Overview

Radial fans, commonly referred to as centrifugal blowers, serve a critical role in the efficient transport of air or gases through the application of centrifugal force. This design makes them particularly suited for scenarios that demand high pressure against resistance. Their key features include:

- Impressive pressure generation

- Compact design

- Versatile blade configuration

These attributes not only enhance their performance but also facilitate a wide range of industrial applications, including:

- HVAC systems

- Dust collection

- Fume extraction

- Cooling systems

Collectively, these aspects underscore the essential role of radial fans in contemporary engineering solutions.

Introduction

Radial fans, commonly referred to as centrifugal blowers, are instrumental in a wide array of industrial applications, leveraging centrifugal force to efficiently transport air or gases. Their distinctive design facilitates higher pressure generation, rendering them essential in environments that require effective air management, such as HVAC systems and electronic cooling.

Yet, as industries continue to evolve, a pressing challenge emerges: how can these fans adapt to fulfill the escalating demands for efficiency and versatility in an ever-changing market?

This article investigates the crucial features and applications of radial fans, examining their significance and the innovations propelling their advancement.

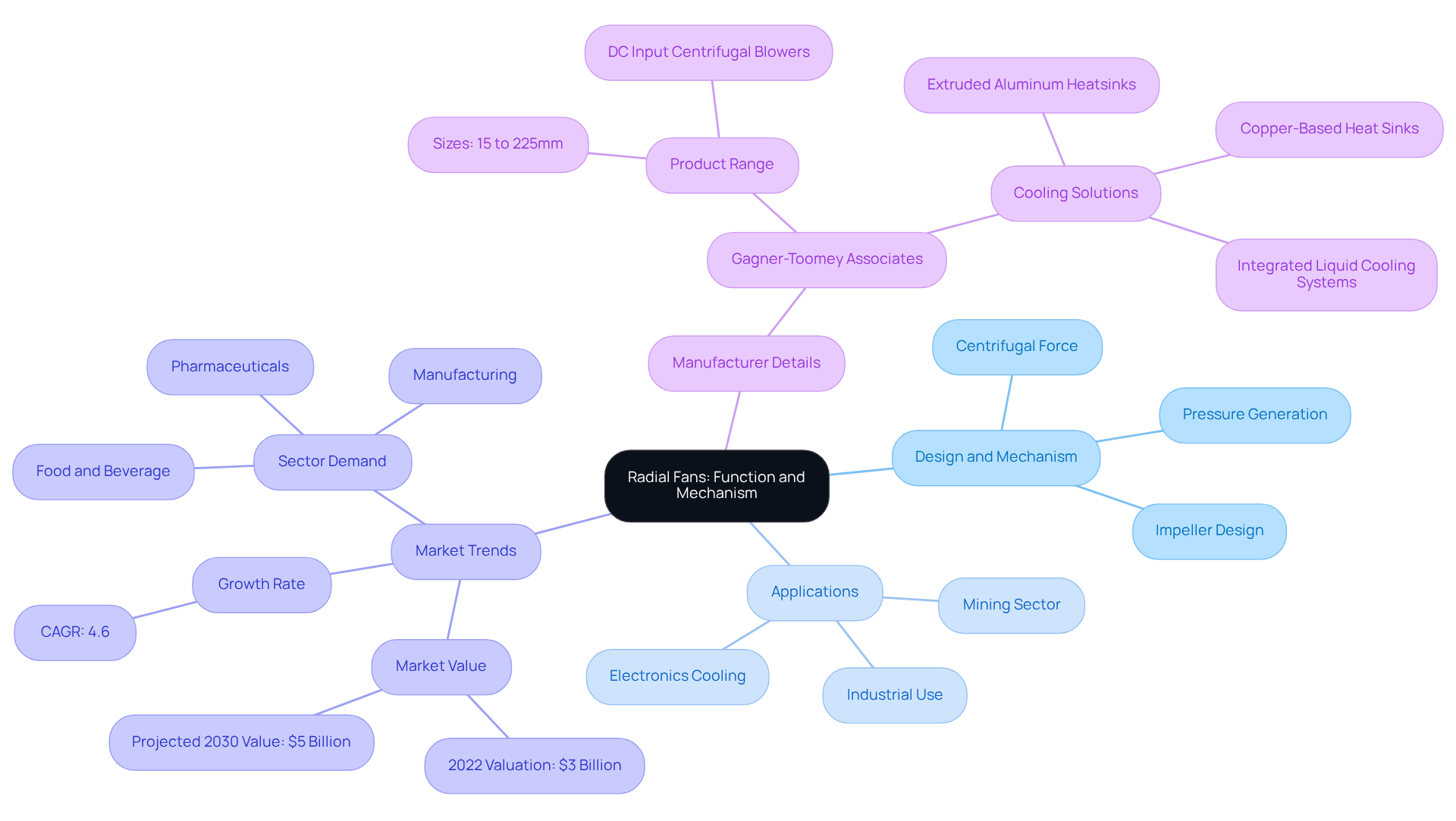

Define Radial Fans: Function and Mechanism

Radial fans, often called centrifugal blowers, are designed to efficiently transport air or gases through a system by utilizing centrifugal force. In contrast to axial devices that draw air parallel to their axis of rotation, radial fans intake air centrally and expel it radially outward. This innovative design of radial fans enables them to generate significantly higher pressures, making radial fans ideal for applications requiring airflow against resistance, such as cooling systems for electronics.

Gagner-Toomey Associates stands out as the world’s largest manufacturer of both standard and custom air-movers, offering an extensive selection of DC input centrifugal blowers and ventilation devices, all optimized for performance, efficiency, and low noise levels. Their product range spans sizes from 15 to 225mm, addressing diverse needs across electronics, automotive, and other sectors. Furthermore, Gagner-Toomey Associates provides IP protection for most models upon request, alongside a variety of cooling solutions, including extruded aluminum heatsinks, copper-based heat sinks, and .

The fundamental operation of circular blowers relies on an impeller, driven by an electric motor, which rotates to create a pressure differential that facilitates airflow. The blades of the impeller are typically curved, enhancing the direction of airflow into a volute or scroll housing that efficiently channels the air. This configuration not only boosts performance but also reduces noise levels and energy consumption.

