Overview

The fundamental distinctions between axial and centrifugal fans stem from their design principles and specific applications. Axial fans are particularly adept at facilitating high-volume, low-pressure airflow, making them ideal for certain environments. In contrast, centrifugal fans are engineered to generate high pressure, which is crucial for systems that require airflow against resistance.

This differentiation is underscored by a comprehensive analysis of each fan type’s strengths and limitations, which highlights their respective efficiencies, noise levels, and optimal use cases across various industries.

Introduction

In the dynamic realm of air movement technology, discerning the distinctions between axial and centrifugal fans is crucial for optimizing performance across diverse applications. Axial fans, characterized by their lightweight design and high-volume airflow capabilities, excel in scenarios demanding efficient cooling and ventilation. In contrast, centrifugal fans thrive in high-pressure environments, delivering robust airflow against resistance, rendering them indispensable in industrial contexts.

As technological advancements continue to unfold, the necessity for clarity regarding the most suitable fan type for specific operational demands becomes increasingly apparent. This article explores the key characteristics, applications, and performance metrics of both fan types, offering valuable insights for engineers and decision-makers alike.

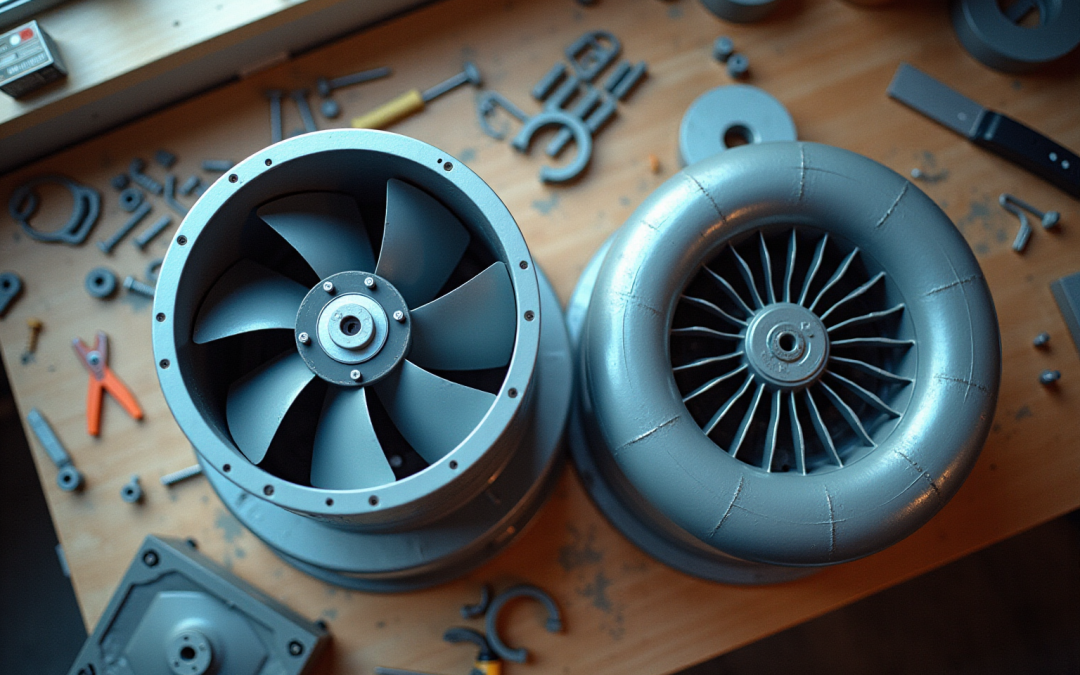

Define Axial and Centrifugal Fans: Key Characteristics and Design Principles

Axial blowers are engineered to move air parallel to their axis, featuring blades that rotate around a central hub. This design generates a low-pressure wind current, making them exceptionally effective for high-volume applications. Their lightweight and compact nature facilitates seamless integration into space-constrained environments. In contrast, radial blowers function by drawing air into their center and expelling it at a right angle through a scroll casing, resulting in enhanced pressure production. This capability renders for applications that require robust airflow against resistance, such as ducted HVAC systems.

Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, offers an extensive range of DC input tube axial devices (sizes from 15 – 280mm) and blowers (sizes from 15 – 225mm), optimized for performance and efficiency across diverse applications, including electronics and automotive sectors. Recent advancements in axial blower technology have markedly improved their efficiency and versatility, with energy savings for conventional models ranging from 28.96% to 34.93%. Meanwhile, centrifugal blowers are increasingly favored in scenarios necessitating higher pressure due to their superior design and efficiency. For example, tube-axial blowers, a subtype of axial devices, excel in medium-pressure, high airflow rate applications, effectively mitigating duct losses and enhancing ventilation performance. A case study titled “Tube-Axial Fan Applications” illustrates that tube-axial devices yield higher pressures and superior efficiencies compared to propeller models, making them well-suited for ducted HVAC installations.

Moreover, Purushothama observes that “FRP devices fabricated by compression moulding/resin transfer moulding technique would have uniform dimensions and consistent quality and lower flow noise and mechanical noise levels compared to the conventional metallic counterparts.” This underscores the significance of fan construction in influencing performance and noise levels.

Key Differences Between Axial and Centrifugal Fans:

-

- Strengths: High-volume airflow, lightweight, compact design, efficient for low-pressure applications.

- Limitations: Less effective in high-pressure scenarios.

-

Centrifugal Fans:

- Strengths: Higher pressure generation, effective against resistance, suitable for ducted systems.

- Limitations: Generally bulkier and heavier than axial units.

This critical distinction in air movement direction and pressure generation is essential when considering axial fan vs centrifugal fan for specific applications.

Explore Applications: Where Axial and Centrifugal Fans Shine

When discussing axial fan vs centrifugal fan, axial units exhibit remarkable efficiency in scenarios necessitating high volume movement at low pressure, making them indispensable in applications such as:

- Cooling electronic devices

- Building ventilation

- Agricultural practices

Their extensive application in HVAC systems underscores their capacity to effectively transport large volumes of air, a critical factor in sustaining optimal indoor environments. Conversely, when comparing axial fan vs centrifugal fan, are designed for applications requiring high pressure and consistent air movement. They excel in environments such as:

- Dust collection systems

- Fume extraction

- Air conditioning units

where their ability to maintain airflow against resistance is crucial. This characteristic positions them as ideal solutions for ducted systems and complex industrial processes, where air must navigate intricate pathways.

The blower market is currently experiencing significant expansion, driven by eco-friendly construction initiatives and an increasing focus on indoor air quality. In 2023, the Asia-Pacific region is anticipated to lead the market, capturing 52.0% of the share. This growth is particularly pertinent to the electronics sector, as the demand for efficient cooling solutions continues to escalate. Addressing challenges such as fluctuating raw material costs and stringent environmental regulations will be vital for companies aiming to retain their competitive advantage in this dynamic environment. These challenges directly affect the applications of axial fan vs centrifugal fan, necessitating innovative strategies to enhance operational efficiency and sustainability. Successful implementations of spinning blowers in industrial processes exemplify their crucial role in boosting operational efficiency and sustainability. Moreover, the National Bureau of Statistics (NBS) of China reported a 4.6% year-over-year increase in industrial output in October 2023, surpassing expectations, which highlights the growing need for effective cooling solutions across various sectors.

