Overview

The article presents a compelling overview of ten significant benefits of high pressure air blowers in the field of electronics engineering. It emphasizes their critical roles in:

- Enhancing operational efficiency

- Reducing costs

- Improving safety standards

These advantages are substantiated by robust evidence showcasing their effectiveness in:

- Temperature regulation

- Energy savings

- Versatility across diverse applications

Ultimately, this demonstrates how high pressure air blowers contribute to overall productivity and sustainability within the electronics sector.

Introduction

High pressure air blowers have emerged as essential tools in the field of electronics engineering, fundamentally changing how engineers tackle cooling and ventilation challenges. Their capacity to enhance air circulation and optimize system performance presents significant advantages, leading to increased efficiency and reduced operational costs.

As industries pursue sustainability and innovation, a critical question arises: how can high pressure air blowers not only address the demands of modern electronics but also contribute to a greener future?

By exploring the multifaceted benefits of these powerful devices, we can uncover their pivotal role in shaping the future of electronics engineering.

Gagner-Toomey Associates: Innovative Solutions for High Pressure Air Blowers in Electronics Engineering

Gagner-Toomey Associates stands at the forefront of delivering innovative solutions specifically designed for the electronics sector, particularly through the application of high pressure air blowers. These fans are pivotal in enhancing air circulation and ventilation systems, which are essential for maintaining the optimal operation of electronic components. By partnering with leading manufacturers, Gagner-Toomey ensures that engineers have access to cutting-edge technology that significantly boosts efficiency across a range of applications, including cooling, power management, and interconnect technologies.

The high-speed fans market, valued at USD 872.1 million in 2023, is projected to grow at a CAGR of over 4.4% from 2024 to 2032, driven by advancements in energy efficiency and industrial automation. Notably, the demand for oil-free and Class 0-certified fans is on the rise, particularly in industries with stringent hygiene standards such as food and beverage and pharmaceuticals. This trend underscores the importance of high-force air devices in ensuring clean and efficient operations.

Case studies illustrate the effective use of high pressure air blower devices in temperature regulation systems for electronics. For instance, the integration of magnetic bearing technology in fans has enhanced energy efficiency and cooling capabilities, making them indispensable in modern electronic applications. Gagner-Toomey Associates remains dedicated to providing expert insights and innovative solutions that empower engineers to address complex challenges within the electronics sector, ensuring they maintain a competitive edge in a rapidly evolving technological landscape.

