Overview

Flexible heat pipe technology is pivotal across various engineering sectors, including:

- Aerospace

- Consumer electronics

- Renewable energy

- Medical devices

- Automotive

- Telecommunications

- Wearable technology

- Industrial processes

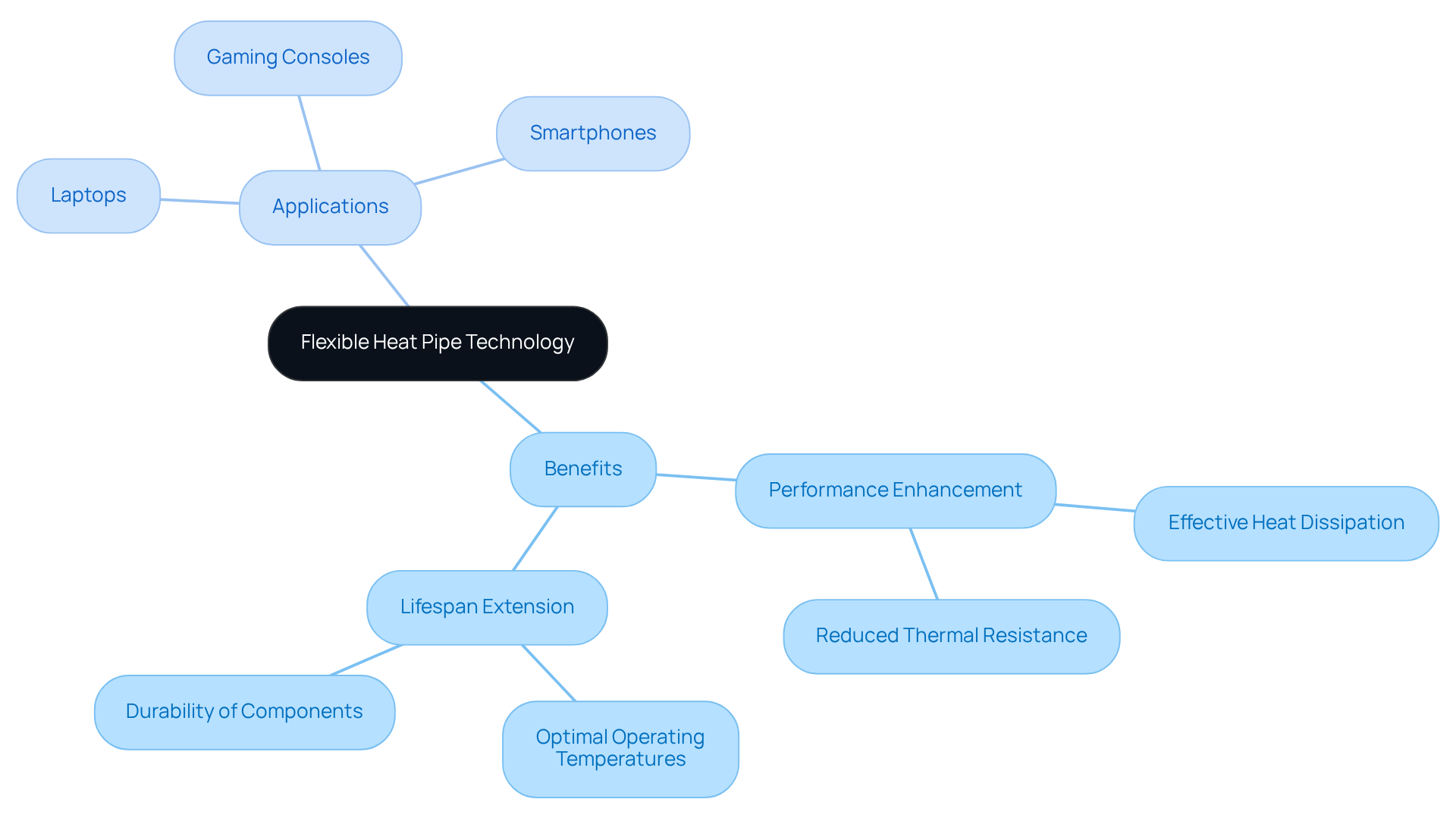

This technology is primarily used for efficient thermal management. This article elucidates how these applications capitalize on the adaptability and passive operation of flexible heat pipes to significantly enhance performance, reliability, and sustainability in diverse environments. In response to the escalating demand for effective cooling solutions in modern technology, it is imperative to recognize the transformative impact of this technology.

Introduction

Flexible heat pipe technology is rapidly transforming the landscape of thermal management across various engineering sectors. With their unique ability to adapt to tight spaces and intricate designs, these innovative conduits significantly enhance the efficiency and reliability of systems in industries ranging from aerospace to consumer electronics.

However, as the demand for effective cooling solutions continues to grow, engineers encounter various challenges in integrating these advanced technologies. This article delves into ten compelling applications of flexible heat pipes, highlighting their benefits and the evolving role they play in modern engineering solutions.

Gagner-Toomey Associates: Pioneering Cooling Solutions with Flexible Heat Pipes

Gagner-Toomey Associates is at the forefront of cooling technology, specializing in flexible heat pipes that provide exceptional thermal management solutions. These innovative systems utilize advanced materials and design principles to significantly of electronic systems across various industries. The versatility of flexible heat pipes is increasingly recognized for their ability to adapt to confined spaces and intricate shapes, making them ideal for modern electronic applications. Their passive operation requires no external power source, leading to energy savings and sustainability.

As the demand for effective cooling solutions escalates, particularly in sectors such as consumer electronics and automotive, Gagner-Toomey’s unwavering commitment to innovation ensures that engineers have access to cutting-edge solutions, including flexible heat pipes, that address the evolving challenges of the electronics market. The anticipated market growth for adaptable thermal conduits by 2025 underscores their critical role in advancing cooling technologies, positioning Gagner-Toomey Associates as a key player in this dynamic landscape.

