Introduction

Mastering the complexities of thermoelectric cooling is crucial for engineers aiming to elevate CPU system performance. By harnessing the Peltier Effect alongside cutting-edge thermoelectric materials, engineers can achieve remarkable enhancements in cooling efficiency. Yet, the path to optimal performance is not without its hurdles. From ensuring effective heat dissipation to selecting the appropriate components, engineers face numerous challenges.

How can they effectively navigate these complexities to fully realize the potential of thermoelectric coolers in demanding applications?

Understand the Peltier Effect in Thermoelectric Cooling

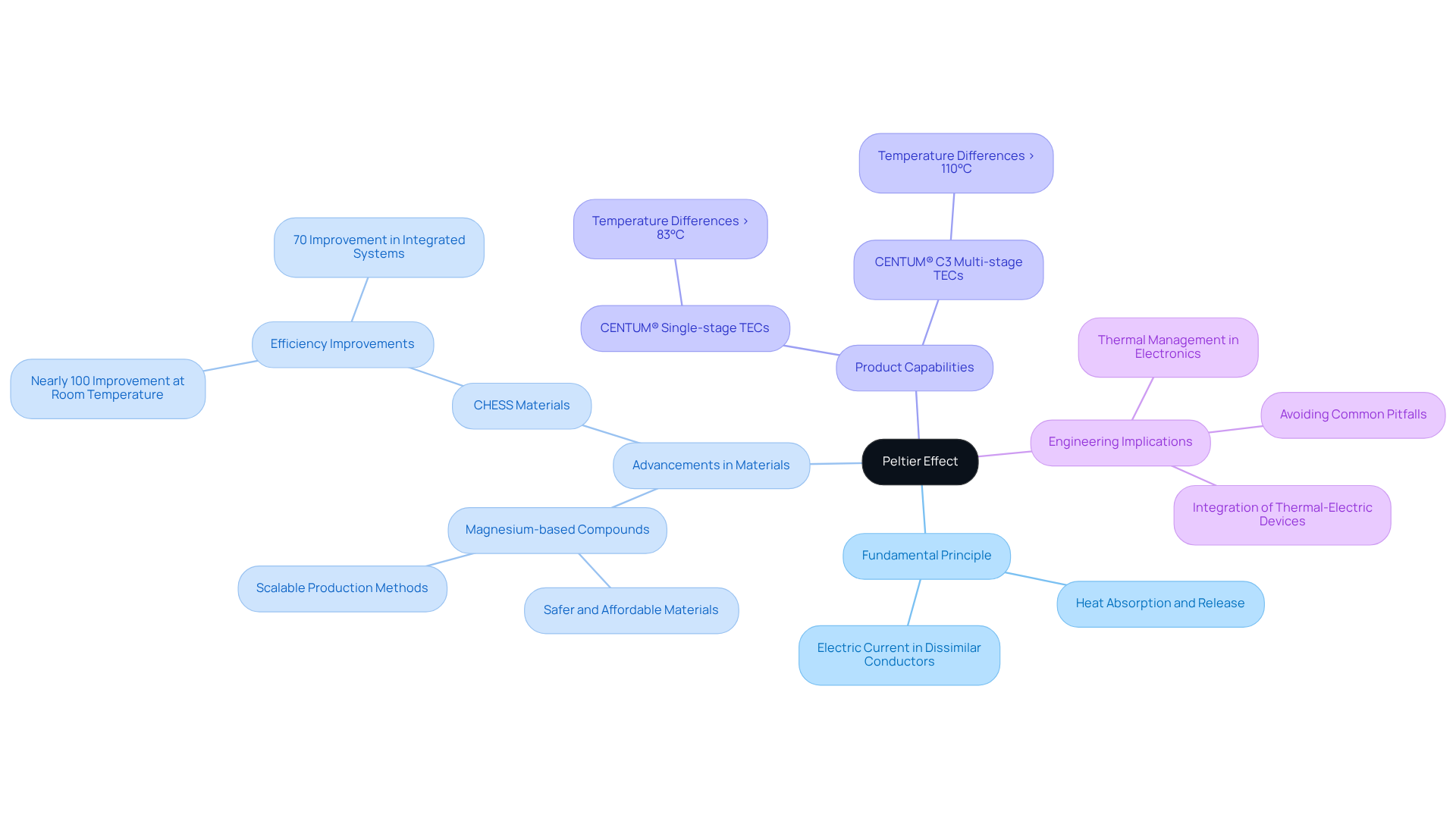

The Peltier Effect represents a fundamental phenomenon where an electric current traversing a junction of two dissimilar conductors leads to heat absorption on one side and heat release on the other. This principle is pivotal in temperature-regulating technology, significantly influencing the design and efficiency of refrigeration systems. Engineers and designers must grasp this effect to enhance thermoelectric coolers (TECs) effectively.

Recent advancements in temperature-regulating materials, including magnesium-based compounds and CHESS materials, have shown remarkable potential in improving heat dissipation performance. For instance, CHESS materials have achieved nearly 100% improvement in efficiency over traditional thermoelectric materials at room temperature, substantially boosting the coefficient of performance (COP) of TECs.

Gagner-Toomey Associates offers an extensive selection of innovative cooling solutions. Their CENTUM® Single-stage TECs can achieve temperature differences exceeding 83°C, while CENTUM® C3 Multi-stage TECs can surpass 110°C. These capabilities make them ideal for demanding heat management applications, such as those involving a thermoelectric cooler cpu for CPU cooling.

By mastering the Peltier Effect and utilizing high-efficiency materials, engineers can design systems that maximize thermal management capabilities in electronics, ensuring optimal performance and reliability. Furthermore, careful selection and integration of thermal-electric devices are crucial for efficient operation, enabling engineers to avoid common pitfalls in real-world applications.