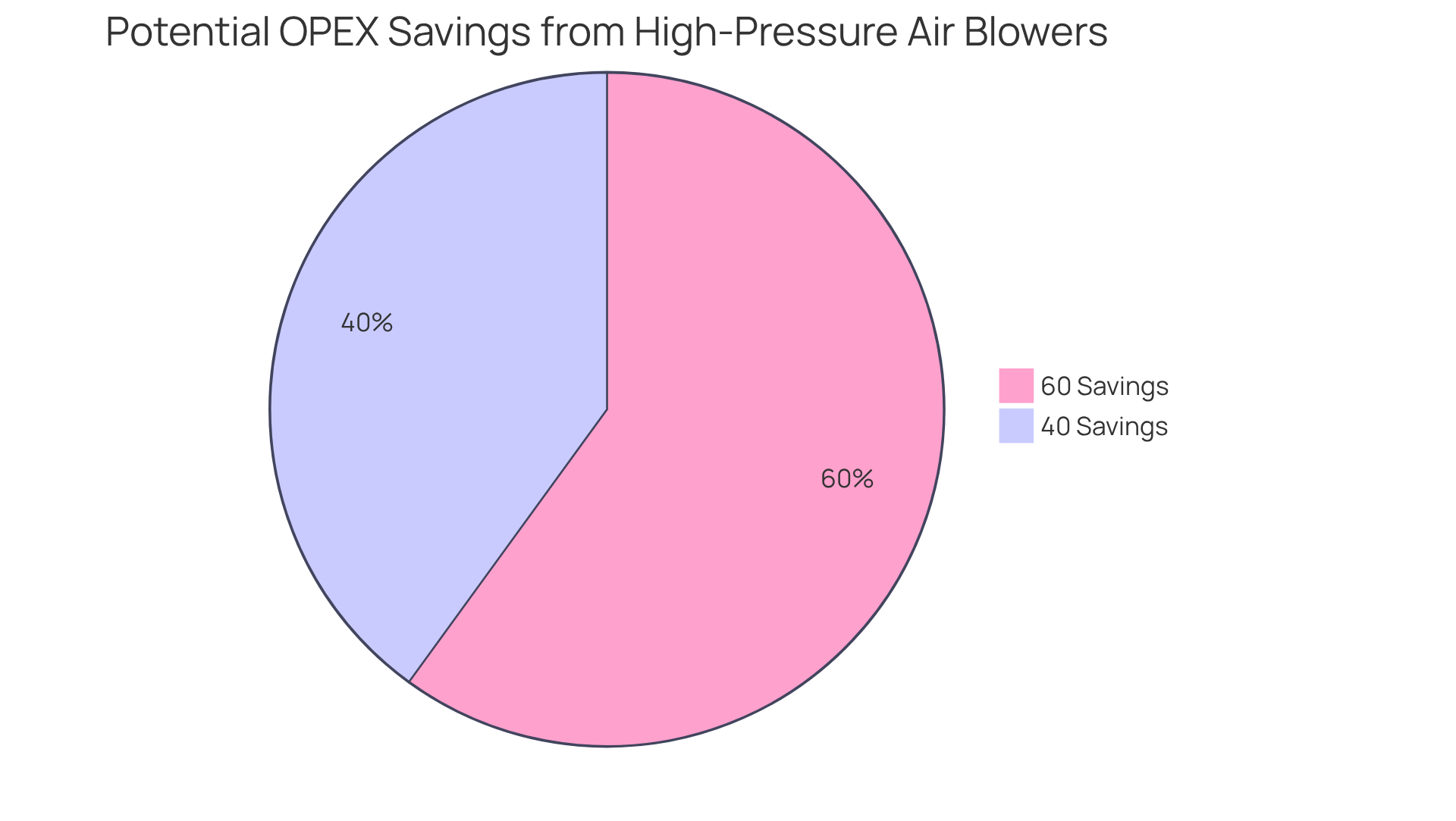

Enhanced Efficiency: How High Pressure Air Blowers Improve System Performance

High pressure air blowers are essential for optimizing system performance by delivering concentrated airflow that effectively cools electronic components. This targeted airflow mitigates thermal buildup, which is crucial for sustaining optimal operating temperatures. By directing high-pressure air precisely, these devices minimize energy waste and significantly enhance overall system efficiency. In data centers, for instance, where maintaining IT equipment can account for up to 40% of energy usage, the adoption of high-pressure air devices can lead to operational expenditure (OPEX) savings of 40-60% due to improved temperature regulation and reduced maintenance costs.

Case studies further illustrate that the implementation of stainless steel centrifugal fans in medical imaging equipment, such as CT and MRI machines, ensures effective heat management, thereby extending the lifespan and reliability of these critical devices. The incorporation of high pressure air blower devices not only enhances the efficiency of temperature regulation but also contributes to the overall performance and durability of electronic systems. This renders them an indispensable resource in the field of electronics engineering.

Cost-Effectiveness: Reducing Operational Costs with High Pressure Air Blowers

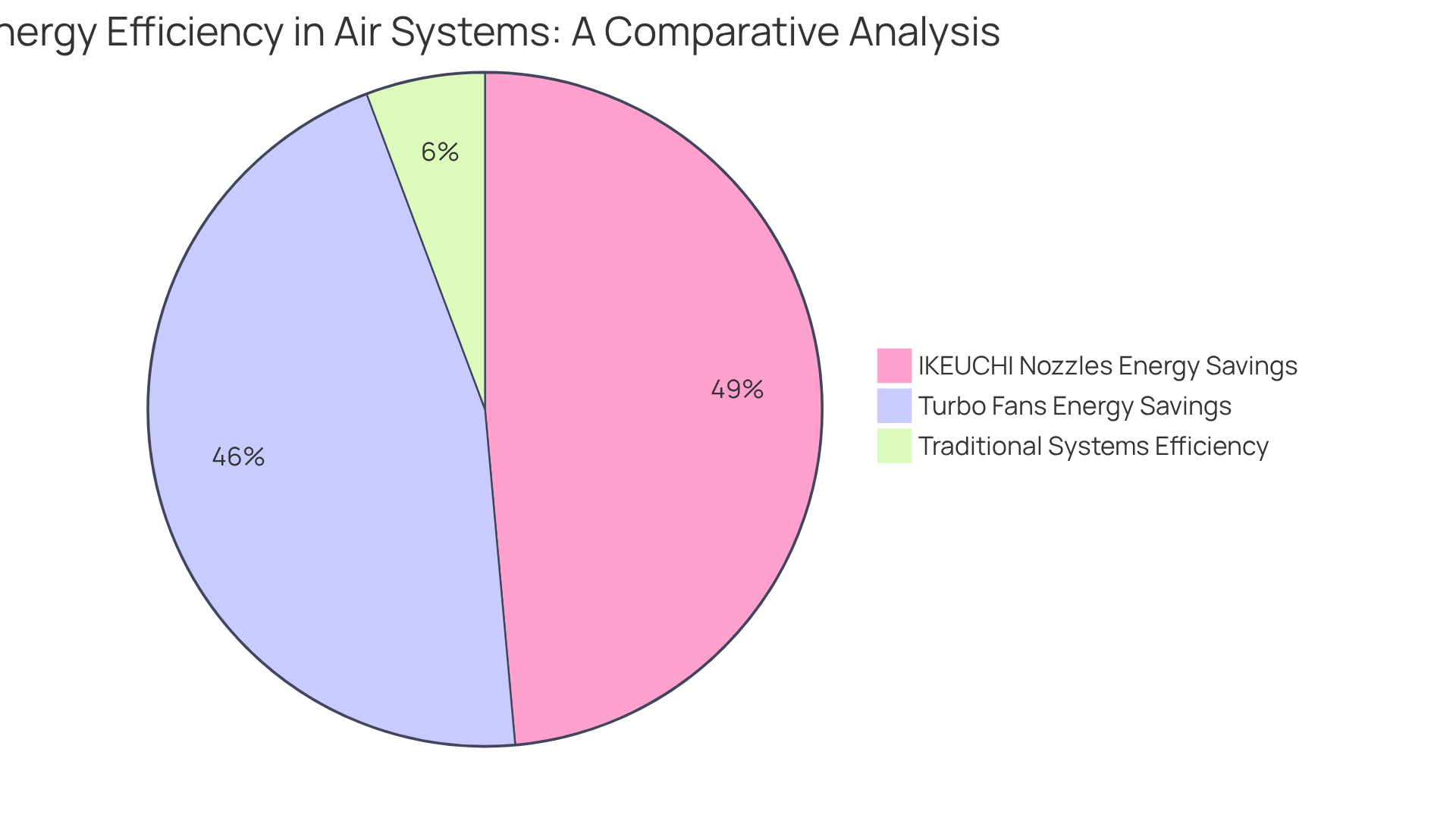

Utilizing a high pressure air blower can lead to substantial reductions in operational expenses. These devices are specifically engineered to consume less energy compared to conventional temperature regulation techniques, such as chilled water systems or large fans. In fact, energy-efficient turbo fans can reduce energy consumption by as much as 80%, resulting in notable decreases in utility expenses. Moreover, only 8-10% of the energy used in compressed air systems is converted into useful energy, underscoring the inefficiency of traditional systems. By lowering energy consumption, companies can not only decrease their utility bills but also minimize maintenance costs associated with more complex cooling systems.