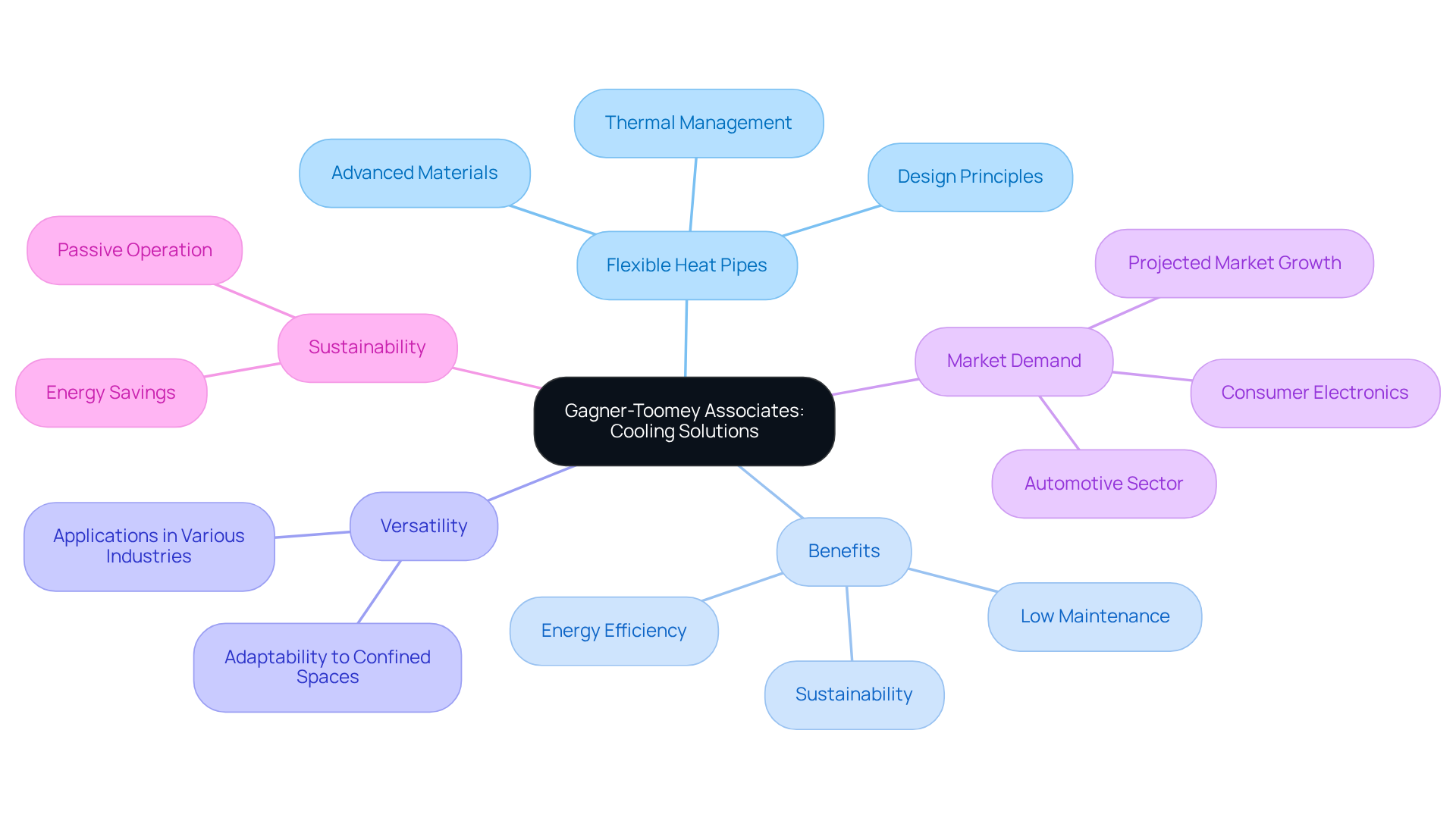

Aerospace: Enhancing Thermal Management with Flexible Heat Pipes

In the aerospace industry, flexible heat pipes are indispensable for regulating thermal loads across critical components. Their unique design allows the flexible heat pipe to conform to various shapes and configurations, facilitating even in constrained spaces such as aircraft engines and avionics. The use of a flexible heat pipe enhances adaptability, which not only improves performance but also significantly boosts the safety and reliability of aerospace systems, ensuring optimal functionality under extreme conditions.

For instance, the integration of flexible heat pipes in modern aircraft engines has been vital for dissipating heat generated by high-density avionics and advanced electronic systems. Aerospace engineers emphasize that these heat management technologies, including flexible heat pipes, are crucial for maintaining system integrity and performance, particularly as aircraft technology evolves.

As the industry progresses toward 2025, the demand for innovative thermal control solutions, including flexible heat pipes, is expected to rise, driven by the need for lightweight and energy-efficient systems that meet the challenges of contemporary aviation.

