Overview

Fan ball bearings represent precision-engineered components that significantly reduce friction in fan systems, thereby ensuring efficient rotation and optimal airflow across a range of applications, particularly in electronics cooling. These components are characterized by their durability and capacity to manage loads effectively. Notably, advancements such as herringbone-grooved supports have been introduced, enhancing performance under extreme conditions. This innovation underscores their critical role in maintaining reliable operation in devices such as CPUs and servers, making fan ball bearings indispensable in modern technology.

Introduction

The intricate world of fan ball bearings plays a pivotal role in modern electronics, where efficient cooling is essential for optimal performance. These precision-engineered components not only reduce friction but also enhance airflow, making them indispensable in various applications, from gaming computers to industrial systems.

However, as technology evolves, so do the challenges associated with maintaining effective temperature regulation. How can advancements in fan ball bearing design meet the increasing demands of high-performance environments? This question underscores the need for innovative solutions that address both current and future requirements in cooling technology.

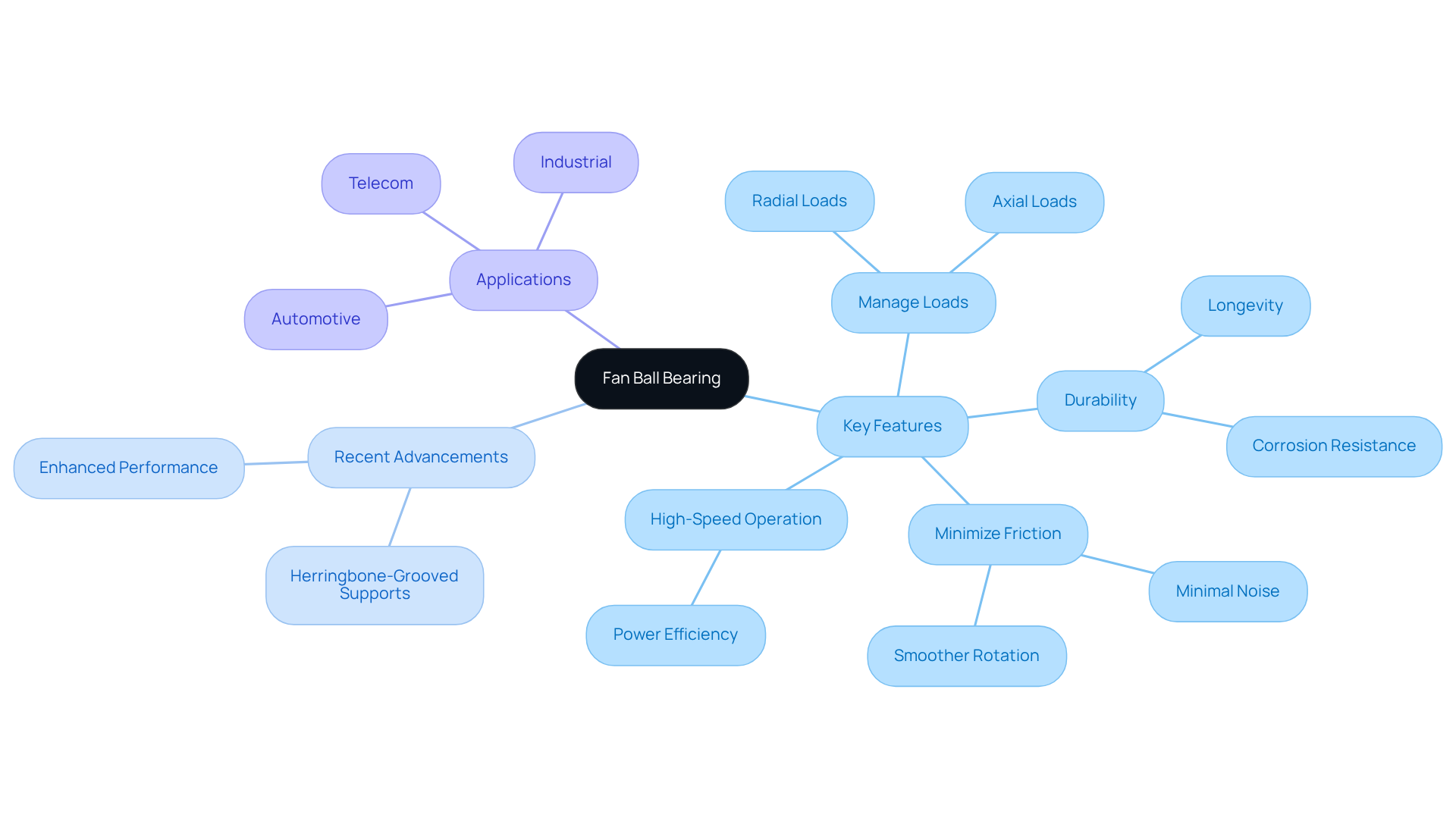

Define Fan Ball Bearing: Key Characteristics and Functionality

A acts as a that utilizes small metal spheres to minimize friction between the rotating shaft and the stationary housing of a fan. This innovative design facilitates smoother and more efficient rotation, which is critical for ensuring in refrigeration applications. Key features of these components encompass their ability to manage both radial and axial loads, , and their capacity to operate at . Such attributes render them particularly beneficial in environments where reliability and longevity are paramount, such as in electronic temperature regulation systems.

Recent advancements in fan ball bearing support technology, including the introduction of herringbone-grooved supports, have significantly enhanced the performance of fan ball bearings under extreme conditions, showcasing notable improvements in and power efficiency. Engineers emphasize the crucial role of these components in achieving efficient , as their performance directly influences the lifespan and reliability of electronic devices.

, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive range of DC input tube axial devices and centrifugal blowers, with sizes ranging from 15 to 280mm and 15 to 225mm respectively, optimized for performance and efficiency across various applications, including Automotive, Telecom, and Industrial sectors. Gagner-Toomey’s comprehensive collection of , featuring CPU chillers and integrated temperature control systems, underscores the importance of high-quality spheres in attaining optimal performance.