For instance, implementing IKEUCHI nozzles can lead to a remarkable reduction in compressed air consumption by 79% to 91%, thereby enhancing overall productivity while simultaneously lowering costs. As IKEUCHI states, “The IKEUCHI technical air nozzles have been developed to maximize the blowing efficiency.” Regular maintenance of these systems is essential, as it helps keep leakage below the acceptable threshold of 10%, ensuring optimal performance and efficiency. Frequent maintenance is vital to control leaks, which should not exceed 10% of production for an efficient installation.

Furthermore, financial incentives available for upgrading to air-moving technology can cover up to 50% of project expenses, limited to $200 per compressor horsepower shifted, making the transition even more appealing. With the right selection and maintenance, high-capacity air devices not only boost energy efficiency but also provide a rapid return on investment, often realized in under a year. This combination of reduced energy usage and lower maintenance requirements positions the high pressure air blower as a superior choice for economical temperature regulation in the electronics sector.

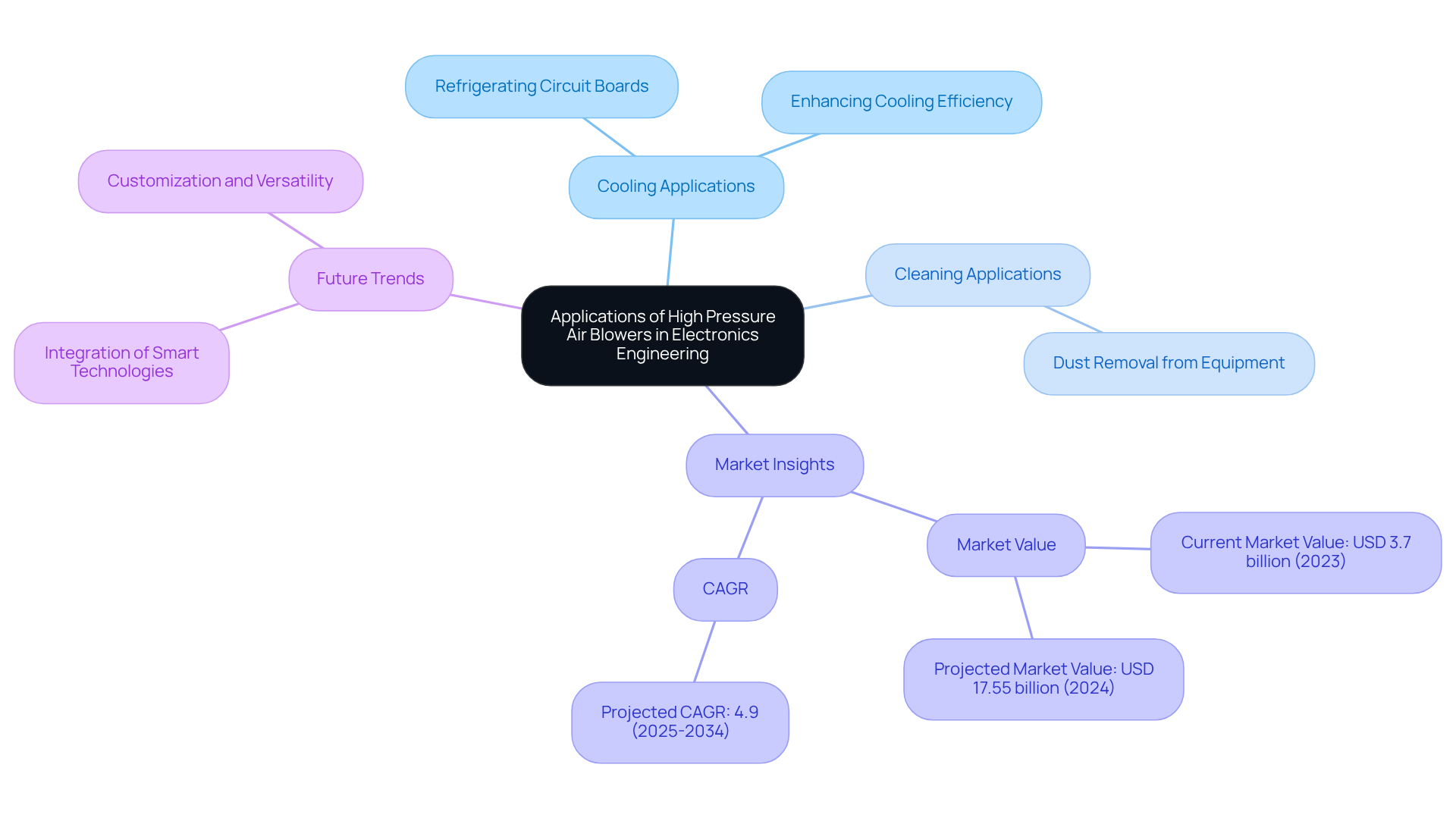

Versatility: Applications of High Pressure Air Blowers in Electronics Engineering

High pressure air blowers are indispensable tools in electronics engineering, demonstrating impressive versatility across a range of applications. Primarily, they are utilized for refrigerating circuit boards, drying components, and cleaning delicate parts. The ability of the high pressure air blower to generate high pressure allows these devices to deliver precise airflow, making them ideal for tasks such as effectively removing dust from sensitive electronic equipment and enhancing the cooling efficiency of high-performance processors.

Current statistics reveal that the industrial air fan market is valued at USD 3.7 billion in 2023, with significant anticipated growth. The market is projected to expand at a compound annual growth rate (CAGR) of 4.9% from 2025 to 2034, potentially reaching an estimated size of USD 17.55 billion in 2024. This trend highlights the escalating demand for such technologies within the electronics sector. Practical examples underscore their effectiveness; for instance, high pressure air blowers are frequently employed in manufacturing environments, particularly in the food and beverage and pharmaceutical industries, where maintaining cleanliness and operational efficiency is paramount.

