Overview

The article addresses the critical challenge of achieving optimal performance through the integration of high static pressure fans. It emphasizes key factors such as:

- Proper sizing

- System resistance

- Regular maintenance

Understanding static pressure in fan systems is paramount; this knowledge allows for the evaluation of performance issues and the implementation of best practices. Collectively, these elements enhance efficiency and reliability in environments characterized by restricted airflow.

Introduction

Understanding the dynamics of airflow is crucial in various engineering applications, particularly regarding fan systems. High static pressure fans are engineered to address the challenges posed by air resistance, rendering them indispensable in environments where airflow is obstructed by filters, ducts, or complex layouts.

As engineers navigate the intricacies of fan integration, they frequently encounter a pivotal question: how can one optimize fan performance while effectively managing static pressure?

This article delves into essential techniques and best practices for mastering high static pressure fan integration, ensuring not only enhanced efficiency but also an extended equipment lifespan.

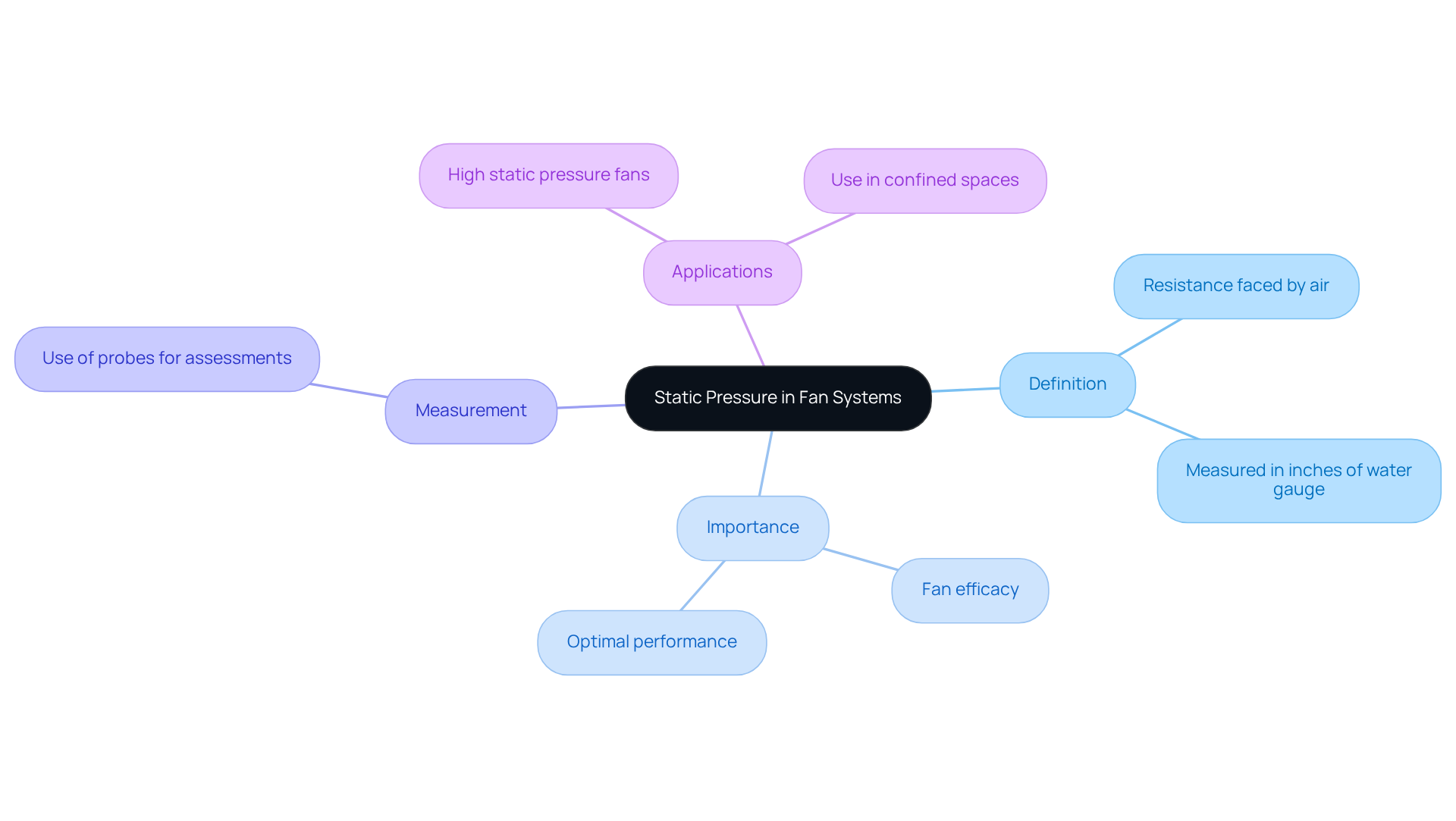

Define Static Pressure in Fan Systems

Static force in fan systems represents the resistance that air encounters as it navigates through various elements, including filters, ducts, and heat sinks. This resistance, quantified in inches of water gauge (in. wg), is critical in determining a fan’s efficacy in pushing air through obstacles.

High resistance fans, specifically high static pressure fans, are engineered to surmount these challenges, making them particularly suitable for applications requiring air movement through confined spaces or complex pathways. For instance, in electronic housings, where installation density significantly impacts airflow, understanding static force is vital for selecting the appropriate fan.

Real-world assessments of static force can be performed using probes inserted into duct systems, enabling precise evaluations of system performance. As noted by industry experts, maintaining optimal static force levels is essential for ensuring efficient fan operation and overall system effectiveness.

