Introduction

Fan PWM control marks a significant advancement in the operation of cooling systems within electronic devices, providing a more efficient and adaptable approach to thermal management. This technology enhances performance by enabling fans to adjust their speed in real-time based on temperature fluctuations, while also significantly lowering energy consumption and noise levels.

As the demand for compact and powerful electronics escalates, one must ask: can traditional cooling methods keep up with the evolving requirements of modern technology?

Delving into the intricacies and benefits of PWM fan control underscores its vital role in shaping the future of electronic design and sustainability.

Define PWM Fan Control

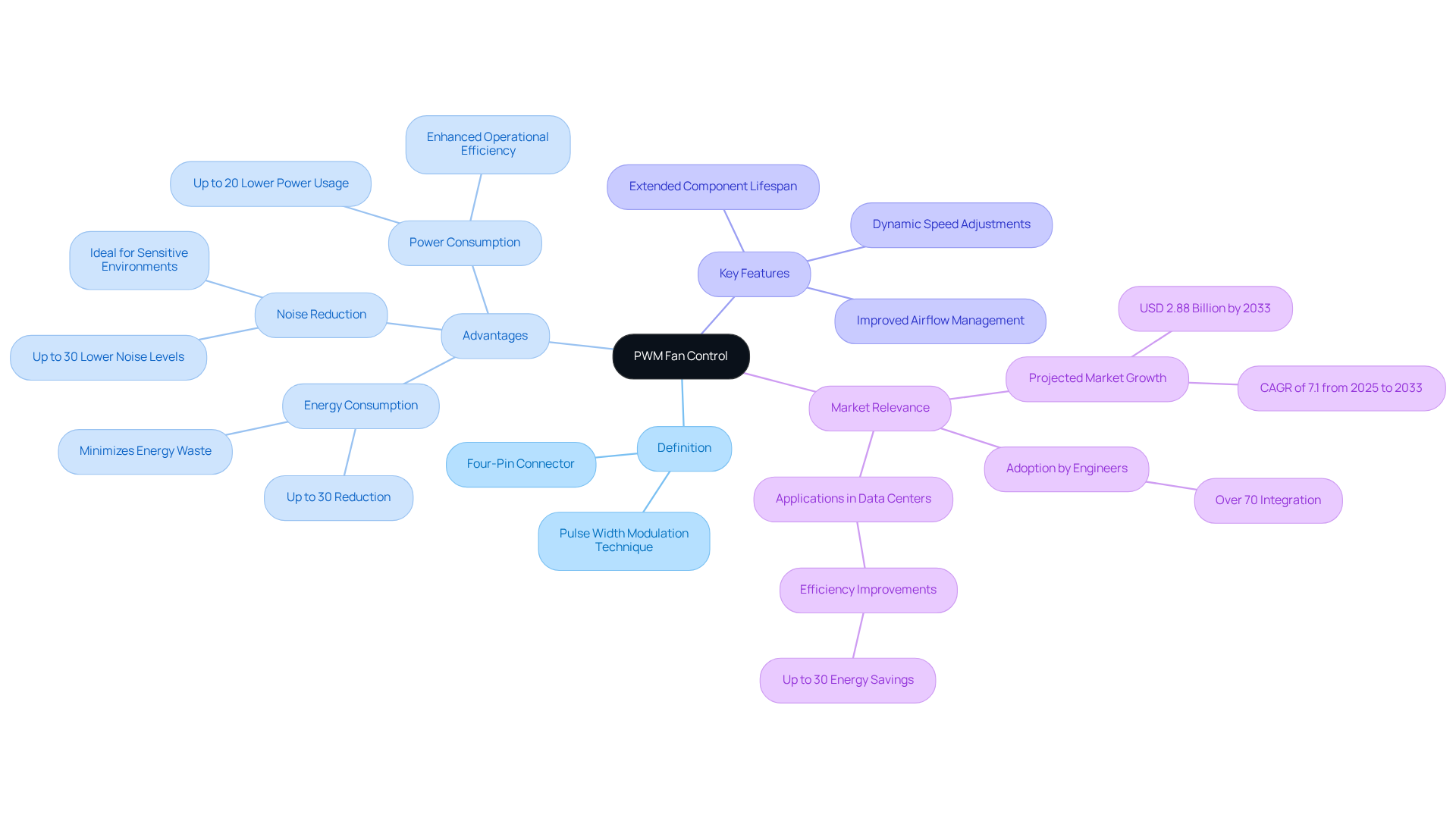

Fan PWM control, or Pulse Width Modulation fan regulation, is an essential method for adjusting fan velocity by modifying the width of electrical pulses sent to the fan motor. Unlike conventional blowers that operate at a steady voltage, PWM blowers utilize a signal that rapidly toggles power on and off, allowing for precise adjustments in rotation rate. This innovative approach significantly boosts efficiency and performance across a range of electronic applications. In fact, over 70% of electronics engineers are now incorporating PWM technology into their designs, underscoring its increasing relevance in the industry.

PWM devices are easily identifiable by their four-pin connector, with an additional pin dedicated to the PWM signal. This configuration facilitates fan PWM control for adjustable speed management tailored to thermal requirements or system specifications, making PWM units particularly effective in environments with fluctuating temperatures, such as data centers and gaming systems. Real-world applications have shown that data centers employing PWM technology can achieve energy efficiency improvements of up to 30%, highlighting the substantial benefits of this advanced cooling solution.

Key features of PWM fan control technology include:

- Minimizing energy consumption by up to 30% compared to traditional fan models.

- Reducing noise levels by as much as 30%.

- Lowering power consumption by up to 20% relative to conventional models.

These advantages position PWM devices as essential components in modern electronic systems, where effective thermal management is critical for maintaining optimal performance and extending the lifespan of components. Gagner-Toomey Associates offers a comprehensive range of PWM units, including DC input Tube Axial models and Centrifugal Blowers, available in sizes from 15 to 280mm, all optimized for performance, efficiency, and low noise. Additionally, most models come with IP protection available upon request. The global PWM fan controller market is projected to reach approximately USD 2.88 billion by 2033, further emphasizing the significance and necessity of PWM technology in the industry.

