Overview

This article provides essential insights into electric blower fans tailored specifically for engineers, underscoring their critical role in efficient thermal management across diverse applications. It delineates key specifications, energy efficiency considerations, installation tips, maintenance practices, troubleshooting methods, and recent technological advancements. Each of these elements equips engineers with the necessary knowledge to select and implement blower fans effectively within their designs.

Introduction

Engineers are confronted with an escalating challenge in managing thermal efficiency within increasingly intricate electronic systems. As the demand for effective cooling solutions intensifies, grasping the nuances of electric blower fans becomes imperative for achieving optimal design and performance. This article explores ten essential insights that not only clarify the technical specifications and applications of these devices but also address the evolving landscape of energy efficiency and maintenance practices.

How can engineers harness these insights to elevate their projects and confront the pressing thermal management challenges of today?

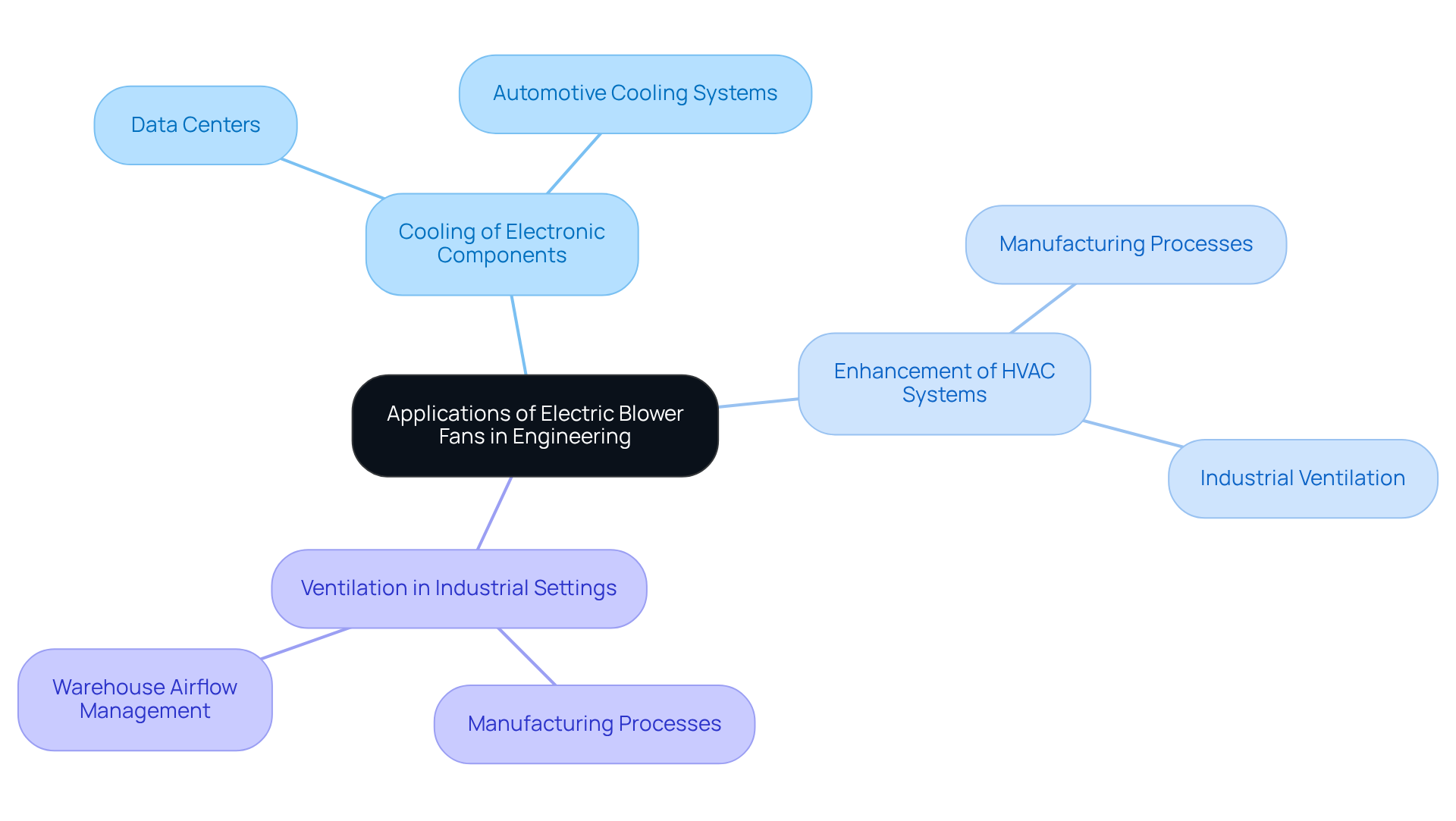

Gagner-Toomey Associates: Innovative Cooling Solutions for Engineers

Gagner-Toomey Associates stands out as a leader in delivering innovative cooling solutions tailored for . The necessity for advanced cooling technologies is paramount for engineers striving for efficient thermal management in their designs. By collaborating with a diverse array of manufacturers, Gagner-Toomey grants access to cutting-edge cooling products, including electric fans, essential for maintaining optimal operating temperatures in electronic components. This unwavering commitment to excellence not only guarantees adherence to stringent industry standards but also significantly boosts product performance. As the demand for effective cooling solutions escalates, particularly in high-density environments such as data centers, Gagner-Toomey remains at the forefront, equipping engineers with the essential tools to address complex thermal challenges.