Furthermore, the adaptability of high pressure air blowers extends to applications in pneumatic conveying and ventilation, reinforcing their significance in contemporary electronics engineering. As industries evolve, the integration of smart technologies and customizable features in air apparatus designs is expected to enhance their functionality. This evolution will render these devices even more valuable in addressing the intricate challenges faced by engineers today, including high maintenance costs and the necessity for improved operational efficiency.

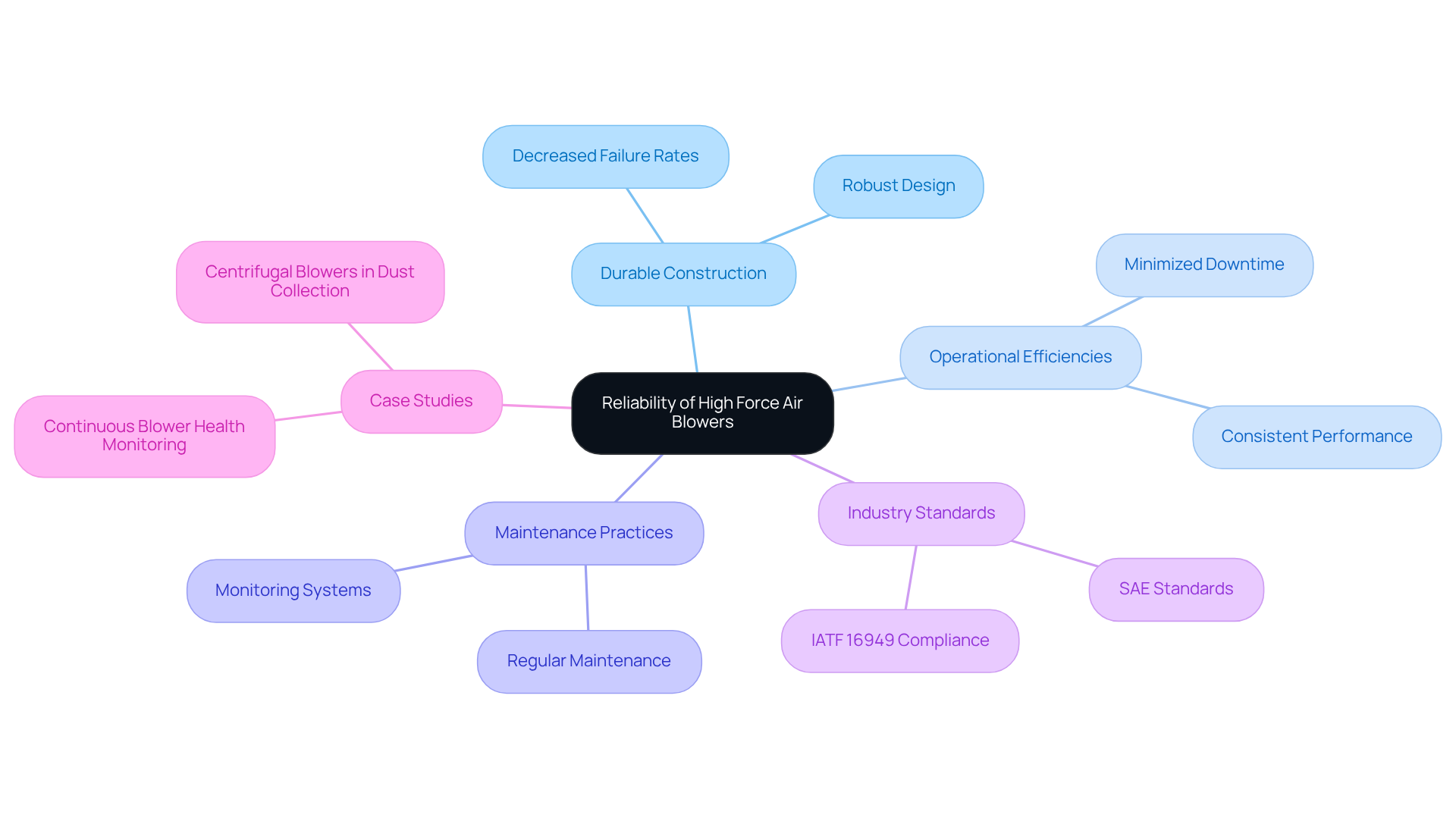

Reliability: Ensuring Consistent Performance with High Pressure Air Blowers

High force air fans are meticulously engineered for reliability, delivering consistent performance even under the most challenging conditions. Their durable construction markedly decreases failure rates when compared to traditional cooling systems, a critical factor in settings where electronic components demand continuous operation.

For instance, high force air devices achieve operational efficiencies that minimize downtime—an essential aspect in electronics applications. Regular maintenance, combined with strict adherence to manufacturing standards, further enhances their reliability, establishing them as a preferred choice among engineers.

Notably, Gagner-Toomey Associates offers state-of-the-art solenoid and rotary boost pump solutions that significantly enhance high pressure air blower devices in electronics applications. These pumps comply with industry standards such as IATF 16949 and SAE, ensuring both quality assurance and performance reliability.

Gagner-Toomey Associates also boasts extensive distribution capabilities, guaranteeing the availability of these vital components. Case studies demonstrate that these devices maintain optimal airflow and cooling efficiency in high-stakes environments, ensuring seamless operation of electronic systems.

This reliability is underscored by industry experts who emphasize the importance of robust fan design in achieving consistent performance, particularly within electronics engineering applications.

Environmental Benefits: Promoting Sustainability with High Pressure Air Blowers

High-pressure air blowers play a crucial role in advancing environmental sustainability by significantly reducing energy consumption and minimizing waste. Their efficient operation can lead to a substantial decrease in carbon emissions compared to traditional temperature control methods, aligning with global initiatives aimed at mitigating the environmental impact of industrial processes. For example, the integration of high-efficiency motors in cooling systems can save approximately 1940 GWh of energy over a decade for 20 kW motors in Malaysia. This translates to considerable utility bill savings and a reduction of 1789 million kg of CO emissions.