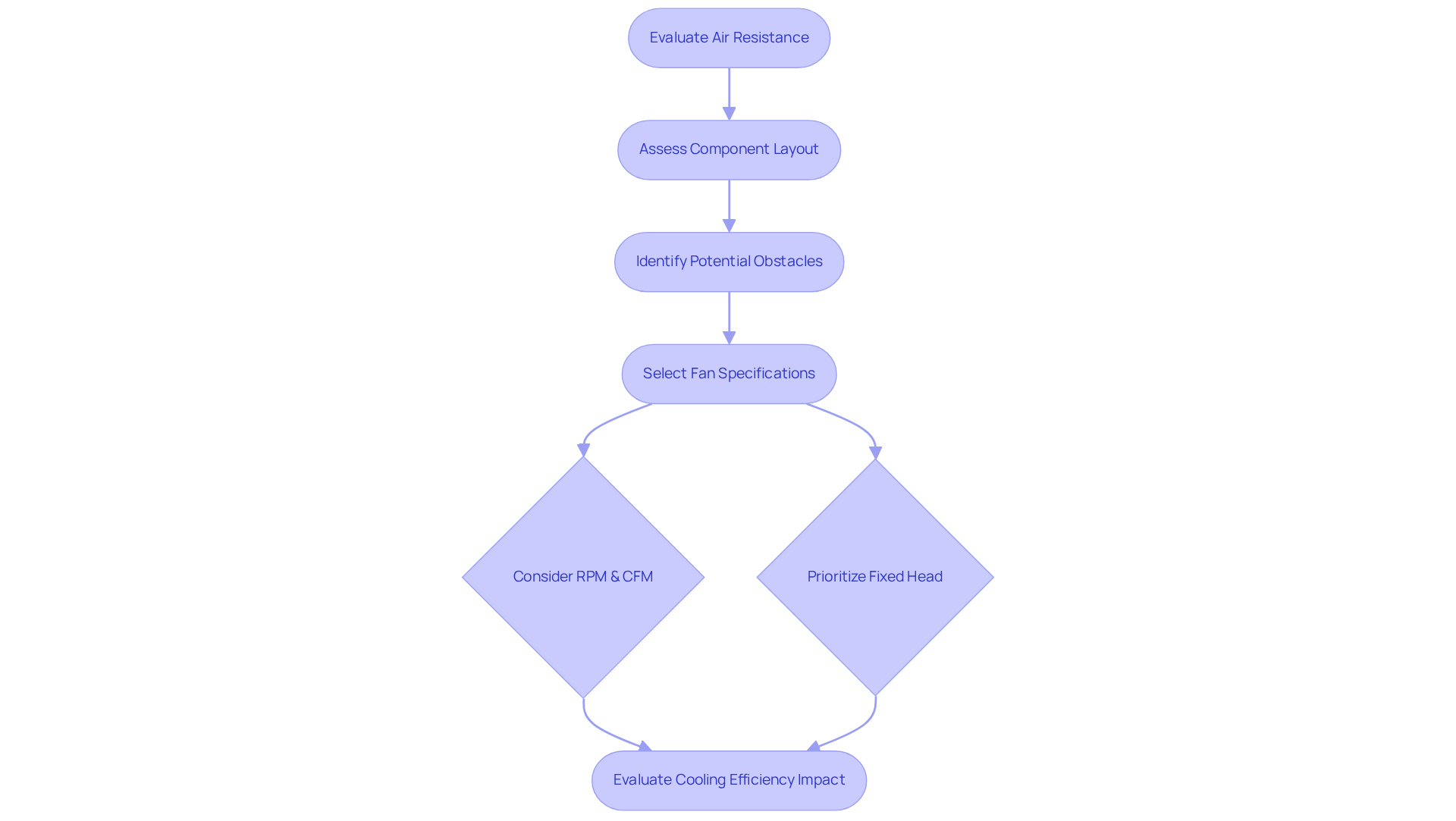

Evaluate the Importance of Static Pressure in Fan Selection

Assessing air resistance is crucial when selecting blowers for electronic systems, particularly in environments with restricted air movement, such as heatsinks and radiators. High static pressure fans are specifically designed to maintain airflow against opposition, ensuring that components remain adequately cooled, unlike standard circulation fans that perform optimally in unobstructed spaces.

The selection process requires a thorough evaluation of the system’s ventilation requirements, component layout, and potential obstacles that could impede airflow. For instance, a fan equipped with a 24.5″ radial blade operating at 3,283 RPM can deliver 8,000 CFM with a fixed head of 30″ of water. However, increasing the speed to 3,550 RPM enhances airflow to 8,650 CFM with a fixed head of 35″ of water, underscoring the importance of fan speed and fixed head in achieving desired airflow rates.

By prioritizing fixed force in the selection of a high static pressure fan, engineers can significantly improve the reliability and efficiency of their systems. This focus not only boosts performance but also prolongs the lifespan of electronic components, as studies indicate that retrofitting existing fans with efficient EC fans can yield energy savings of up to 60%.

Understanding the Fan Laws, which illustrate the relationship between fan speed, airflow, and resistance, further emphasizes the necessity of assessing resistance to improve cooling efficiency in electronic systems.

