Introduction

Understanding the complexities of cooling solutions is crucial for engineers navigating the intricate landscape of electronic systems. PWM (Pulse Width Modulation) and DC (Direct Current) fans emerge as two prominent options, each presenting unique characteristics and advantages tailored to specific applications. The challenge, however, lies in determining which fan type is most appropriate for a given scenario. Factors such as efficiency, noise levels, and operational mechanisms must be considered.

What are the key differences that can significantly influence performance and user experience? This exploration will clarify these distinctions, guiding engineers toward informed decisions.

Define PWM and DC Fans: Key Characteristics

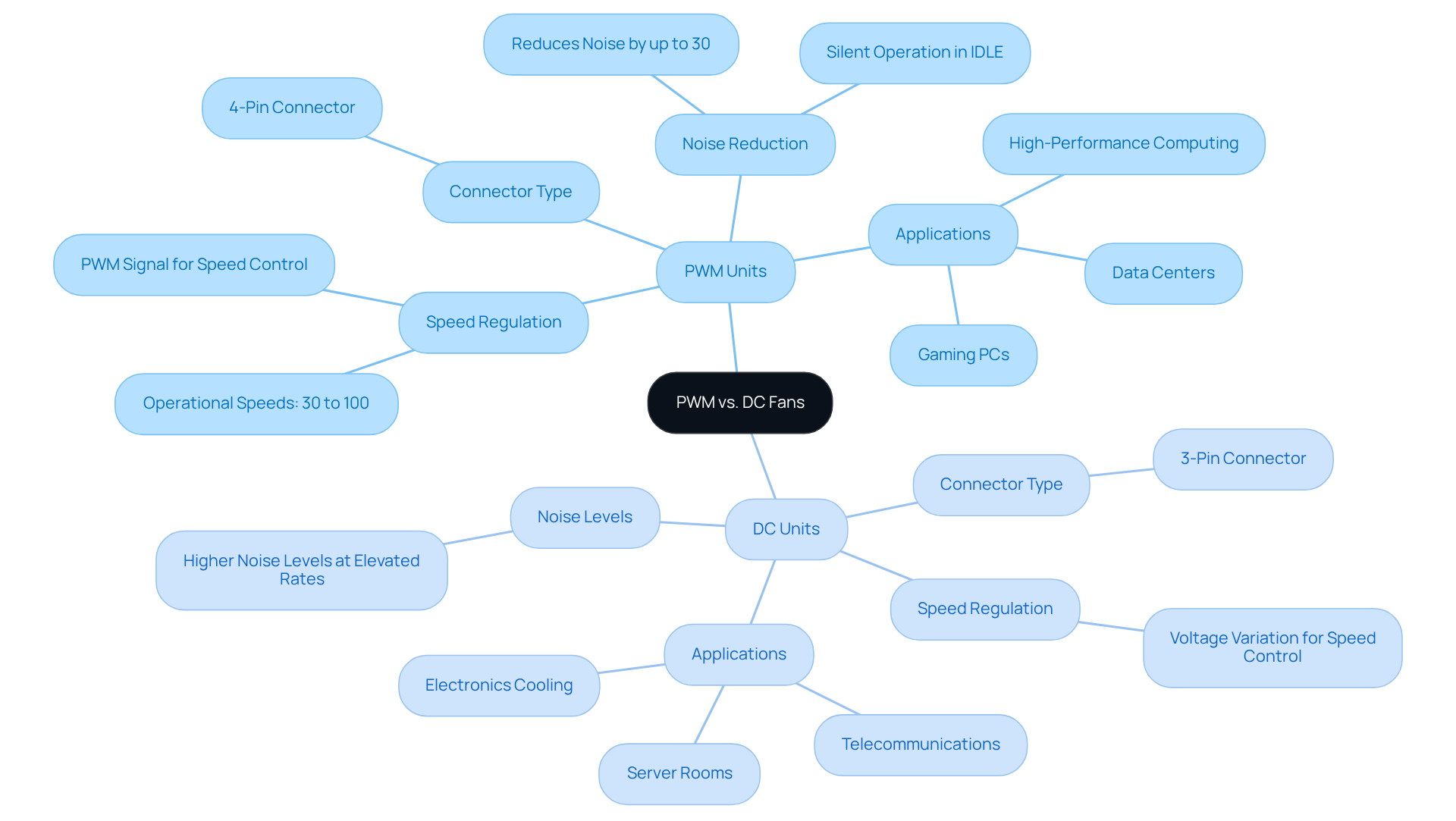

PWM (Pulse Width Modulation) devices and DC (Direct Current) units represent two prevalent cooling solutions in electronic systems, highlighting the difference between PWM and DC through their unique characteristics and applications.

