Overview

This article examines the essential features of chiller fans that electronics engineers must consider, emphasizing critical aspects such as:

- Airflow efficiency

- Noise levels

- Energy efficiency

- Durability

- Size

- Control options

- System compatibility

- Maintenance requirements

- Blade design

Each feature is underpinned by data and insights that illustrate its significance in optimizing performance and ensuring effective cooling solutions in electronic applications. This comprehensive analysis aids engineers in making informed decisions for their designs, ultimately enhancing their projects’ effectiveness.

Introduction

As the demand for advanced cooling solutions in the electronics sector surges, the role of chiller fans becomes increasingly critical. These devices not only enhance the performance and longevity of electronic components but also address the challenges posed by miniaturization and complexity in modern systems. This article explores ten key features of chiller fans that electronics engineers must consider to optimize their designs and ensure efficient temperature regulation.

How can engineers navigate the intricate balance between performance, energy efficiency, and noise control in their cooling solutions?

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineers

Gagner-Toomey Associates leads the charge in delivering innovative temperature control solutions specifically tailored for the electronics sector. By focusing on critical areas such as power management and advanced thermal control technologies, the company collaborates with a diverse range of manufacturers renowned for their state-of-the-art products. This commitment to excellence guarantees that engineers have access to the latest advancements in temperature control solutions, which are vital for enhancing the performance and longevity of electronic components.

As the global electronics thermal management solutions market is projected to reach approximately $11.65 billion by 2031, the demand for efficient temperature regulation technologies is on the rise, driven by the miniaturization of devices and the increasing complexity of electronic systems. Moreover, the integration of AI-powered temperature regulation optimization is anticipated to lower energy consumption in data centers by up to 40%, underscoring the transformative potential of these innovative solutions.

Gagner-Toomey Associates remains steadfast in its dedication to equipping engineers with the necessary tools to navigate these advancements and optimize their designs.