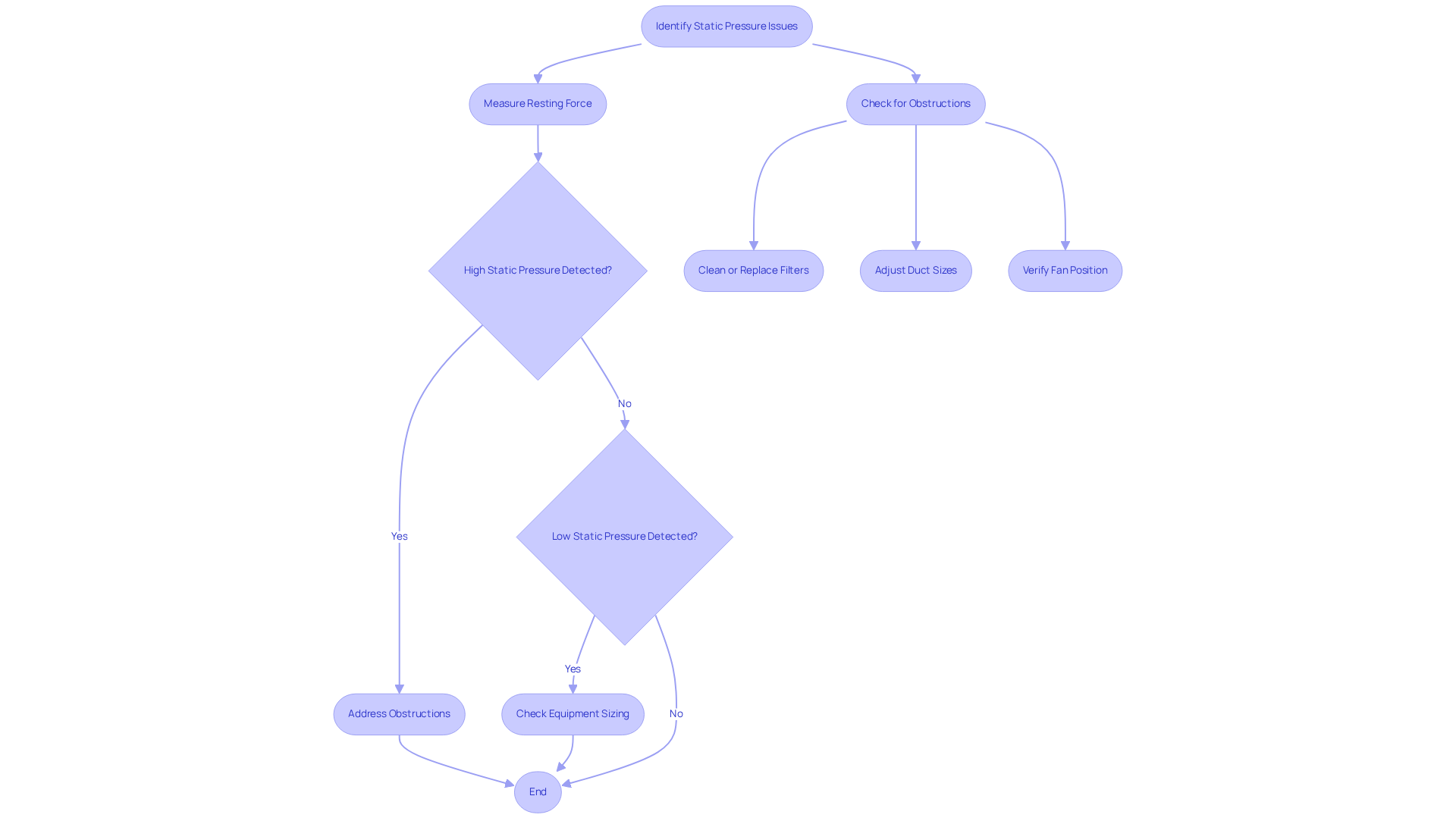

Identify and Troubleshoot Static Pressure-Related Performance Issues

Performance problems related to static pressure in high static pressure fan systems significantly impact airflow, increase noise levels, and lead to overheating components. Engineers must begin by measuring the resting force at various locations within the system using a manometer. Elevated fixed readings often indicate obstructions or limitations in the air movement pathway, such as blocked filters or improperly sized ducts. Heightened air resistance indicates excessive opposition within the ductwork, which stresses the HVAC system and escalates energy consumption, particularly when using a high static pressure fan.

For instance, a one-inch filter that should be replaced every 90 days might need changing every 30 days to avert a decline in air movement, as obstructed air filters can elevate resistance in duct systems if not replaced for several months. Conversely, low fixed force may signify that the fan is inadequately matched to the system’s requirements, potentially resulting in inefficient operation and increased energy use.

Common performance issues linked to fixed airflow in a high static pressure fan include:

- Unbalanced circulation, which can create warm and cool zones within a building.

- Excessive noise from motors working harder to overcome airflow restrictions.

Troubleshooting steps should encompass:

- Cleaning or replacing filters.

- Adjusting duct sizes.

