Overview

The article addresses the implementation of heat exchange units in electronic systems, highlighting their essential function in thermal management to enhance both performance and reliability. It delineates a systematic approach for effective implementation, which includes:

- Evaluating thermal requirements

- Selecting suitable units

- Designing integration

- Installing systems

- Optimizing performance

This underscores the significance of these units in satisfying the thermal demands of contemporary electronics.

Introduction

The efficiency and longevity of electronic systems fundamentally depend on effective thermal management, positioning heat exchange units as a critical component in modern design. As the demand for high-performance electronics escalates, it becomes essential for engineers and designers to understand the various types of heat exchangers—spanning from air-cooled systems to innovative earth-air solutions. However, the real challenge lies in mastering the implementation of these units to optimize performance while adeptly navigating the complexities of thermal dynamics and system integration.

What strategies can be employed to ensure seamless integration and maximize efficiency in electronic applications?

Explore the Fundamentals of Heat Exchange Units

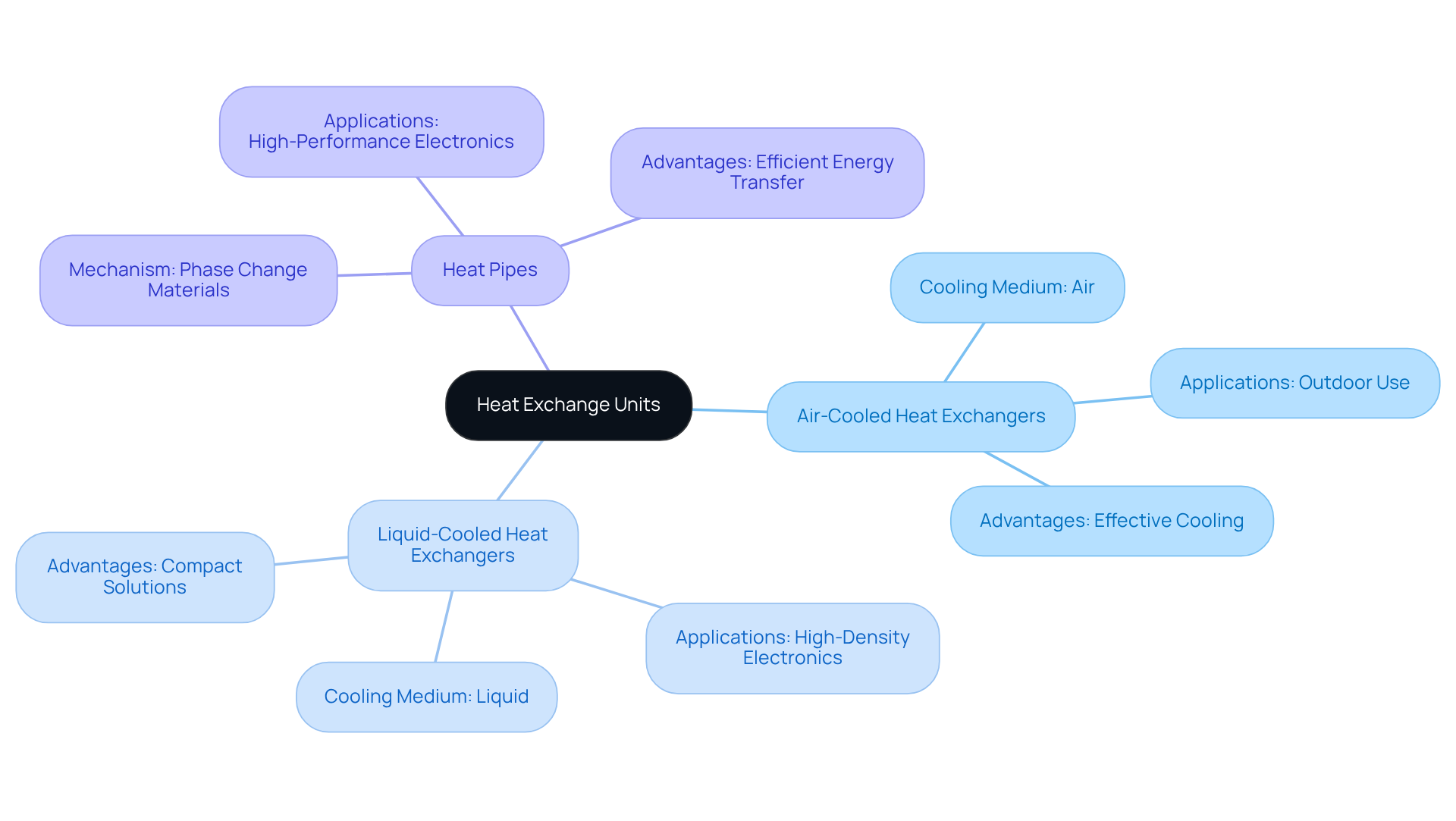

The performance and reliability of electronic systems greatly depend on heat exchange units, which are indispensable devices that facilitate the transfer of energy between fluids without allowing them to mix. The increasing demand for in the electronics industry underscores their significance. Key types of heat exchangers include:

- Air-Cooled Heat Exchangers: These units employ air as the cooling medium and are commonly utilized in outdoor applications, delivering effective cooling across diverse environments.