Context and Importance in Electronics

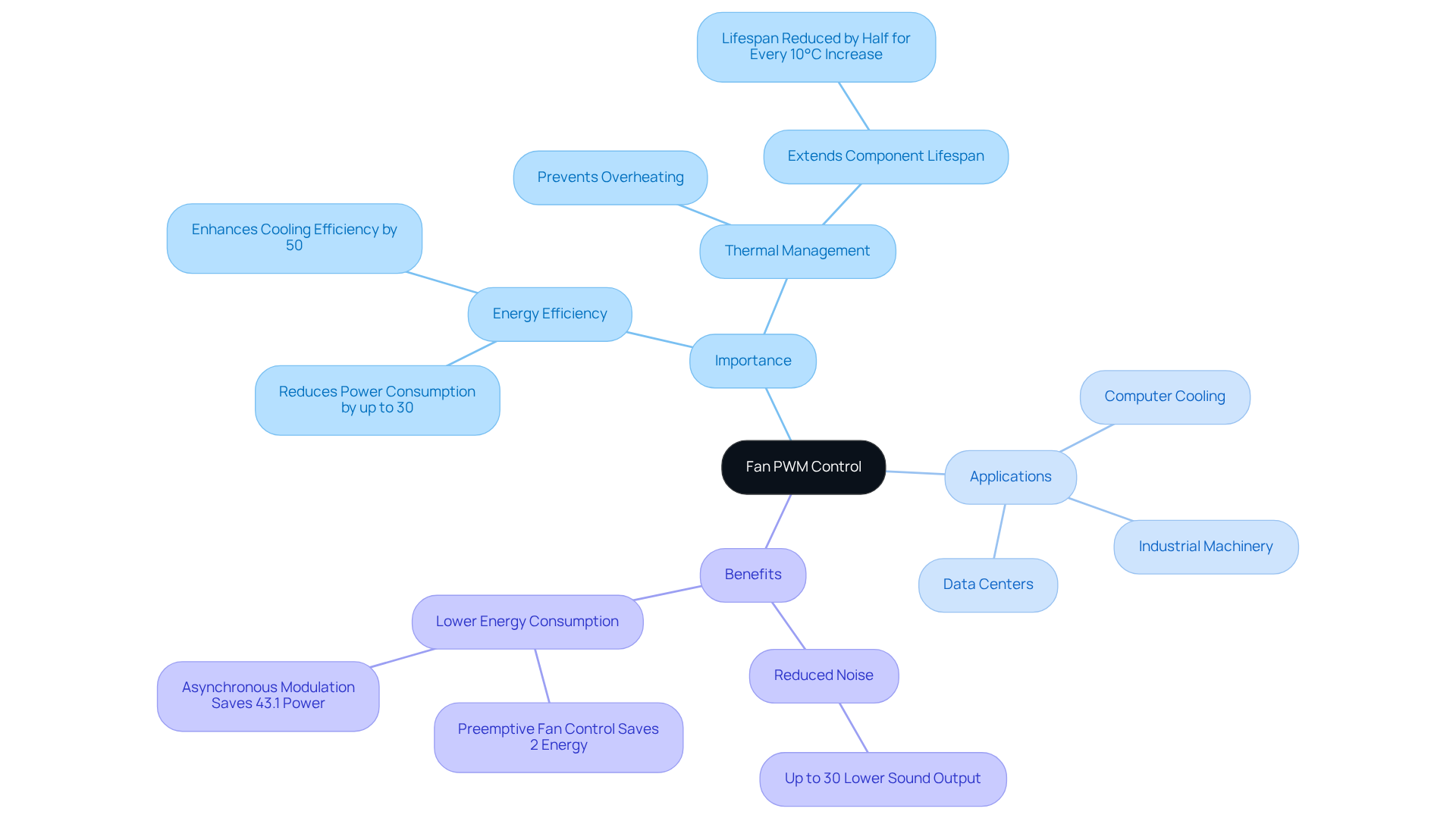

Fan PWM control has emerged as a critical component in the electronics sector, driven by the increasing demand for energy-efficient solutions. As electronic devices grow more compact and powerful, effective thermal management becomes essential to prevent overheating and ensure optimal performance. PWM blowers find extensive application in various scenarios, from computer cooling systems to industrial machinery, where precise temperature regulation is vital.

By utilizing fan PWM control to enable fans to operate at varying speeds based on real-time thermal conditions, PWM technology significantly enhances cooling efficiency. This adaptability not only reduces noise levels but also lowers energy consumption, making fan PWM control a preferred choice in modern electronic designs. Such features align seamlessly with the industry’s ongoing shift towards sustainability and efficiency, underscoring the importance of integrating PWM technology into modern applications.

