Introduction

Understanding the dynamics of cooling systems is crucial for engineers aiming to optimize PC performance. The ongoing debate between static pressure and airflow in fans presents a significant opportunity to enhance thermal management, especially in high-density setups. However, the challenge lies in identifying which fan type is best suited for specific applications, as each offers distinct advantages and limitations. This article explores the intricacies of static pressure versus airflow, providing engineers with the insights necessary to make informed decisions regarding their cooling solutions.

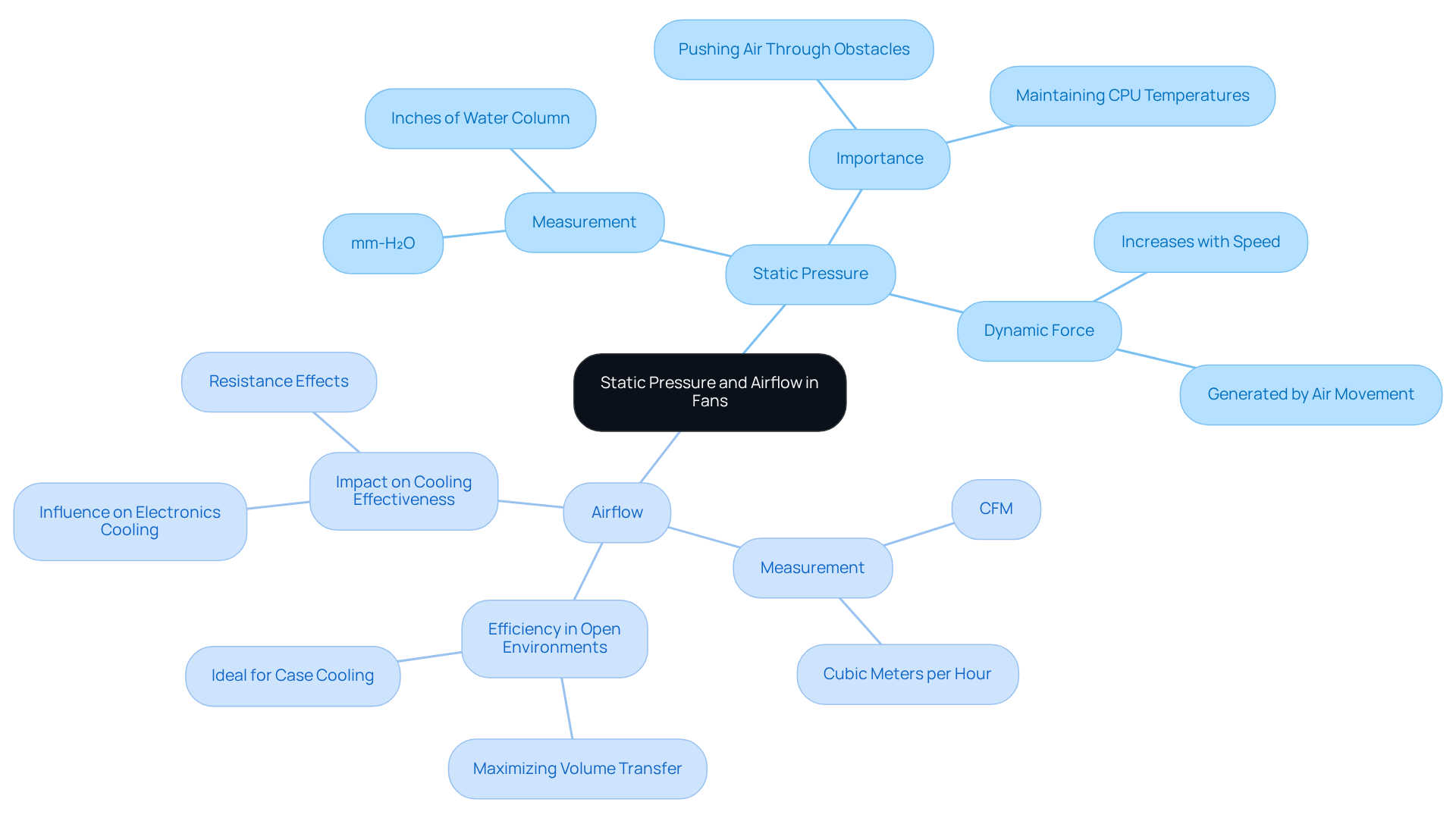

Define Static Pressure and Airflow in Fans

Static force represents the exertion by air within a system, measured in mm-H₂O or inches of water column. This metric is crucial as it reflects a fan’s capability to push air through obstacles such as filters, radiators, or confined spaces, highlighting the importance of understanding pc fans static pressure vs airflow. Conversely, the movement of air indicates the volume a fan can transfer, typically quantified in cubic feet per minute (CFM). Airflow devices are engineered to maximize this volume in open environments. In contrast, non-moving airflow units, like those offered by Gagner-Toomey Associates, are specifically designed to sustain airflow against resistance.

For instance, static airflow devices can maintain CPU temperatures 3 degrees Celsius lower than standard ventilation units in radiator configurations, underscoring their efficiency in high-resistance situations. Gagner-Toomey stands out as the world’s largest manufacturer of standard and custom air-movers, boasting a comprehensive portfolio of DC input Tube Axial fans ranging from 15 to 280mm and Centrifugal Blowers from 15 to 225mm. These products are optimized for performance and efficiency across various applications, including Automotive, Telecom, and Industrial sectors.

Moreover, dynamic force, generated by the movement of air and increasing with speed, plays a vital role in fluid dynamics. Understanding the relationship between fixed force, air movement, and dynamic force is essential for engineers when evaluating pc fans static pressure vs airflow to select the appropriate fan for specific applications. Both metrics significantly influence cooling effectiveness in electronics. It’s also important to recognize that air movement can decrease considerably, while energy consumption tends to surge when resistance approaches 0.9 inches w.g. This highlights the practical consequences of resistance in fan choice, emphasizing the need for informed decision-making in engineering applications.