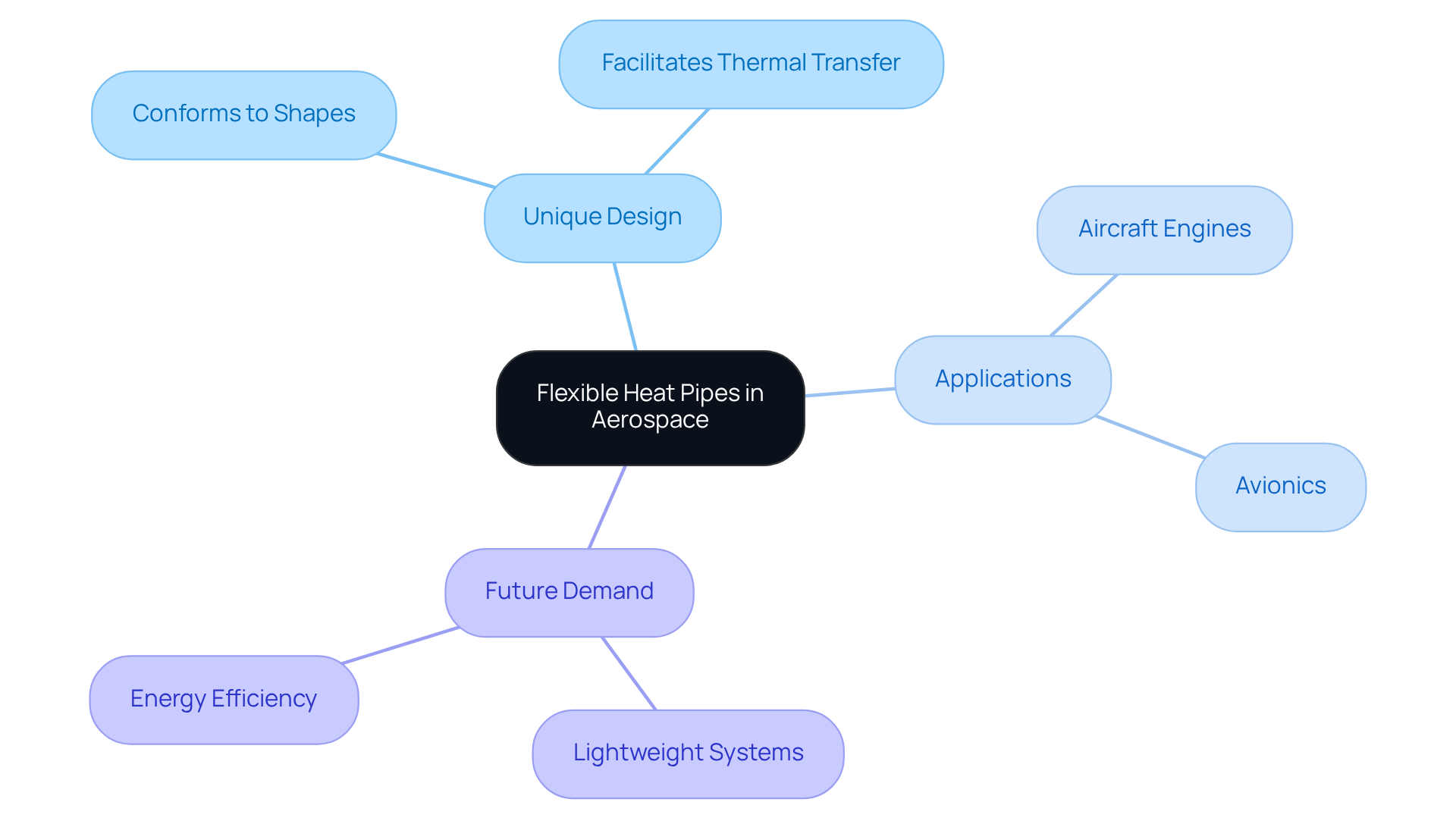

Consumer Electronics: Optimizing Performance with Flexible Heat Pipe Technology

Adaptable thermal conduits play a pivotal role in consumer electronics, effectively dissipating heat generated by components such as CPUs and GPUs. Their lightweight and compact design facilitates seamless integration into devices including laptops, smartphones, and gaming consoles. By maintaining optimal operating temperatures, these conduits not only enhance performance but also extend the lifespan of electronic devices. This capability provides a significant competitive advantage in the rapidly evolving consumer market, underscoring the necessity of incorporating in modern technology.

Renewable Energy: Utilizing Flexible Heat Pipes in Solar Thermal Applications

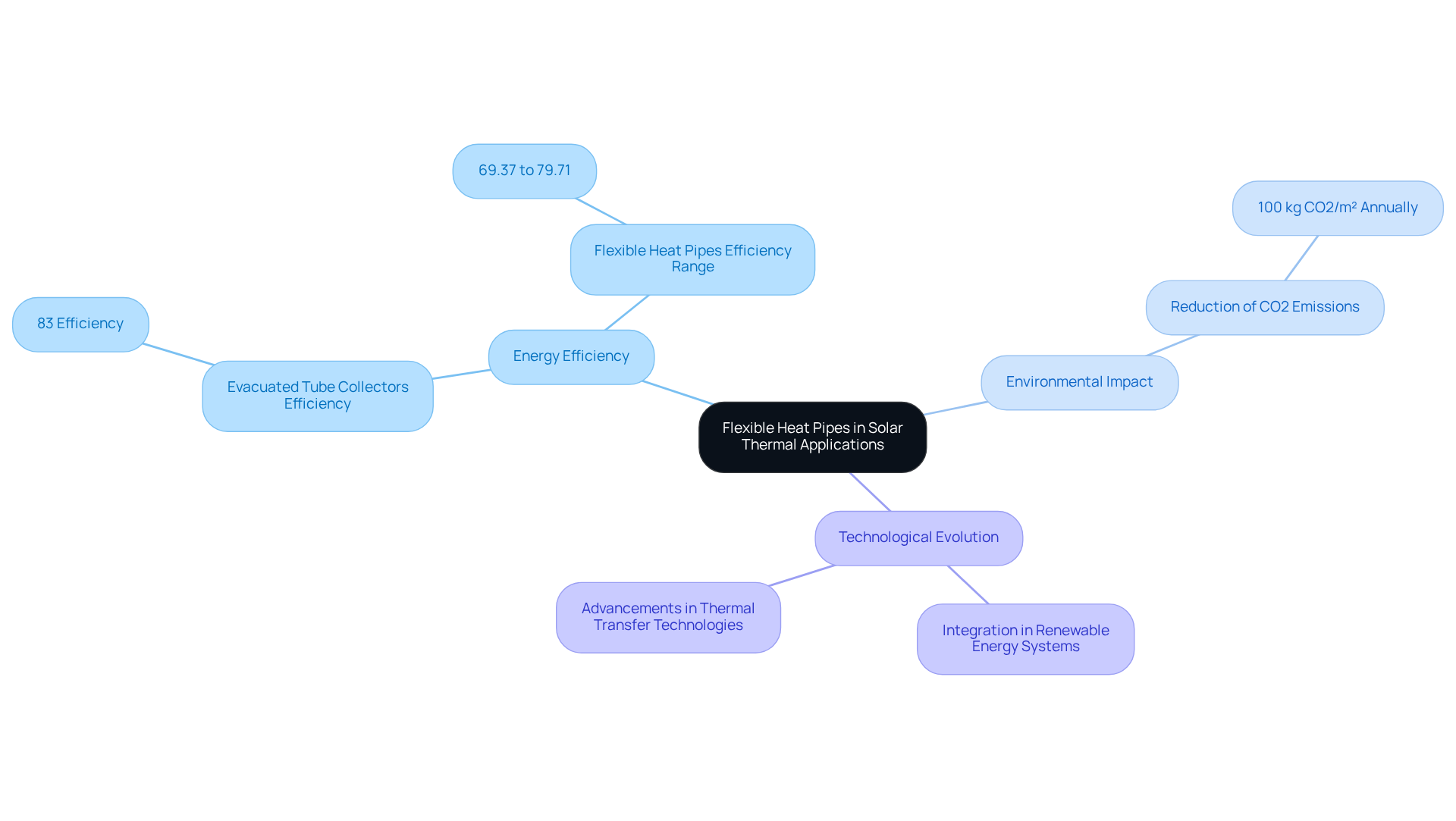

In renewable energy systems, particularly within solar energy applications, flexible heat pipes play a crucial role in enhancing energy transfer efficiency. Their innovative design facilitates effective heat collection from solar panels, enabling efficient transfer to storage systems or direct application in heating through the use of a flexible heat pipe. This capability significantly boosts the overall , with evacuated tube collectors achieving efficiencies of approximately 83%.