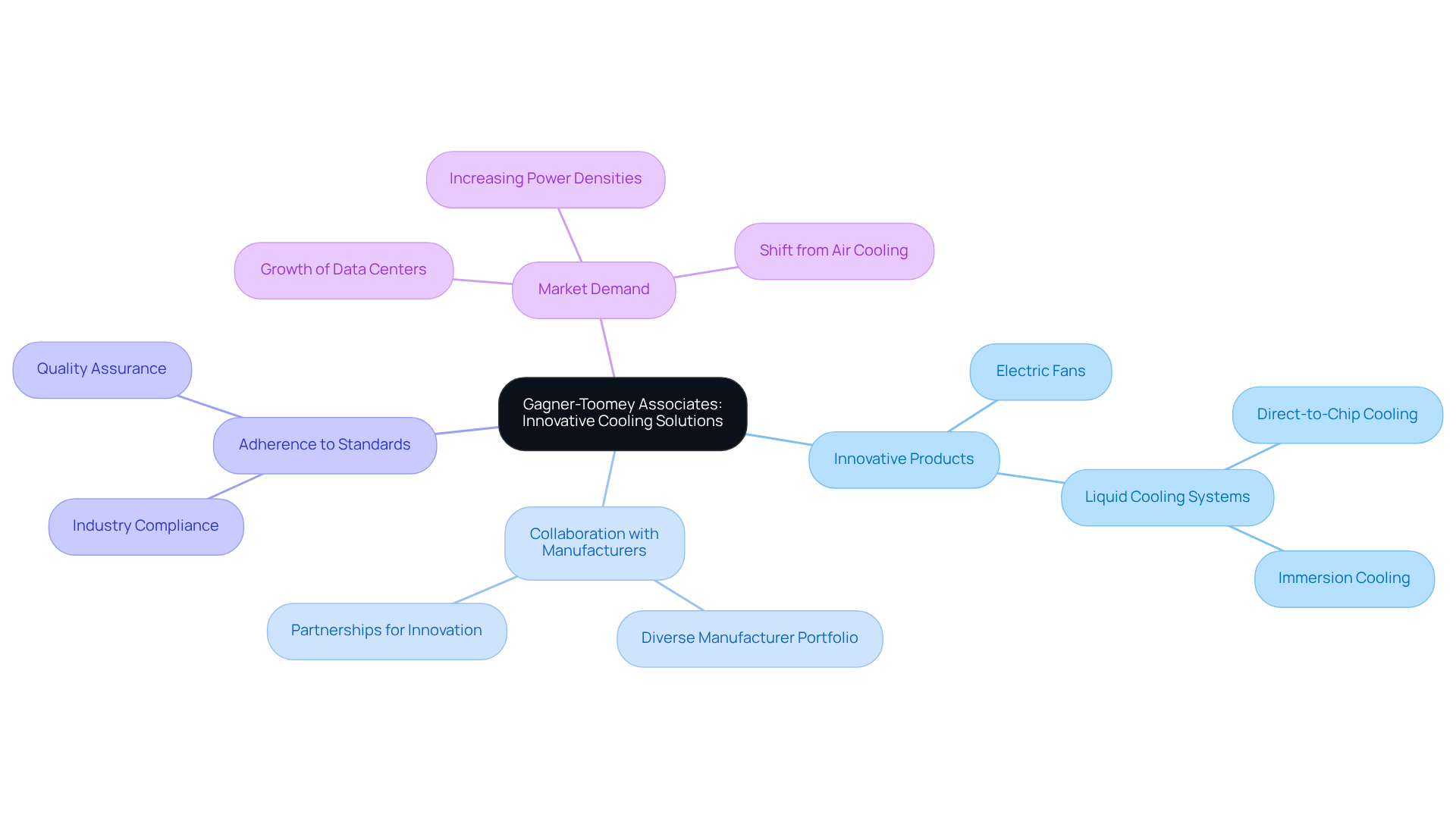

Understanding the Difference Between Fans and Blowers

Fans and ventilators serve distinct yet crucial roles in .

- Electric blower fans are specifically engineered to move large volumes of air with minimal pressure change, making them ideal for general ventilation purposes.

- In contrast, ventilators generate greater pressure and can direct air in a specific direction, which is essential for applications requiring focused air movement.

- Understanding these distinctions empowers engineers to select the appropriate device tailored to their project’s ventilation needs, thereby ensuring effective thermal management and optimal system performance.