Compare Characteristics of Static Pressure and Airflow Fans

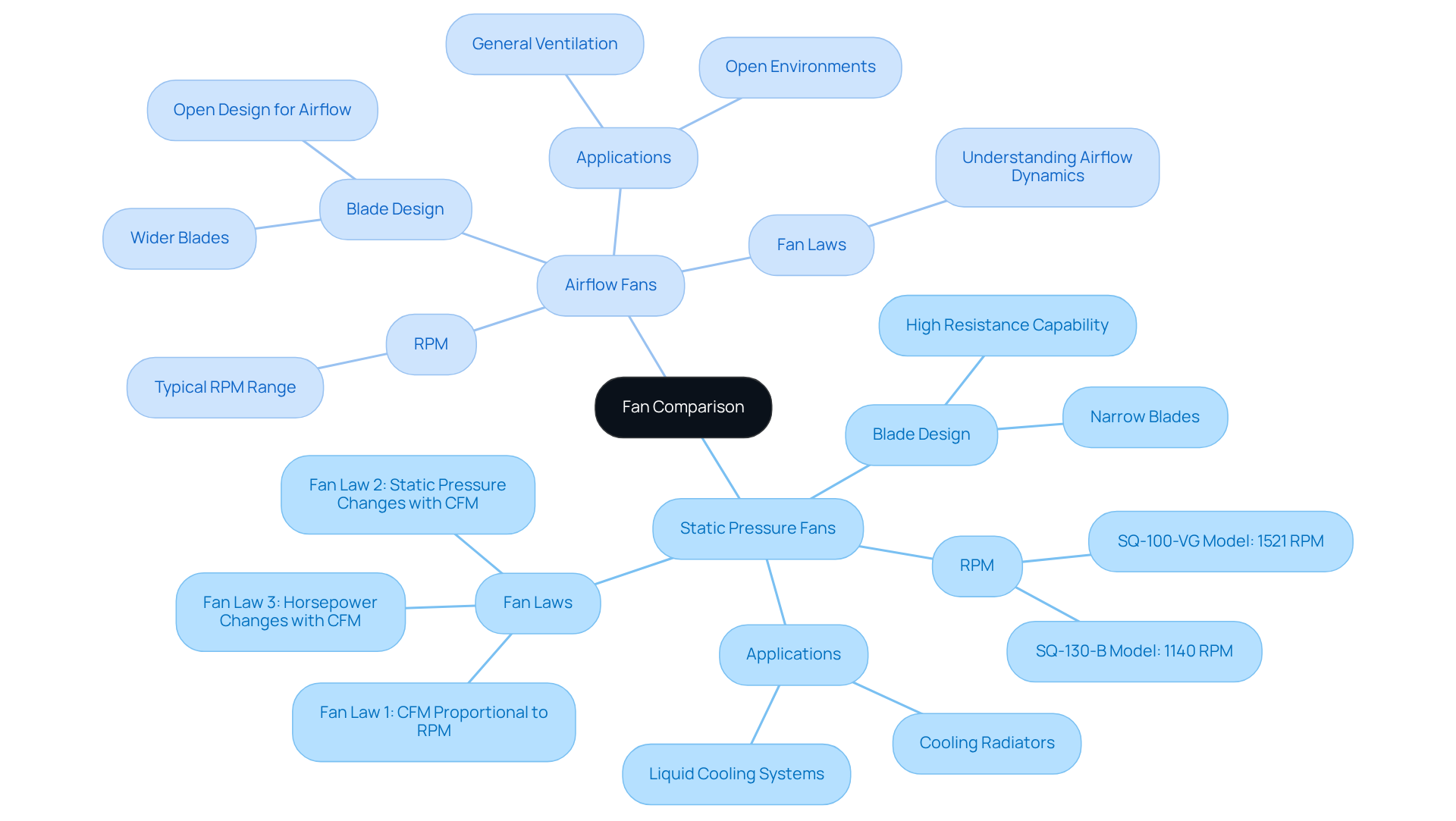

Static airflow devices are engineered with blades that generate substantial force, enabling efficient air movement through dense barriers such as filters and heatsinks. Take, for instance, the SQ-100-VG model, which operates at 1521 RPM. This elevated RPM is characteristic of static pressure devices, crucial for maintaining circulation in confined spaces.

In contrast, ventilators feature wider blades designed to move large volumes of air with minimal resistance, making them ideal for open environments. Airflow devices typically exceed 100 CFM for air circulation, underscoring their efficiency in unrestricted settings. While fixed airflow devices excel in applications like cooling radiators, airflow machines shine in general ventilation scenarios where air can circulate freely.

As Tim De Stasio, an HVAC and building performance consultant, points out, grasping these distinctions is vital for engineers when selecting the right fan type for specific cooling requirements. Furthermore, consider Fan Law 1, which states that CFM varies proportionally with RPM, and Fan Law 2, which indicates that the force changes with the square of CFM. These principles illustrate the performance dynamics between devices and ventilators, particularly regarding pc fans static pressure vs airflow, guiding informed decisions in fan selection.

