Overview

The article delivers crucial insights for electronics engineers, elucidating the distinctions and applications of blower cooling fans versus traditional fans. It emphasizes their unique roles in air movement and thermal management, addressing a fundamental challenge faced by engineers. By detailing essential technical parameters—such as airflow requirements, static force, energy efficiency, and cost considerations—it provides the necessary framework for selecting the optimal cooling solution for electronic systems. These insights are critical for engineers striving to enhance performance and reliability in their designs.

Introduction

Understanding the nuances between blowers and fans is crucial for electronics engineers tasked with optimizing thermal management in their designs. Blower cooling fans, in particular, serve a vital role in directing airflow to prevent overheating in compact electronic systems, thereby ensuring longevity and performance.

However, with a plethora of options available, engineers face the challenge of determining the most suitable device for their specific applications. This article delves into essential insights surrounding blower cooling fans, offering guidance on differentiating between blowers and fans, while highlighting key considerations for effective selection in electronic environments.

Clarify the Basics of Blowers and Fans

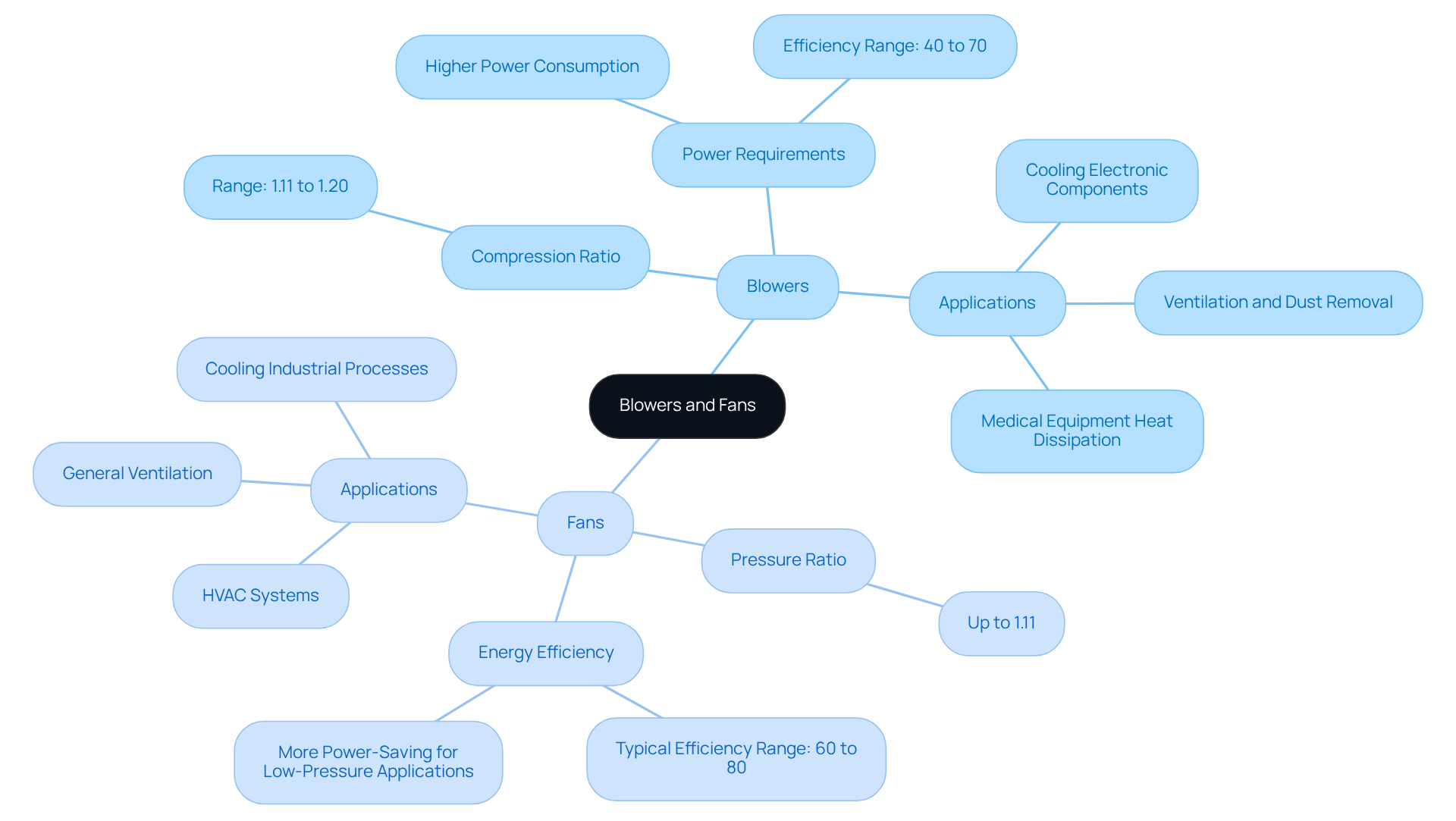

Blowers and fans are indispensable devices in air movement, each fulfilling distinct roles based on their design and operational principles. A blower cooling fan is engineered to generate greater force, making it ideal for applications that require directed airflow, such as cooling electronic components in confined spaces. Conversely, a fan is designed to circulate larger volumes of air at lower forces, making it suitable for general ventilation purposes.