Current market trends indicate a robust growth trajectory for circular blowers, with the global centrifugal blowers market valued at approximately $3 billion in 2022 and projected to reach $5 billion by 2030, reflecting a compound annual growth rate (CAGR) of 4.6%. This expansion is fueled by rising demand across multiple sectors, including food and beverage, pharmaceuticals, and manufacturing, where effective air management is vital.

Practical applications of radial fans in electronics cooling systems underscore their efficacy. For example, backward-curved centrifugal blowers from Gagner-Toomey Associates are extensively utilized in industrial settings for air management and dust collection, maintaining low noise levels while effectively generating negative pressure. Radial fans are crucial cooling devices for ensuring optimal thermal performance in electronic equipment, emphasizing their essential role in contemporary engineering solutions. Additionally, the mining sector is anticipated to spearhead end-user growth in the centrifugal market, illustrating the diverse applications of centrifugal devices across various industries.

As noted by industry experts, ‘Centrifugal blowers are recognized for their dependability and versatility, rendering them essential in numerous industrial applications.’ This assertion reinforces the advantages of radial devices across a range of uses, further solidifying their importance in the market.

Explore Key Characteristics of Radial Fans

Radial fans are characterized by several key features that make them exceptionally effective in industrial applications, especially those offered by Gagner-Toomey Associates, the largest manufacturer of standard and custom air-movers for cooling across various sectors like Electronics and Automotive.

- High Pressure Generation: These devices excel at generating significant static pressure, making them particularly suitable for environments with high resistance, such as long duct runs or systems equipped with filters. Radial blade ventilators achieve the highest pressures of nearly any industrial configuration, which is essential for efficient air movement in challenging environments.

- Compact Design: Radial blowers typically have a more compact footprint compared to their axial counterparts. This design advantage facilitates easier incorporation into confined spaces, making them ideal for applications where space is limited, such as electronic cooling systems.

- Versatile Blade Design: The blades of circular ventilators can be configured in various designs, including backward-curved and forward-curved options. This versatility enables performance optimization tailored to specific operational needs, thereby enhancing their effectiveness across a range of applications.

- Durability: Constructed from robust materials such as carbon steel and high-yield steels, these devices are engineered to withstand severe conditions. Their strong structural design ensures resilience and longevity, positioning them as a reliable choice for industrial settings.

- Efficiency: While circular blowers may exhibit lower airflow rates than axial models, they maintain high efficiency at increased pressures. This characteristic makes them suitable for a wide array of industrial applications, particularly where pressure is a critical factor. Additionally, circular blowers are recognized for their self-cleaning capabilities, which can reduce labor costs and extend operational lifespan.