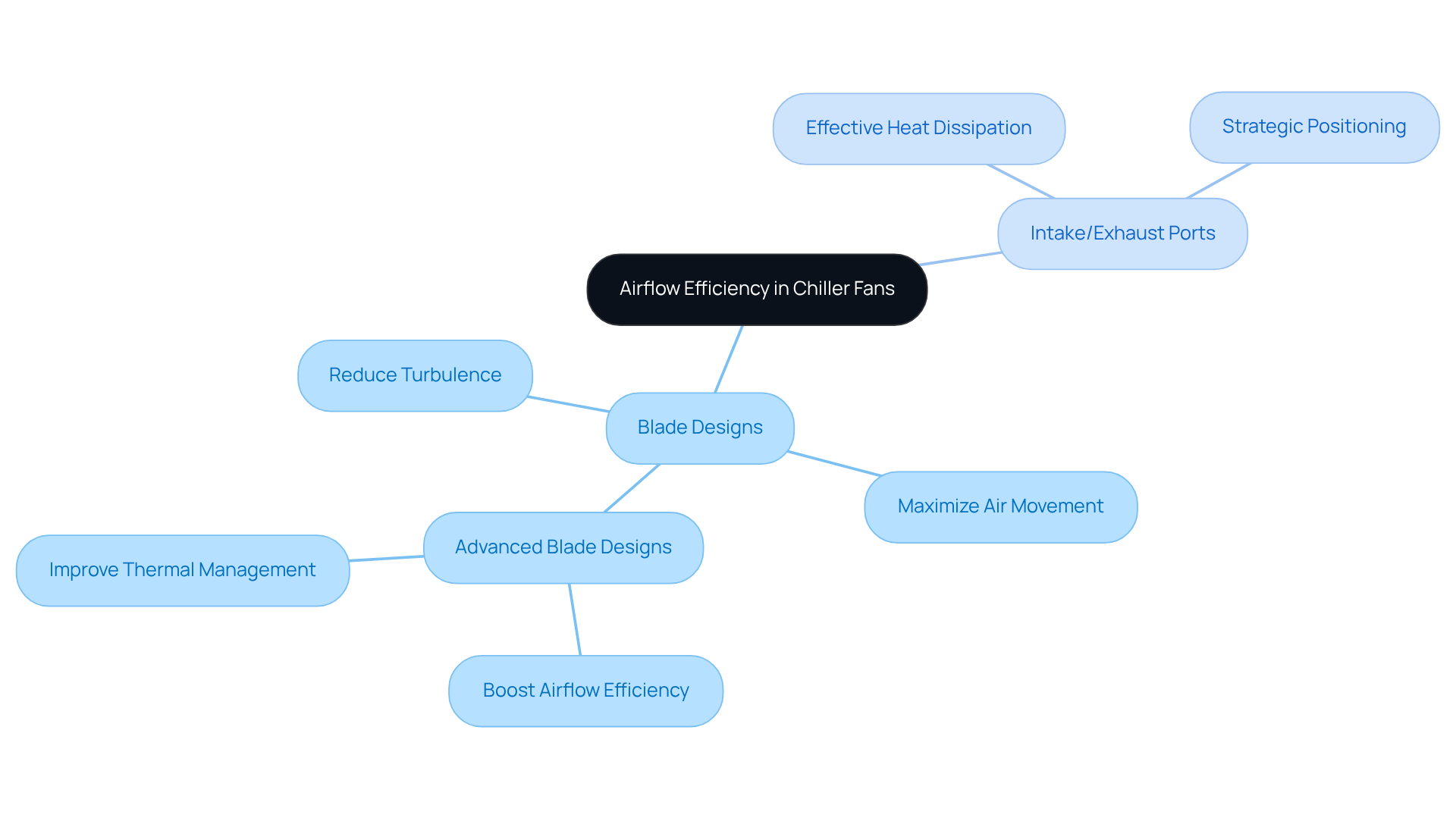

Airflow Efficiency: Maximizing Performance in Chiller Fans

The effectiveness of air circulation is crucial in chiller fan units, as it directly impacts the cooling capacity and performance of electronic systems. Engineers must prioritize devices that deliver high airflow rates while minimizing energy consumption. Key factors to consider include:

- Optimized blade designs, which enhance airflow performance by reducing turbulence and maximizing air movement.

- Strategically positioned intake and exhaust ports, which are essential for ensuring effective heat dissipation from critical components.

For instance, advanced blade designs in modern chiller fans can significantly boost airflow efficiency, leading to improved thermal management and energy savings. By concentrating on these elements, engineers can elevate the performance of their cooling systems, ensuring the optimal operation of electronic devices in 2025 and beyond.

Noise Levels: Ensuring Quiet Operation in Chiller Fans

Chiller fans play a critical role in maintaining optimal conditions in sensitive environments such as laboratories and data centers, where excessive noise can significantly disrupt operations. Engineers must prioritize units that incorporate advanced noise-reduction technologies. These include:

- Fluid-dynamic blade designs

- Vibration-damping materials

- Sound-absorbing substances like foam lining within server cases

All of these effectively minimize sound emissions. Research indicates that implementing aerodynamic modifications can lead to a remarkable 97.5% reduction in fan noise, thereby enhancing both operational efficiency and user comfort.

Furthermore, it is essential to recognize that fan noise escalates with the fifth power of fan speed; thus, even minor reductions in speed can yield substantial decreases in noise levels. Selecting devices with lower RPM ratings is vital for achieving quieter operations while maintaining adequate airflow efficiency. This strategy not only ensures adherence to health standards—given that prolonged exposure to noise levels exceeding 85 decibels can result in irreversible auditory damage—but also fosters a more conducive working environment, especially in scenarios where excessive noise can interfere with critical processes.

By integrating these innovative technologies, including a chiller fan, engineers can effectively mitigate noise pollution, safeguarding both personnel well-being and the integrity of sensitive equipment.