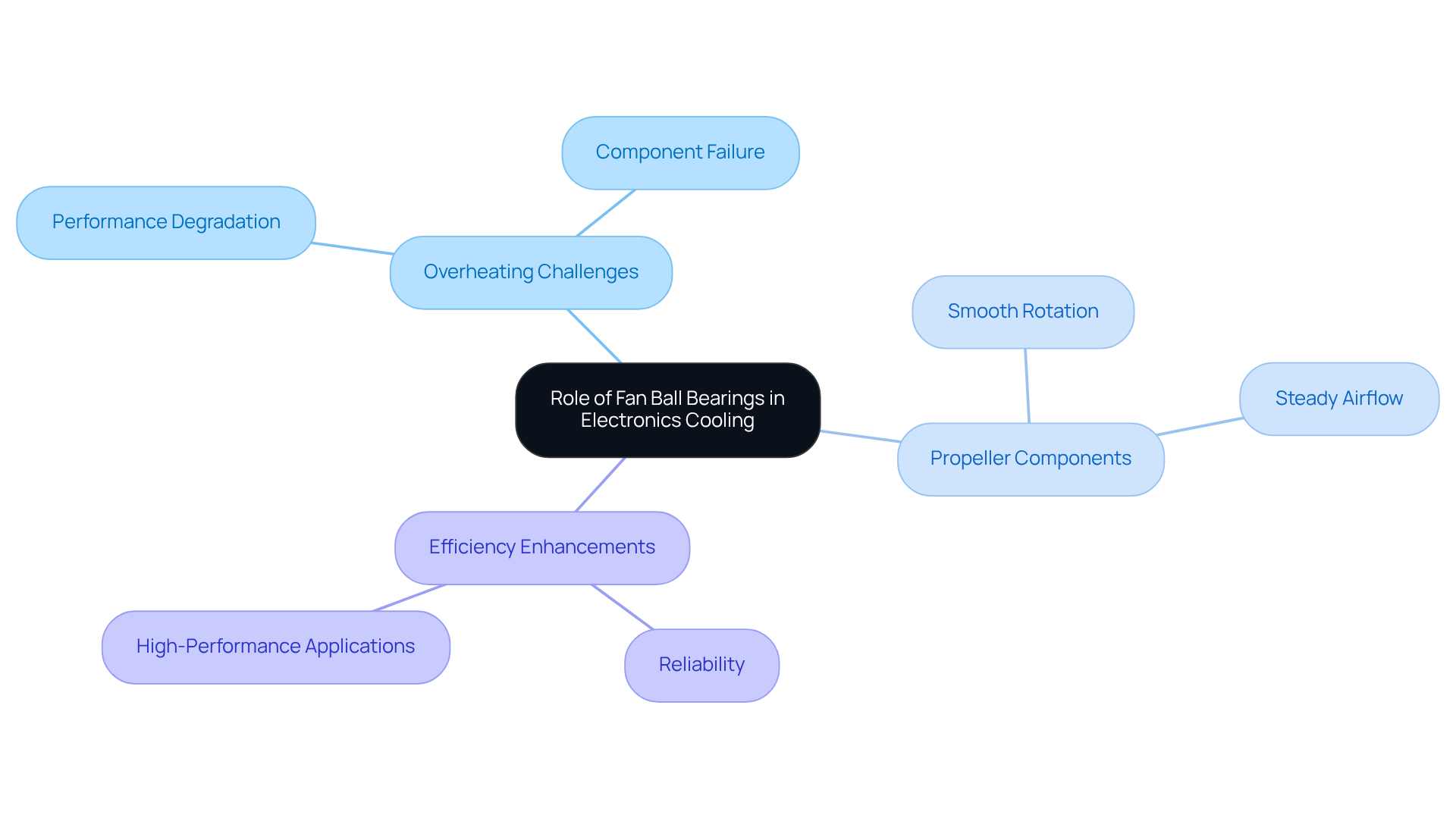

Contextualize the Role of Fan Ball Bearings in Electronics Cooling

In electronics, overheating presents a significant challenge, often leading to performance degradation or component failure. Propeller components play a vital role in by enabling motors to operate efficiently, thereby facilitating the dissipation of heat generated by electronic devices. By promoting , these components ensure steady airflow, which is crucial for maintaining optimal temperatures in CPUs, GPUs, and other essential parts. Notably, the integration of rolling elements in with enhances their , making them a preferred choice in .