- Blowers: Operate with a compression ratio ranging from 1.11 to 1.20, delivering concentrated airflow essential for efficient cooling and ventilation in tight environments. Due to these elevated ratio levels, they typically require more power to compress air, which can influence energy efficiency and operational costs.

- Fans: Generally achieve a pressure ratio of up to 1.11, enabling extensive air circulation without significant pressure fluctuations. Fans are often more energy-efficient than exhaust devices for low-pressure applications, presenting a cost-effective solution for numerous scenarios.

Grasping these distinctions is critical for engineers engaged in designing systems that necessitate effective thermal management. For instance, in intelligent manufacturing, cooling systems are integrated into automated production lines to prevent overheating of vital electronic devices, thereby ensuring optimal performance and longevity.

Case studies underscore the importance of selecting the appropriate apparatus: air movers are frequently employed in medical settings to dissipate heat from imaging equipment, while circulation devices are utilized in HVAC systems to facilitate efficient airflow. The blower market was valued at US$ 7.6 billion in 2022 and is projected to reach US$ 12.2 billion by 2031, reflecting the growing demand for these technologies. By understanding these fundamental differences, engineers can make informed decisions that enhance system efficiency and address specific cooling requirements, such as implementing a blower cooling fan. Historical context, such as the earliest reference to centrifugal devices in 1556 and the evolution of the Guibal design, further enriches the understanding of these technologies. Insights from industry experts highlight the critical importance of comprehending these devices in contemporary engineering applications.