PWM Units: Featuring a four-pin connector, PWM devices utilize the fourth pin to send a PWM signal that precisely regulates rotation. This capability allows for meticulous adjustments to speed, enabling operation at as low as 20% of maximum capacity without stalling. Such flexibility proves particularly beneficial in noise-sensitive environments, where maintaining low sound levels is paramount. In fact, PWM technology can reduce noise output by up to 30% compared to traditional cooling methods, making these devices ideal for applications like gaming PCs and data centers, where efficient cooling and silent operation are essential.

DC Enthusiasts: In contrast, DC enthusiasts typically use a three-pin connector and adjust the rotation rate by varying the voltage supplied to the motor. While simpler in design, DC motors generally struggle to achieve the low speeds that PWM units can, potentially resulting in higher noise levels at elevated rates. They are commonly employed in scenarios where a constant speed is acceptable, such as telecommunications and server rooms. Although the initial investment for DC systems may be higher, their energy efficiency can lead to significant long-term savings, consuming up to 70% less power than AC models.

Understanding the difference between PWM and DC is crucial for engineers when selecting the appropriate fan type for specific applications. The choice directly influences cooling efficiency, noise levels, and overall system performance.

Examine Operational Mechanisms: How PWM and DC Fans Work

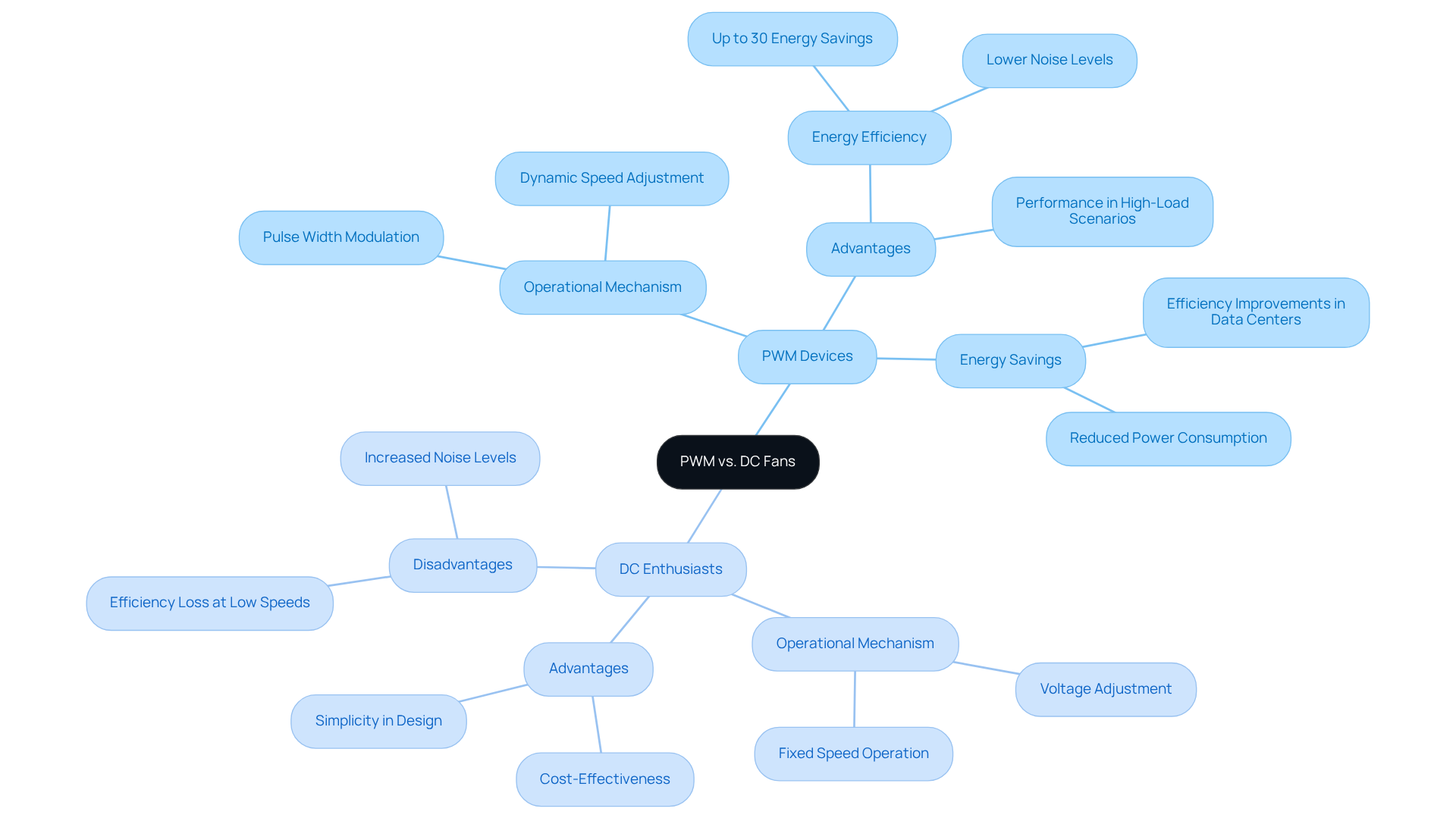

The difference between PWM and DC devices is significant in their operational mechanisms, which influence their performance and suitability for various applications.

PWM Devices: These devices utilize pulse width modulation (PWM) to control their operation. By rapidly switching the power on and off, the PWM signal regulates the duty cycle, determining the average power delivered to the fan. This method enables smooth velocity transitions, enhancing energy efficiency and reducing noise levels. PWM units can function at reduced rates without stalling, making them ideal for environments where noise minimization is crucial. In practical applications, the difference between PWM and DC technology is that PWM can achieve energy savings of up to 30% compared to conventional DC devices, particularly during periods of low cooling demand. As noted by Matt Safford, “PWM units are crucial for contemporary electronics, balancing performance and efficiency in a manner that conventional counterparts cannot.”