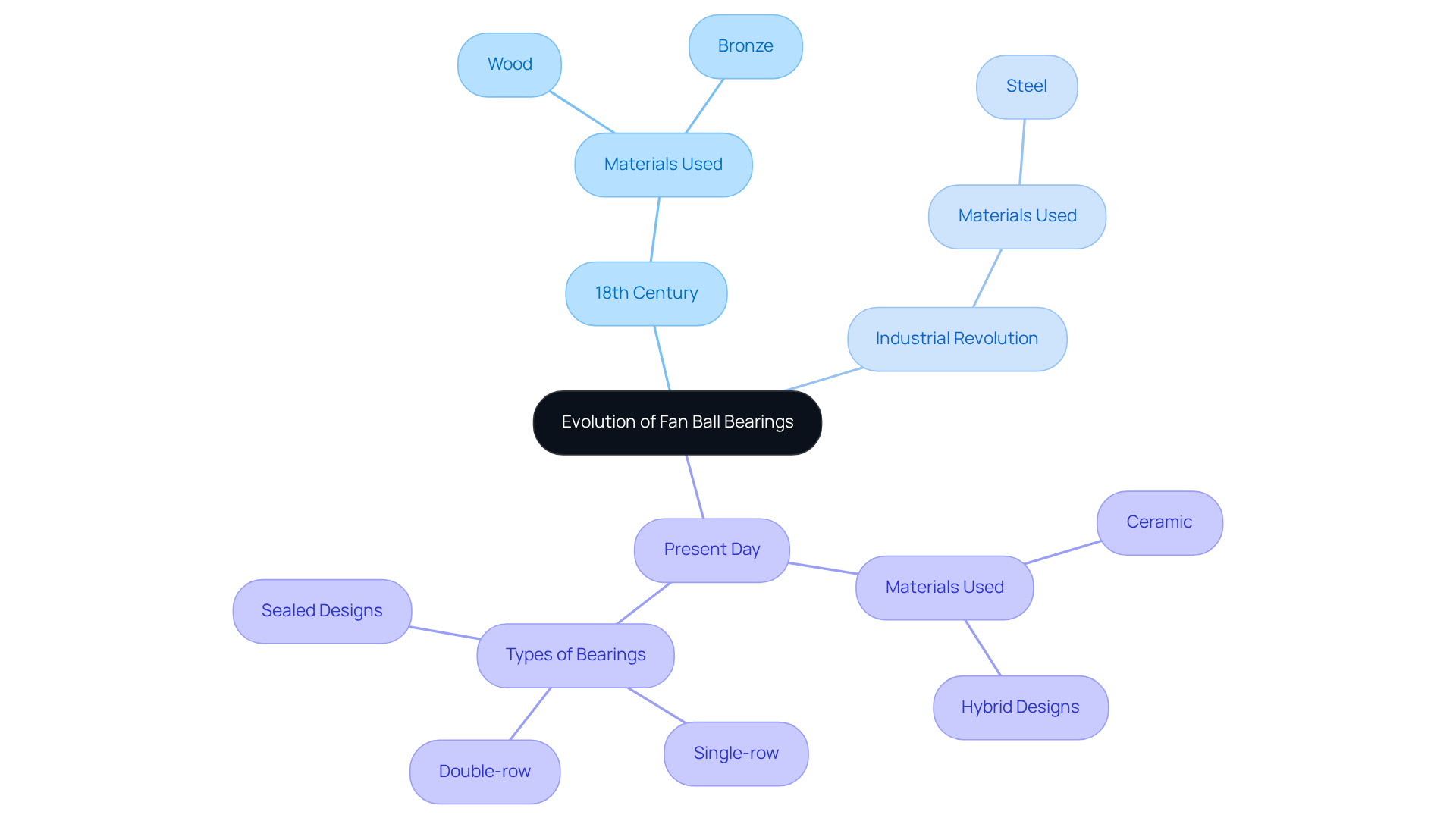

Trace the Evolution and Variations of Fan Ball Bearings

The concept of has its roots in the 18th century, with significant advancements occurring during the Industrial Revolution. Initially, these supports were fashioned from wood or bronze; however, the advent of steel spheres and revolutionized their design. Presently, are available in various forms, including:

- Single-row

- Double-row

- Sealed designs

Each tailored for specific applications. Furthermore, innovations such as and have emerged, enhancing performance in extreme conditions. These developments have rendered sphere rollers not only more effective and durable but also suitable for a wider range of .

Examine Practical Applications of Fan Ball Bearings in Electronics

Fan components are integral to a wide range of electronic devices, including computers, servers, and telecommunications apparatus. In high-performance gaming computers, for instance, lubricated components are essential for ventilation systems that prevent excessive heat during intense gaming sessions. This necessity extends to data centers, where is critical for ; here, play a crucial role in delivering optimal airflow.

Furthermore, industries such as automotive and aerospace utilize spherical components in to . The unique ability of ball bearings to function effectively under varying loads and temperatures renders them indispensable in these applications.

Conclusion

Fan ball bearings are indispensable components that significantly enhance the efficiency and reliability of cooling systems across various electronic applications. Their innovative design, featuring small metal spheres that minimize friction, facilitates smoother operation and optimal airflow—elements that are crucial for maintaining the performance of devices such as CPUs and GPUs. Recent advancements in fan ball bearing technology, including superior materials and cutting-edge designs, have further cemented their role in effective thermal management.

This article highlights several key characteristics of fan ball bearings:

- Their capacity to handle radial and axial loads

- Exceptional durability

- Low noise production