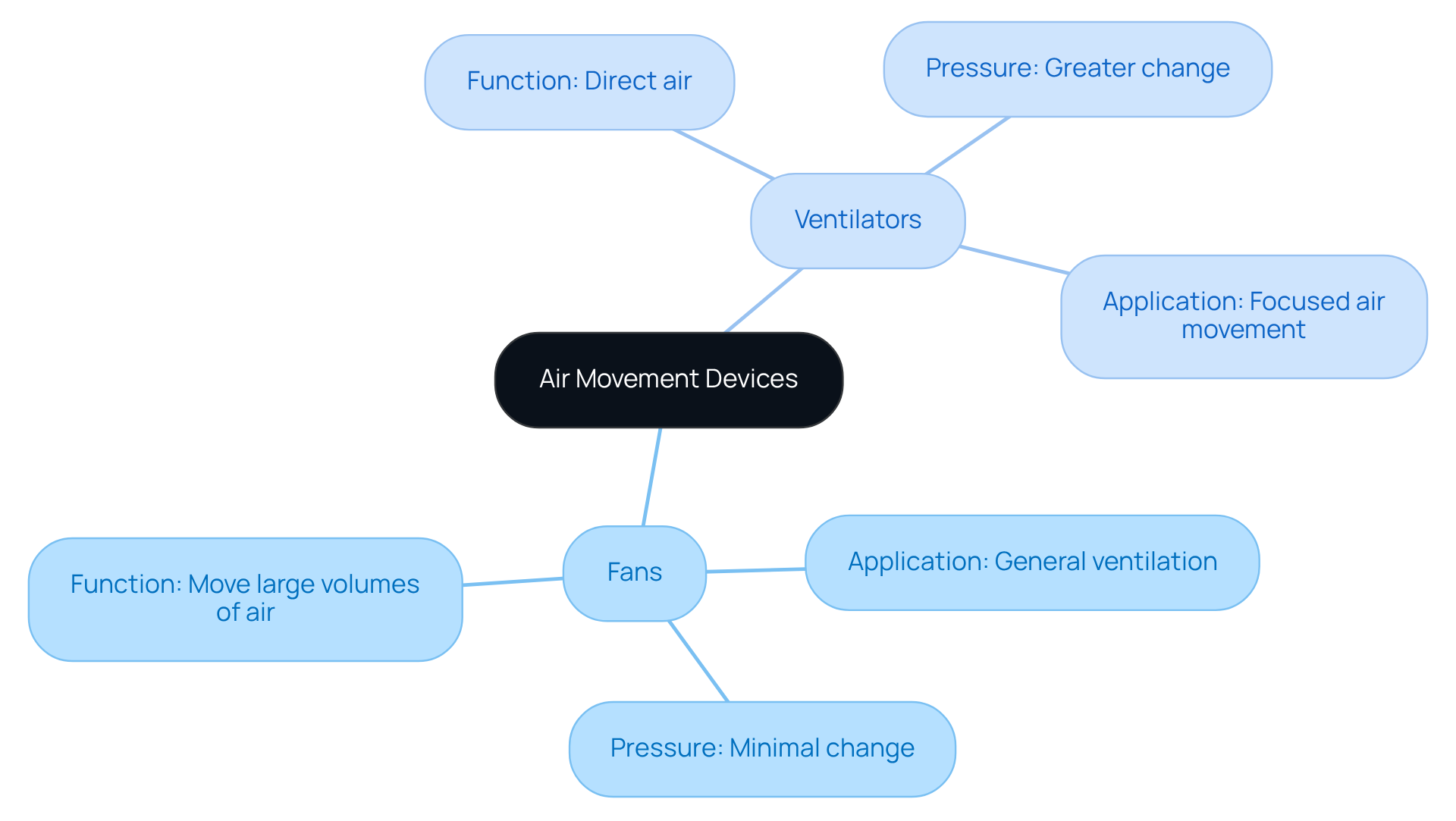

Applications of Electric Blower Fans in Engineering

Electric air movers play a crucial role in various engineering applications, including:

- The cooling of electronic components

- Enhancement of HVAC systems

- Provision of ventilation in industrial settings

Their effectiveness is particularly notable in scenarios requiring concentrated airflow, such as:

- Data centers

- Automotive cooling systems

- Manufacturing processes

Understanding these applications allows engineers to strategically integrate into their designs, thereby ensuring optimal functionality and reliability.

Key Technical Specifications for Electric Blower Fans

Choosing electric blower fans requires careful consideration of several key technical specifications to ensure optimal performance. Engineers must prioritize the ventilation rate, typically measured in cubic feet per minute (CFM), and static pressure, both of which significantly influence the effectiveness of electric blower fans across various applications. For instance, a fan delivering 5,000 CFM can achieve an efficiency of 50%, underscoring the importance of aligning ventilation requirements with operational needs.

Power consumption and noise levels are equally critical factors; electric blower fans must operate efficiently while minimizing sound output to maintain a conducive working environment. Dimensions also play a pivotal role in installation feasibility, as the available physical space can restrict fan size and configuration.

The type of motor used in electric blower fans is another essential consideration. AC motors are prevalent due to their reliability, whereas electric blower fans, which often use DC motors, provide advantages in speed control and energy efficiency. Engineers should also assess durability ratings to ensure the fan can endure the specific conditions of its application.

Real-world examples vividly illustrate the impact of these specifications. In grain drying applications, for example, understanding the relationship between airflow and static pressure is vital. At a grain depth of 14 feet, a static pressure of 7.8 inches of water is required at a flow rate of 1.25 CFM per bushel, highlighting the necessity for precise calculations in fan selection.

Ultimately, a comprehensive understanding of these technical specifications empowers engineers to of electric blower fans, ensuring that their designs meet both efficiency and operational requirements.