Furthermore, it supports the transition to sustainable energy solutions, aligning with global initiatives aimed at reducing carbon footprints. Solar heating solutions have the potential to decrease carbon dioxide emissions by nearly 100 kg CO2/m² of collector array annually when compared to natural gas heating.

Recent research indicates that the integration of flexible heat pipes can stabilize energy efficiency within a range of 69.37% to 79.71%, underscoring their vital role in advancing renewable energy systems. As the adoption of flexible heat pipes rises, they are increasingly recognized as essential components in the evolution of thermal transfer technologies.

Professor Tim Dwyer emphasized, ‘Solar thermal solutions offer an opportunity to significantly reduce carbon dioxide emissions,’ further reinforcing their importance in the renewable energy sector.

Medical Devices: Ensuring Reliability with Flexible Heat Pipe Solutions

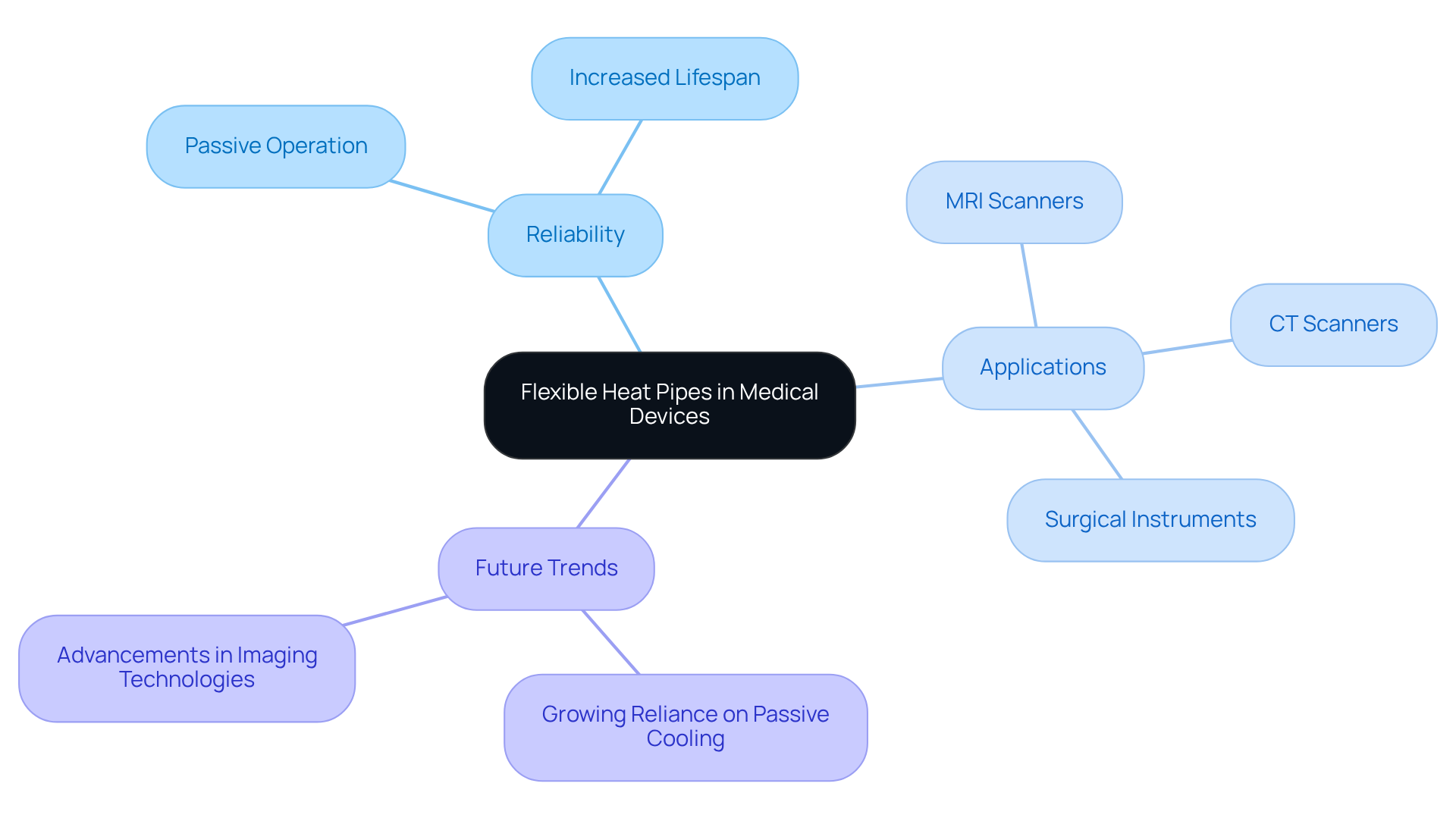

Adaptable thermal conduits, such as flexible heat pipes, are increasingly essential in medical equipment for managing the heat generated by electronic components. Their , characterized by the absence of moving parts, significantly enhances reliability—an aspect that is vital for applications such as imaging equipment and surgical instruments. By efficiently transferring heat away from sensitive components, flexible heat pipes ensure the optimal performance and safety of medical devices, particularly during critical procedures.

Experts in medical technology emphasize that the reliability of thermal conduits markedly extends the lifespan and effectiveness of devices, making them a preferred choice within the industry. Current trends in temperature management for 2025 indicate a growing reliance on passive cooling solutions, particularly the use of flexible heat pipes, as advancements in imaging technologies demand more efficient cooling methods. Notable examples include their implementation in MRI and CT scanners, where maintaining temperature stability is crucial for accurate diagnostics and patient safety.

As the medical device sector evolves, the role of flexible heat pipes in enhancing temperature regulation becomes increasingly pivotal.