DC Enthusiasts: Conversely, DC enthusiasts modify their pace by adjusting the voltage supplied to the motor. An increase in voltage results in a higher fan rotation, while a decrease leads to a reduction in pace. However, this approach can be less effective at lower velocities, as DC motors often struggle to maintain consistent performance without stalling. Reports indicate that DC enthusiasts may experience a significant decrease in efficiency, especially when underpowered, leading to reduced airflow and increased noise levels. In fact, DC enthusiasts can reduce velocity by as much as 40% when underpowered. Consequently, while DC enthusiasts are economical and straightforward, they may not meet the demands of high-performance applications where precise control and efficiency are essential.

Compare Performance Metrics: Efficiency, Noise, and Power Consumption

When comparing PWM and DC fans, several performance metrics stand out as crucial:

-

Efficiency: PWM fans lead the way in efficiency, thanks to their ability to dynamically adjust speed based on thermal demands. This adaptability enables them to operate at lower power levels while still providing effective cooling. In contrast, the difference between PWM and DC devices is that DC devices typically run at a constant speed, leading to higher energy consumption, especially when full power isn’t necessary. Research shows that the difference between PWM and DC devices can result in energy savings of up to 30% when using PWM models. Additionally, PWM fans can reduce their rotation by as much as 40% of their rated performance, making them suitable for various thermal management scenarios.

-

Noise Levels: PWM fans are generally quieter than their DC counterparts, especially at lower speeds. Their capability to operate at reduced rates without stalling minimizes noise during periods of low cooling demand. Conversely, the difference between PWM and DC fans is evident as DC fans often generate more noise due to running at higher speeds to maintain airflow, which can be a disadvantage in noise-sensitive environments.