Differentiate Between Blowers and Fans: Technical Insights

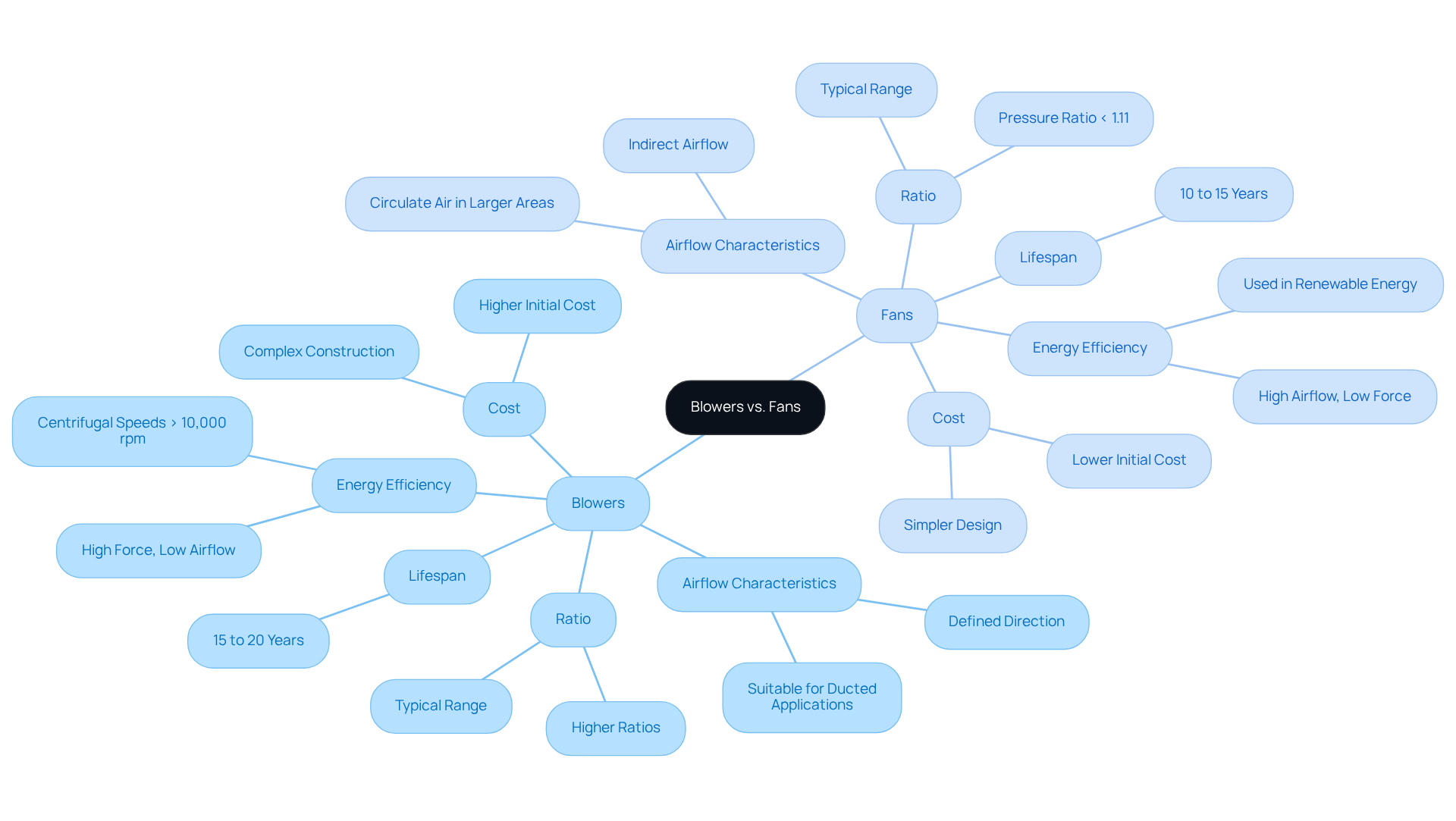

To effectively differentiate between blowers and fans, engineers must consider several critical technical parameters:

-

Ratio: Blowers typically operate with a ratio ranging from 1.11 to 1.2, but they can achieve higher ratios, usually between 1.2 and 2.0. This capability allows blowers to generate greater static pressure compared to fans, which generally function below 1.11. Consequently, blower cooling fans are ideal for applications requiring focused airflow, such as HVAC systems where air must be directed through ducts.

-

Airflow Characteristics: Blowers are specifically engineered to move air in a defined direction, making them suitable for confined spaces or ducted applications. In contrast, fans are designed to circulate air within larger areas, providing indirect airflow. This directional capability is crucial for efficiently dissipating heat from specific components in electronic systems with the help of a blower cooling fan.

-

Energy Efficiency: Blowers excel in scenarios demanding high force with reduced airflow, while fans are more effective when high airflow and low force are required. For instance, centrifugal blowers can reach speeds exceeding 10,000 rpm, making them suitable for high-pressure applications, whereas air circulators are commonly utilized in renewable energy sectors, such as wind and solar, where airflow takes precedence over pressure.

-

Lifespan Comparison: Blowers typically last between 15 to 20 years, while fans have a lifespan of 10 to 15 years, contingent upon maintenance. This longevity is a significant consideration for engineers planning for long-term performance.

-

Cost Considerations: Fans are generally less expensive initially due to their simpler design, while blowers tend to be more costly because of their intricate construction. Understanding these cost differences is essential for engineers making budget-conscious decisions.

By grasping these technical insights, engineers can select the appropriate device, specifically a blower cooling fan, based on specific cooling requirements, ensuring optimal performance in their electronic systems. Research examples, such as the ‘Functionality of Fans in HVAC Systems,’ illustrate that fans play a vital role in maintaining comfortable indoor climates by effectively distributing heated or cooled air, while blowers are necessary for situations requiring substantial air movement with minimal pressure variation.