In conclusion, radial fans from Gagner-Toomey Associates offer a combination of high pressure generation, compact design, versatile blade configurations, durability, and operational efficiency, making them a valuable asset in .

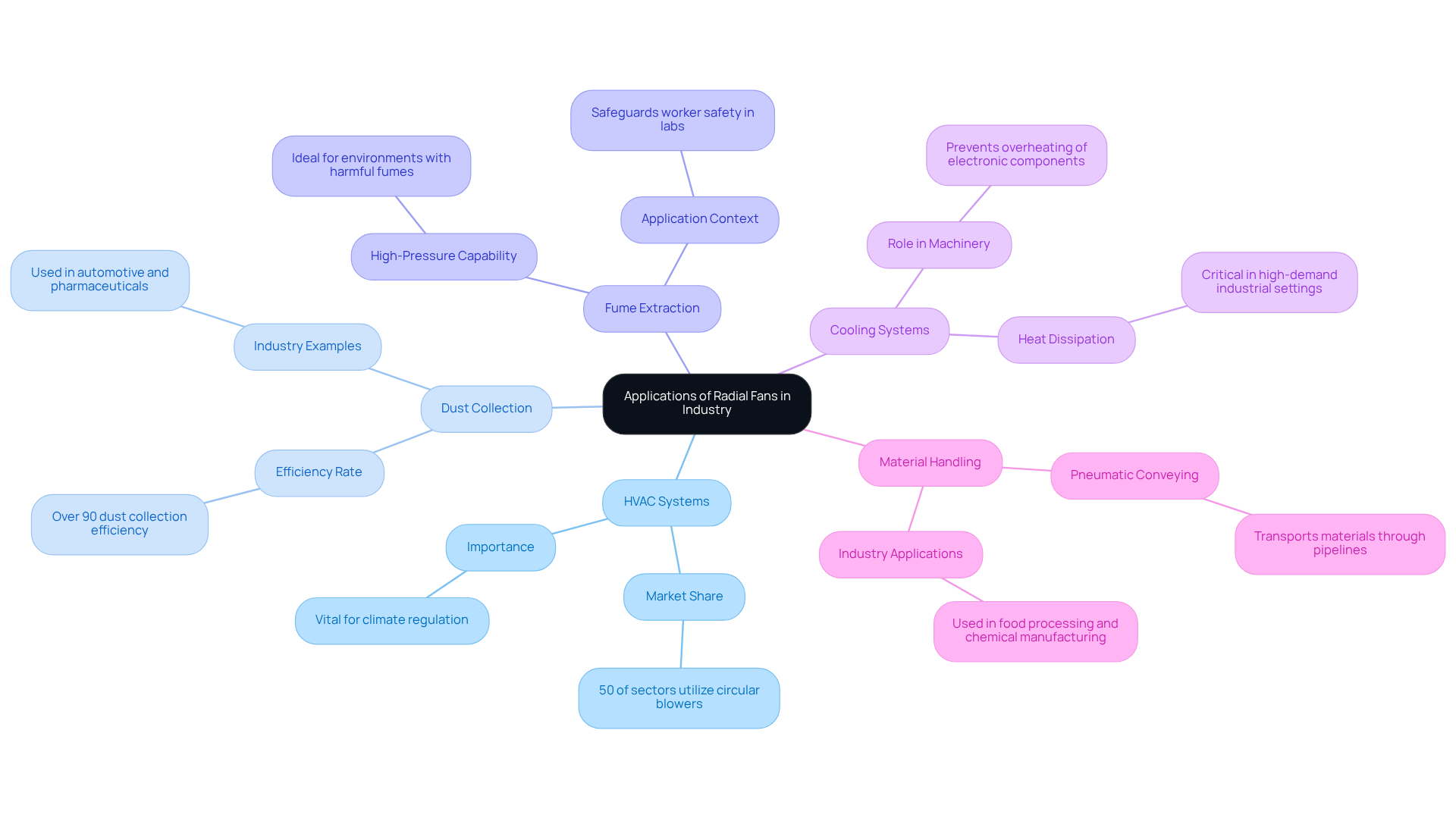

Examine Applications of Radial Fans in Industry

Radial fans are essential in numerous industrial applications due to their capacity to generate high pressure and effective airflow. Key applications include:

- Radial fans are integral to HVAC systems, facilitating air circulation and maintaining indoor air quality. Approximately 50% of sectors utilize circular blowers in their HVAC systems, underscoring their significance in climate regulation. HVAC systems lead the demand for circular blowers, accounting for a 50% market share, which highlights their vital role in this sector.