Evaluate Pros and Cons of Each Fan Type

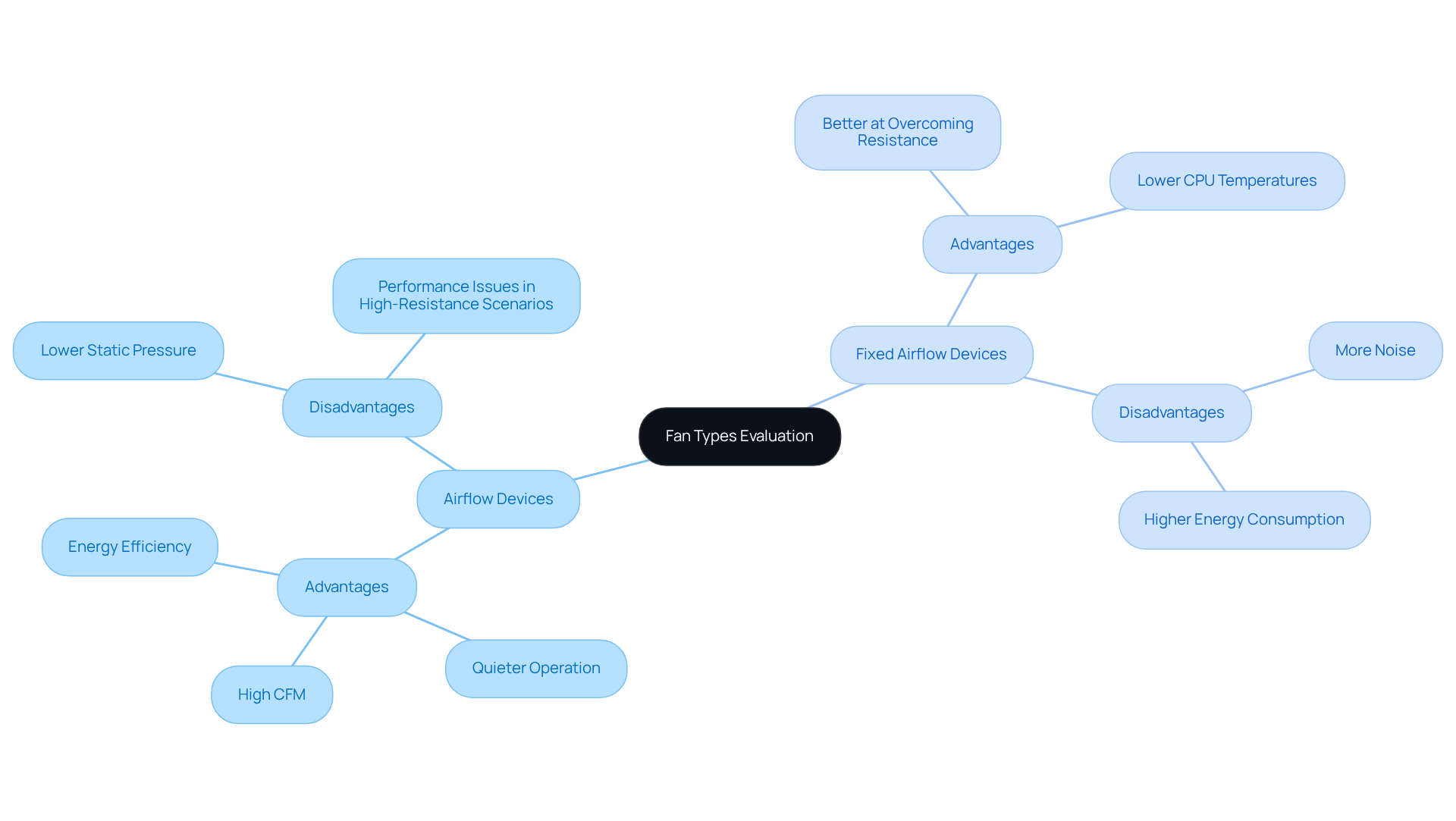

Airflow devices are designed to transport significant amounts of air efficiently, making them particularly advantageous in open cases where unrestricted circulation is possible. Typically exceeding 100 CFM, these devices facilitate swift air movement, enhancing overall system ventilation. Their quieter operation and energy efficiency are notable benefits, especially in environments where noise reduction is crucial. However, it’s important to note that in the context of PC fans static pressure vs airflow, ventilation devices generally have lower resistance ratings, around 1.0 inH2O. This limitation can hinder their performance in high-resistance scenarios, such as moving air through dense components like radiators or CPU coolers, potentially leading to overheating in tightly packed systems.

In contrast, fixed airflow devices excel at overcoming resistance, which is a key consideration in the discussion of PC fans static pressure vs airflow, making them ideal for setups that include radiators or filters. They maintain CPU temperatures approximately 3 degrees Celsius lower than airflow devices in radiator configurations, highlighting the advantages of PC fans static pressure vs airflow due to their ability to generate greater force ratings, typically around 3.0 inH2O. However, this enhanced performance comes at a cost; fixed airflow devices often produce more noise and consume more energy due to their design.

Real-world examples illustrate these dynamics effectively. In a recent case study, users reported significant improvements in thermal management after upgrading to static pressure units, which emphasizes the relevance of PC fans static pressure vs airflow in systems with dense heatsinks. Conversely, ventilation devices have proven effective in configurations where components are distributed, allowing for optimal cooling without excessive noise. Engineers must carefully consider these factors, weighing the specific layout and cooling demands of their systems to select the most suitable fan type.