-

Power Consumption: The difference between PWM and DC units is that PWM units can consume up to 30% less energy than DC units, particularly in situations where variable speed operation is advantageous. This significant reduction in power consumption not only lowers operational costs but also enhances the sustainability of electronic designs. Furthermore, PWM fans utilize a four-pin connector, allowing for dynamic control based on system temperature, a notable advantage over DC devices that typically employ a three-pin connector.

Assess Application Suitability: Choosing Between PWM and DC Fans

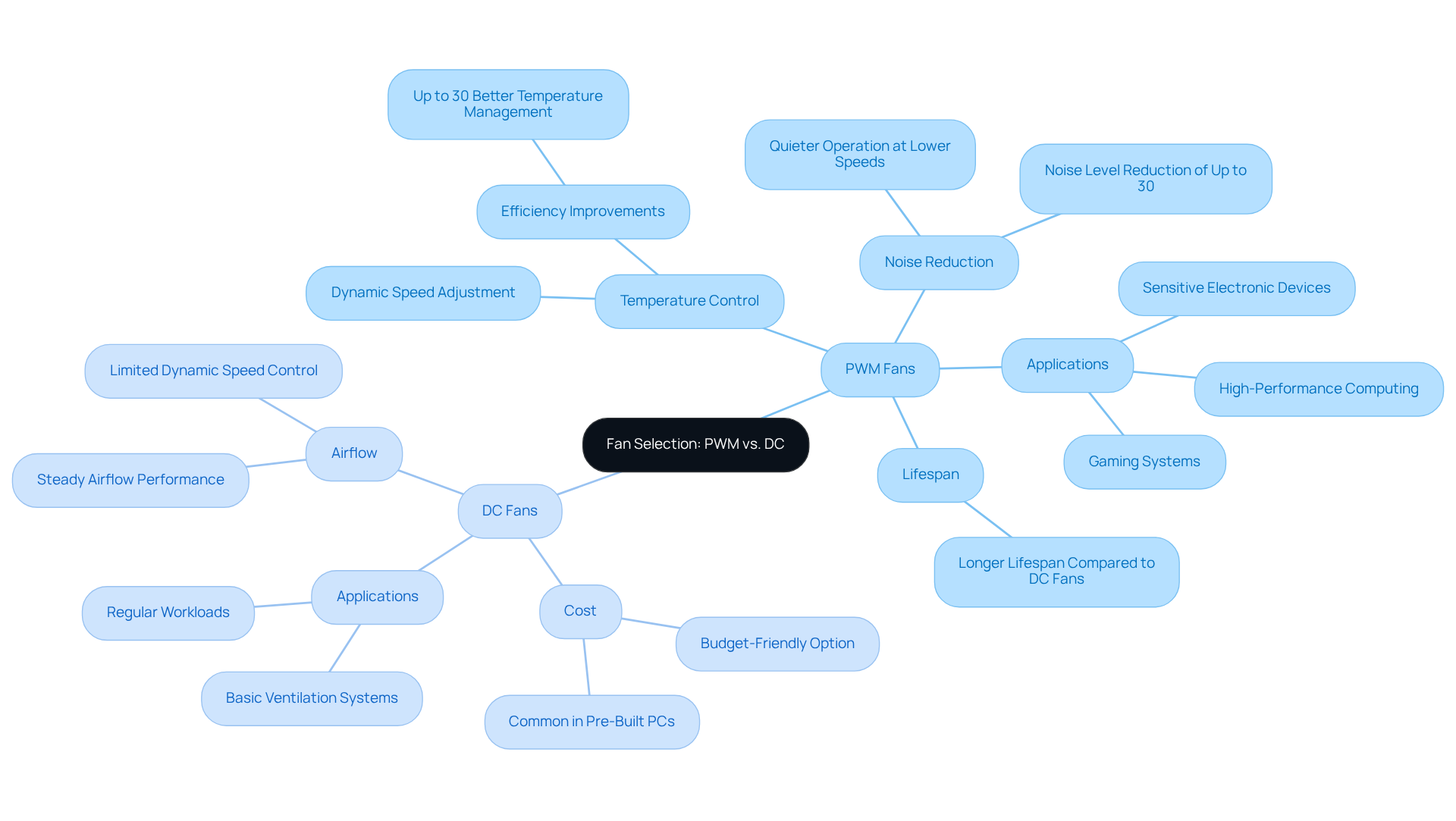

Understanding the difference between PWM and DC fans is crucial for optimizing performance in various applications.