Automotive: Advancing Electric Vehicle Cooling with Flexible Heat Pipes

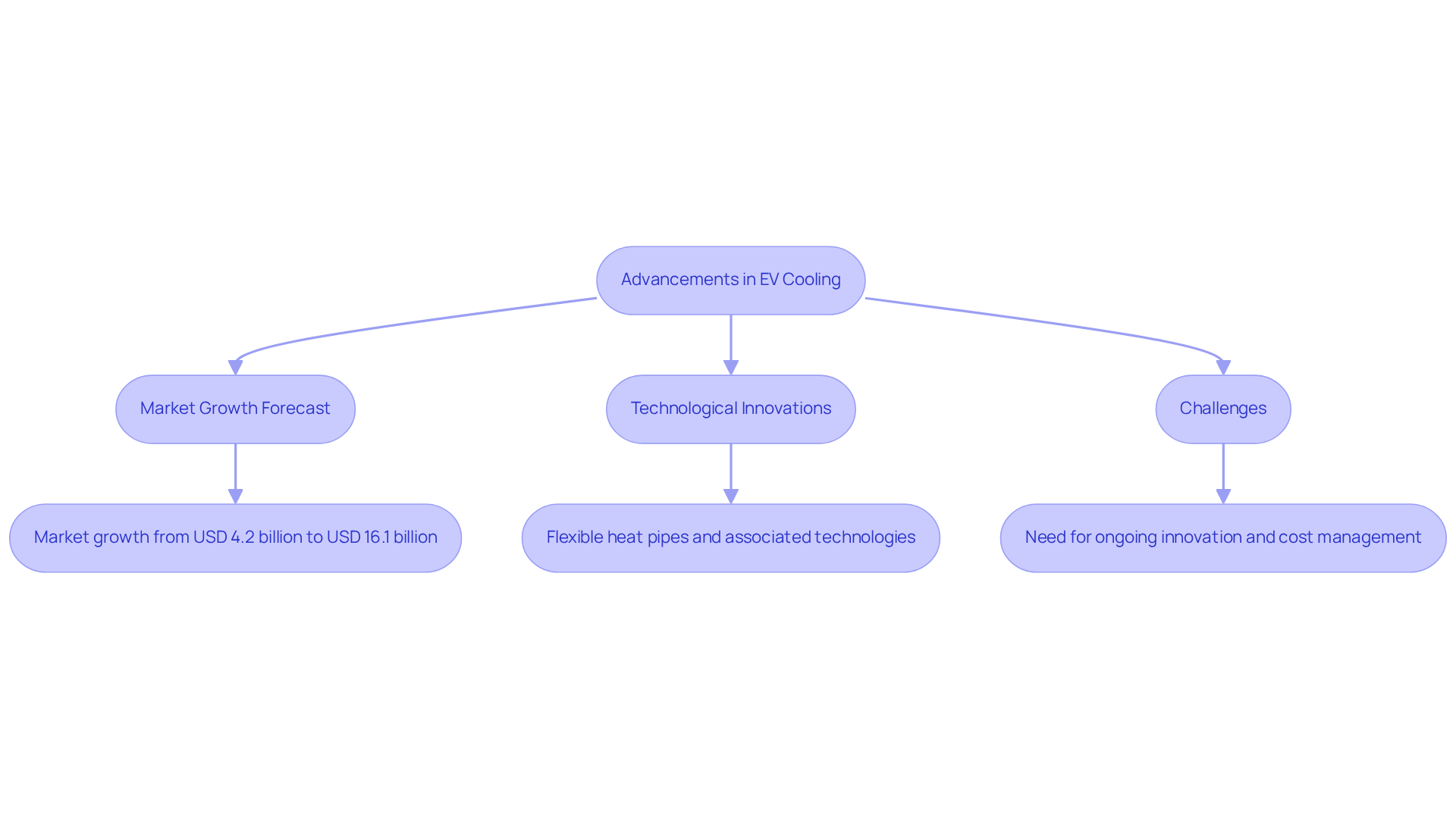

In the automotive industry, adaptable conduits play a crucial role in addressing the temperature challenges associated with electric vehicles (EVs). These conduits effectively and power electronics, ensuring that these components operate within safe temperature ranges. By enhancing heat management, the flexible heat pipe significantly contributes to the overall efficiency and performance of EVs, thus supporting the industry’s transition towards sustainable transportation solutions.

The global market for electric vehicle battery temperature management systems is projected to rise from USD 4.2 billion in 2025 to USD 16.1 billion by 2034, reflecting a compound annual growth rate (CAGR) of 21.4% from 2025 to 2035. This trend underscores the increasing reliance on advanced heating solutions. Automotive engineers emphasize that efficient temperature regulation is essential for optimizing battery longevity and performance, with flexible heat pipes emerging as a pivotal technology in this field. As industry experts have noted, “Breakthroughs in thermal management technology, such as innovations in active cooling, cost-effective air conditioning, and advanced battery thermal management, provide a strong foundation for market expansion.”

Nevertheless, challenges persist, including the necessity for ongoing innovation to keep pace with advancing battery technologies and the pressure to reduce costs while maintaining high performance. As the automotive sector embraces electrification, the impact of thermal conduits on EV battery performance will be instrumental in shaping the future of sustainable mobility. Companies like Denso Corporation and BorgWarner are leading the way with their innovative cooling technologies, further underscoring the importance of adaptable thermal conduits in enhancing EV performance.