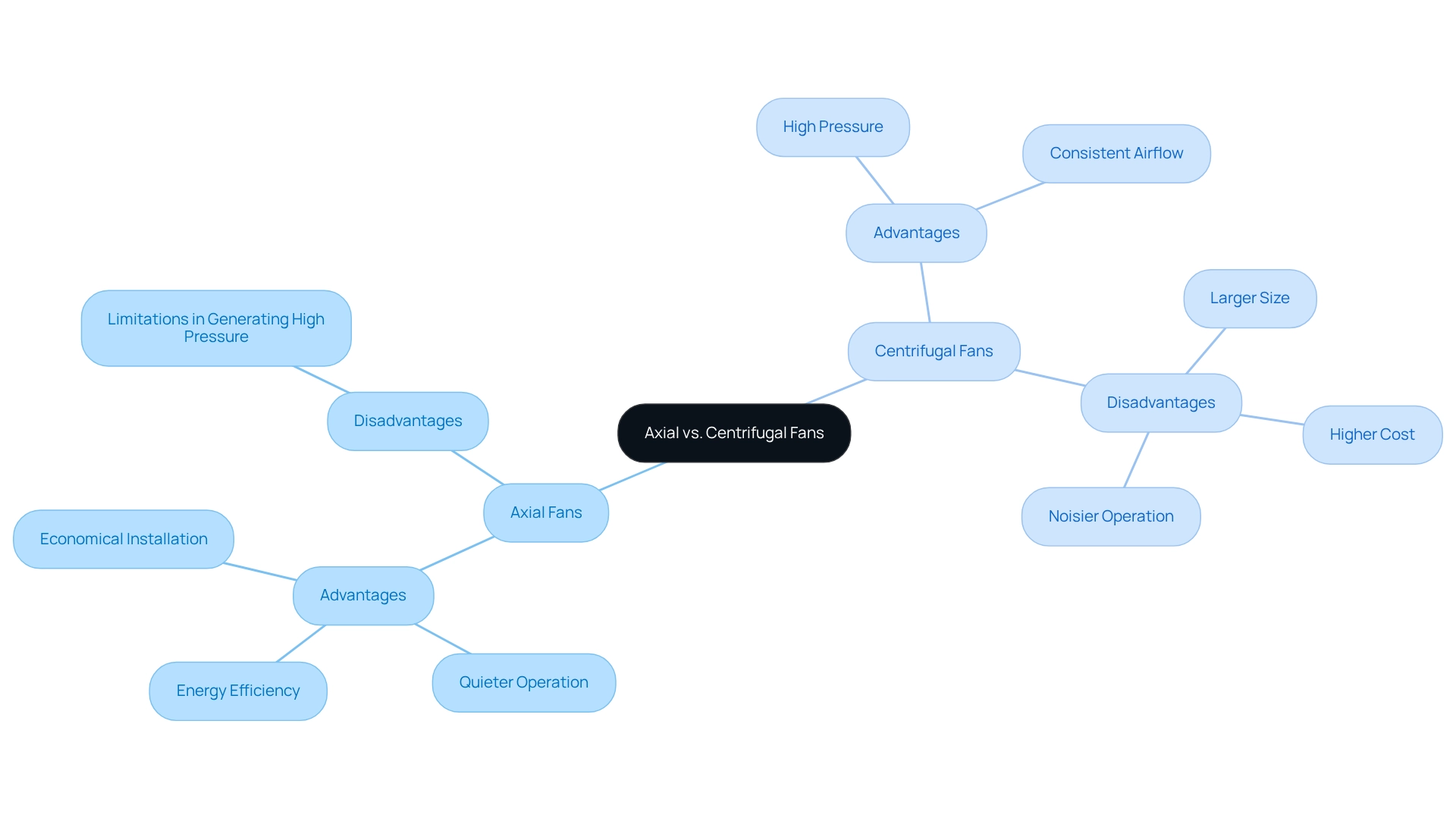

Compare Advantages and Disadvantages: Axial vs. Centrifugal Fans

Axial blowers are renowned for their exceptional energy efficiency and quieter operation, making them ideal for noise-sensitive applications. Their installation is typically more economical and straightforward compared to radial blowers. However, axial blowers have limitations in generating high pressure, which can hinder their effectiveness in certain situations. Conversely, radial blowers are designed to excel in environments that require higher pressures and consistent airflow against resistance, rendering them suitable for industrial applications. Despite their advantages, radial blowers tend to be larger, more costly, and noisier, which can pose significant drawbacks in environments where sound levels are critical.

In terms of energy efficiency, axial fan vs centrifugal fan shows that axial fans outperform centrifugal fans, particularly in scenarios where the volume of airflow is prioritized over pressure. To maximize the performance of both fan types, are essential. Regular maintenance and cleaning of both blower types can significantly enhance their lifespan and efficiency, ensuring optimal ventilation and cooling capabilities. As one expert noted, “Check the fan efficiency and make adjustments if needed so that the circulation and cooling can be optimal.”

Research indicates that while radial blowers are effective in targeted air movement applications, such as furnaces and industrial air management, axial blowers provide advantages in noise-sensitive environments, delivering a quieter alternative without compromising efficiency. The airflow and pressure characteristics of axial fan vs centrifugal fan systems are fundamental differentiators, with axial units offering high-volume, low-pressure airflow and centrifugal units providing low-volume, high-pressure airflow.

Evaluate Performance Metrics: Efficiency, Noise, and Cost Considerations

When comparing axial fan vs centrifugal fan, axial blowers are recognized for their affordability in high-volume, low-pressure applications, generally operating at reduced energy consumption rates. Under optimal conditions, their efficiency can reach up to 70%. Notably, the 12-bladed fan design boasts a Best Efficiency Point (BEP) of 0.050, underscoring its performance metrics for specific applications.