- Verifying that the high static pressure fan is correctly positioned and powered.

Additionally, large air returns can lead to an unbalanced air conditioning system, compounding airflow challenges. Regular inspection and maintenance of duct systems are essential, as dirty or compact coils can heighten airflow resistance. By systematically addressing these concerns, engineers can restore optimal performance to their systems, ensuring efficient operation and enhanced indoor air quality.

Maintaining an optimal fixed force of approximately 0.5 inches is crucial for minimizing noise and protecting equipment, ultimately boosting the overall efficiency of HVAC systems. Delaying professional evaluation of fixed force issues can lead to system failures and increased costs, underscoring the importance of timely maintenance.

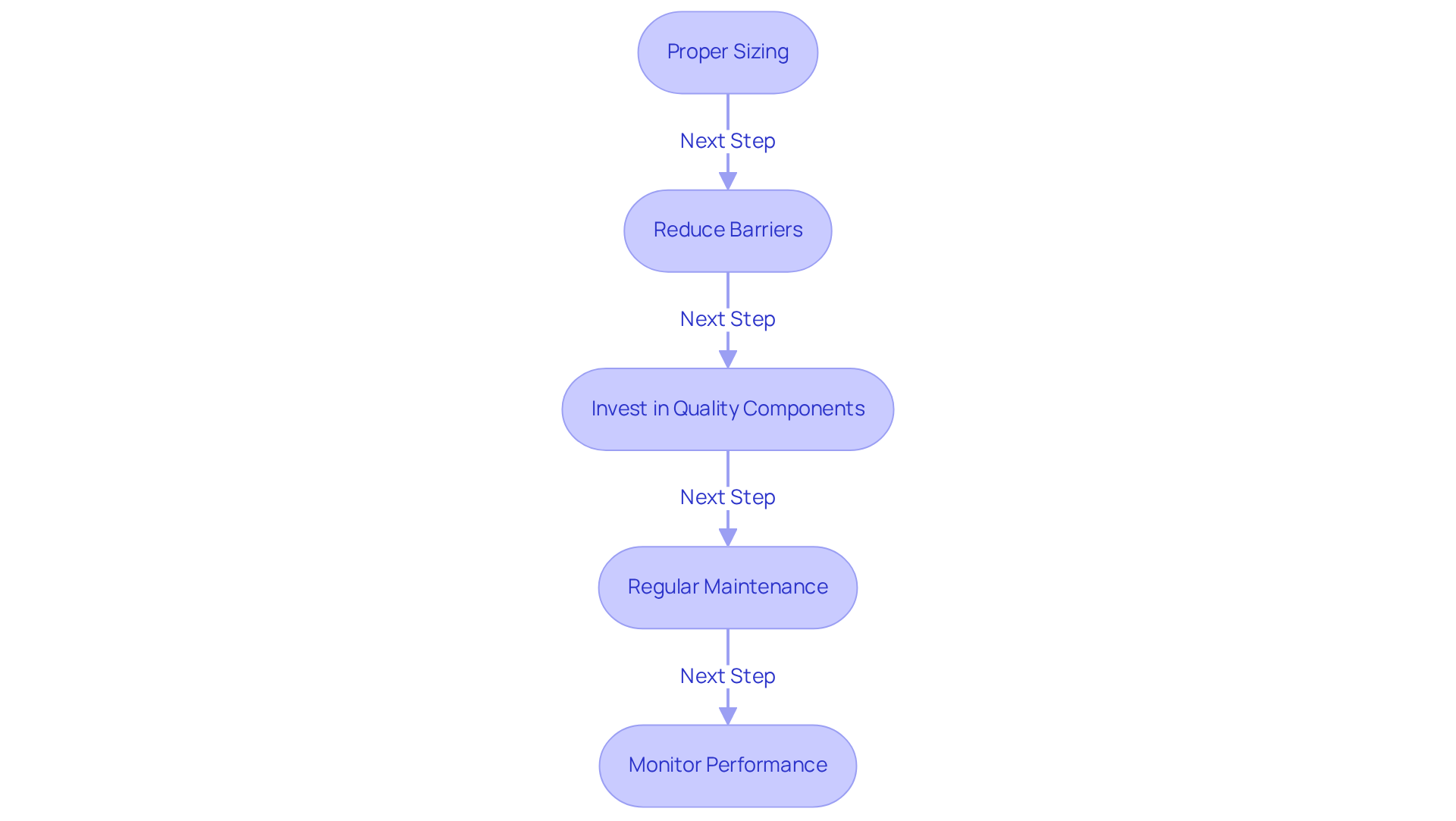

Implement Best Practices for High Static Pressure Fan Integration

To achieve optimal performance when integrating high static pressure fans, several best practices must be adhered to:

- Proper Sizing: It is crucial to ensure that the fan’s specifications align with the system’s ventilation and resistance requirements. Incorrect sizing can lead to inefficiencies; studies indicate that a mere 10% increase in air movement may necessitate a 33% increase in horsepower, potentially overloading motors rated for lower capacities.

- Reduce Barriers: Establishing a clear path for air movement is essential to minimize turns and restrictions, as these factors can significantly increase resistance and reduce efficiency. In confined spaces, air movement can diminish to negligible levels once maximum atmospheric pressure is reached, underscoring the importance of unobstructed routes.

- Investing in quality components, especially high-quality fans and accessories designed for high static pressure applications, guarantees reliability and performance in environments where air resistance is a critical factor.

- Regular Maintenance: Implementing a maintenance schedule to clean filters and check for blockages is vital. Blocked filters can lead to substantial increases in energy costs and reduced air circulation, making regular maintenance essential for consistent performance.

- Monitor Performance: Utilizing sensors to continuously monitor airflow and temperature enables real-time adjustments to maintain optimal conditions. This proactive approach can prevent issues associated with fixed imbalances, ensuring that systems operate effectively.

By adhering to these best practices, engineers can ensure that high static pressure fans operate efficiently, thereby contributing to the overall success of their electronic systems.