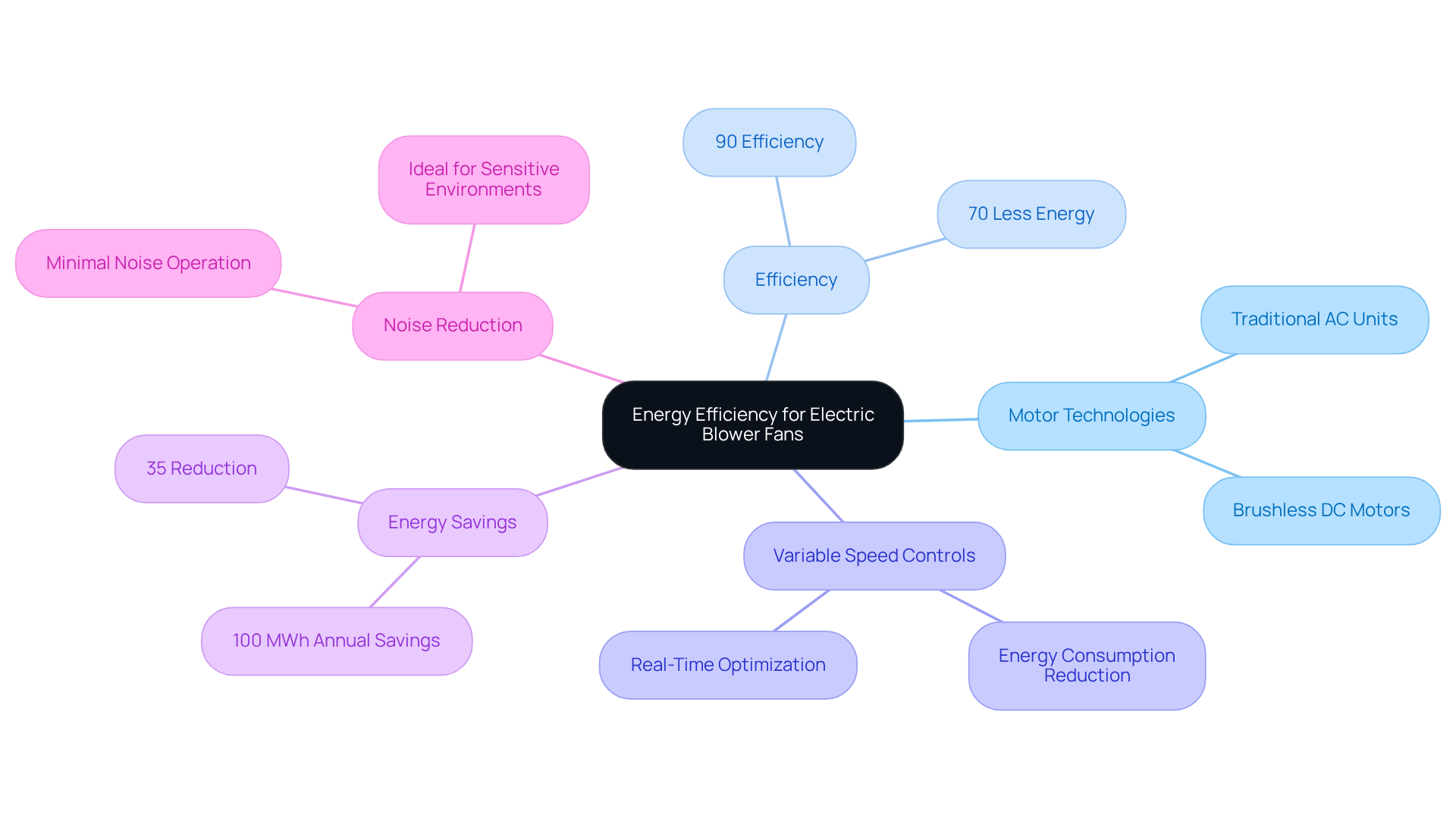

Energy Efficiency Considerations for Electric Blower Fans

Energy efficiency is a critical consideration when selecting electric blower fans. Engineers must prioritize devices featuring advanced motor technologies, particularly brushless DC motors, renowned for their exceptional efficiency and lower energy consumption.

Research indicates that can operate at efficiencies of up to 90%, utilizing 70% less energy compared to traditional AC units. Furthermore, the integration of variable speed controls allows for the optimization of operations based on real-time cooling needs, significantly reducing energy usage.

Practical applications reveal that adopting these technologies can result in considerable energy savings; for instance, retrofitting fan motors with variable speed drives achieved annual savings of 100 MWh, translating to a 35% reduction in consumption prior to retrofitting. Additionally, EC units are engineered to function with minimal noise, making them ideal for environments sensitive to sound.

By concentrating on energy-efficient designs, engineers not only promote sustainability initiatives but also effectively reduce operational costs through the use of electric blower fans.