Furthermore, it traces the evolution of these components from their historical origins to the modern variations available today, including sealed and hybrid designs. Such developments underscore the critical importance of fan ball bearings in diverse sectors, such as automotive, telecommunications, and industrial applications, where effective temperature regulation is paramount.

In conclusion, recognizing the significance of fan ball bearings transcends their mechanical function; they are pivotal in ensuring the longevity and efficiency of electronic devices. As technology continues to advance, the role of fan ball bearings will remain essential in meeting the growing demands for enhanced cooling solutions. Embracing innovations in this field can lead to improved device performance and reliability, making it imperative for industries to prioritize the integration of high-quality fan ball bearings in their systems.

Frequently Asked Questions

What is a fan ball bearing?

A fan ball bearing is a precision-engineered component that uses small metal spheres to reduce friction between the rotating shaft and the stationary housing of a fan, facilitating smoother and more efficient rotation.

What are the key characteristics of fan ball bearings?

Key characteristics include the ability to manage both radial and axial loads, exceptional durability, high-speed operation with minimal noise, and enhanced performance under extreme conditions.

How do fan ball bearings contribute to refrigeration applications?

They ensure optimal airflow, which is critical for effective temperature management in refrigeration applications, influencing the lifespan and reliability of electronic devices.

What recent advancements have been made in fan ball bearing technology?

Recent advancements include the introduction of herringbone-grooved supports, which improve performance under extreme conditions, enhance corrosion resistance, and increase power efficiency.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering a wide range of DC input tube axial devices and centrifugal blowers, optimized for various applications including Automotive, Telecom, and Industrial sectors.

What types of thermal regulation solutions does Gagner-Toomey provide?

They provide solutions such as CPU chillers and integrated temperature control systems, highlighting the importance of high-quality spheres for optimal performance.