Conclusion

Mastering the integration of high static pressure fans is essential for achieving optimal performance in environments where airflow is challenged by various obstacles. Understanding the significance of static pressure and its impact on fan efficiency enables engineers to make informed decisions that enhance system reliability and prolong the lifespan of electronic components.

This article explored the critical aspects of static pressure, including its definition, the importance of fan selection based on resistance, and common performance issues linked to airflow dynamics. Key insights highlighted the necessity of:

- Proper sizing

- Reducing barriers to airflow

- Regular maintenance

- The use of quality components

These practices not only improve efficiency but also contribute to energy savings and better overall system performance.

Ultimately, prioritizing high static pressure fan integration is not merely a technical requirement; it is a strategic approach to optimizing HVAC systems. By implementing the best practices outlined, engineers can ensure that their systems operate efficiently, mitigating potential issues and enhancing indoor air quality. Embracing these techniques will lead to a more effective and sustainable approach to fan system management, paving the way for advancements in engineering applications.

Frequently Asked Questions

What is static pressure in fan systems?

Static pressure in fan systems refers to the resistance that air faces as it moves through components like filters, ducts, and heat sinks. It is measured in inches of water gauge (in. wg) and is crucial for determining a fan’s effectiveness in moving air through obstacles.

What are high static pressure fans designed for?

High static pressure fans are specifically designed to overcome high resistance challenges, making them suitable for applications that require air movement through confined spaces or complex pathways.

Why is understanding static pressure important in electronic housings?

In electronic housings, where installation density greatly affects airflow, understanding static pressure is essential for selecting the appropriate fan to ensure efficient air movement.

How can static pressure be assessed in real-world applications?

Static pressure can be assessed by using probes inserted into duct systems, which allows for precise evaluations of system performance.

Why is maintaining optimal static pressure levels important?

Maintaining optimal static pressure levels is important for ensuring efficient fan operation and the overall effectiveness of the system.