Conversely, in the discussion of axial fan vs centrifugal fan, radial blowers excel in high-pressure scenarios, often achieving efficiencies that exceed 80%, although they tend to be less efficient at lower pressures. Performance evaluations of rotary blowers in high-pressure contexts confirm their effectiveness in demanding applications, particularly in the discussion of axial fan vs centrifugal fan, where noise generation is a critical consideration; axial units typically produce noise levels around 60 dB, while centrifugal devices may generate higher noise levels due to their design and operational speeds.

From a financial standpoint, axial blowers usually have a lower initial purchase price. However, it is essential to evaluate the total cost of ownership, which should include maintenance and energy consumption over time. Recent research emphasizes the importance of adjusting airfoil pitch angles in axial devices to enhance performance metrics, particularly in aerospace applications. As highlighted by John P Kizito from North Carolina Agricultural and Technical State University, these design considerations are crucial for improving efficiency.

Furthermore, case studies have validated the efficiency metrics of axial fans in electronics applications, confirming their reliability across various operational conditions. This evidence supports the strategic use of axial fan vs in diverse settings, encouraging industry professionals to consider their advantages in both cost and performance.

Conclusion

Understanding the distinctions between axial and centrifugal fans is essential for making informed decisions in air movement technology. Axial fans, characterized by their lightweight design and high-volume airflow capabilities, are ideal for applications requiring efficient cooling and ventilation in low-pressure environments. Their energy efficiency and quieter operation render them a popular choice for noise-sensitive applications. Conversely, centrifugal fans excel in high-pressure scenarios, providing robust airflow against resistance, which makes them indispensable in industrial contexts and complex systems.

When selecting the appropriate fan type, it is crucial to consider the specific operational demands of the application. Axial fans shine in areas such as HVAC systems and electronics cooling, while centrifugal fans are better suited for dust collection and air conditioning units. Both fan types present unique advantages and limitations; axial fans are generally more cost-effective and easier to install, whereas centrifugal fans offer superior pressure generation.

Ultimately, the ongoing advancements in fan technology and the growing market demand for efficient cooling solutions underscore the importance of understanding these differences. Engineers and decision-makers must carefully evaluate performance metrics, including efficiency, noise levels, and cost considerations, to optimize air movement solutions tailored to their specific needs. By making informed choices, organizations can enhance operational efficiency, sustainability, and overall performance in their respective industries.

Frequently Asked Questions

What are axial blowers and how do they operate?

Axial blowers are designed to move air parallel to their axis, featuring blades that rotate around a central hub. This design generates a low-pressure wind current, making them effective for high-volume applications.

What are the advantages of using axial blowers?

Axial blowers are lightweight, compact, and can be easily integrated into space-constrained environments. They are particularly efficient for low-pressure applications.

How do radial blowers differ from axial blowers?

Radial blowers draw air into their center and expel it at a right angle through a scroll casing, resulting in enhanced pressure production. This makes them suitable for applications that require robust airflow against resistance, such as ducted HVAC systems.

What advancements have been made in axial blower technology?

Recent advancements have significantly improved the efficiency and versatility of axial blowers, with energy savings for conventional models ranging from 28.96% to 34.93%.

What types of applications are tube-axial blowers suited for?

Tube-axial blowers excel in medium-pressure, high airflow rate applications and are effective in mitigating duct losses and enhancing ventilation performance, making them well-suited for ducted HVAC installations.

What is the significance of fan construction in performance and noise levels?

The construction of fans, such as those made from FRP (fiberglass reinforced plastic) using compression moulding or resin transfer moulding techniques, can lead to uniform dimensions, consistent quality, and lower flow and mechanical noise levels compared to conventional metallic fans.

What are the key differences between axial and centrifugal fans?

- Axial Fans: High-volume airflow, lightweight, compact design, and efficient for low-pressure applications, but less effective in high-pressure scenarios.\n- Centrifugal Fans: Higher pressure generation, effective against resistance, and suitable for ducted systems, but generally bulkier and heavier than axial units.

Why is it important to consider the air movement direction and pressure generation when choosing between axial and centrifugal fans?

The critical distinction in air movement direction and pressure generation is essential for selecting the appropriate fan type for specific applications, ensuring optimal performance.