Telecommunications: Improving Data Center Efficiency with Flexible Heat Pipes

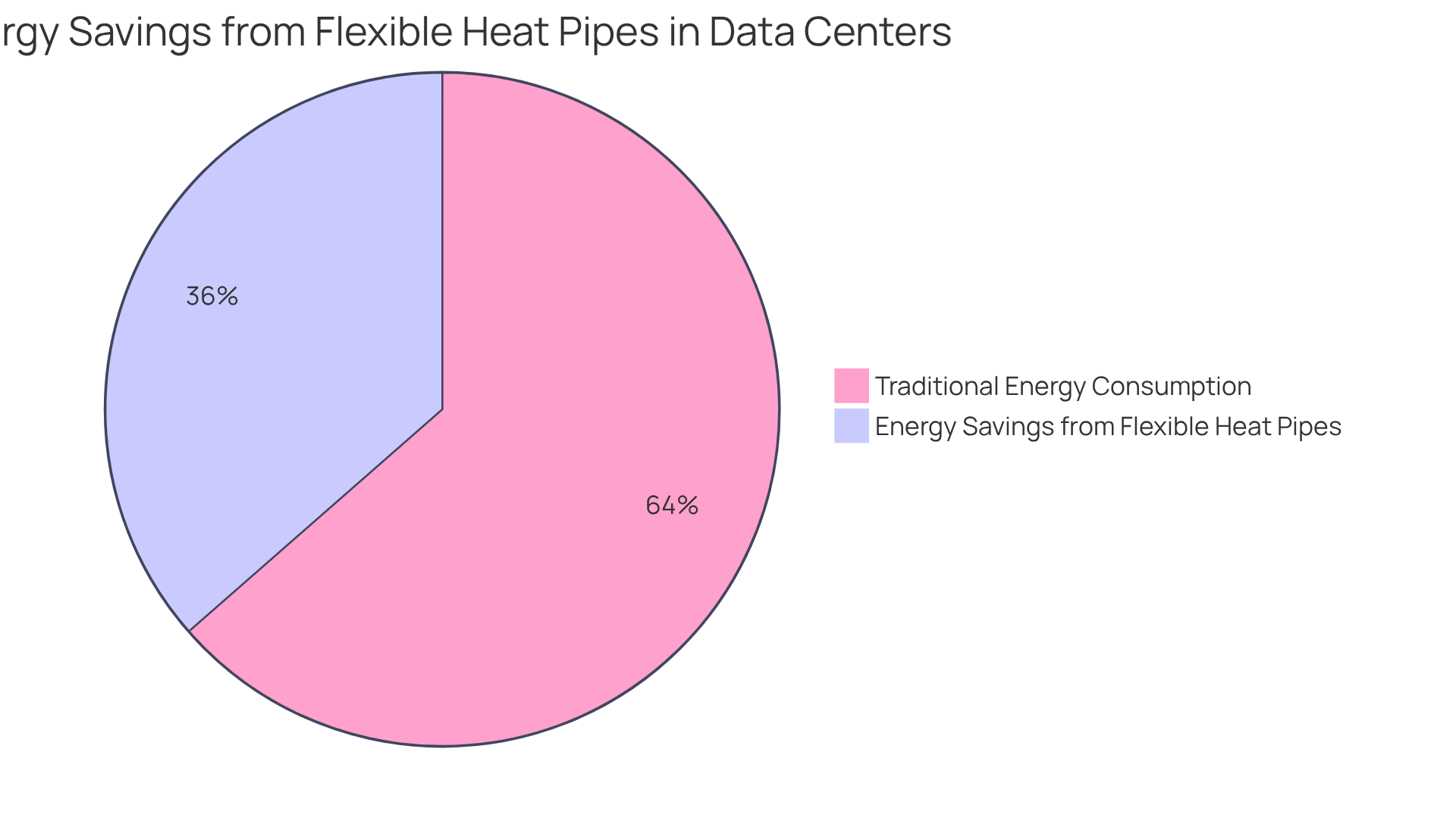

Versatile thermal conduits are revolutionizing in data centers, significantly enhancing energy efficiency. By adeptly transferring heat away from densely packed servers, these innovative solutions help maintain optimal operating temperatures, thereby reducing reliance on energy-intensive air conditioning systems. This transition not only decreases operational costs but also strengthens the reliability of telecommunications infrastructure.

A recent study underscores that the implementation of adaptable thermal conduits can yield energy savings of up to 36.45%, illustrating their effectiveness in modern data centers. Industry experts assert that such advancements are vital for addressing the escalating demands of high-density workloads, particularly in environments that support AI and high-performance computing.

As the telecommunications sector continues to evolve, the integration of adaptable thermal conduits stands out as a critical strategy for achieving sustainable and efficient operations.

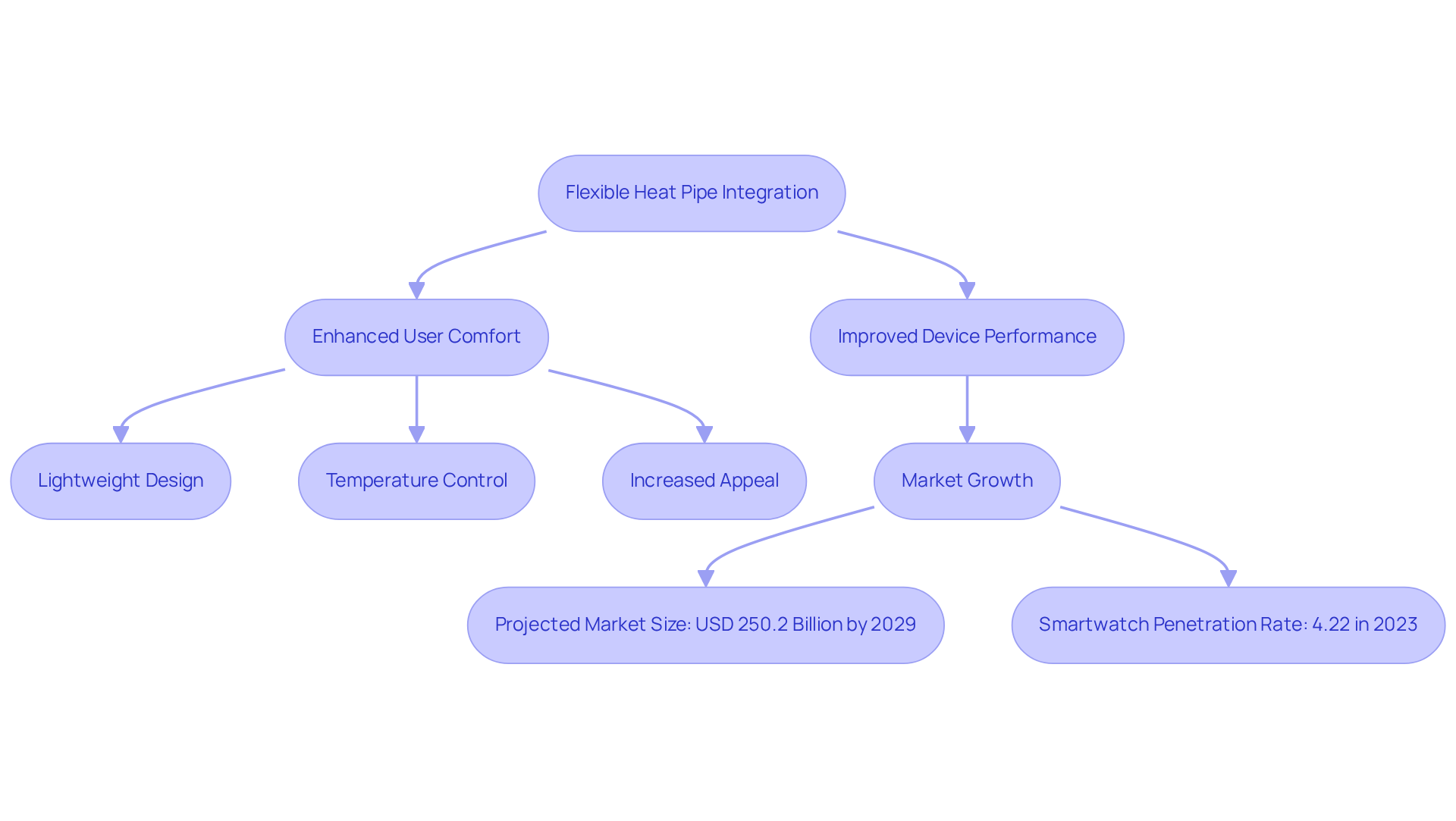

Wearable Technology: Enhancing Comfort with Flexible Heat Pipe Integration

In the realm of wearable technology, adaptable thermal conduits play a crucial role in regulating the warmth generated by electronic components, thereby ensuring user comfort. Their lightweight and flexible design allows for seamless integration into garments and accessories, providing without adding unnecessary bulk. By maintaining optimal temperatures, these devices with flexible heat pipes significantly enhance performance and comfort, making them increasingly appealing to consumers.