Implement Effective Thermoelectric Cooler Operation Techniques

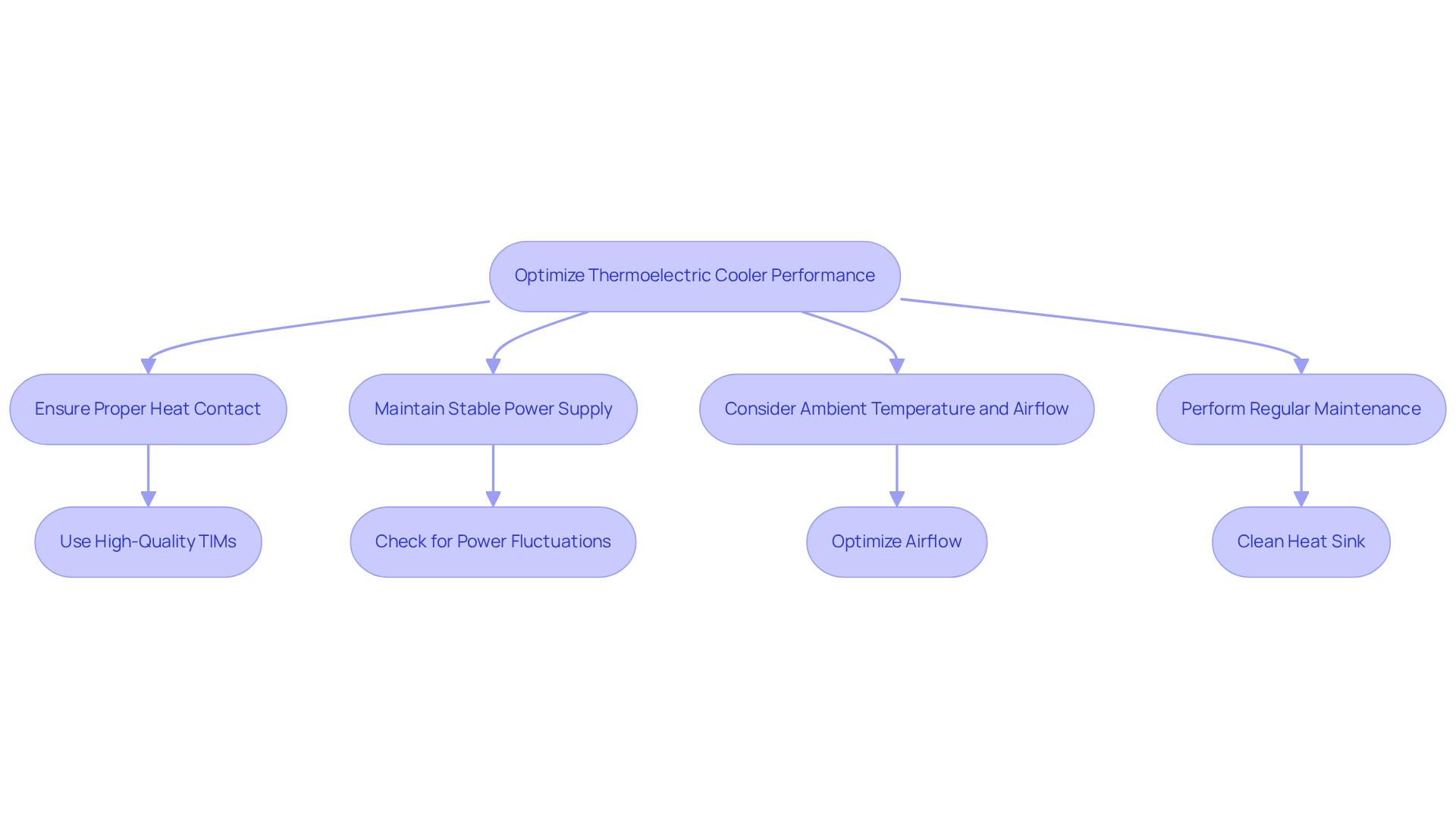

To achieve optimal performance from a thermoelectric cooler CPU, it is crucial to implement several operational techniques. First, ensure proper heat contact between the heat sink and the thermoelectric cooler CPU. This can be accomplished by utilizing high-quality thermal interface materials (TIMs) that effectively minimize thermal resistance. Moreover, a stable power supply is essential for the thermoelectric cooler CPU; fluctuations can lead to inefficiencies and compromised temperature control. Engineers must also consider the ambient temperature and airflow around the thermoelectric cooler CPU, as these factors significantly influence its performance. For example, a study demonstrated that incorporating a dual-thermoelectric-liquid hybrid system can enhance temperature reduction effectiveness by optimizing energy transfer. Finally, regular maintenance, such as cleaning the heat sink and ensuring unobstructed airflow, can further enhance the effectiveness of the thermoelectric cooler CPU.