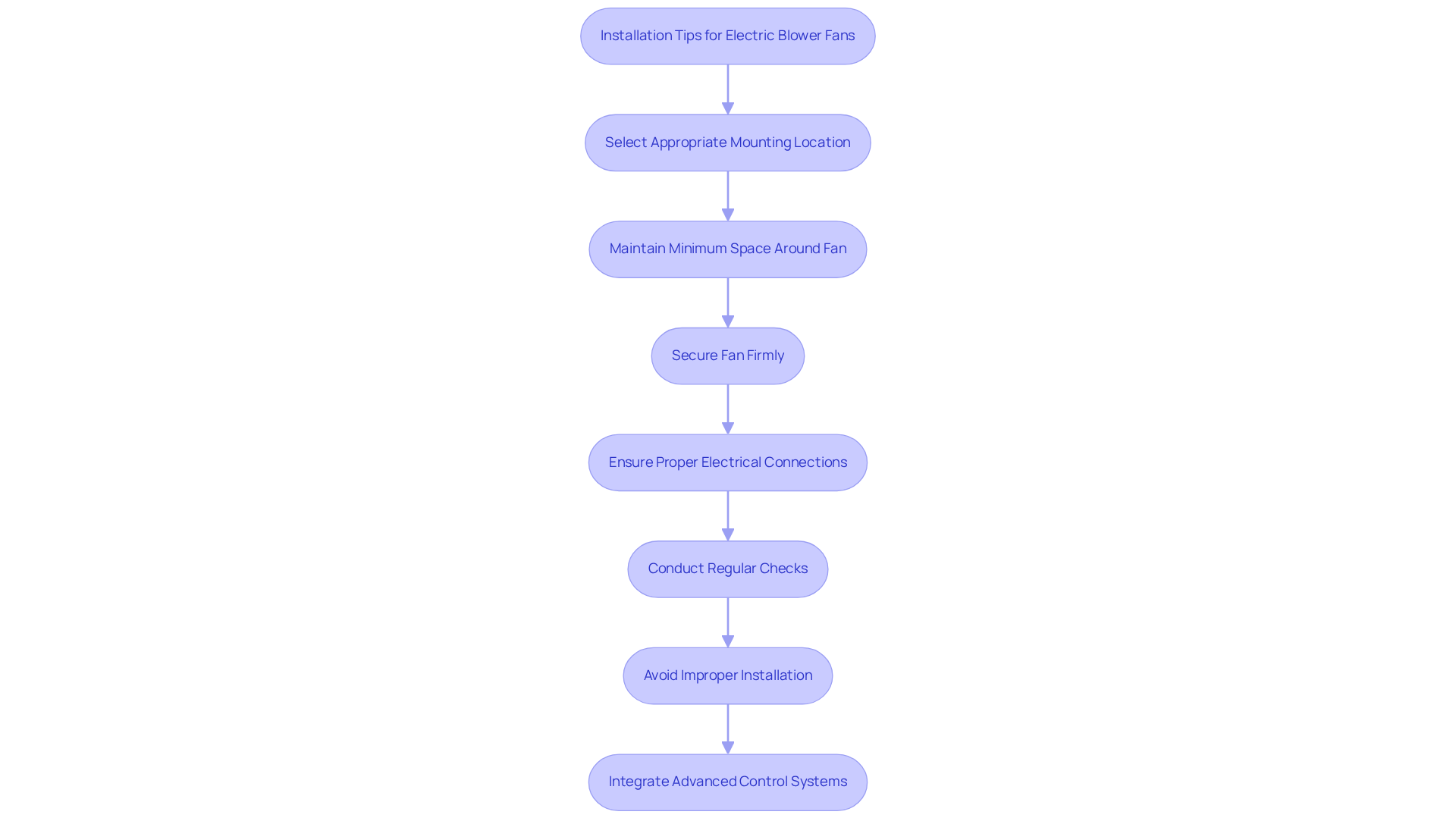

Installation Tips for Electric Blower Fans

To achieve optimal efficiency in electric blower fans, engineers must adhere to the established best practices during their installation.

- Selecting the appropriate mounting location is crucial; positioning the fan at least 3-5 feet away from walls significantly enhances circulation and eliminates barriers that may hinder functionality.

- Furthermore, it is imperative to maintain a minimum space of 30 cm around the fan to facilitate proper ventilation and airflow.

- Securing the fan firmly is essential to prevent vibrations and noise, which may signal underlying issues.

- Proper electrical connections, following manufacturer guidelines, are critical for ensuring safe and efficient operation.

- Conducting regular post-installation checks for vibrations and noise can aid in early identification of potential problems, allowing for timely maintenance.

- Moreover, improper installation can lead to considerable efficiency losses, underscoring the necessity of adhering to these best practices.

- The integration of can further optimize fan operation, as evidenced by numerous successful implementations across various sectors, particularly those utilizing PWM technology for enhanced cooling efficiency.

By following these guidelines, engineers can significantly reduce the risk of operational inefficiencies and extend the lifespan of electric blower fans.

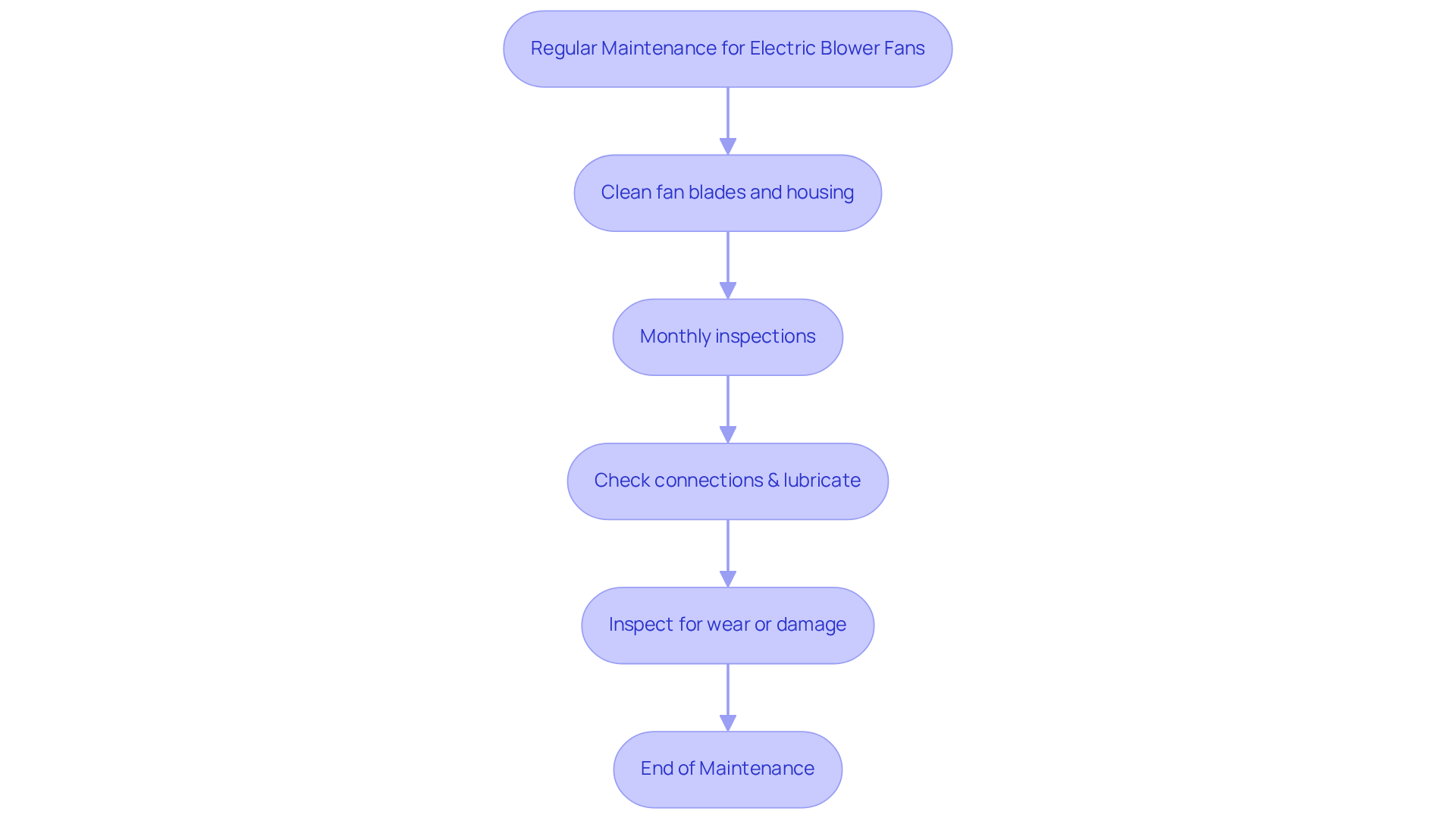

Maintenance Practices for Optimal Performance of Electric Blower Fans

is essential for optimizing the performance and longevity of electric blower fans. Engineers must implement a systematic routine that includes:

- Cleaning fan blades and housing to eliminate dust and debris, which can significantly hinder airflow and efficiency.