Energy Efficiency: Reducing Costs with Advanced Chiller Fans

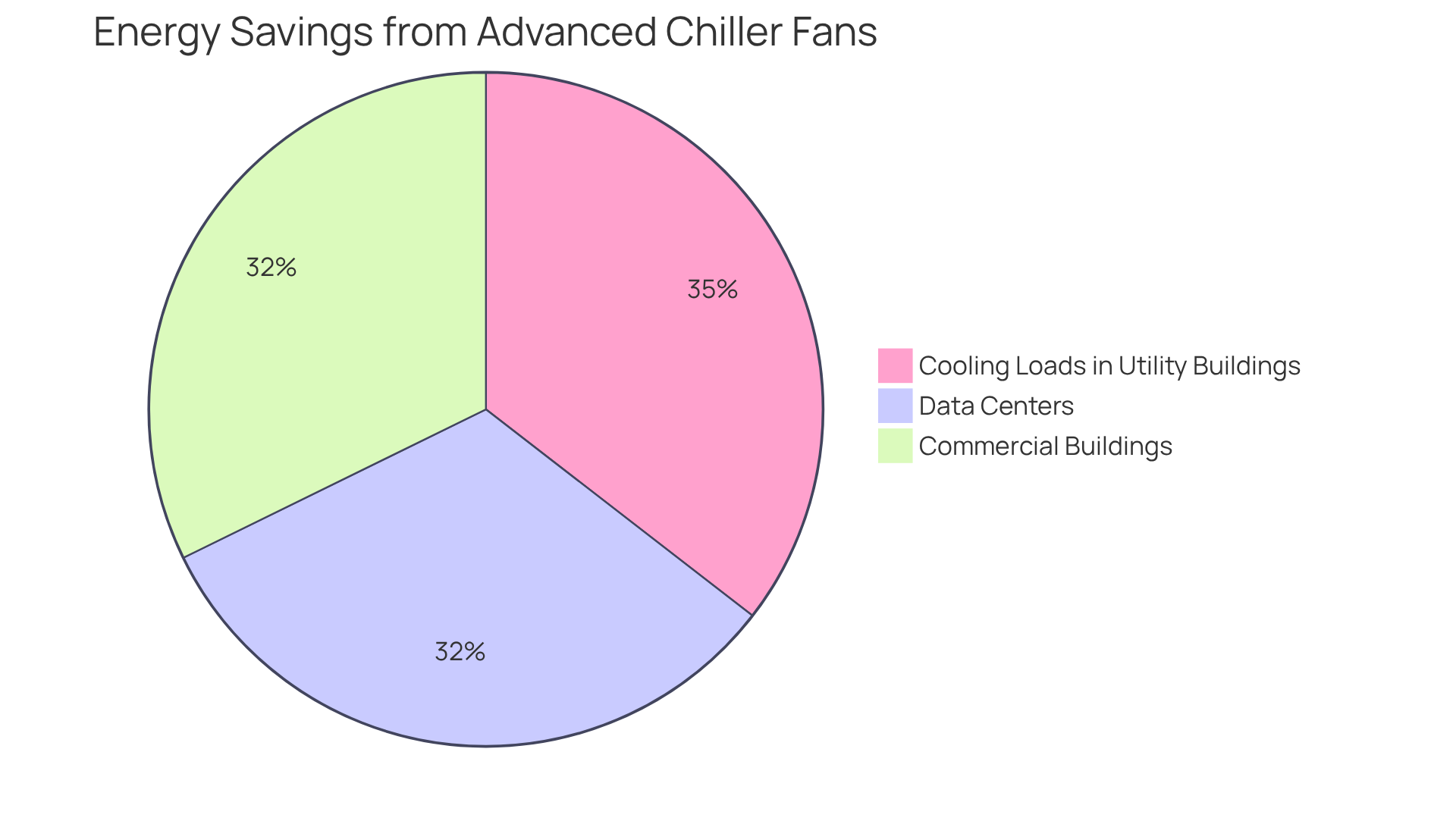

Advanced chiller fan units are engineered for optimal energy efficiency, prominently featuring electronically commutated (EC) motors that significantly reduce power consumption. These motors not only enhance performance but also ensure lower operational costs, establishing them as a prudent choice for engineers dedicated to sustainability.

By implementing energy-efficient ventilation systems, facilities can realize substantial savings over time, particularly in large-scale scenarios where temperature regulation demands are considerable. For instance, data centers utilizing advanced temperature regulation technologies have reported energy savings of up to 40%, underscoring the financial benefits of investing in high-efficiency temperature control solutions.

Moreover, the integration of these devices contributes to a more sustainable operational model, aligning with the growing emphasis on reducing carbon footprints within the industry. Importantly, cooling loads can account for up to 44% of the total energy demand in utility buildings such as hospitals, highlighting the essential role of efficient cooling systems, including the chiller fan.

According to the U.S. Department of Energy, commercial buildings can achieve energy savings of up to 40% by upgrading to energy-efficient HVAC systems, further highlighting the economic advantages of these technologies.

Durability and Build Quality: Ensuring Longevity in Chiller Fans

Durability and construction quality are critical factors in the selection of chillers, particularly in industrial environments where they are subjected to harsh conditions. Engineers must prioritize devices constructed from high-quality materials, such as corrosion-resistant metals and robust plastics, to ensure their longevity.

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers a comprehensive range of DC input Tube Axial units and Centrifugal Blowers, all optimized for superior performance and efficiency.

Additionally, features like reinforced housings and sealed bearings significantly enhance the durability of these devices, making them suitable for continuous operation in demanding applications, particularly within the electronics and automotive sectors.