- Dust Collection: In manufacturing environments, centrifugal blowers efficiently extract dust and particulate matter from the air, ensuring a cleaner workspace. Research indicates that radial fans can achieve exceeding 90%, making them indispensable for compliance with health and safety regulations. The growing demand for ventilation systems, driven by new regulations, further emphasizes the importance of these devices in maintaining a safe working environment.

- Fume Extraction: These devices are employed in laboratories and industrial processes to eliminate harmful fumes and gases, thereby safeguarding worker safety. Their capability to manage high-pressure applications makes them ideal for environments where air quality is paramount.

- Cooling Systems: Radial fans play a critical role in cooling electronic components and machinery, preventing overheating and ensuring optimal performance. Their design facilitates effective heat dissipation, which is crucial in high-demand industrial settings.

- Material Handling: In processes involving pneumatic conveying, circular blowers transport materials through pipelines, showcasing their versatility across various industrial contexts. This functionality is particularly advantageous in sectors such as food processing and chemical manufacturing, where efficient material movement is essential.

Real-world examples underscore the effectiveness of circular blowers in dust collection systems, with case studies demonstrating their application in industries such as automotive and pharmaceuticals. HVAC experts assert that integrating circular blowers enhances system efficiency and air quality, aligning with the increasing demand for energy-efficient solutions in industrial settings. As noted by industry specialists, the increasing prevalence of smart technologies and IoT capabilities is further optimizing the performance of radial fans across diverse applications.

Conclusion

Radial fans, or centrifugal blowers, are essential in industrial air management, efficiently transporting air and gases through their innovative design. Their capability to produce high pressure renders them crucial in various applications, spanning HVAC systems to electronic cooling, thereby ensuring optimal performance in environments that require effective airflow against resistance.

Key characteristics of radial fans include:

- Their compact design

- Versatile blade configurations

- Exceptional durability

These attributes enhance their efficiency and reliability in diverse industrial settings, such as:

- Dust collection

- Fume extraction

- Material handling

The market for radial fans is projected to reach $5 billion by 2030, highlighting their growing importance across multiple sectors, driven by the increasing demand for advanced air management solutions.

As industries evolve, embracing technological innovations and efficiency, the significance of radial fans will continue to rise. Their adaptability and effectiveness in tackling modern air management challenges establish them as critical components in various applications. Investing in high-quality radial fans not only boosts operational efficiency but also fosters a safer and cleaner working environment, thereby reinforcing their vital role in contemporary industrial practices.

Frequently Asked Questions

What are radial fans and how do they function?

Radial fans, also known as centrifugal blowers, are designed to transport air or gases using centrifugal force. They intake air centrally and expel it radially outward, generating higher pressures compared to axial devices, making them suitable for applications requiring airflow against resistance.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest manufacturer of standard and custom air-movers, providing a wide range of DC input centrifugal blowers and ventilation devices. Their products are optimized for performance, efficiency, and low noise levels, with sizes ranging from 15 to 225mm.

What is the basic operational mechanism of circular blowers?

Circular blowers operate using an impeller driven by an electric motor. The rotating impeller creates a pressure differential that facilitates airflow. The curved blades of the impeller enhance airflow direction into a volute or scroll housing, improving performance while reducing noise and energy consumption.

What is the market trend for centrifugal blowers?

The global centrifugal blowers market was valued at approximately $3 billion in 2022 and is projected to reach $5 billion by 2030, with a compound annual growth rate (CAGR) of 4.6%. This growth is driven by increasing demand in sectors like food and beverage, pharmaceuticals, and manufacturing.

What are some practical applications of radial fans?

Radial fans are widely used in electronics cooling systems, industrial air management, and dust collection. They are essential for maintaining low noise levels while generating negative pressure, ensuring optimal thermal performance in electronic equipment.

How are radial fans utilized in the mining sector?

The mining sector is expected to lead the growth in the centrifugal market, showcasing the diverse applications of radial fans across various industries, including effective air management and cooling solutions.

What advantages do centrifugal blowers offer according to industry experts?

Industry experts recognize centrifugal blowers for their dependability and versatility, highlighting their essential role in numerous industrial applications.