- Monthly inspections in environments characterized by heavy dust or continuous operations.

- Checking for loose connections and lubricating moving parts according to the manufacturer’s guidelines, as proper lubrication reduces friction and prolongs the life of bearings and other components.

- Conducting inspections for signs of wear or damage; identifying potential issues before they lead to unexpected failures is key.

For instance, a monthly inspection frequency for bearings is recommended. A mining company that adopted a thorough maintenance schedule reported a remarkable 20% reduction in power costs, underscoring the financial benefits of proactive upkeep. Moreover, robust ventilators can endure between 10 to 50 years with proper maintenance, providing a benchmark for engineers. By creating a maintenance timetable that encompasses these essential tasks and referring to the ventilation unit manual for specific instructions, engineers can significantly prolong the lifespan of air circulation devices, such as electric blower fans, and ensure they operate at optimal efficiency.

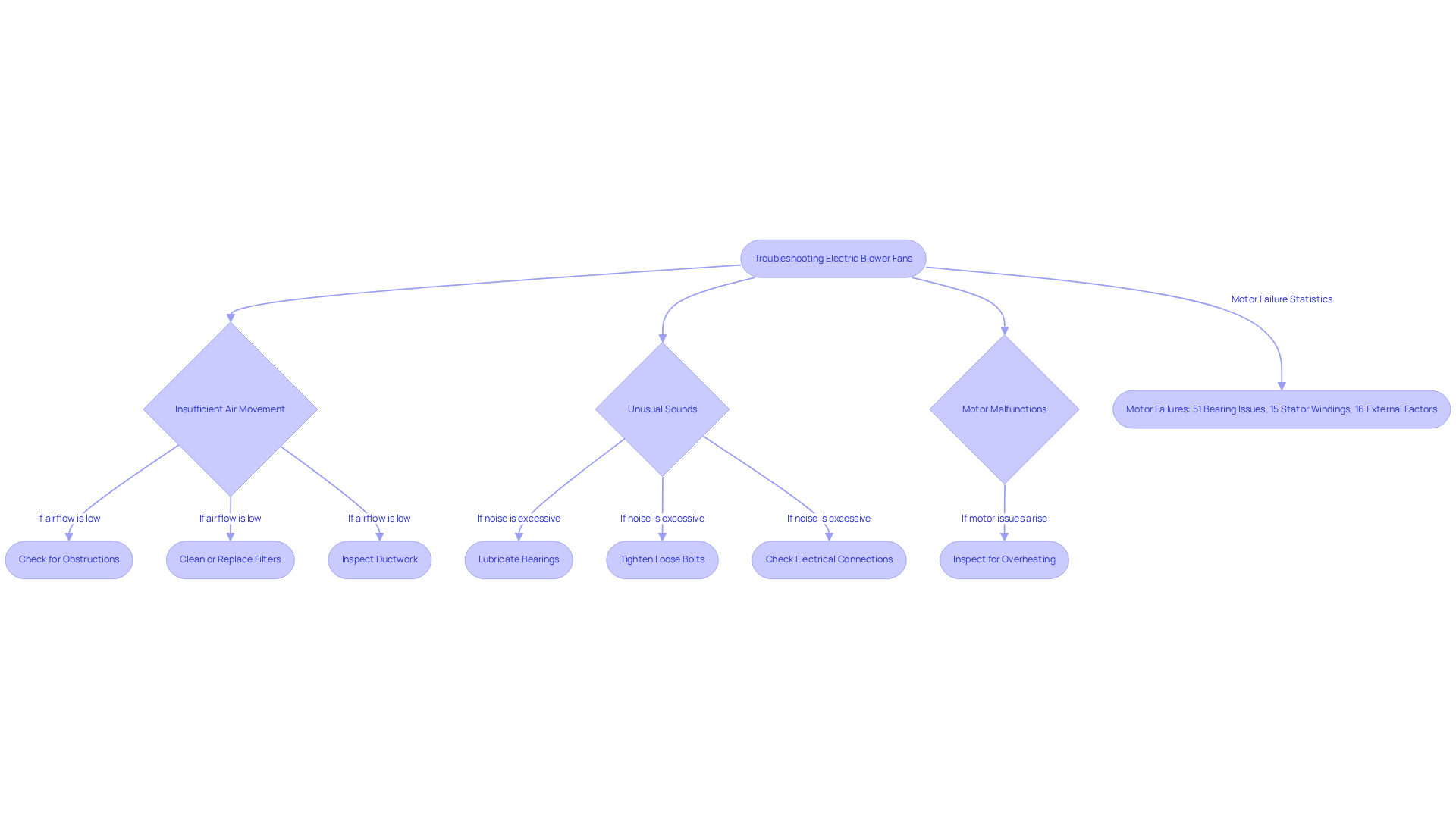

Troubleshooting Electric Blower Fans: Common Issues and Solutions

Common issues with electric blower fans include insufficient air movement, unusual sounds such as clanking and rattling, and motor malfunctions. Engineers should first investigate potential obstructions in the airflow path, which may involve blocked filters and damaged electric blower fan blades, and confirm that the electric blower fans are receiving proper power. If the fan produces excessive noise, this may suggest a need for lubrication, worn bearings, or misalignment. Engineers should tighten any loose bolts and lubricate bearings as necessary. Should the noise continue, balancing the fan blades and realigning the motor to the shaft of the electric blower fans can effectively reduce vibrations and enhance efficiency.