Guide Selection of Fans Based on PC Building Needs

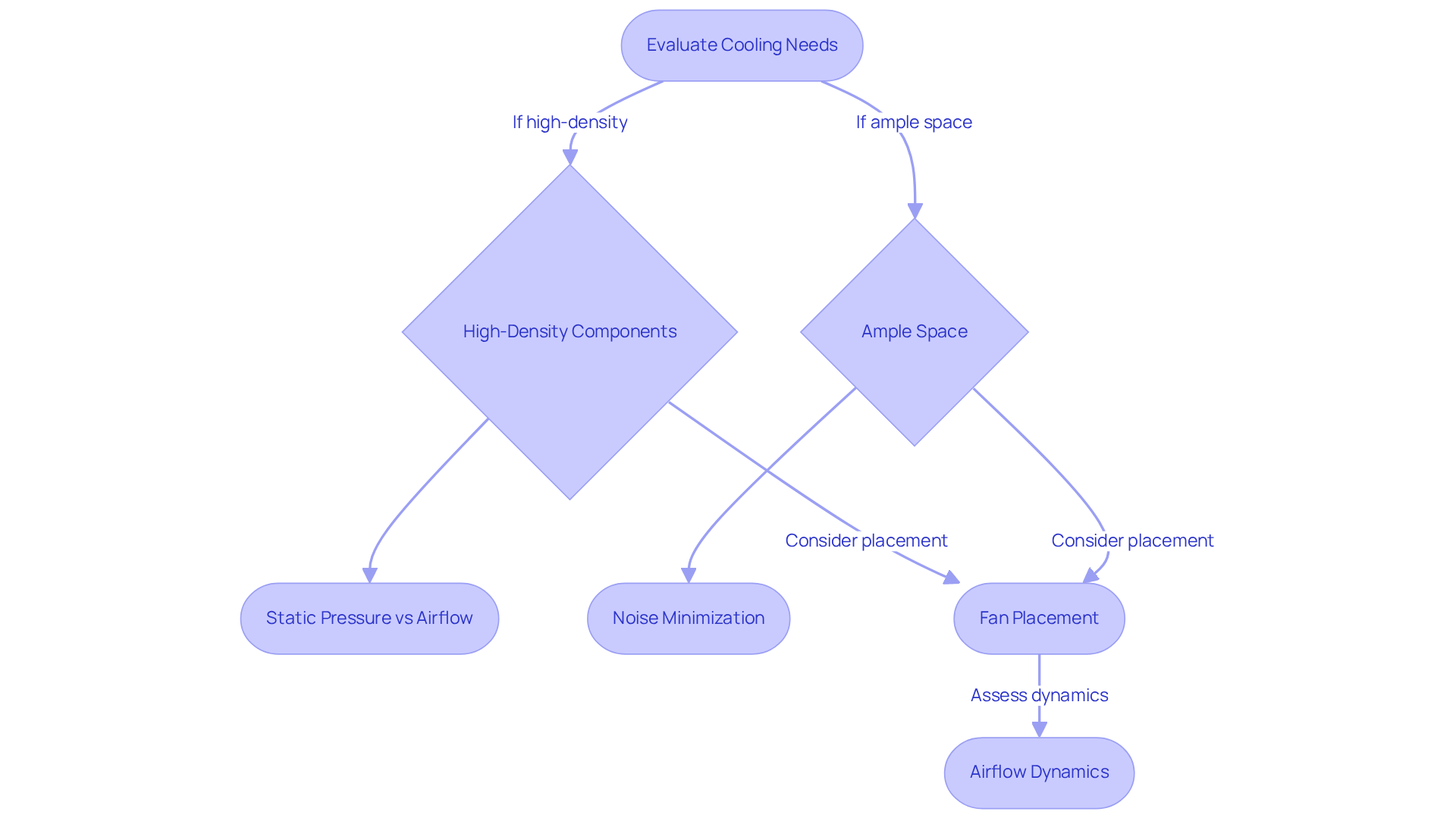

When selecting airflow devices for PC builds, engineers must consider the specific cooling requirements of their components. For systems featuring high-density components, such as liquid cooling configurations, understanding PC fans static pressure vs airflow is essential to ensure adequate circulation through radiators. Conversely, in scenarios with ample space and fewer obstructions, ventilation devices can provide effective cooling while minimizing noise. Typically, intake ventilators are positioned at the front or bottom of the case, while exhaust ventilators are located at the rear and top. This strategic placement is essential for optimizing air movement dynamics within the case.