Technical Characteristics and Operation

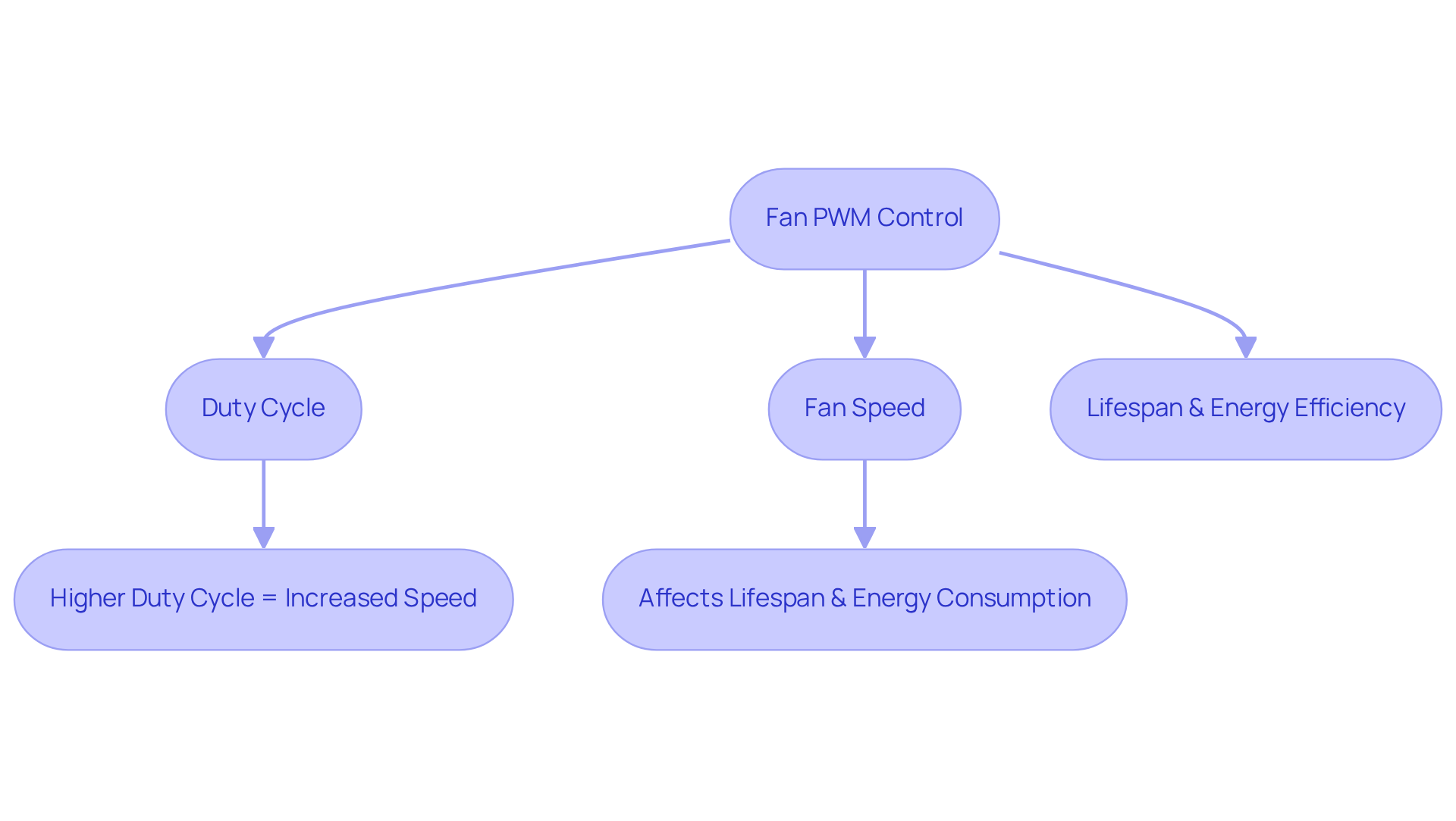

Fan PWM control is a sophisticated method that modulates pulse width to dictate how long the fan receives power during each cycle. Typically, the PWM signal frequency is set between 20 kHz and 25 kHz, a range that minimizes audible noise while ensuring effective operation. The duty cycle, which represents the ratio of ‘on’ time to the total cycle time, plays a crucial role in controlling fan rotation. A higher duty cycle leads to increased fan rotation, while a lower duty cycle results in decreased rotation. For instance, a 50% duty cycle effectively reduces the fan pace, illustrating the direct relationship between duty cycle and operational efficiency.

This precise regulating mechanism not only enables smooth transitions in fan speed but also significantly decreases wear on the motor, thereby prolonging its lifespan. Research indicates that systems utilizing fan PWM control can achieve lifespan enhancements of up to 50% compared to conventional fan management techniques. Furthermore, PWM units are adept at responding quickly to temperature changes, making them particularly suitable for scenarios that require rapid cooling adjustments.