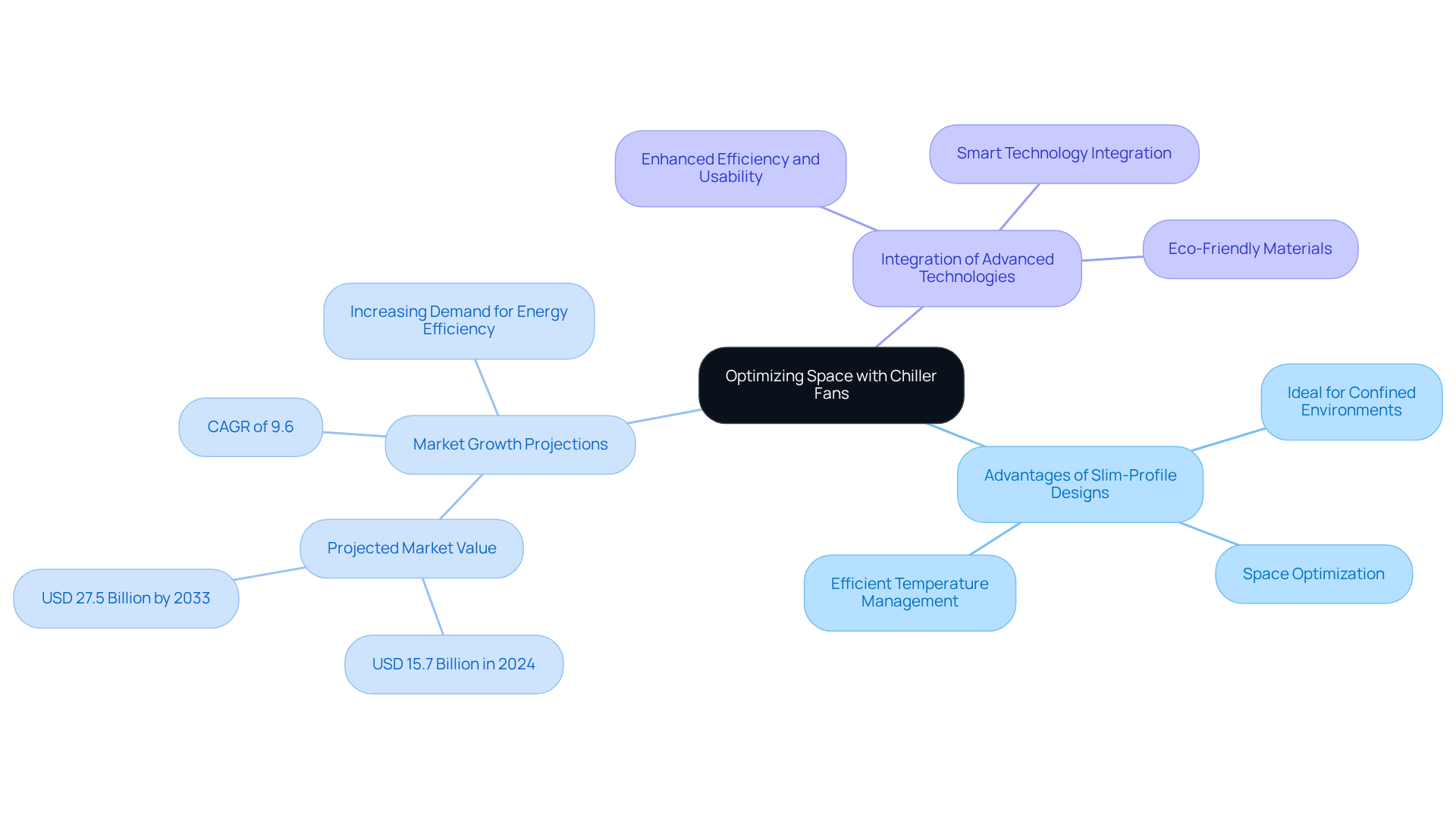

Size and Form Factor: Optimizing Space with Chiller Fans

In electronic applications where space is often restricted, the dimensions and design of chiller units become crucial. Engineers must prioritize compact fan designs that deliver substantial airflow without occupying excessive space.

- Slim-profile ventilators and compact models are particularly advantageous for confined environments, facilitating efficient temperature management while optimizing the available area.

- Notably, the compact fan market is projected to experience significant growth, with designs increasingly tailored for electronics, reflecting a shift toward energy-efficient and space-saving solutions.

- As the demand for optimized temperature regulation solutions escalates, the integration of advanced technologies in compact fan designs will further enhance their efficiency and usability in confined spaces.