- Liquid-Cooled Heat Exchangers: By leveraging liquids to absorb heat, these exchangers offer efficient cooling solutions in compact spaces, making them particularly suitable for high-density electronic applications.

- Heat Pipes: Utilizing phase change materials, these devices efficiently transfer energy, rendering them ideal for high-performance electronics where effective temperature management is crucial.

The critical nature of these heat exchange units is further emphasized by industry leaders who highlight the necessity of robust thermal management in electronics. As Jim Klimek, global product manager for thermal transfer at Xylem, notes, “Demand for gasketed plate exchangers, which has emerged as the primary technology for thermal transfer, is anticipated to be particularly strong due to their high energy efficiency, compact size, and low cost.” This insight reflects the sector’s shift towards more sustainable and efficient technologies, reinforcing the vital role of heat exchange units in optimizing electronic performance. Additionally, advanced pump technologies, such as solenoid and rotary boost pumps, are essential for precision applications within thermal management systems. Gagner-Toomey Associates provides innovative solutions, including solenoid pumps capable of functioning up to 16 Bar and rotary boost pumps equipped with a DC brushless motor and EMI suppression circuit, which enhance the efficiency of temperature exchange processes. is projected to expand significantly, with Europe holding a 31.9% share in 2022, underscoring its relevance in broader industry trends. Understanding these fundamentals is critical for selecting the appropriate exchanger for specific applications, ensuring optimal thermal management and enhancing overall system reliability. For further information, please visit our product website or locate a distributor.