Motor failures present a significant challenge, with 51% of failures linked to bearing issues, 15% related to stator windings, and 16% arising from external factors. To accurately diagnose motor problems, engineers must and verify that the motor is not overloaded. Regular maintenance, which includes monitoring for overheating and ensuring adequate ventilation, can avert many motor-related complications. The use of high-quality components can also extend the lifespan of electric blower fans. In scenarios necessitating motor replacement, costs may vary from $500 to $1500, contingent upon the unit’s size and specifications.

Having a troubleshooting guide readily available can streamline the process of identifying and resolving these prevalent fan issues, ultimately extending the equipment’s lifespan and minimizing downtime.

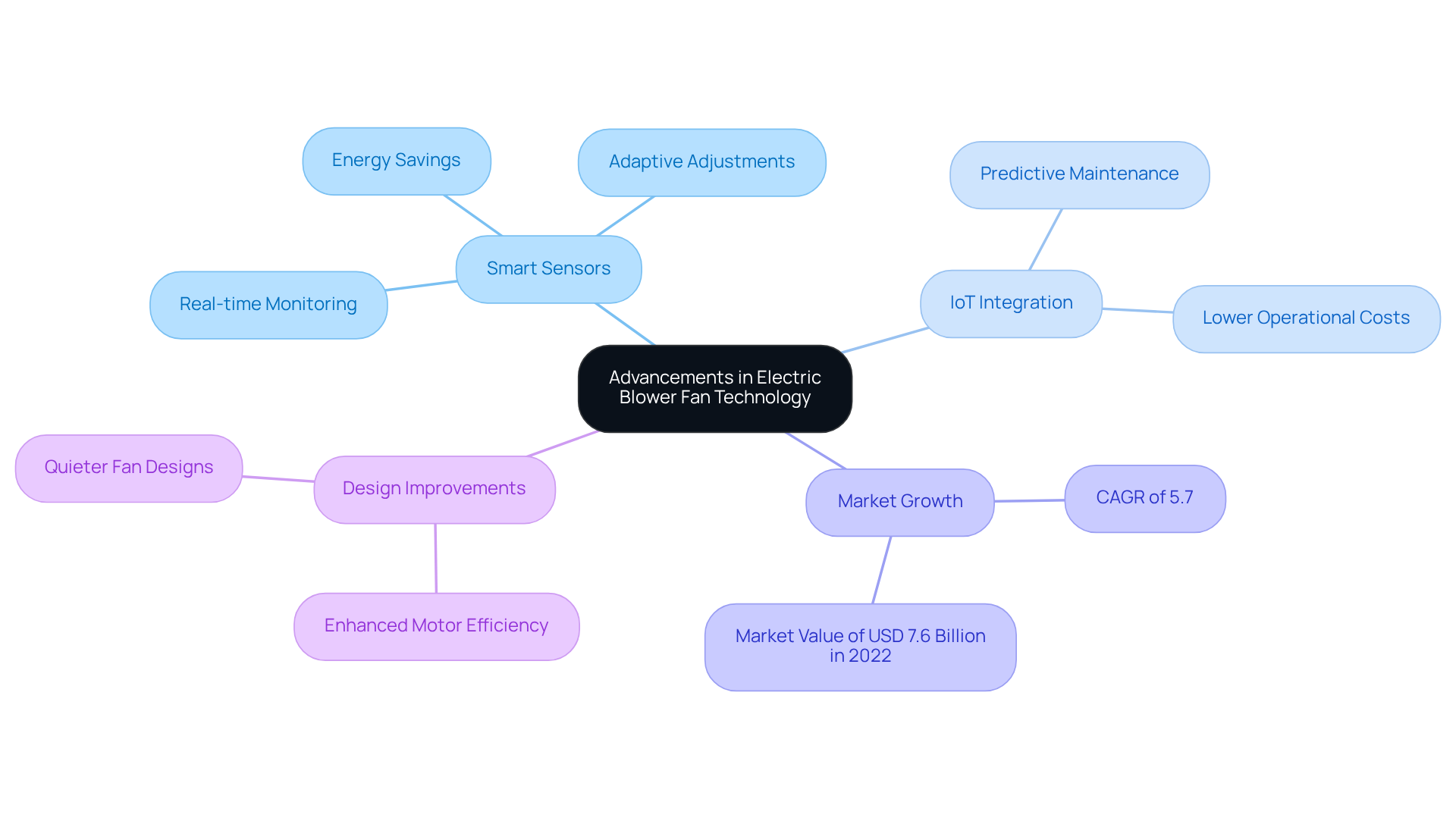

Recent Advancements in Electric Blower Fan Technology

Recent advancements in electric fan technology prominently feature the integration of smart sensors, which enable real-time monitoring and adaptive adjustments based on varying environmental conditions. This innovation enhances operational efficiency and contributes to significant .

The worldwide ventilation and exhaust industry, valued at approximately USD 7.6 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2031, driven by the increasing demand for intelligent features in HVAC systems.

Furthermore, IoT integration facilitates predictive maintenance, lowering downtime and operational expenses. Enhancements in motor efficiency and the creation of quieter fan designs are also improving functionality while minimizing energy usage.

Engineers should prioritize these advancements when selecting air-moving devices, considering factors such as smart sensor capabilities and IoT integration. This approach ensures they leverage the most effective and innovative solutions available, ultimately leading to enhanced system efficiency and sustainability.