Evaluate Performance Metrics for Optimal Cooler Selection

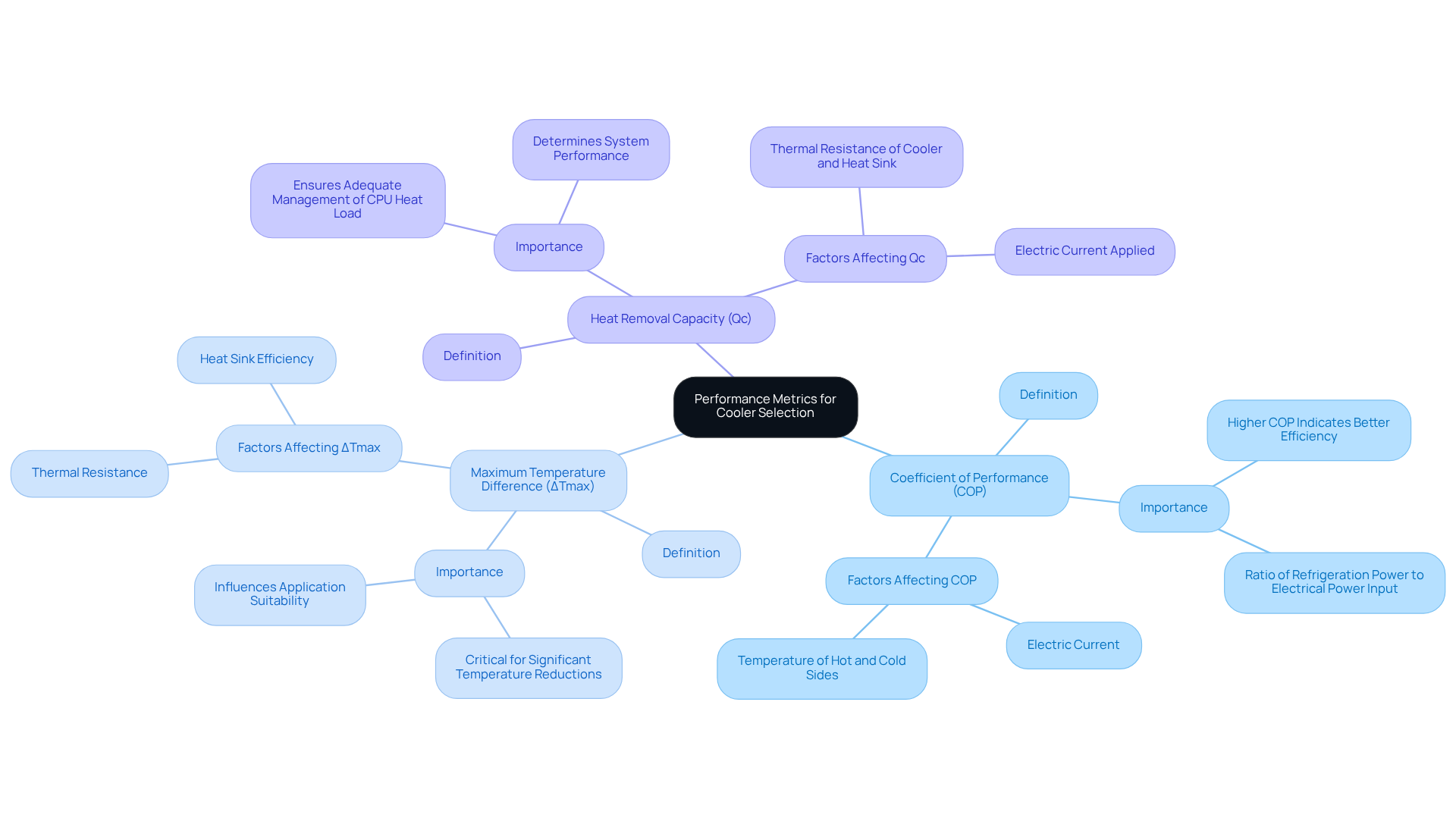

Selecting an efficient thermoelectric cooler (TEC) necessitates a thorough evaluation of critical performance indicators, including the coefficient of performance (COP), maximum temperature difference (ΔTmax), and heat removal capacity (Qc). The COP, which is the ratio of refrigeration power to electrical power input, stands as a vital measure of the cooler’s efficiency; a higher COP signifies superior performance. As Diana Enescu aptly points out, “The thermoelectric figure of merit indicates if a material is a good thermoelectric cooler,” emphasizing the necessity of assessing the COP during the selection process.

ΔTmax plays a crucial role, as it represents the maximum temperature difference achievable by the TEC, particularly important for applications demanding significant temperature reductions. Additionally, understanding the cooling capacity is essential to ensure that the TEC can adequately manage the CPU’s heat load. Engineers must also consider the thermal resistance of both the cooler and the heat sink, as these elements greatly impact overall system performance. Enescu further highlights that “the quality of a cooler depends on parameters such as the electric current applied at the couple of N-type and P-type thermoelements,” underscoring the importance of these metrics.

By systematically evaluating these performance indicators, engineers can make informed decisions that enhance cooling solutions, ensuring optimal operation in challenging environments.