Analyze Earth-Air Heat Exchanger Design and Functionality

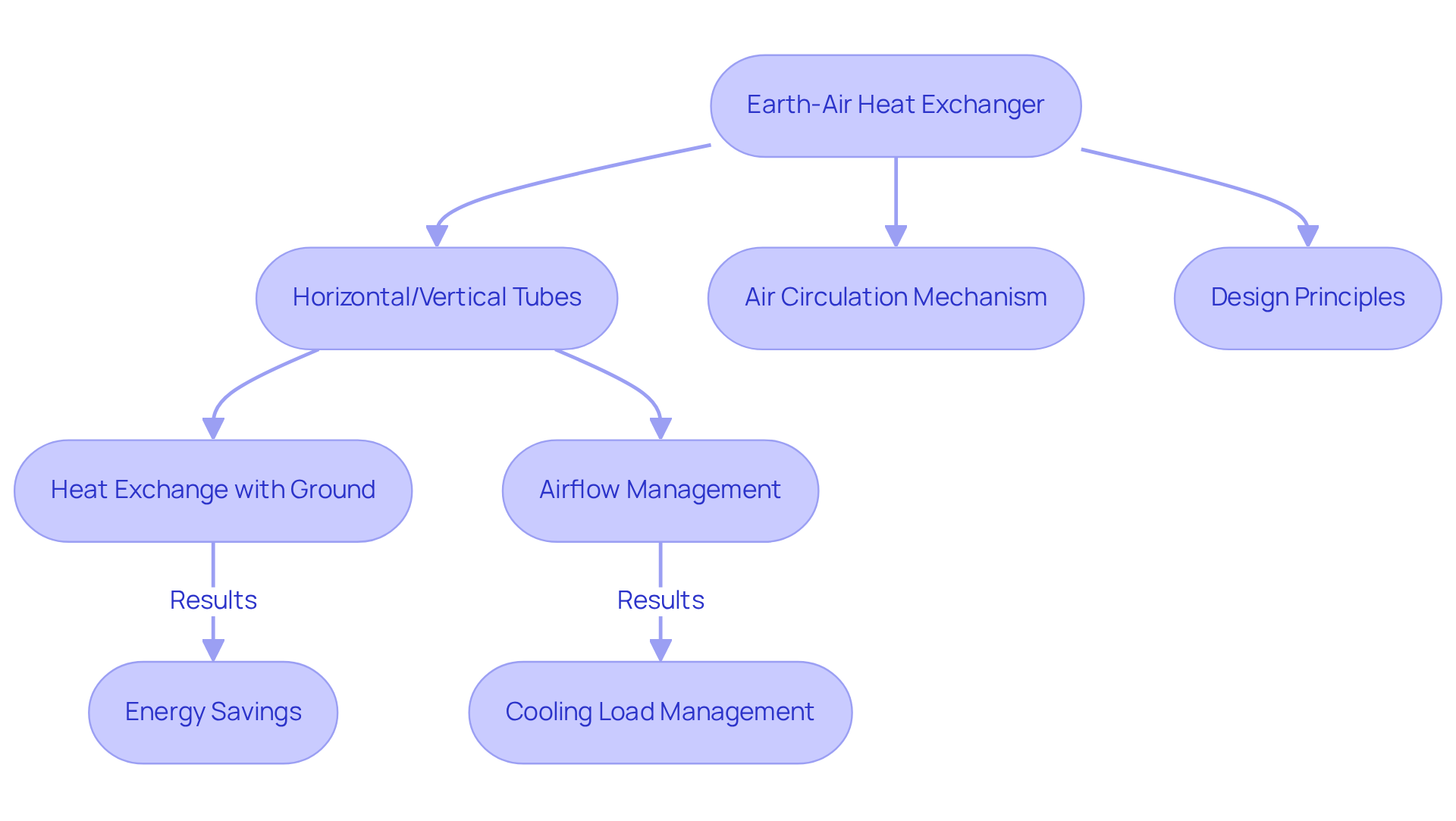

Earth-air thermal exchangers (EAHEs) leverage the stable temperatures of the ground to precondition air for buildings, significantly enhancing energy efficiency. The design typically incorporates:

- Horizontal or Vertical Tubes: These tubes are buried underground, facilitating air flow through them while exchanging heat with the surrounding earth.

- Air Circulation Mechanism: Air movement is achieved through fans or natural convection, ensuring effective thermal transfer.

Functionality: As air traverses the tubes, it either absorbs or dissipates heat based on seasonal conditions. During summer, the cooler ground temperature effectively cools the incoming air, while in winter, it warms the air, thereby lowering the requirement for heating. The heat exchange unit provides dual functionality that not only improves efficiency but also reduces dependence on traditional HVAC solutions.

Successful implementations of EAHEs have demonstrated significant power savings, with setups achieving an annual conservation estimate of 5,375 kWh. Studies suggest that these setups can lower cooling usage by 30-50% and yearly power consumption by 25-40%. Furthermore, integrating EAHEs with other passive strategies can further optimize energy performance, establishing them as a viable solution for sustainable building designs.

Recent research underscores the importance of design principles, such as ideal pipe depth and diameter, which greatly impact the performance of the setup. For instance, increasing the pipe diameter from 50.8 mm to 76.2 mm can lower air temperature from 20 °C to 18.6 °C, illustrating the critical role of design in maximizing efficiency. Additionally, utilizing materials with enhanced thermal conductivity, such as metallic waste products for backfill, can improve thermal performance by nearly 80% compared to traditional sand.