Select the Right Blower or Fan: Key Considerations

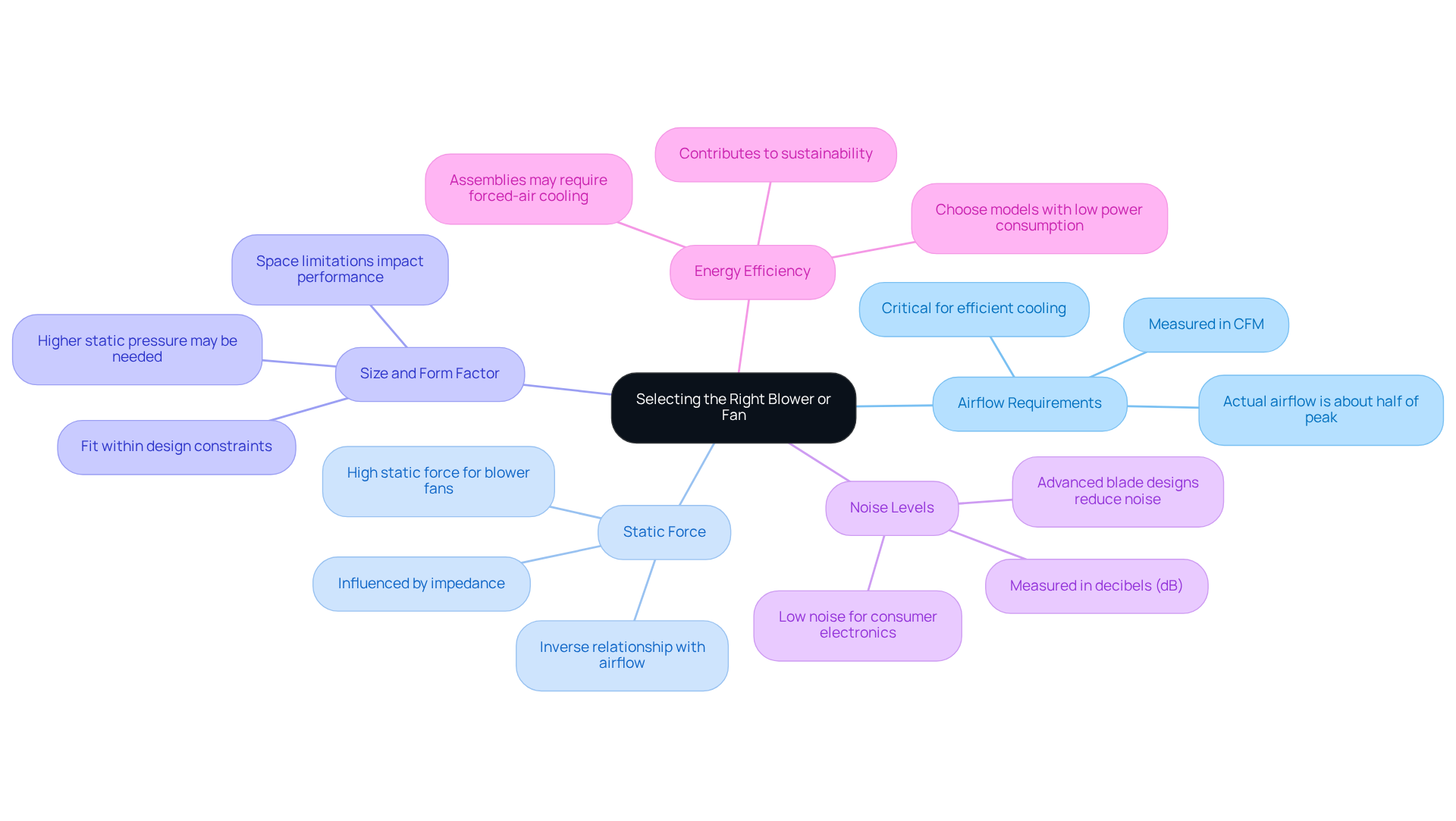

When selecting the right blower cooling fan for electronic applications, engineers must consider several key factors to ensure optimal performance and effective cooling.

- Airflow Requirements: First, it is essential to determine the necessary airflow, typically measured in cubic feet per minute (CFM), based on the heat generated by the components. For example, a fan rated at 100 CFM may realistically operate at around 75 CFM under typical conditions. Moreover, for most forced air cooling applications, actual airflow is approximately half of the fan’s peak airflow. Understanding the actual airflow required is crucial for achieving efficient cooling.