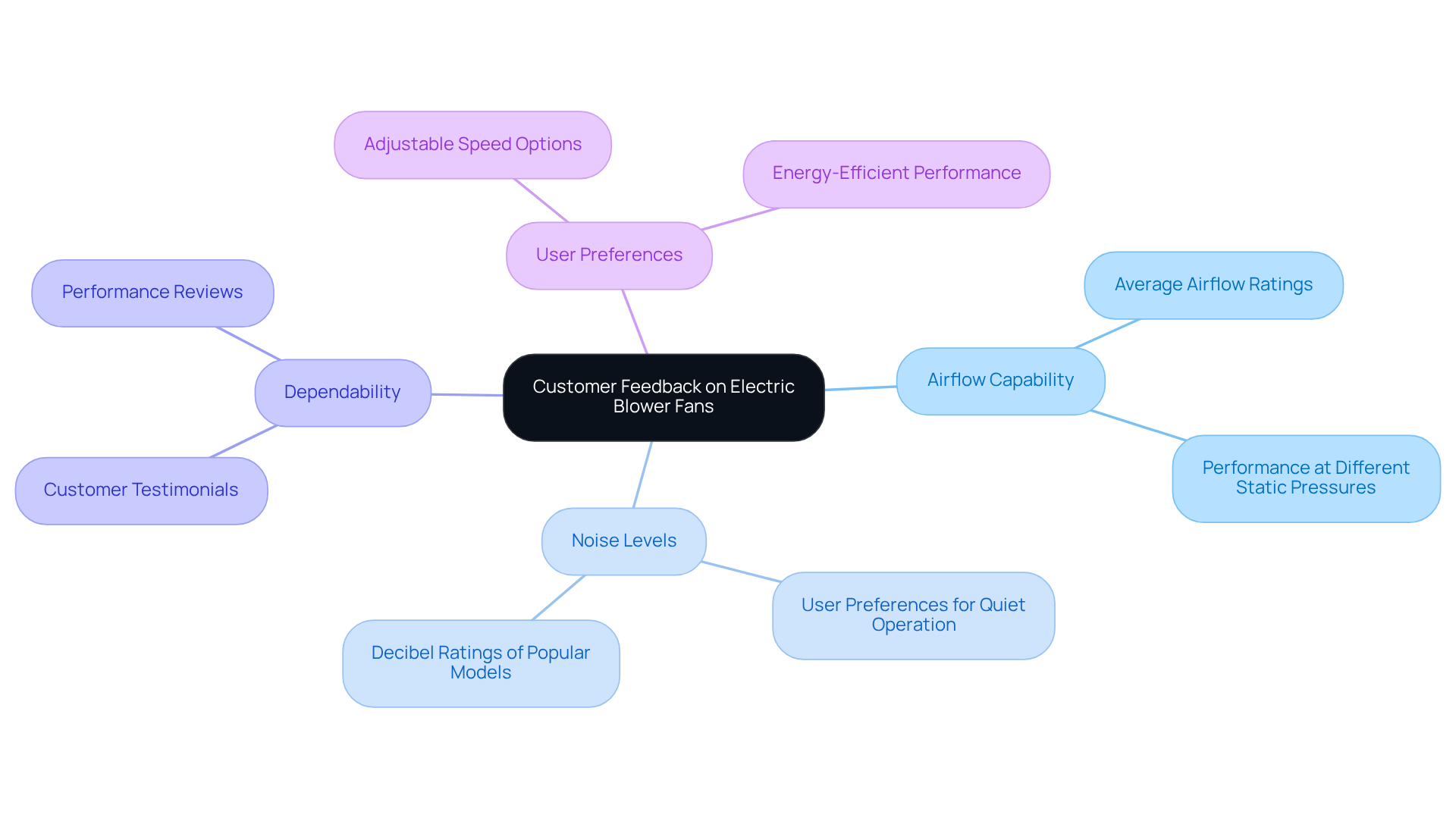

Customer Feedback: Insights on Electric Blower Fan Performance

Customer feedback on electric air circulators plays a crucial role in highlighting key efficiency indicators, including:

- Airflow capability

- Noise levels

- Dependability

Users frequently express a strong preference for devices that offer:

For engineers, reviewing customer testimonials and performance reviews becomes essential in identifying electric blower fans that consistently meet or exceed expectations. This feedback not only informs product selection but also serves as a valuable resource when choosing components for engineering projects.

Conclusion

Electric blower fans are essential for effective thermal management in engineering, particularly within the electronics sector. Their capacity to efficiently move air and maintain optimal operating temperatures is critical for enhancing product performance and ensuring compliance with industry standards. As the demand for advanced cooling solutions continues to rise, understanding the various applications and specifications of electric blower fans enables engineers to make informed decisions that align with their project requirements.

This article provides key insights into the distinctions between fans and blowers, the importance of technical specifications, energy efficiency considerations, installation best practices, and maintenance protocols. Each section underscores how these factors contribute to the overall effectiveness and longevity of electric blower fans across diverse engineering applications. Moreover, recent advancements in technology, such as smart sensors and IoT integration, highlight the evolving landscape of air-moving devices, ensuring engineers are equipped with innovative solutions to meet contemporary challenges.

In conclusion, the strategic integration of electric blower fans not only enhances operational efficiency but also promotes sustainability within engineering projects. By prioritizing energy-efficient designs and adhering to best practices in installation and maintenance, engineers can significantly improve the performance and reliability of their systems. Embracing these insights will ultimately lead to more effective thermal management solutions, fostering innovation and excellence in engineering endeavors.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leader in providing innovative cooling solutions specifically designed for the electronics industry, focusing on efficient thermal management.

How does Gagner-Toomey Associates support engineers?

Gagner-Toomey collaborates with various manufacturers to offer access to advanced cooling products, including electric fans, which help maintain optimal operating temperatures in electronic components.

Why is effective cooling important in engineering?

Effective cooling is crucial for ensuring adherence to industry standards and improving product performance, especially in high-density environments like data centers.

What is the difference between fans and blowers?

Electric blower fans are designed to move large volumes of air with minimal pressure change for general ventilation, while ventilators generate greater pressure and can direct air specifically, which is necessary for applications requiring focused airflow.

What are some applications of electric blower fans in engineering?

Electric blower fans are used for cooling electronic components, enhancing HVAC systems, and providing ventilation in industrial settings.

In what scenarios are electric blower fans particularly effective?

They are especially effective in data centers, automotive cooling systems, and manufacturing processes, where concentrated airflow is necessary for optimal functionality and reliability.