Control Options: Customizing Performance in Chiller Fans

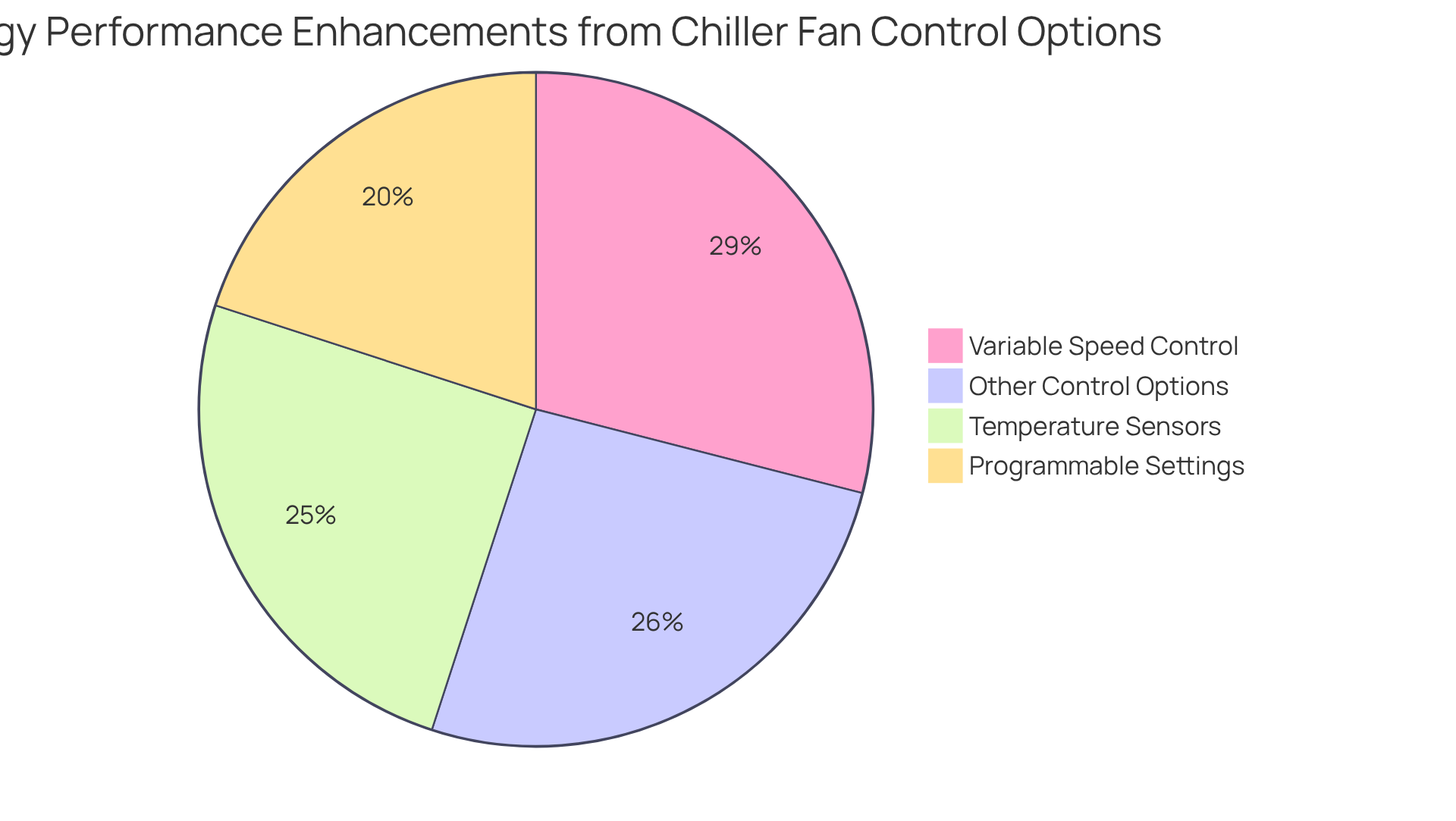

Contemporary chiller fans are increasingly equipped with advanced control options that empower engineers to customize performance to meet specific cooling requirements. Notably, attributes such as variable speed control can enhance energy performance by as much as 29% when integrated with condensing temperature control, as evidenced by recent studies. Furthermore, temperature sensors and programmable settings enable these devices to optimize performance, significantly reducing energy consumption. For instance, research indicates that variable-speed blowers can achieve an 8.8% increase in energy efficiency ratio as speeds are adjusted from nominal to maximum. As Luigi Schibuola emphasizes, variable speed drive (VSD) technology can be seamlessly implemented in HVAC systems to align with actual load demands, bolstering the case for engineers to prioritize units equipped with these advanced control capabilities. By adopting such technologies, they can enhance system performance and adaptability, ensuring that chiller fan solutions remain both effective and sustainable in the rapidly evolving electronics landscape.