The tachometer in PWM systems provides real-time feedback on actual fan speed (RPM), enhancing precision and ensuring optimal thermal management. Additionally, fan PWM control can reduce energy consumption by up to 50%, further underscoring its efficiency over traditional methods. This adaptability is vital in modern electronics, where effective thermal management is critical for performance and reliability.

Benefits of PWM Control in Fan Systems

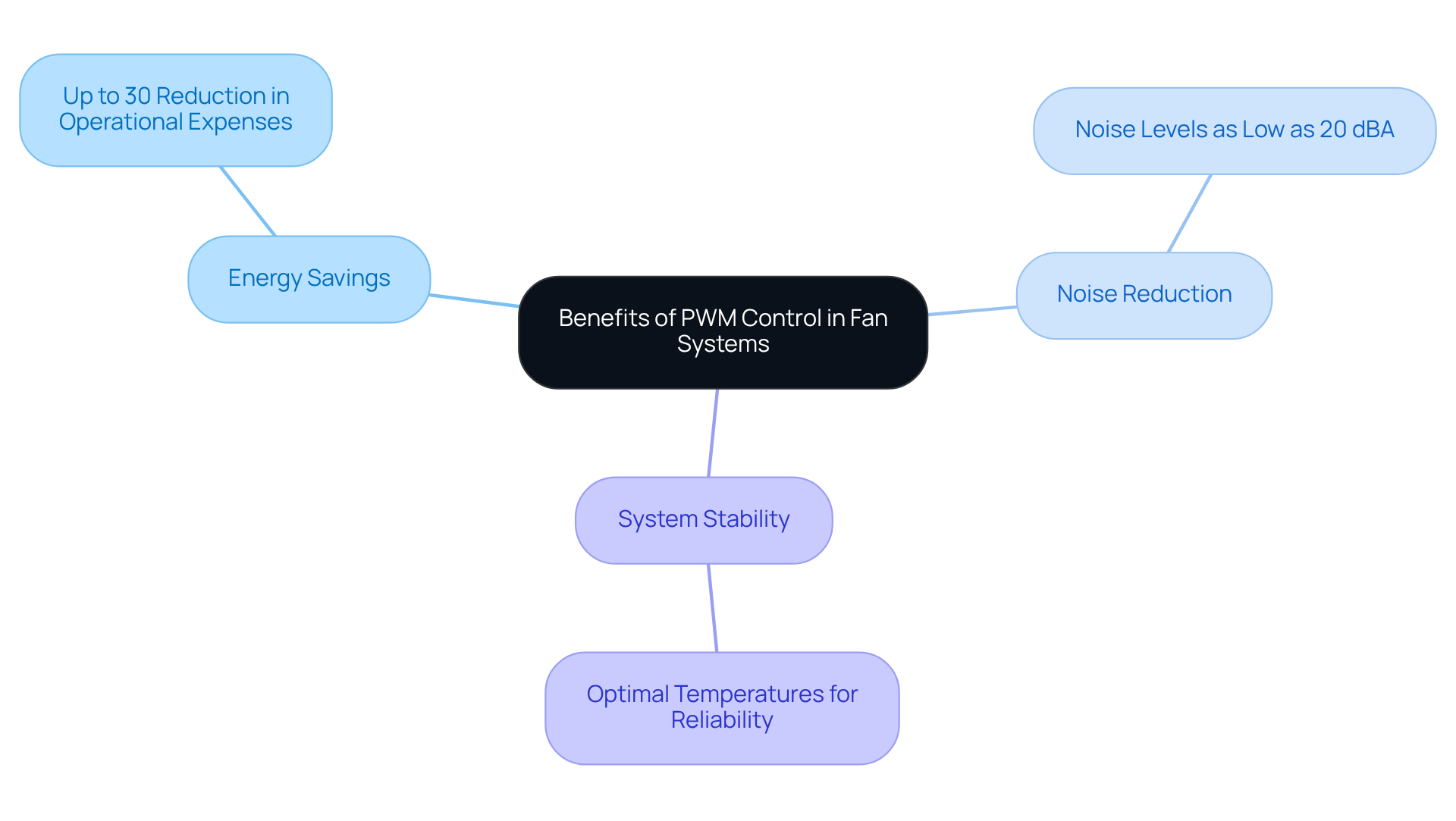

Fan PWM control in systems provides significant advantages that enhance both performance and efficiency. One of the most compelling benefits is the substantial energy savings achieved through dynamic adjustments based on thermal requirements. This capability can reduce operational expenses by up to 30%. Such adaptability not only conserves energy but also minimizes heat generation, fostering a more sustainable operation.