Moreover, many high pressure air blower devices are engineered to function without harmful refrigerants, which enhances their eco-friendliness and supports the transition towards greener technologies in electronics engineering. Case studies demonstrate that industries employing these advanced devices not only improve operational efficiency but also foster a more sustainable future by adhering to stringent environmental regulations and reducing their carbon footprint. Additionally, the potential financial losses from ineffective air compressor systems underscore the economic benefits of utilizing high pressure air blowers.

Ease of Maintenance: Simplifying Upkeep with High Pressure Air Blowers

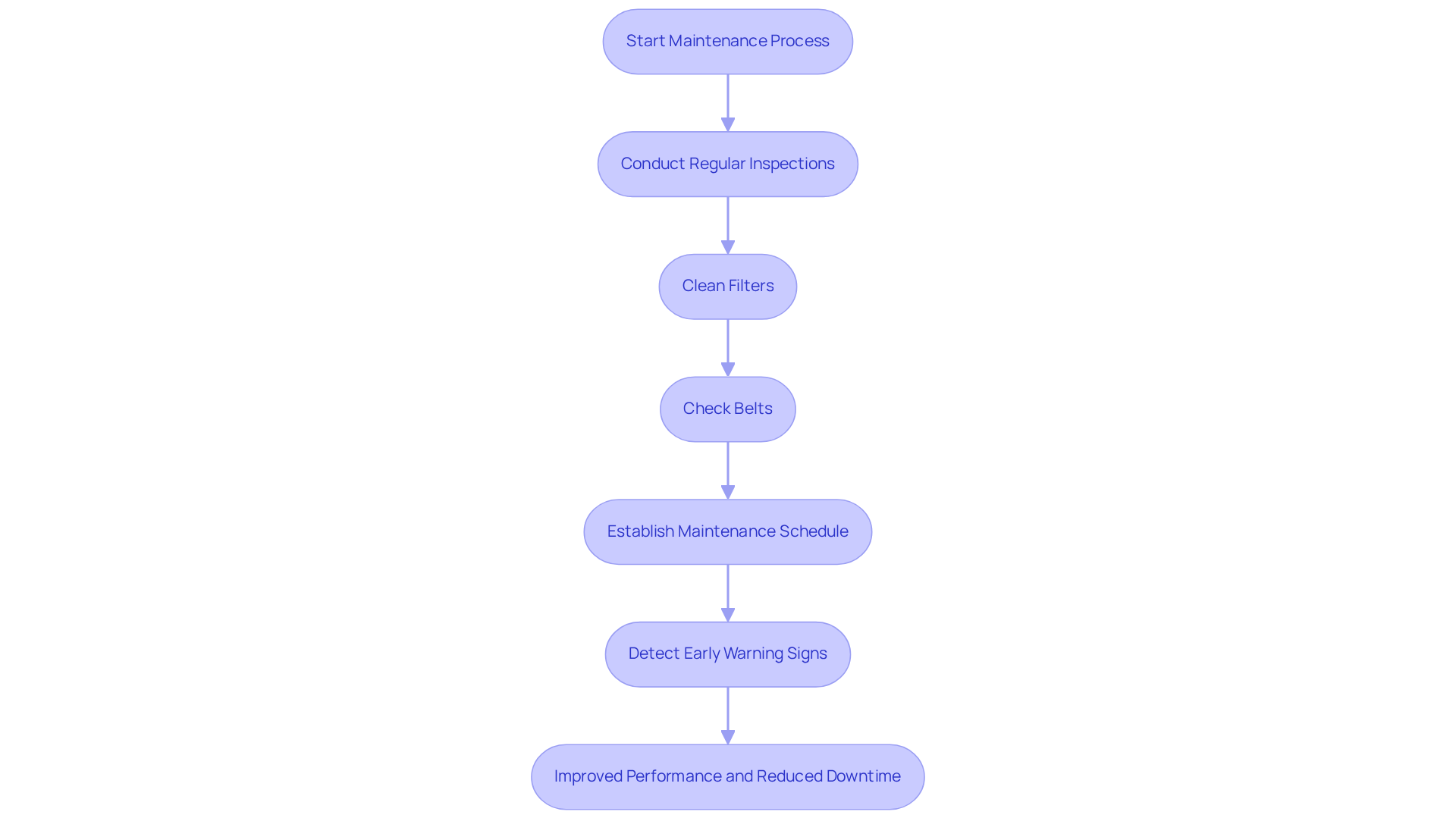

High force air fans are engineered for straightforward maintenance, featuring easily accessible components that facilitate regular inspections and repairs. Routine tasks, such as filter cleaning and belt checks, can be performed quickly, significantly minimizing downtime. This efficient maintenance not only guarantees optimal system performance but also boosts overall productivity.

For example, establishing a structured maintenance schedule can significantly reduce the likelihood of unexpected failures; proactive servicing enables maintenance teams to detect early warning signs of wear and tear, including unusual noises or overheating. Furthermore, data indicates that well-maintained devices lead to decreased energy consumption, thereby improving operational costs.

By prioritizing ease of maintenance, high-velocity air devices contribute to a more reliable and cost-effective solution for electronics engineering applications.