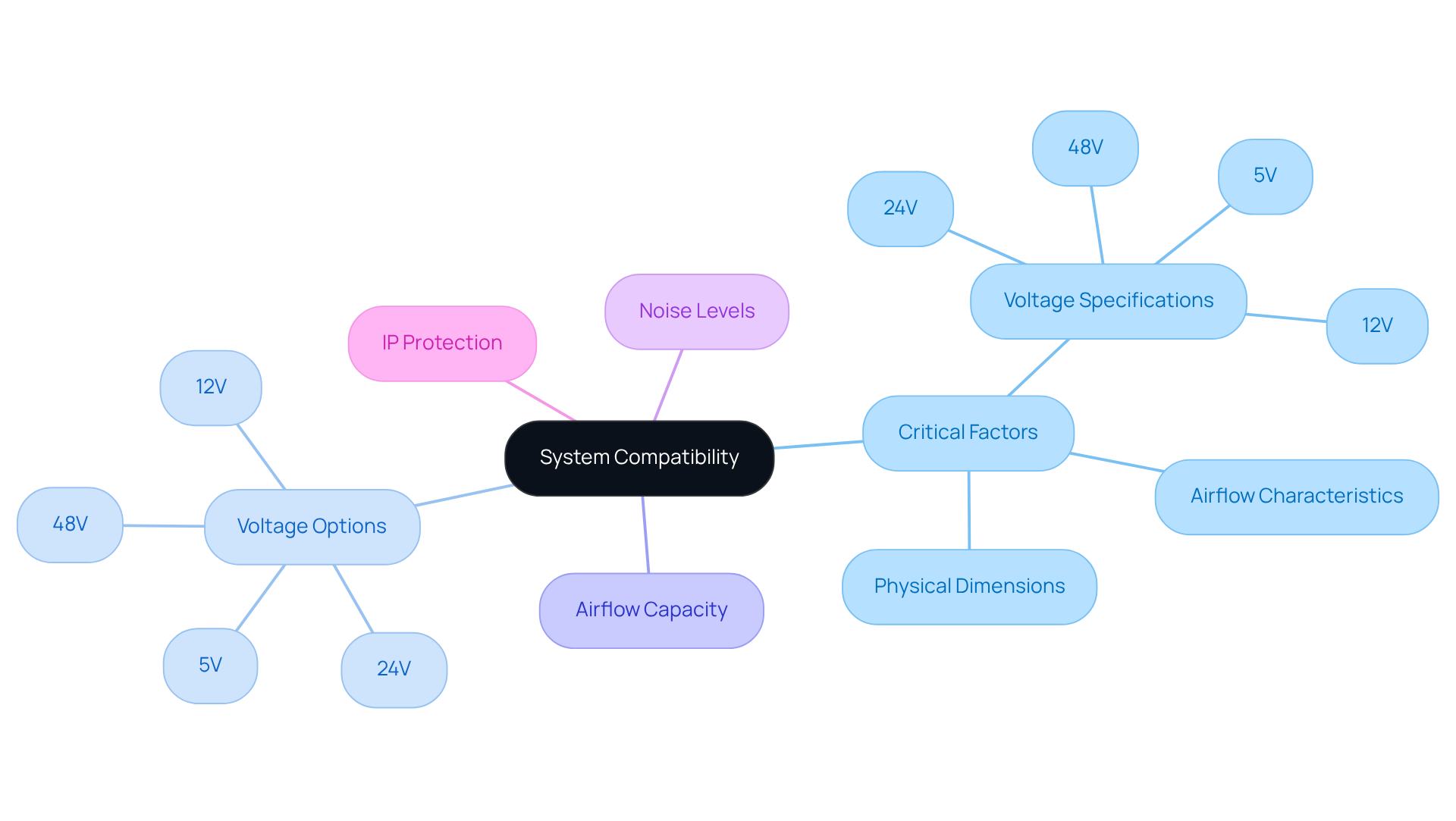

System Compatibility: Ensuring Seamless Integration of Chiller Fans

Selecting chiller fan units requires engineers to prioritize compatibility with existing systems, focusing on critical factors such as voltage specifications, physical dimensions, and airflow characteristics. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, offers an extensive array of DC input tube axial devices and centrifugal blowers. These products are available in sizes ranging from 15 to 280mm and 15 to 225mm, respectively.

Fans engineered for universal compatibility across diverse systems can significantly simplify the integration process. This strategic approach minimizes the potential for operational issues and guarantees that cooling solutions perform optimally within their designated applications. Common voltage options for a chiller fan typically encompass:

- 5V

- 12V

- 24V

- 48V

These options cater to a broad spectrum of electronic devices. Furthermore, engineers must evaluate the airflow capacity, noise levels, and IP protection features present in most models, as these factors can substantially influence overall system performance. By addressing these considerations, engineers can facilitate seamless integration and enhance the reliability of cooling solutions in their projects.

