Introduction

Understanding airflow is crucial for electronics engineers aiming to boost the efficiency and reliability of their systems. Effective thermal management relies on a solid grasp of airflow fundamentals, including convection principles and the functions of different fan types. As electronic devices grow more complex and their cooling needs escalate, engineers must ask: how can they optimize airflow to prevent overheating and ensure peak performance? This article explores best practices for enhancing fan airflow, providing insights into airflow parameters, fan selection, and strategic placement. By mastering these elements, engineers can empower themselves in their pursuit of efficient cooling solutions.

Understand Airflow Fundamentals in Electronic Systems

Airflow in electronic systems is crucial for managing the heat generated by components. Engineers must grasp the principles of convection, conduction, and radiation to enhance cooling efficiency effectively.

-

Convection – the transfer of heat through fluid motion – plays a pivotal role in this process. It explains how fans air flow can effectively cool components. For instance, directing air towards heat-producing elements can significantly improve thermal management. Additionally, engineers should consider how wind direction and velocity impact heat dissipation, as these factors directly affect cooling performance.

-

Understanding static pressure and impedance in airflow is equally essential. High impedance settings necessitate devices that can generate sufficient static pressure to ensure optimal fans air flow.

-

Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, provides a comprehensive portfolio of DC input tube axial devices (ranging from 15 to 280mm) and centrifugal blowers (from 15 to 225mm). These products are optimized for performance, efficiency, and low noise. By strategically designing enclosures and selecting appropriate fans from Gagner-Toomey’s extensive range, engineers can develop systems that maximize temperature regulation efficiency and ensure reliable operation.

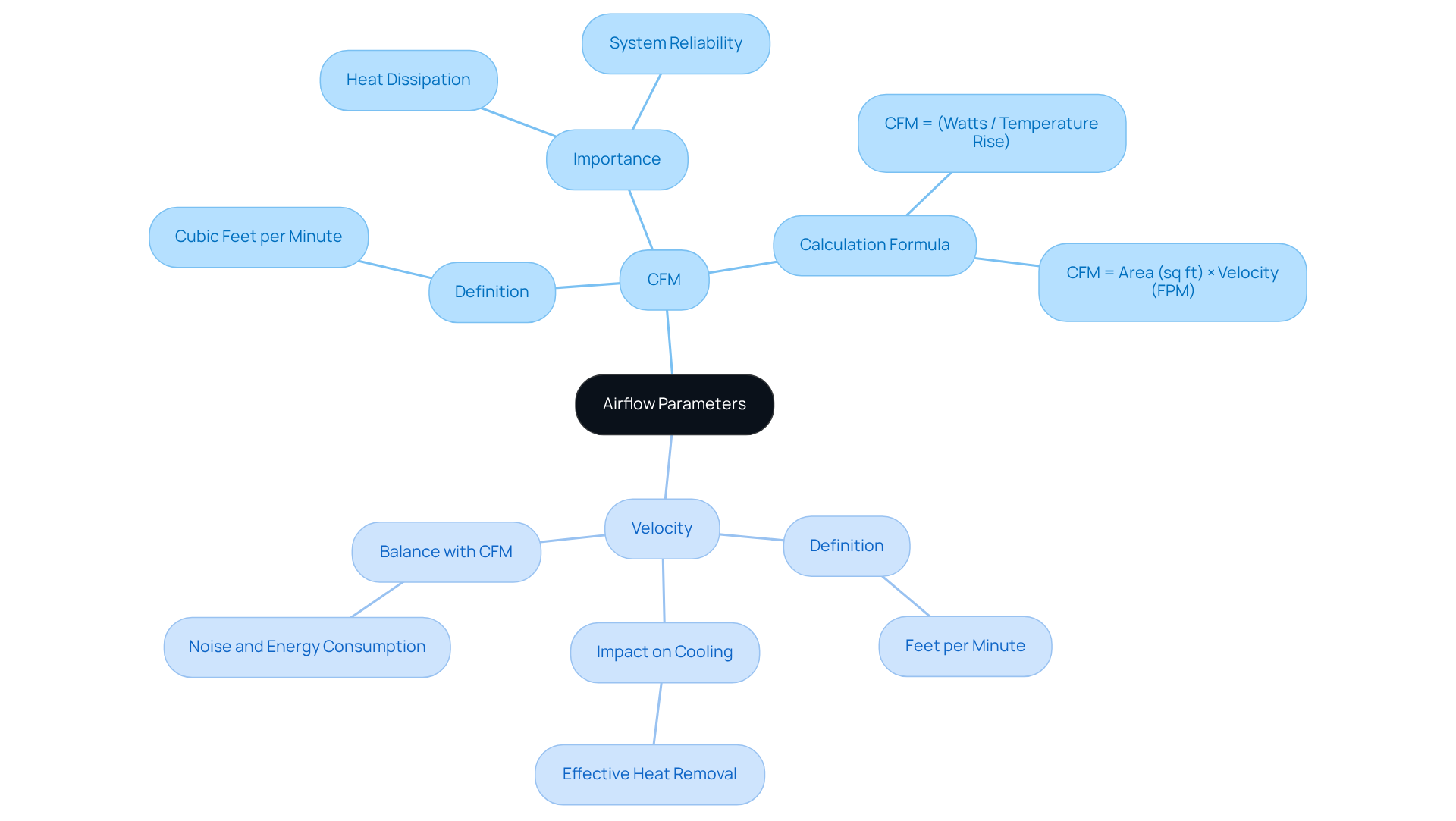

Evaluate Key Airflow Parameters: CFM and Velocity

CFM, or Cubic Feet per Minute, is a crucial measurement that quantifies the volume of air a fan can move in one minute. Understanding and calculating the required CFM is essential for engineers, particularly when addressing the heat dissipation needs of their components. For instance, if a component generates 50 watts of heat, engineers can apply the formula CFM = (Watts / Temperature Rise) to determine the necessary ventilation.