Address Challenges in Thermoelectric Cooler Integration

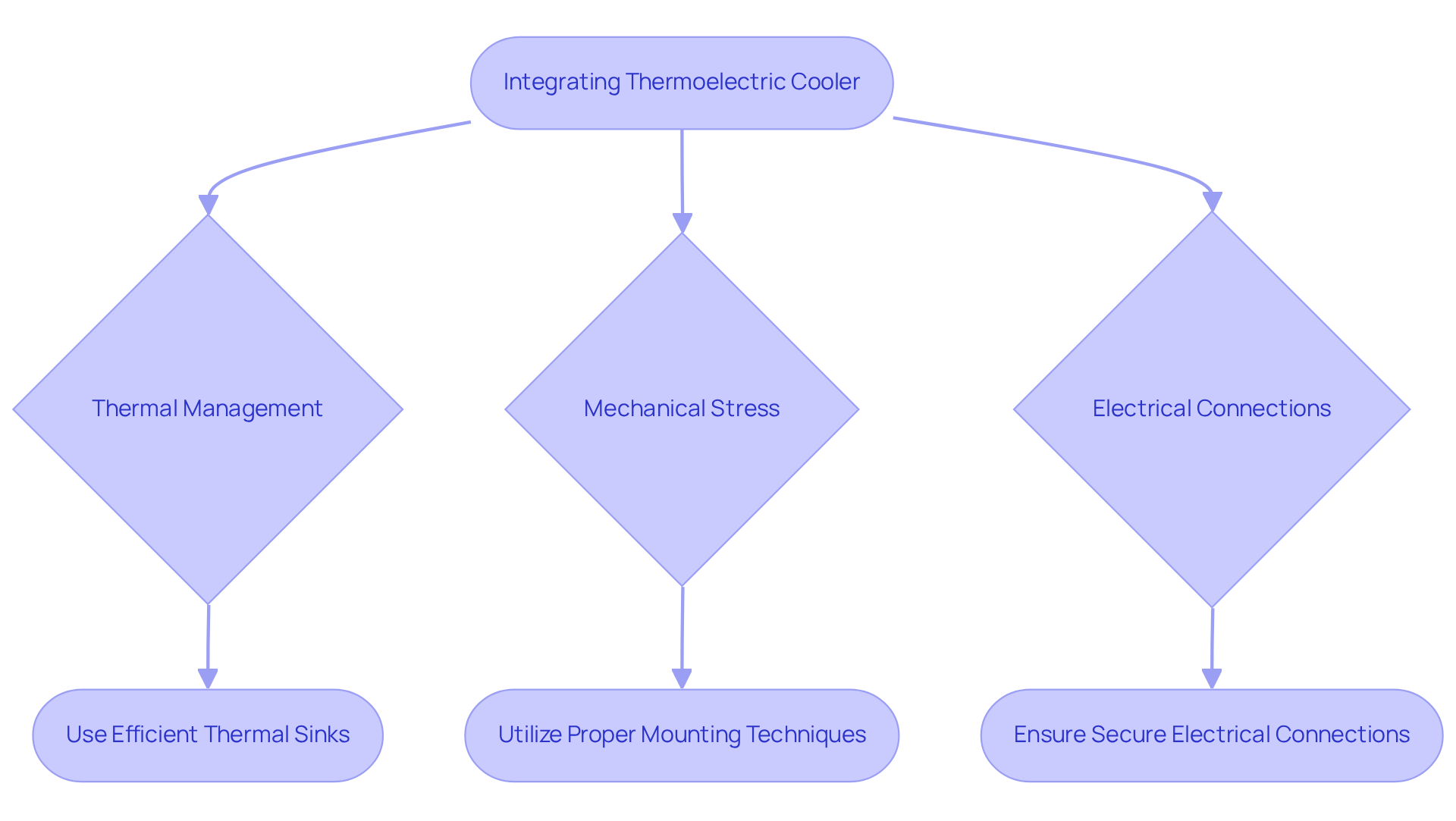

Integrating a thermoelectric cooler CPU into electronic systems presents significant challenges, particularly in thermal management, mechanical stress, and electrical connections. A primary concern is ensuring effective temperature dissipation from the hot side of the TEC. To address this, employing efficient thermal sinks is crucial, as they can significantly enhance temperature rejection. Inadequate temperature removal can lead to a performance decline of up to 30%. Additionally, engineers should consider integrating fans to further boost airflow and improve temperature regulation efficiency.