Maintenance Requirements: Keeping Chiller Fans in Optimal Condition

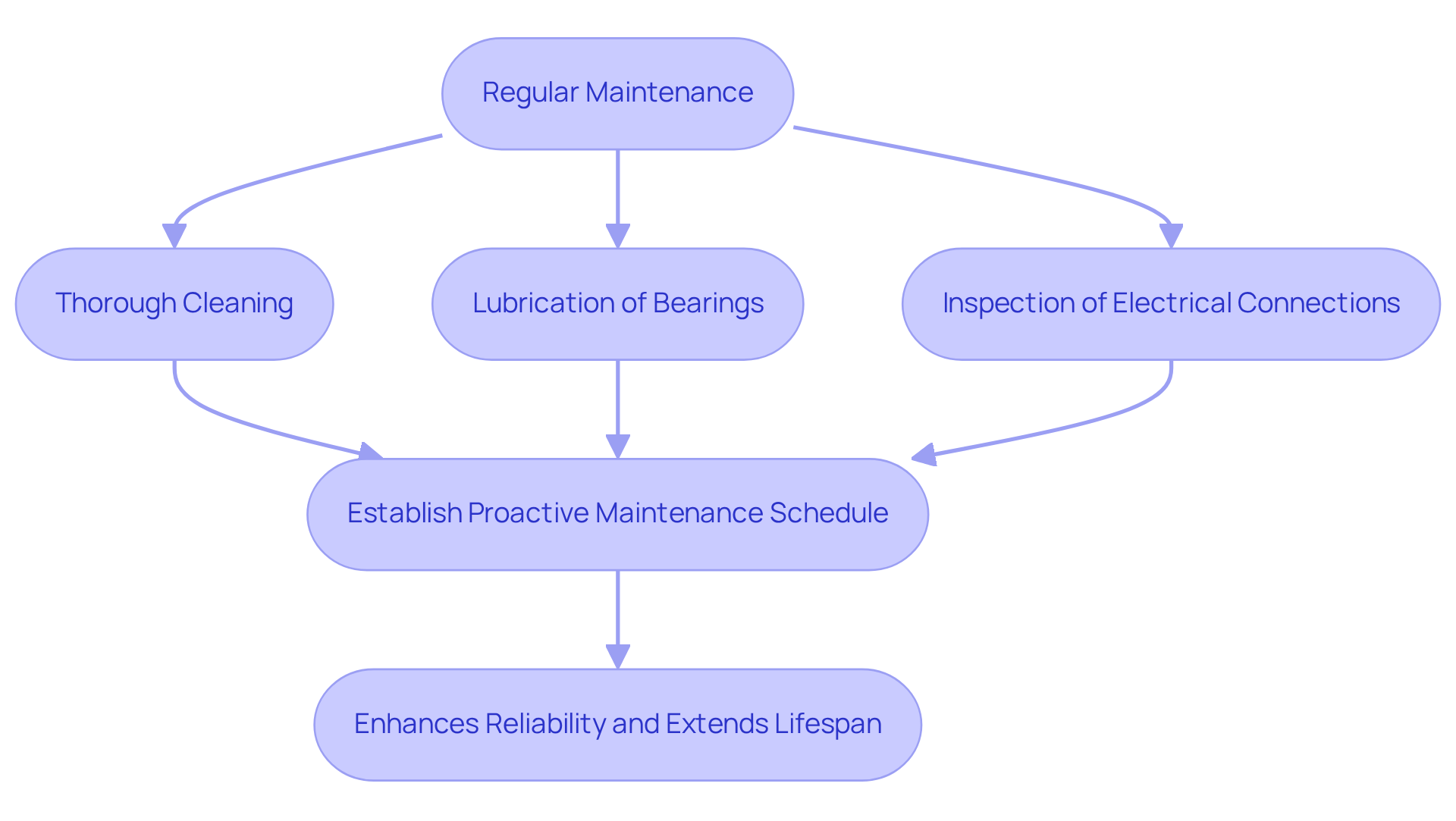

To ensure the chiller fan operates at its optimal performance, regular maintenance is essential. This encompasses:

- Thorough cleaning to eliminate dust accumulation

- Lubrication of bearings to reduce friction

- Inspection of electrical connections for security

Establishing a proactive maintenance schedule not only enhances the reliability of chiller units in critical applications but also significantly extends their lifespan. Consistent maintenance can lower costs and guarantee efficient operation, thus preventing unexpected breakdowns and minimizing energy consumption.

Effective strategies for maintaining ventilation systems include:

- Monitoring efficiency metrics

- Addressing minor issues before they escalate

This ensures peak performance and energy savings. As Rob Ezold, a senior mechanical engineer with over 35 years of experience, asserts, “Implementing a proactive maintenance approach can significantly extend the lifespan of chiller units and enhance their reliability in critical applications.