Safety: Enhancing Workplace Safety with High Pressure Air Blowers

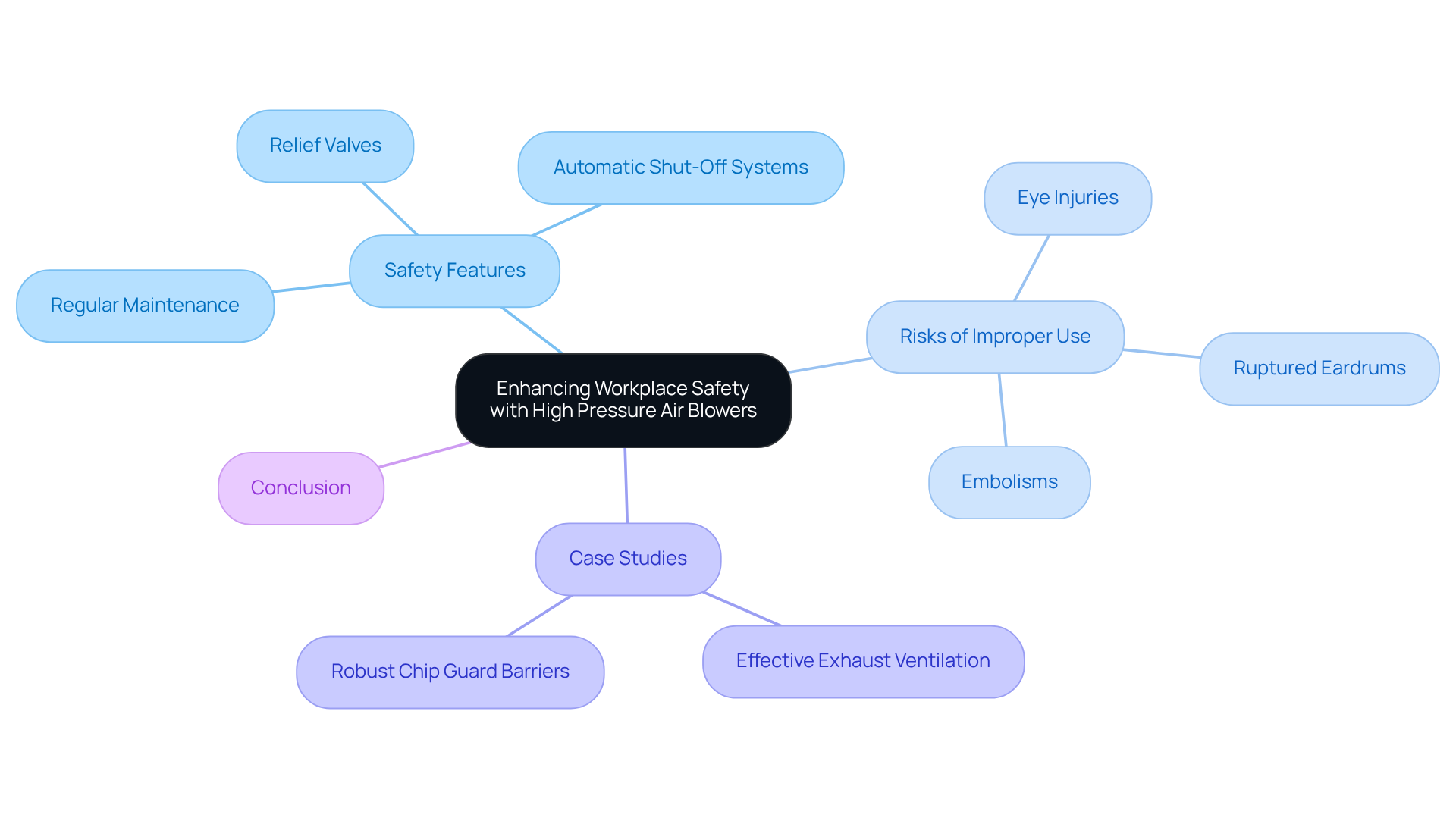

High force air blowers significantly enhance workplace safety by delivering a controlled and efficient airflow management system. Their design effectively mitigates the risks associated with traditional cooling methods, such as water leaks and electrical hazards. Essential safety features, including relief valves and automatic shut-off systems, are critical in numerous models, ensuring safe operation even under high-demand conditions.

Statistics indicate that improper use of compressed air can result in severe injuries, with misdirected jets leading to eye injuries or ruptured eardrums. In fact, compressed air can generate enough force to inflict serious internal injuries, such as embolisms, which can be fatal. In workplaces utilizing high force air devices, the implementation of these safety features has been linked to a reduction in accident rates. For instance, regular maintenance and inspection of ventilators can prevent mechanical failures, while ATEX-rated fans are vital in environments with combustible dust, thus minimizing ignition hazards.

Case studies illustrate the positive impact of high velocity air devices on workplace safety. One notable example reveals how effective exhaust ventilation systems, paired with high-quality extraction fans, significantly lowered the risks associated with airborne contaminants and equipment failures. Additionally, a case study on the effects of flying debris underscores the importance of robust chip guard barriers to avert serious eye injuries. Moreover, organizations that prioritize safety training, as highlighted in the special report on safety training, have documented a substantial decrease in workplace injuries, emphasizing the necessity of integrating safety measures into operational practices.

In conclusion, high pressure air blower devices not only improve operational efficiency but also play a crucial role in fostering a safer working environment within the electronics industry. Routine maintenance and inspection of fans are essential to prevent mechanical failures and ensure continuous safety.