Moreover, the payback period for EAHE installations is under two years, emphasizing their financial feasibility. The (SEER) for these heat exchange units is estimated to be between 2-3, further highlighting their effectiveness compared to traditional HVAC units. As noted by Sanjay Kumar Singh, “the EAHE approach, if properly designed, can be a viable and economical alternative to replace conventional air-conditioning units.”

In practical applications, an EAHE unit can cool up to 25 individuals across 10 rooms, managing a cooling load of approximately 53 kW. A study conducted in Ahmedabad revealed a temperature decrease of 14 °C during summer months, underscoring the effectiveness of EAHE technologies in climates similar to Chandīgarh.

In summary, EAHEs represent a promising technology for energy-efficient building designs, effectively utilizing the earth’s thermal properties to meet indoor climate control needs while contributing to significant energy savings.

Implement Heat Exchange Units in Electronic Systems

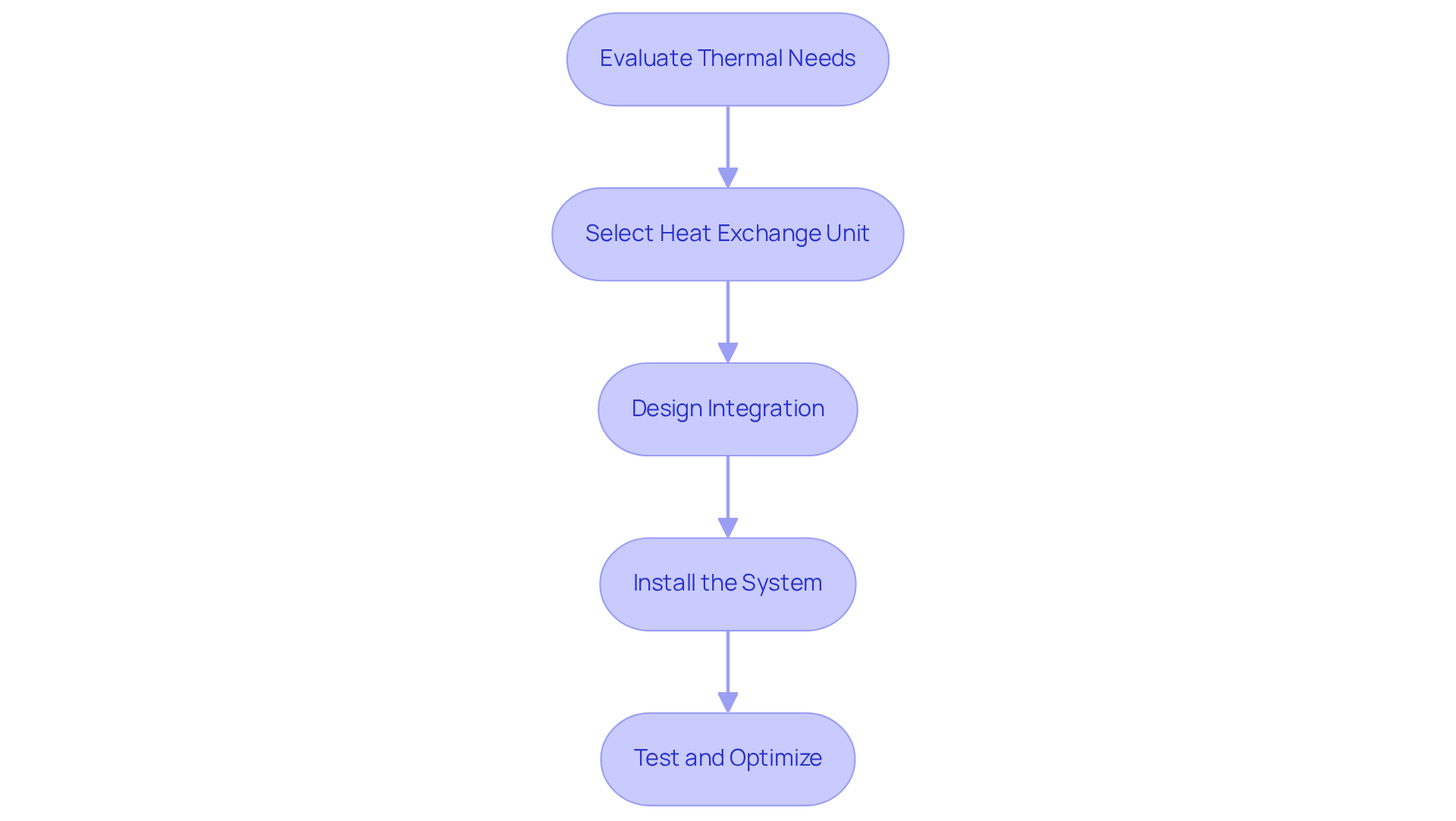

To implement heat exchange units in electronic systems, it is essential to follow a systematic approach:

- Evaluate Thermal Needs: Begin by ascertaining the thermal load generated by the electronic components. This assessment is critical for selecting the appropriate type of heat exchange unit.

- Select the appropriate heat exchange unit: Based on the identified temperature requirements, choose from air-cooled, liquid-cooled, or pipe solutions, ensuring that the heat exchange unit is compatible with the system’s demands.

- Design integration involves strategically organizing the arrangement of the heat exchange unit within the setup. This design phase should prioritize optimal airflow and accessibility for maintenance tasks.

- Install the System: Adhere to the manufacturer’s guidelines during installation. It is imperative to ensure that all connections are secure and free from leaks to maintain system integrity.

- Test and Optimize: Following installation, conduct thorough thermal performance evaluations. This step is vital to confirm that the system operates within the . Adjust fan speeds or flow rates as necessary to enhance overall performance.

By diligently following these steps, engineers can effectively manage heat within electronic systems, thereby significantly enhancing reliability and performance.

Conclusion

The implementation of heat exchange units is crucial for enhancing the performance and reliability of electronic systems. These units play a vital role in efficient thermal management, ensuring that electronic components operate within optimal temperature ranges. As the demand for advanced cooling solutions continues to rise, understanding the different types of heat exchangers and their applications becomes essential for engineers and designers alike.

Key insights from the article highlight the importance of selecting the right type of heat exchange unit, whether it be:

- air-cooled

- liquid-cooled

- earth-air thermal exchangers

Each type has its unique advantages and suitability for various applications, with earth-air heat exchangers demonstrating significant energy savings and sustainability benefits. Furthermore, employing systematic approaches during implementation—from evaluating thermal needs to optimizing performance—ensures effective integration and maximizes the operational efficiency of electronic systems.

In light of these considerations, the significance of mastering heat exchange unit implementation cannot be overstated. By prioritizing effective thermal management, engineers can not only enhance the reliability of electronic systems but also contribute to broader sustainability goals within the industry. As technology evolves, embracing innovative thermal solutions will be key to meeting the challenges of tomorrow’s electronic applications.

Frequently Asked Questions

What are heat exchange units and why are they important?

Heat exchange units are devices that facilitate the transfer of energy between fluids without allowing them to mix. They are crucial for the performance and reliability of electronic systems, particularly in managing thermal energy efficiently.

What are the main types of heat exchangers?

The main types of heat exchangers include: – Air-Cooled Heat Exchangers: Use air as the cooling medium and are effective in outdoor applications. – Liquid-Cooled Heat Exchangers: Utilize liquids to absorb heat, suitable for compact spaces and high-density electronic applications. – Heat Pipes: Employ phase change materials to transfer energy efficiently, ideal for high-performance electronics.

What is the significance of gasketed plate exchangers in thermal management?

Gasketed plate exchangers are highlighted as a primary technology for thermal transfer due to their high energy efficiency, compact size, and low cost, making them increasingly important in the electronics industry.

What role do advanced pump technologies play in thermal management systems?

Advanced pump technologies, such as solenoid and rotary boost pumps, are essential for precision applications within thermal management systems, enhancing the efficiency of temperature exchange processes.

What is the market outlook for thermal exchangers?

The thermal exchanger market is projected to expand significantly, with Europe holding a 31.9% share in 2022, indicating its relevance in broader industry trends.

How can one select the appropriate heat exchanger for specific applications?

Understanding the fundamentals of heat exchange units is critical for selecting the appropriate exchanger, ensuring optimal thermal management and enhancing overall system reliability. For more information, readers are encouraged to visit the product website or locate a distributor.