Blade Design: Enhancing Performance in Chiller Fans

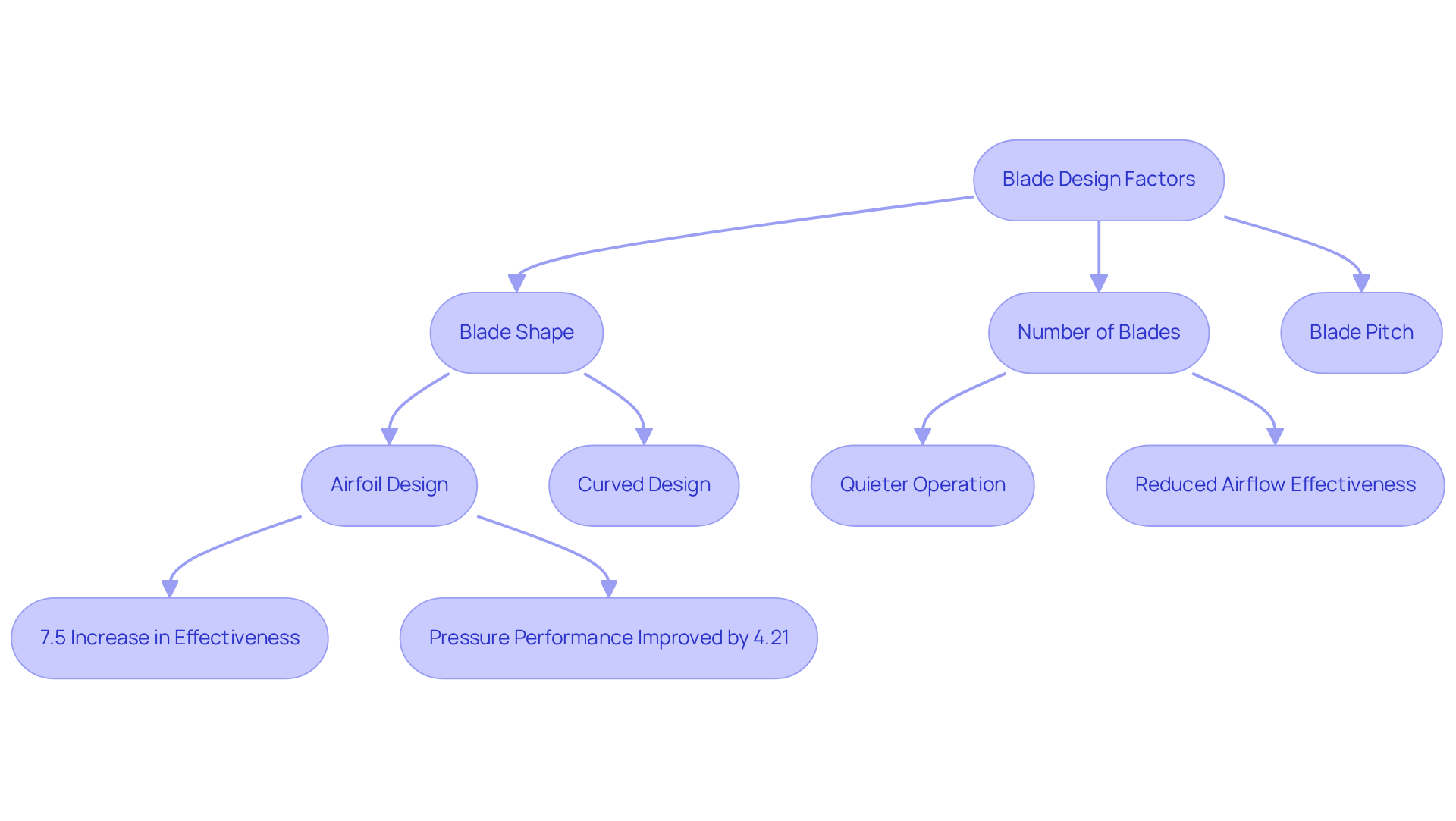

The design of fan blades is pivotal in enhancing the efficiency of chiller fans, especially those produced by Gagner-Toomey Associates, a leader in both custom and standard cooling solutions. Engineers must prioritize blade shapes that optimize airflow while minimizing turbulence; airfoil and curved designs are especially effective. Research indicates that optimizing blade structure can yield significant improvements in fan performance, with forward-swept blades demonstrating a 7.5% increase in effectiveness under low flow conditions. Moreover, overall pressure performance improved by 4.21% following optimization, underscoring the efficacy of advanced blade designs.

The quantity of blades and their pitch are critical factors that influence both performance and noise levels. For instance, five-blade units offer quieter operation but may sacrifice some airflow effectiveness compared to three-blade models. Selecting chiller fans with meticulously designed blade shapes from Gagner-Toomey Associates can enhance temperature management and reduce noise, making them ideal for sensitive electronic applications. Furthermore, the flow rate of the fan increased by 1.18 m/min post-optimization, while the static pressure at the design operating condition rose by 12.7 Pa, with a static pressure performance improvement of 3.2%.

Ultimately, the appropriate blade design not only improves airflow but also contributes to a more stable and efficient cooling system. Gagner-Toomey Associates provides an extensive product line of DC input Tube Axial fans and Centrifugal Blowers, each optimized for performance, efficiency, and low noise, catering to a variety of industrial applications.

Conclusion

The significance of chiller fans in electronics engineering is paramount, particularly as the demand for efficient cooling solutions escalates. These fans are essential in sustaining optimal operating conditions for electronic components, thereby enhancing performance and extending longevity. By comprehending the key features of chiller fans, engineers are empowered to make informed decisions that optimize their designs and address the evolving challenges within the electronics sector.

Throughout this article, critical aspects such as:

- airflow efficiency

- noise levels

- energy efficiency

- durability

have been underscored as vital considerations for engineers. The incorporation of advanced technologies, including variable speed controls and innovative blade designs, significantly contributes to performance enhancement while simultaneously reducing operational costs. Furthermore, a focus on maintenance practices and system compatibility ensures that chiller fans function effectively across diverse applications.

As the electronics landscape continues to transform, embracing these cutting-edge cooling solutions is imperative for engineers seeking to refine their designs. By prioritizing the selection of high-quality chiller fans that align with the latest advancements, engineers can not only elevate system performance but also play a pivotal role in fostering a more sustainable and efficient future in electronics. The insights provided in this article serve as a valuable resource for those striving to adeptly navigate the complexities of temperature regulation in electronic systems.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for delivering innovative temperature control solutions specifically tailored for the electronics sector, focusing on power management and advanced thermal control technologies.

How does Gagner-Toomey Associates support electronics engineers?

The company collaborates with a diverse range of manufacturers to provide engineers with access to the latest advancements in temperature control solutions, which are vital for enhancing the performance and longevity of electronic components.

What is the projected market size for global electronics thermal management solutions by 2031?

The global electronics thermal management solutions market is projected to reach approximately $11.65 billion by 2031.

What factors are driving the demand for efficient temperature regulation technologies?

The demand is driven by the miniaturization of devices and the increasing complexity of electronic systems.

How can AI-powered temperature regulation optimization benefit data centers?

AI-powered temperature regulation optimization is anticipated to lower energy consumption in data centers by up to 40%.

What is crucial for maximizing performance in chiller fans?

The effectiveness of air circulation is crucial, as it directly impacts the cooling capacity and performance of electronic systems.

What factors should engineers consider for airflow efficiency in chiller fans?

Engineers should consider optimized blade designs to enhance airflow performance and strategically positioned intake and exhaust ports for effective heat dissipation.

What technologies can help ensure quiet operation in chiller fans?

Technologies include fluid-dynamic blade designs, vibration-damping materials, and sound-absorbing substances like foam lining within server cases.

How much can aerodynamic modifications reduce fan noise?

Aerodynamic modifications can lead to a remarkable 97.5% reduction in fan noise.

Why is it important to select chiller fans with lower RPM ratings?

Selecting devices with lower RPM ratings is vital for achieving quieter operations while maintaining adequate airflow efficiency, as fan noise escalates with the fifth power of fan speed.

What health standards should be considered regarding noise levels?

Prolonged exposure to noise levels exceeding 85 decibels can result in irreversible auditory damage, making it essential to manage noise levels in sensitive environments.