Technological Advancements: Innovations in High Pressure Air Blowers

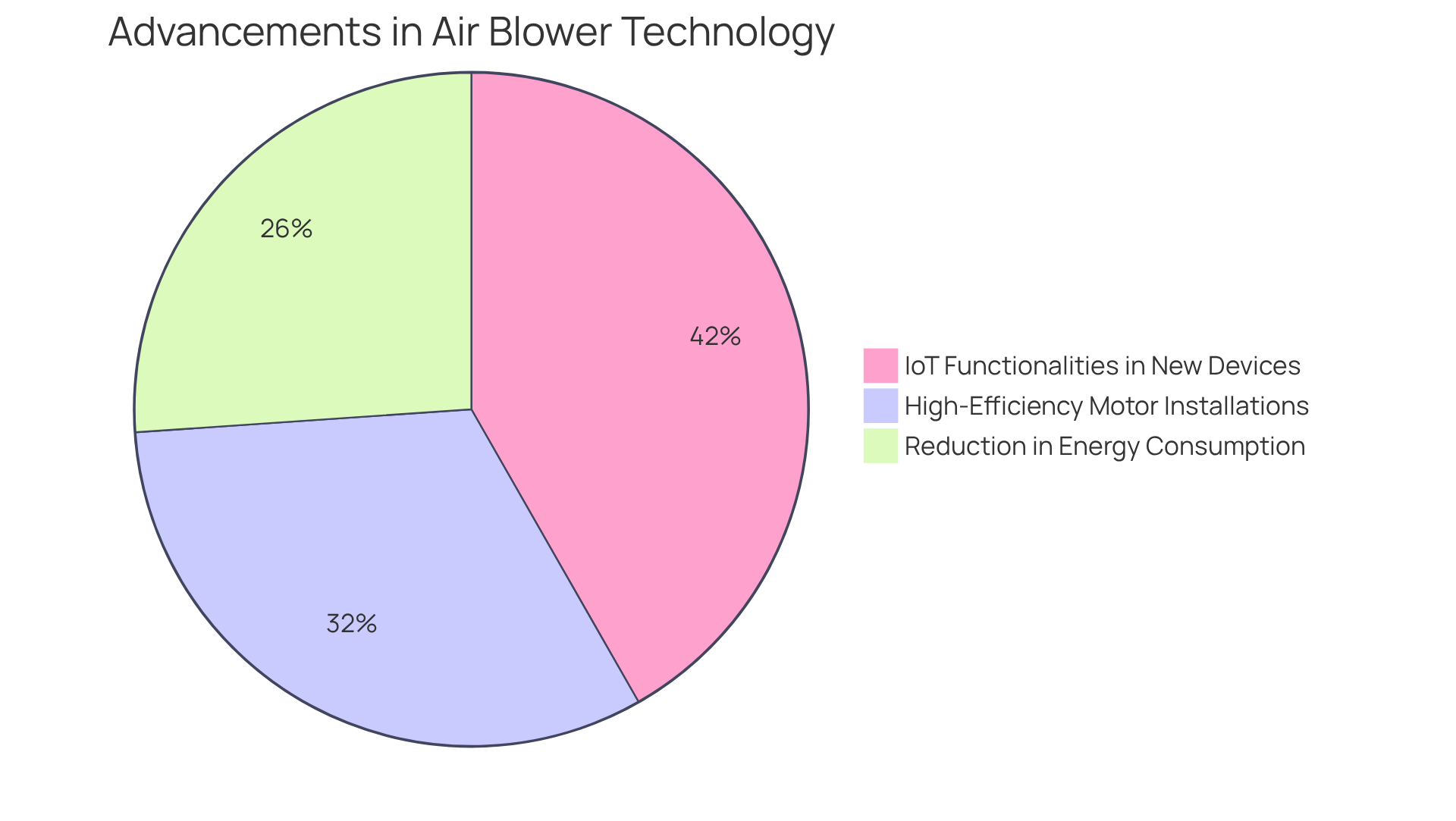

Recent advancements in high pressure air blower technology have markedly enhanced motor efficiency, with high-efficiency motors now utilized in approximately 37% of installations. This progress has led to a notable 30% reduction in energy consumption when compared to traditional fixed-speed models. Innovations such as variable speed drives facilitate precise airflow adjustments, optimizing performance to align with specific application requirements. These technological developments not only improve efficiency but also contribute to quieter operation, making fans suitable for diverse environments.

For example, RAETTS turbo units, outfitted with advanced control systems, allow for real-time monitoring and adjustments, resulting in a 25% decrease in energy usage within wastewater treatment facilities, where around 44% of newly established plants employ high-efficiency air devices. Furthermore, the integration of IoT functionalities in over 48% of newly installed air devices enables predictive maintenance, thereby enhancing operational reliability.

These advancements highlight the industry’s transition towards energy-efficient solutions, propelled by stringent environmental regulations and the increasing demand for technologies like high pressure air blowers that enhance air movement performance. As Cherish Cai noted, “Turbo fans play a critical role in various sectors, providing the necessary airflow and pressure for processes such as wastewater treatment, pneumatic conveying, and aeration.