Mechanical stress during installation can jeopardize the integrity of the TEC. Therefore, it is essential to utilize proper mounting techniques and materials that minimize this risk. For instance, using interface materials (TIMs) with optimal conductivity can enhance heat transfer while ensuring mechanical stability. Furthermore, electrical connections must be secure and capable of handling the current load without overheating, as failures in this area can result in system malfunctions.

Regular monitoring and maintenance of the temperature regulation system are vital for identifying and addressing potential issues before they escalate into significant failures. A TEC-based battery thermal management system, for example, has proven effective in maintaining a 100 Ah battery pack temperature below 40 °C, showcasing the benefits of integrating a thermoelectric cooler CPU in proactive thermal management strategies. By tackling these challenges directly, engineers can significantly enhance the longevity and effectiveness of their thermoelectric cooling solutions, ensuring optimal performance in demanding applications.

Conclusion

Mastering thermoelectric cooling techniques is crucial for optimizing CPU performance, as it leverages the Peltier Effect to regulate temperature effectively. Understanding and applying these principles allows engineers to enhance the efficiency and reliability of thermoelectric coolers (TECs), ensuring they meet the demanding needs of modern electronic systems.

Key insights from this discussion underscore the significance of:

- Selecting high-efficiency materials

- Implementing effective operational techniques

- Evaluating critical performance metrics

Ensuring proper thermal contact, maintaining a stable power supply, and addressing integration challenges are vital in maximizing the performance of thermoelectric cooler CPUs. Recent advancements in materials and technology, such as CHESS compounds, significantly contribute to achieving superior cooling capabilities.

Ultimately, the successful application of thermoelectric cooling relies on a proactive approach to design, implementation, and maintenance. By prioritizing these best practices, engineers can not only overcome integration challenges but also fully harness the potential of thermoelectric coolers across various applications. Embracing these strategies will pave the way for enhanced thermal management solutions, ensuring optimal performance in increasingly complex electronic environments.

Frequently Asked Questions

What is the Peltier Effect?

The Peltier Effect is a phenomenon where an electric current passing through a junction of two different conductors results in heat absorption on one side and heat release on the other. This effect is essential for temperature-regulating technology, particularly in refrigeration systems.

Why is the Peltier Effect important for engineers and designers?

Understanding the Peltier Effect is crucial for engineers and designers as it allows them to enhance the efficiency and design of thermoelectric coolers (TECs), which are vital for effective thermal management in various applications.

What advancements have been made in thermoelectric materials?

Recent advancements include the development of magnesium-based compounds and CHESS materials, which have shown significant improvements in heat dissipation performance, with CHESS materials achieving nearly 100% efficiency improvement over traditional thermoelectric materials at room temperature.

What are the capabilities of Gagner-Toomey Associates’ TECs?

Gagner-Toomey Associates offers CENTUM® Single-stage TECs that can achieve temperature differences exceeding 83°C, and CENTUM® C3 Multi-stage TECs that can surpass 110°C, making them suitable for demanding heat management applications.

How does mastering the Peltier Effect benefit thermal management in electronics?

By mastering the Peltier Effect and using high-efficiency materials, engineers can design systems that optimize thermal management capabilities, ensuring better performance and reliability in electronic devices.

What is crucial for the efficient operation of thermoelectric devices?

The careful selection and integration of thermal-electric devices are crucial for efficient operation, helping engineers avoid common pitfalls in real-world applications.