As the smart wearables market is projected to reach USD 250.2 billion by 2029, the incorporation of such technologies is becoming essential. Industry specialists assert that effective heat management is critical for user satisfaction, as it directly impacts the usability and comfort of wearable devices. The rising penetration rate of smartwatches, which escalated from 1.30% in 2020 to 4.22% in 2023, underscores the growing importance of temperature control solutions in this evolving market.

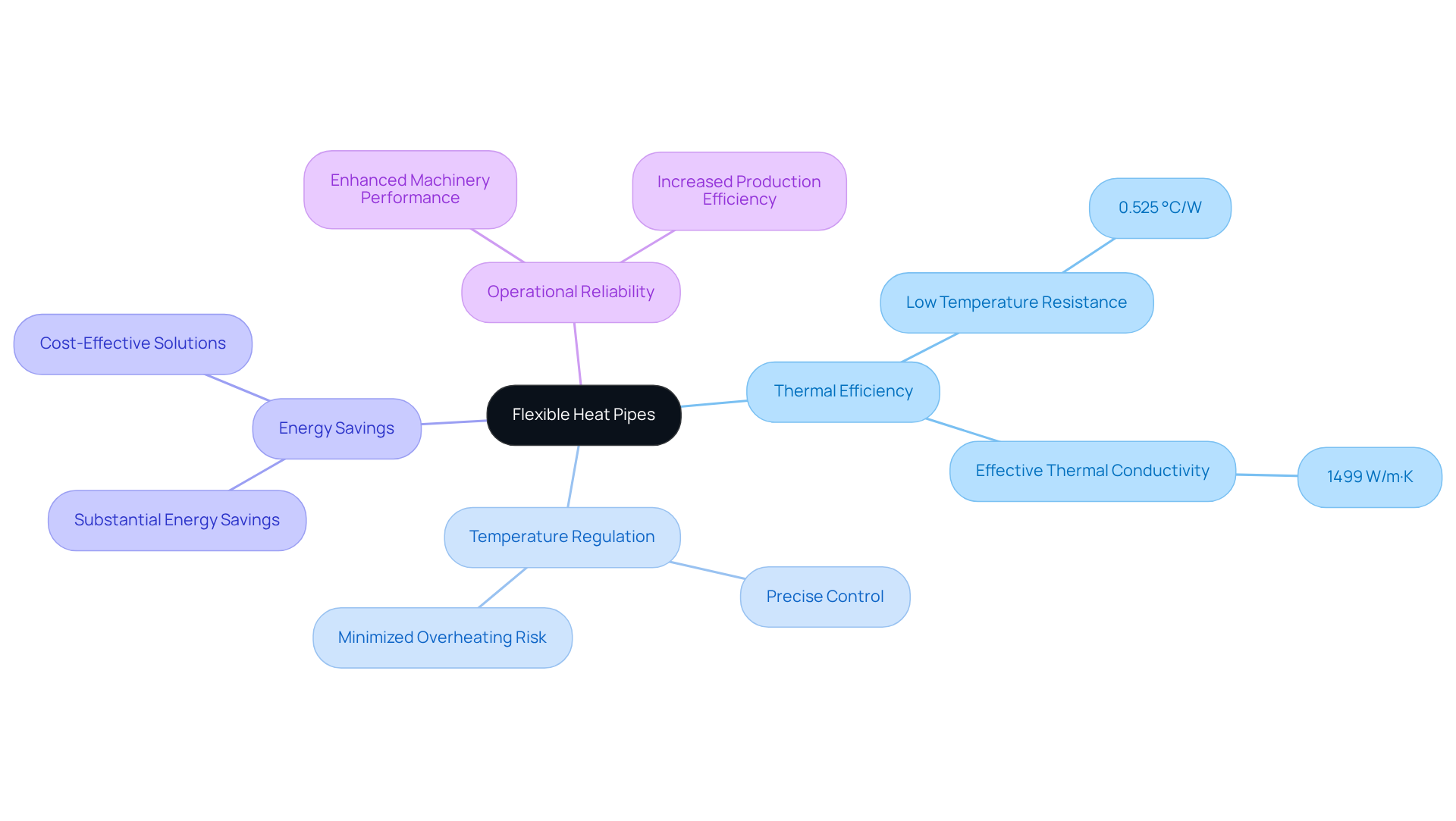

Industrial Processes: Boosting Thermal Efficiency with Flexible Heat Pipes

Adaptable conduits, such as flexible heat pipes, are revolutionizing industrial operations by significantly enhancing energy efficiency. Their , which utilize a flexible heat pipe, facilitate precise temperature regulation in manufacturing machinery, effectively minimizing the risk of overheating and thereby boosting overall productivity.

Research indicates that flexible heat pipes can achieve a low temperature resistance of 0.525 °C/W, even after extensive flexing, making them ideally suited for dynamic production environments. By integrating these cutting-edge temperature control solutions, companies can realize substantial energy savings while simultaneously improving operational reliability.

Practical applications demonstrate that adaptable conduits not only elevate machinery performance but also contribute to increased production efficiency, establishing them as essential components in modern industrial systems.