Moreover, engineers should assess the overall airflow dynamics within the case, balancing intake and exhaust systems to create an optimal cooling environment. A common recommendation is to maintain a ratio of slightly more intake devices than exhaust, generally around 2:1 or 3:2. This positive airflow configuration helps reduce dust accumulation and enhances overall system efficiency.

Understanding the distinct characteristics of fan types, including the differences in PC fans static pressure vs airflow, is crucial. For instance, when evaluating PC fans static pressure vs airflow, stationary airflow devices are designed to overcome resistance in confined spaces, making them suitable for high-density setups. In contrast, airflow devices excel in open environments where air can circulate freely. By analyzing the specific cooling needs of components, such as overclocked CPUs and GPUs, engineers can make informed decisions that significantly enhance system performance.

Real-world examples illustrate the effectiveness of fixed airflow devices in high-density configurations, especially when analyzing PC fans static pressure vs airflow. For example, in a mid-tower case equipped with liquid cooling, the discussion of PC fans static pressure vs airflow highlights how employing static pressure units can improve cooling efficiency, ensuring that critical components remain within optimal temperature ranges. The T-FORCE RT-X120 ARGB fan, featuring a long-life sleeve bearing, operates at a noise level of 36.9 dB(A) while delivering an impressive airflow of 71.12 CFM at a rotational speed of 2500 RPM, exemplifying the balance between performance and noise management.

Additionally, it is vital to consider the lifespan of fan bearings, with sleeve bearings typically lasting around 30,000 hours and long-life sleeve bearings reaching up to 50,000 hours. This information aids engineers in selecting devices that not only meet performance standards but also offer durability. Regular maintenance, including cleaning fan filters and the case interior, is essential to sustain airflow and prevent dust buildup, thereby ensuring optimal cooling performance.

In conclusion, engineers should meticulously evaluate their cooling needs and the specific characteristics of fans to choose the most appropriate options for their PC builds, ultimately leading to enhanced performance and longevity.

Conclusion

Understanding the nuances between static pressure and airflow in PC fans is crucial for engineers aiming to optimize cooling solutions. The choice between these two types of fans can significantly impact system performance, particularly in environments where space and resistance are key considerations. By grasping the distinction between static pressure, which excels in overcoming resistance, and airflow, designed for volume movement, engineers can make informed decisions that enhance their builds.

The essential characteristics of both fan types reveal that static pressure devices are suited for high-density applications, such as liquid cooling systems, while airflow fans thrive in open environments. Key insights include the importance of fan RPM, noise levels, and energy consumption, along with practical implications of selecting the right fan based on specific cooling needs. Real-world examples illustrate how understanding these dynamics leads to improved thermal management and system longevity.

Ultimately, the significance of choosing the right fan type cannot be overstated. Engineers must assess their unique cooling requirements carefully, considering factors such as component layout and airflow dynamics. By doing so, they can ensure optimal performance and efficiency in their PC builds, paving the way for enhanced system reliability and longevity.

Frequently Asked Questions

What is static pressure in fans?

Static pressure represents the exertion by air within a system, measured in mm-H₂O or inches of water column. It reflects a fan’s capability to push air through obstacles such as filters or radiators.

How is airflow measured in fans?

Airflow is the movement of air that indicates the volume a fan can transfer, typically quantified in cubic feet per minute (CFM).

What is the difference between static pressure and airflow in fans?

Static pressure measures a fan’s ability to push air through obstacles, while airflow measures the volume of air a fan can move, often optimized for open environments.

How do static airflow devices perform compared to standard ventilation units?

Static airflow devices can maintain CPU temperatures 3 degrees Celsius lower than standard ventilation units in radiator configurations, demonstrating their efficiency in high-resistance situations.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest manufacturer of standard and custom air-movers, offering a range of DC input Tube Axial fans and Centrifugal Blowers optimized for performance and efficiency across various applications.

What role does dynamic force play in fluid dynamics?

Dynamic force, generated by the movement of air and increasing with speed, is crucial in fluid dynamics and helps engineers evaluate the relationship between static pressure and airflow in fan selection.

Why is understanding resistance important when choosing fans?

Understanding resistance is important because air movement can decrease significantly while energy consumption tends to increase when resistance approaches 0.9 inches w.g., affecting cooling effectiveness in electronics.