PWM Fans are particularly suited for scenarios demanding precise temperature control and noise reduction. They excel in high-performance computing, gaming systems, and sensitive electronic devices. Their unique ability to operate at lower speeds without stalling makes them ideal for environments where quiet operation is paramount. This capability not only enhances user experience but also prolongs the lifespan of sensitive components.

On the other hand, DC Fans are more appropriate for simpler applications where cost is a significant factor. They are commonly used in basic ventilation systems or situations where steady airflow suffices. In less demanding environments, the advantages of PWM control may not justify the additional expense, making DC fans a practical choice.

In summary, engineers must weigh factors such as cooling requirements, noise tolerance, and budget constraints when selecting fans for their projects, considering the difference between PWM and DC. By carefully considering these elements, they can ensure optimal performance and efficiency in their designs.

Conclusion

Understanding the distinctions between PWM and DC fans is crucial for engineers seeking to optimize their electronic systems. Both types serve the fundamental purpose of cooling, yet their operational mechanisms, efficiency, and suitability for various applications differ significantly.

PWM fans provide precise speed control, reduced noise levels, and enhanced energy efficiency, making them ideal for environments where performance and quiet operation are paramount. In contrast, DC fans offer a simpler, cost-effective solution for applications that do not require the same level of control or efficiency.

Key points highlighted throughout this discussion include:

- The operational differences between PWM and DC fans

- Their respective performance metrics regarding efficiency, noise, and power consumption

- The contexts in which each type excels

For instance, PWM fans can achieve energy savings of up to 30% and operate quietly at lower speeds. On the other hand, DC fans may be more suitable for basic ventilation tasks but often generate more noise and consume more power.

Ultimately, the choice between these two fan types hinges on specific project requirements, including cooling needs, budget constraints, and acceptable noise levels. Engineers are encouraged to carefully evaluate their cooling requirements and the operational environments of their projects when selecting between PWM and DC fans. By understanding the advantages and limitations of each type, informed decisions can be made that enhance system performance while also considering energy efficiency and cost-effectiveness.

Embracing the right fan technology not only optimizes cooling but also contributes to the longevity and reliability of electronic systems.

Frequently Asked Questions

What is PWM in the context of cooling solutions?

PWM (Pulse Width Modulation) refers to a type of cooling solution that uses a four-pin connector to send a PWM signal, allowing for precise regulation of fan rotation speed.

How does a PWM fan operate compared to a DC fan?

A PWM fan can operate at speeds as low as 20% of its maximum capacity without stalling, enabling meticulous speed adjustments. In contrast, a DC fan uses a three-pin connector and varies its rotation rate by changing the voltage supplied, which generally results in less precise speed control.

What are the noise characteristics of PWM fans?

PWM technology can reduce noise output by up to 30% compared to traditional cooling methods, making PWM fans suitable for noise-sensitive environments such as gaming PCs and data centers.

In what applications are PWM fans most beneficial?

PWM fans are ideal for applications requiring efficient cooling and silent operation, such as gaming PCs and data centers.

What is a key limitation of DC fans?

DC fans typically struggle to achieve low speeds like PWM units can, which may result in higher noise levels at elevated speeds.

Where are DC fans commonly used?

DC fans are commonly employed in situations where a constant speed is acceptable, such as telecommunications and server rooms.

What are the energy efficiency benefits of DC fans?

Although the initial investment for DC systems may be higher, they can be significantly more energy-efficient, consuming up to 70% less power than AC models, leading to long-term savings.

Why is it important for engineers to understand the differences between PWM and DC fans?

Understanding the differences is crucial for engineers when selecting the appropriate fan type, as it directly impacts cooling efficiency, noise levels, and overall system performance.