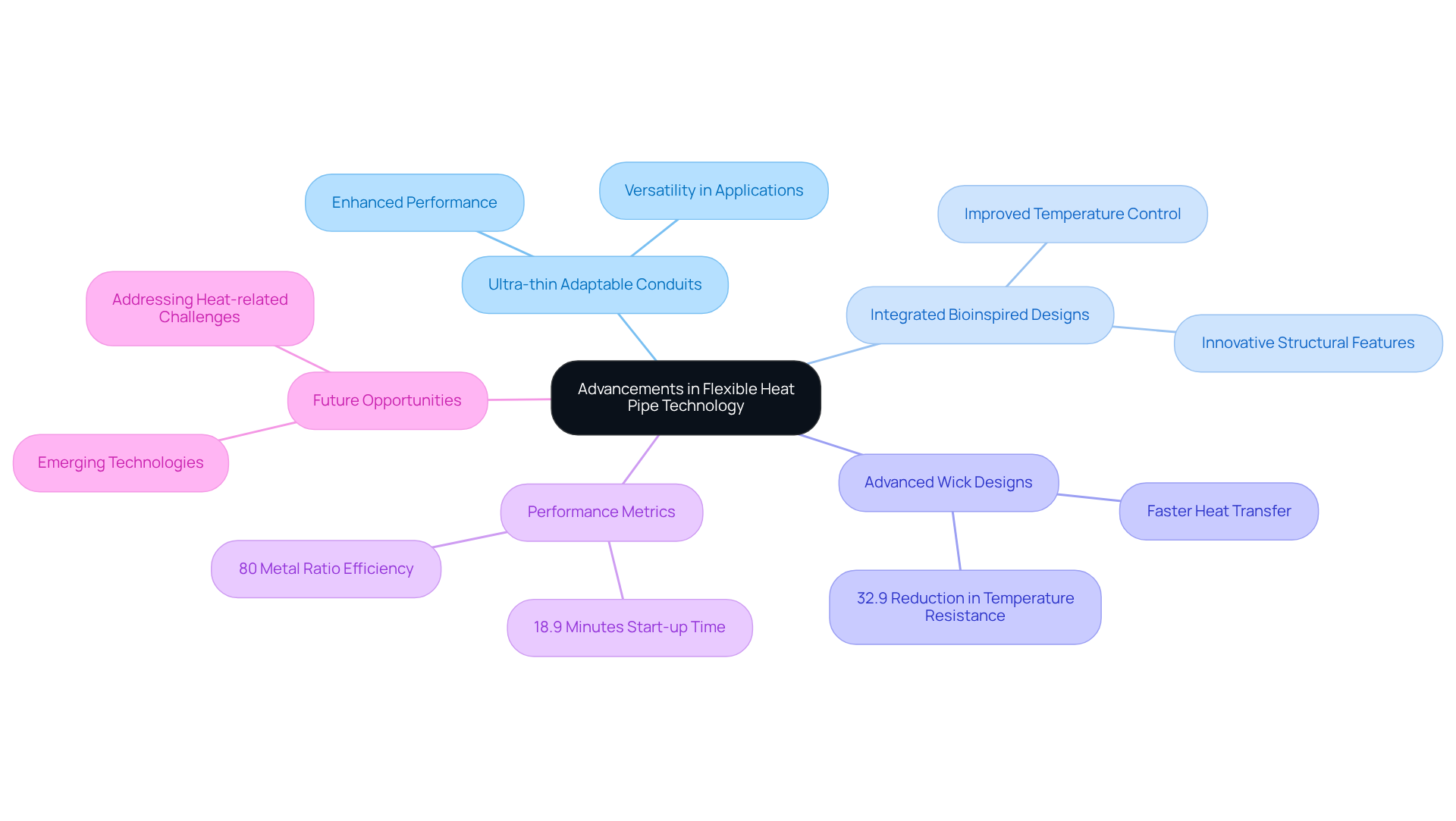

Innovative Designs: Advancements in Flexible Heat Pipe Technology

Recent progress in adaptable energy transfer technology has led to the creation of designs that deliver enhanced performance and versatility. Innovations such as ultra-thin adaptable conduits and those featuring integrated bioinspired designs are pushing the boundaries of temperature control.

For instance, adaptable thermal conduits equipped with advanced wick designs and tailored filling ratios have demonstrated a reduction in temperature resistance by over 32.9% compared to conventional adaptable thermal conduits, alongside quicker start-up times. Specifically, the start-up duration of an adaptable thermal conduit with an 80% metal ratio is reduced to 18.9 minutes, marking a decrease of 37.69% relative to traditional thermal systems.

These advancements not only enhance the efficiency of existing applications but also pave the way for new opportunities in utilizing adaptable conduits within , solidifying their role as a crucial component in the future of temperature control.

The integration of specialized low-boiling point working fluids is vital for operation at extremely low temperatures, further amplifying the significance of flexible heat pipes in addressing heat-related challenges across various sectors.

As Steve Jobs aptly stated, “Innovation distinguishes between a leader and a follower,” underscoring the critical nature of these advancements in the dynamic field of thermal management.

Conclusion

Flexible heat pipe technology emerges as a transformative force across diverse engineering sectors, delivering innovative solutions for effective thermal management. These adaptable conduits are essential in enhancing performance, safety, and sustainability in applications spanning aerospace, consumer electronics, renewable energy, and beyond. Their capacity to conform to unique shapes and operate passively without external power not only boosts efficiency but also meets the increasing demand for environmentally friendly technologies.

In this article, we explored key applications of flexible heat pipes, underscoring their critical roles in industries such as aerospace, automotive, telecommunications, and medical devices. The advantages of these systems encompass improved thermal regulation, enhanced device longevity, and substantial energy savings, which are increasingly vital in today’s technology-driven landscape. Furthermore, recent advancements in design and materials are pushing the boundaries of what flexible heat pipes can achieve, paving the way for their integration into emerging technologies and applications.

As industries evolve and the demand for efficient thermal management solutions escalates, the importance of flexible heat pipes cannot be overstated. Adopting these innovative technologies not only addresses current challenges but also positions organizations at the forefront of sustainable engineering practices. The future of thermal management resides in the adaptability and efficiency of flexible heat pipes, rendering them indispensable for engineers striving to meet the demands of modern technology and environmental responsibility.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates specializes in cooling technology, particularly flexible heat pipes that enhance thermal management solutions for electronic systems across various industries.

How do flexible heat pipes work?

Flexible heat pipes utilize advanced materials and design principles to improve the efficiency and reliability of thermal management. They operate passively without requiring an external power source, leading to energy savings and sustainability.

What industries benefit from flexible heat pipes?

Flexible heat pipes are beneficial in industries such as aerospace, consumer electronics, and automotive, where effective cooling solutions are essential.

What advantages do flexible heat pipes offer in aerospace applications?

In aerospace, flexible heat pipes help regulate thermal loads in critical components, conforming to various shapes and configurations. This enhances adaptability, performance, safety, and reliability under extreme conditions.

How do flexible heat pipes impact consumer electronics?

In consumer electronics, flexible heat pipes effectively dissipate heat from components like CPUs and GPUs, maintaining optimal operating temperatures. This improves performance and extends the lifespan of devices such as laptops, smartphones, and gaming consoles.

What is the expected market trend for flexible heat pipes by 2025?

The demand for innovative thermal control solutions, including flexible heat pipes, is anticipated to rise by 2025, driven by the need for lightweight and energy-efficient systems in various industries.

Why are flexible heat pipes considered sustainable?

Flexible heat pipes operate passively without needing an external power source, which contributes to energy savings and supports sustainability efforts in thermal management technologies.