- Static Force: Next, evaluate the static force requirements of the specific application. Blower cooling fans are generally preferred for high static force needs, whereas axial fans are suitable for lower force scenarios. The relationship between airflow and static force is inversely proportional; as one increases, the other decreases. It is vital to recognize that actual airflow and static resistance are influenced by impedance, which can significantly affect fan performance.

- Size and Form Factor: Consideration of the available space within the electronic enclosure is also critical. The blower cooling fan must fit within the design constraints while still providing adequate cooling. Space limitations and obstructions can impact performance, potentially necessitating a fan with higher static pressure capabilities to meet cooling demands.

- Noise Levels: Additionally, evaluate the acceptable noise levels for the application. Noise levels are quantified in decibels (dB), and certain cooling devices operate more quietly than others. This factor can be particularly significant in consumer electronics. Opting for models designed for low noise or those featuring advanced blade designs can greatly enhance user experience, especially in noise-sensitive environments.

- Energy Efficiency: Finally, look for energy-efficient models that can deliver the required performance without excessive power consumption. Assemblies consuming as little as 25 watts may still require forced-air cooling, making it imperative to choose efficient fans that contribute to the overall sustainability of the design.

By taking these considerations into account, engineers can effectively select the most appropriate blower or fan, ensuring optimal cooling and performance of their electronic systems.

Conclusion

Understanding the distinctions between blower cooling fans and traditional fans is crucial for engineers aiming to optimize thermal management in electronic applications. This article highlights the unique characteristics and operational principles of each device, emphasizing that the right choice can significantly impact the performance and longevity of electronic systems.

Key insights include the technical specifications that set blowers apart from fans, such as:

- Pressure ratios

- Airflow characteristics

- Energy efficiency

The necessity of selecting the appropriate blower cooling fan based on specific requirements—like airflow needs, static force, and noise levels—was also discussed. These considerations are vital for ensuring that electronic components remain cool and function effectively, particularly in high-demand environments.

Ultimately, the importance of blower cooling fans in enhancing electronic performance cannot be overstated. As technology evolves and the demand for efficient cooling solutions grows, engineers must remain informed about best practices for selecting these devices. By doing so, they not only improve the reliability and efficiency of their designs but also contribute to the sustainability of electronic systems in an increasingly competitive landscape.

Frequently Asked Questions

What is the primary difference between blowers and fans?

Blowers are designed to generate greater force for directed airflow, making them suitable for applications like cooling electronic components in confined spaces. Fans, on the other hand, circulate larger volumes of air at lower forces, making them ideal for general ventilation purposes.

What is the operational pressure ratio of blowers and how does it affect their performance?

Blowers operate with a compression ratio ranging from 1.11 to 1.20, which allows them to deliver concentrated airflow essential for efficient cooling and ventilation in tight environments. This higher ratio requires more power to compress air, influencing energy efficiency and operational costs.

How do fans differ in terms of pressure ratio and energy efficiency?

Fans generally achieve a pressure ratio of up to 1.11, enabling extensive air circulation without significant pressure fluctuations. They are often more energy-efficient than exhaust devices for low-pressure applications, making them a cost-effective solution for many scenarios.

Why is it important for engineers to understand the differences between blowers and fans?

Understanding these distinctions is critical for engineers designing systems that require effective thermal management. Selecting the appropriate device can enhance system efficiency and address specific cooling requirements.

Can you provide examples of applications for blowers and fans?

Blowers are frequently used in medical settings to dissipate heat from imaging equipment, while fans are utilized in HVAC systems to facilitate efficient airflow.

What is the projected market growth for blowers?

The blower market was valued at US$ 7.6 billion in 2022 and is projected to reach US$ 12.2 billion by 2031, indicating a growing demand for these technologies.

What historical context is relevant to the development of blowers and fans?

The earliest reference to centrifugal devices dates back to 1556, and the evolution of designs, such as the Guibal design, provides insights into the development of these technologies.

What insights do industry experts provide regarding blowers and fans?

Industry experts emphasize the critical importance of comprehending the functionalities and applications of blowers and fans in contemporary engineering applications.