

How does the thermal load of components affect blower design?

The thermal load of the components being cooled is crucial in determining the fan’s capacity and efficiency, influencing the overall design and performance.

Why is aerodynamic blade design important in fan technology?

Aerodynamic blade design is important because it helps achieve the desired air movement and static pressure, especially in high-density electronic environments.

What role do energy-efficient motors play in blower design?

Energy-efficient motors are vital for optimizing performance and ensuring that the fan operates effectively while consuming less power.

How can engineers enhance the effectiveness and durability of blower designs?

Engineers can enhance effectiveness and durability by prioritizing critical factors such as airflow and pressure needs, as well as incorporating advanced technologies in their designs.