Equally important is the velocity of air, measured in feet per minute (FPM), as it directly influences how effectively air can remove heat from surfaces. Engineers must strive for a harmonious balance between CFM and velocity to ensure efficient cooling while optimizing fans air flow and minimizing noise and energy consumption.

To achieve accurate measurements, utilizing tools such as anemometers is recommended. These instruments provide precise data on wind speed, enabling engineers to optimize their cooling solutions effectively.

Select Appropriate Fans Based on System Requirements

When selecting blowers, engineers must conduct a thorough evaluation of several critical factors, including:

- Fans air flow

- Static pressure ratings

- Noise levels

- Energy efficiency

Axial blowers excel in high airflow applications, ensuring fans air flow that is ideal for refreshing large volumes of air in designated areas. As Ryan Smoot notes, ‘Axial blowers effectively and efficiently move high volumes of air, enhancing fans air flow to cool objects or ventilate spaces.’ Conversely, centrifugal blowers are designed for higher static pressure environments, making them suitable for precise temperature control in electronics applications that generate significant heat. For example, centrifugal fans are commonly utilized in compact devices like laptops, thanks to their capability to expel air at a 90-degree angle, which enhances directionality.

Engineers should also take into account the fans air flow and its operating environment, including temperature and humidity, to ensure reliability and optimal performance. Moreover, incorporating variable speed drives (VFDs) can greatly improve fan performance by enabling dynamic adjustments based on real-time thermal conditions. This adaptability not only leads to energy savings but also extends the fan’s lifespan, ensuring consistent efficiency in critical applications.

The global cooling fan market is projected to reach USD 8125.2 million by 2024, underscoring the necessity of selecting the appropriate fan to meet the escalating demands of the electronics industry.

Optimize Fan Placement and Orientation for Maximum Efficiency

To achieve optimal efficiency in fans air flow, engineers must strategically position devices to create a balanced airflow pattern. For instance, placing intake vents at the front or bottom of an enclosure and exhaust vents at the rear or top fosters effective air circulation. Proper orientation is crucial; intake units should draw air in while exhaust units push air out, which helps to maintain optimal fans air flow, preventing turbulence and enhancing cooling performance.

The spacing between fans and components is equally significant, as it minimizes obstructions and allows for unimpeded ventilation. Regular maintenance, including cleaning dust filters and ensuring clear pathways, is essential for sustaining optimal fans air flow over time. Furthermore, maintaining at least 2 inches of clearance around any intake or exhaust is vital for proper fans air flow, as emphasized by EIC’s ThermoTEC series.

Statistics reveal that a balanced intake and exhaust configuration, such as two intake fans and one exhaust fan, can improve fans air flow and lower CPU temperatures by 5-10°C under load, achieving a case temperature of 42°C in such setups. Real-world examples demonstrate that effective fan orientation not only boosts efficiency but also contributes to the longevity and reliability of electronic components. As EIC Solutions emphasizes, directing fans air flow towards AC intakes significantly enhances cooling performance, underscoring the importance of thoughtful fan placement.

Conclusion

Effective management of airflow in electronic systems is crucial for ensuring optimal performance and extending the lifespan of components. Understanding the principles of convection, static pressure, and the specific requirements of various fan types allows engineers to significantly boost cooling efficiency. The strategic selection and placement of fans, along with careful consideration of airflow parameters such as CFM and velocity, lay the groundwork for successful thermal management.

Key insights have emerged throughout this discussion:

- The importance of airflow fundamentals

- The critical role of accurate CFM calculations

- The necessity of selecting appropriate fans based on system needs

Moreover, optimizing fan placement and orientation can lead to substantial improvements in cooling performance. Collectively, these elements contribute to the effective regulation of temperature within electronic devices, preventing overheating and ensuring reliable operation.

The significance of airflow optimization cannot be overstated. As the electronics industry evolves, engineers must adopt best practices and leverage innovative cooling solutions to meet growing demands. By prioritizing airflow management, professionals can enhance the efficiency and reliability of electronic systems, paving the way for technological advancements and improved user experiences.

Frequently Asked Questions

Why is airflow important in electronic systems?

Airflow is crucial for managing the heat generated by components in electronic systems, enhancing cooling efficiency.

What principles must engineers understand to improve cooling efficiency?

Engineers must grasp the principles of convection, conduction, and radiation to effectively enhance cooling efficiency.

What role does convection play in cooling electronic components?

Convection, the transfer of heat through fluid motion, is pivotal as it explains how airflow from fans can effectively cool components by directing air towards heat-producing elements.

How do wind direction and velocity affect heat dissipation?

Wind direction and velocity impact heat dissipation directly, affecting the overall cooling performance of electronic systems.

What is the significance of static pressure and impedance in airflow?

Understanding static pressure and impedance is essential, as high impedance settings require devices that can generate sufficient static pressure to ensure optimal airflow from fans.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering a comprehensive portfolio of DC input tube axial devices and centrifugal blowers optimized for performance, efficiency, and low noise.

How can engineers maximize temperature regulation efficiency in their systems?

Engineers can maximize temperature regulation efficiency by strategically designing enclosures and selecting appropriate fans from Gagner-Toomey’s extensive range of products.