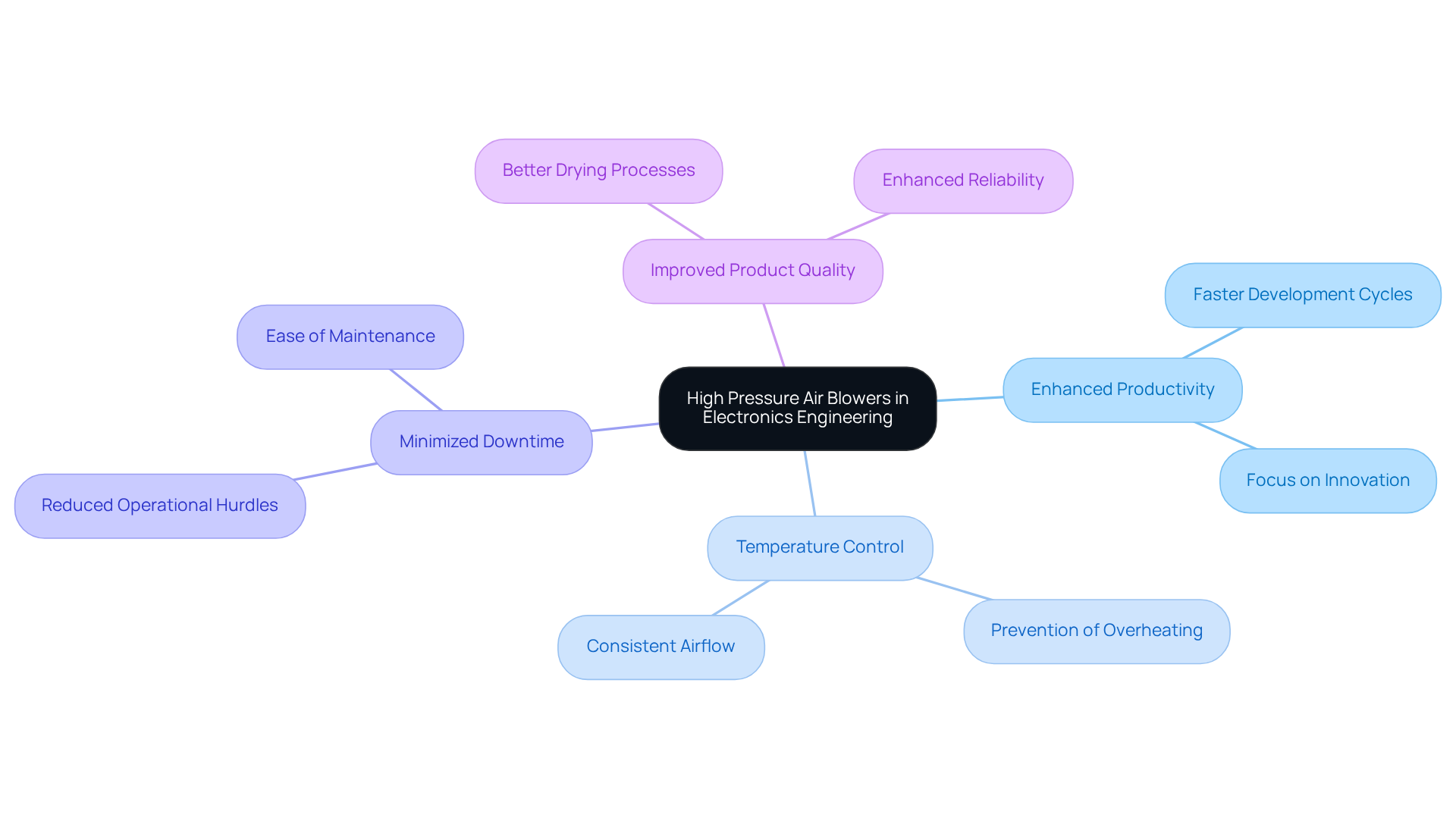

Increased Productivity: The Overall Impact of High Pressure Air Blowers in Electronics Engineering

High pressure air blowers play a pivotal role in enhancing productivity within electronics engineering. They provide effective temperature control solutions that prevent overheating, thereby minimizing downtime and empowering engineers to concentrate on innovation rather than operational hurdles.

For instance, companies in the electronics manufacturing sector have reported substantial productivity gains by integrating high pressure air blowers into their workflows. These devices optimize processes by incorporating a high pressure air blower to ensure consistent airflow, which is essential for cooling machinery and sustaining optimal operating conditions.

Consequently, development cycles are expedited, resulting in superior product quality and a quicker time-to-market. Moreover, the ease of maintenance associated with these devices alleviates operational challenges, allowing teams to focus on critical engineering tasks.

In summary, the adoption of high pressure air blowers not only enhances efficiency but also cultivates an environment that promotes innovation and excellence in electronics engineering.

Conclusion

High pressure air blowers signify a transformative technology in electronics engineering, delivering numerous advantages that enhance operational efficiency, reduce costs, and promote sustainability. Their capacity to provide targeted airflow not only alleviates thermal buildup but also markedly elevates the performance and reliability of electronic systems. As industries increasingly depend on these devices, the influence of high pressure air blowers transcends mere functionality, shaping the future of engineering practices.

This article underscores critical benefits, including:

- Enhanced efficiency

- Cost-effectiveness

- Versatility in applications

- The significance of reliability and maintenance

High pressure air blowers yield substantial energy savings, lower operational costs, and improved workplace safety. Moreover, the integration of innovative technologies—such as IoT functionalities and high-efficiency motors—exemplifies the industry’s dedication to advancing air movement solutions that align with environmental sustainability goals.

As the demand for high pressure air blowers continues to escalate, it becomes imperative for engineers and industry professionals to adopt these technologies. By doing so, they can optimize their operations while fostering a culture of innovation and excellence within the electronics sector. Investing in high pressure air blower technology is not merely a choice; it constitutes a strategic move toward achieving greater efficiency, safety, and sustainability in a rapidly evolving landscape.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for delivering innovative solutions specifically designed for the electronics sector, particularly through the application of high pressure air blowers that enhance air circulation and ventilation systems.

How do high pressure air blowers benefit electronic components?

High pressure air blowers improve air circulation and cooling, which helps maintain optimal operating temperatures for electronic components, thus enhancing overall system performance and efficiency.

What is the projected market growth for high-speed fans?

The high-speed fans market, valued at USD 872.1 million in 2023, is projected to grow at a CAGR of over 4.4% from 2024 to 2032, driven by advancements in energy efficiency and industrial automation.

Why is there a rising demand for oil-free and Class 0-certified fans?

There is an increasing demand for oil-free and Class 0-certified fans due to stringent hygiene standards in industries such as food and beverage and pharmaceuticals.

How do high pressure air blowers contribute to cost savings in operations?

High pressure air blowers can reduce operational expenses by consuming significantly less energy compared to traditional cooling methods, leading to utility bill reductions and lower maintenance costs.

What are the energy savings associated with energy-efficient turbo fans?

Energy-efficient turbo fans can reduce energy consumption by as much as 80%, resulting in substantial decreases in utility expenses.

What role do IKEUCHI nozzles play in air consumption?

Implementing IKEUCHI nozzles can lead to a reduction in compressed air consumption by 79% to 91%, enhancing productivity while lowering costs.

What is the importance of regular maintenance for high pressure air blower systems?

Regular maintenance is essential to keep leakage below 10% and ensure optimal performance and efficiency of high pressure air blower systems.

Are there financial incentives for upgrading to air-moving technology?

Yes, financial incentives are available for upgrading to air-moving technology, covering up to 50% of project expenses, limited to $200 per compressor horsepower shifted.

How quickly can companies expect a return on investment from high pressure air blowers?

Companies can often realize a rapid return on investment from high pressure air blowers in under a year, thanks to reduced energy usage and lower maintenance requirements.