In terms of noise reduction, PWM units excel by operating at lower speeds when maximum cooling capacity isn’t necessary. This feature makes them ideal for noise-sensitive environments, such as home theaters and workplaces. For example, PWM fans can produce noise levels as low as 20 dBA, whereas traditional fans often exceed 30 dBA, thereby significantly improving acoustic comfort.

Furthermore, PWM technology enhances system stability by maintaining optimal temperatures, which is crucial for the reliability and longevity of electronic components. This aspect is particularly vital in high-performance computing and industrial applications, where precise airflow management is essential. The ability to fine-tune fan speeds ensures that cooling is both efficient and effective, preventing overheating and extending the lifespan of critical components.

In conclusion, the integration of fan PWM control in fan systems is essential for achieving superior energy efficiency, reduced noise levels, and enhanced operational stability. By embracing this technology, organizations can not only improve their operational performance but also contribute to a more sustainable future.

Conclusion

Fan PWM control stands as a significant leap forward in electronic cooling systems, enabling precise adjustments to fan speeds in response to real-time thermal conditions. This cutting-edge technology not only boosts energy efficiency but also plays a vital role in sustaining optimal performance and prolonging the lifespan of electronic components.

Key benefits of PWM fan control are substantial, including:

- Energy savings of up to 30%

- Reduced noise levels

- Enhanced operational stability

The capability to dynamically adjust fan speeds ensures effective cooling while minimizing unnecessary energy consumption and noise. This makes PWM fans the preferred choice across various applications, from data centers to home theaters.

Adopting fan PWM control transcends merely integrating a new technology; it signifies a commitment to a more sustainable and efficient future in electronics. As the demand for compact and powerful devices escalates, incorporating PWM technology becomes essential for achieving optimal thermal management, reducing environmental impact, and enhancing overall system performance. Organizations and engineers are urged to explore the advantages of PWM fan control to maintain a competitive edge in the rapidly evolving electronics landscape.

Frequently Asked Questions

What is PWM fan control?

PWM fan control, or Pulse Width Modulation fan regulation, is a method for adjusting fan speed by modifying the width of electrical pulses sent to the fan motor, allowing for precise adjustments in rotation rate.

How does PWM fan control differ from traditional fan models?

Unlike traditional fans that operate at a steady voltage, PWM fans use a signal that rapidly toggles power on and off, enhancing efficiency and performance in various electronic applications.

How can PWM technology improve energy efficiency?

Data centers using PWM technology can achieve energy efficiency improvements of up to 30%, significantly reducing energy consumption compared to traditional fan models.

What are the key features of PWM fan control technology?

Key features include minimizing energy consumption by up to 30%, reducing noise levels by as much as 30%, and lowering power consumption by up to 20% compared to conventional models.

What types of PWM units are available from Gagner-Toomey Associates?

Gagner-Toomey Associates offers a range of PWM units, including DC input Tube Axial models and Centrifugal Blowers, available in sizes from 15 to 280mm, optimized for performance, efficiency, and low noise.

What is the projected market value for PWM fan controllers by 2033?

The global PWM fan controller market is projected to reach approximately USD 2.88 billion by 2033, highlighting the growing importance of PWM technology in the industry.

How can PWM fan control benefit environments with fluctuating temperatures?

PWM fan control is particularly effective in environments with fluctuating temperatures, such as data centers and gaming systems, allowing for adjustable speed management tailored to thermal requirements.