Overview

This article underscores the critical importance of mastering fan performance curves for effective system design, illustrating how they enable engineers to optimize airflow and efficiency across various applications. It elaborates on the intricate relationship between airflow, static pressure, and power consumption, supplemented by practical examples and statistical data that underscore the necessity of selecting the appropriate fan based on performance characteristics. This careful selection is paramount for achieving optimal operational efficiency, thus highlighting the need for engineers to apply this knowledge in their designs.

Introduction

Understanding the dynamics of airflow is crucial in engineering, particularly in the design of efficient ventilation systems. Fan performance curves are essential tools that illustrate the relationship between airflow, static pressure, and power consumption, guiding engineers in selecting the appropriate fans for specific applications.

However, mastering these curves poses a challenge, as engineers must optimize system performance while balancing efficiency and noise levels. By leveraging this knowledge, engineers can enhance operational reliability and energy efficiency in their designs.

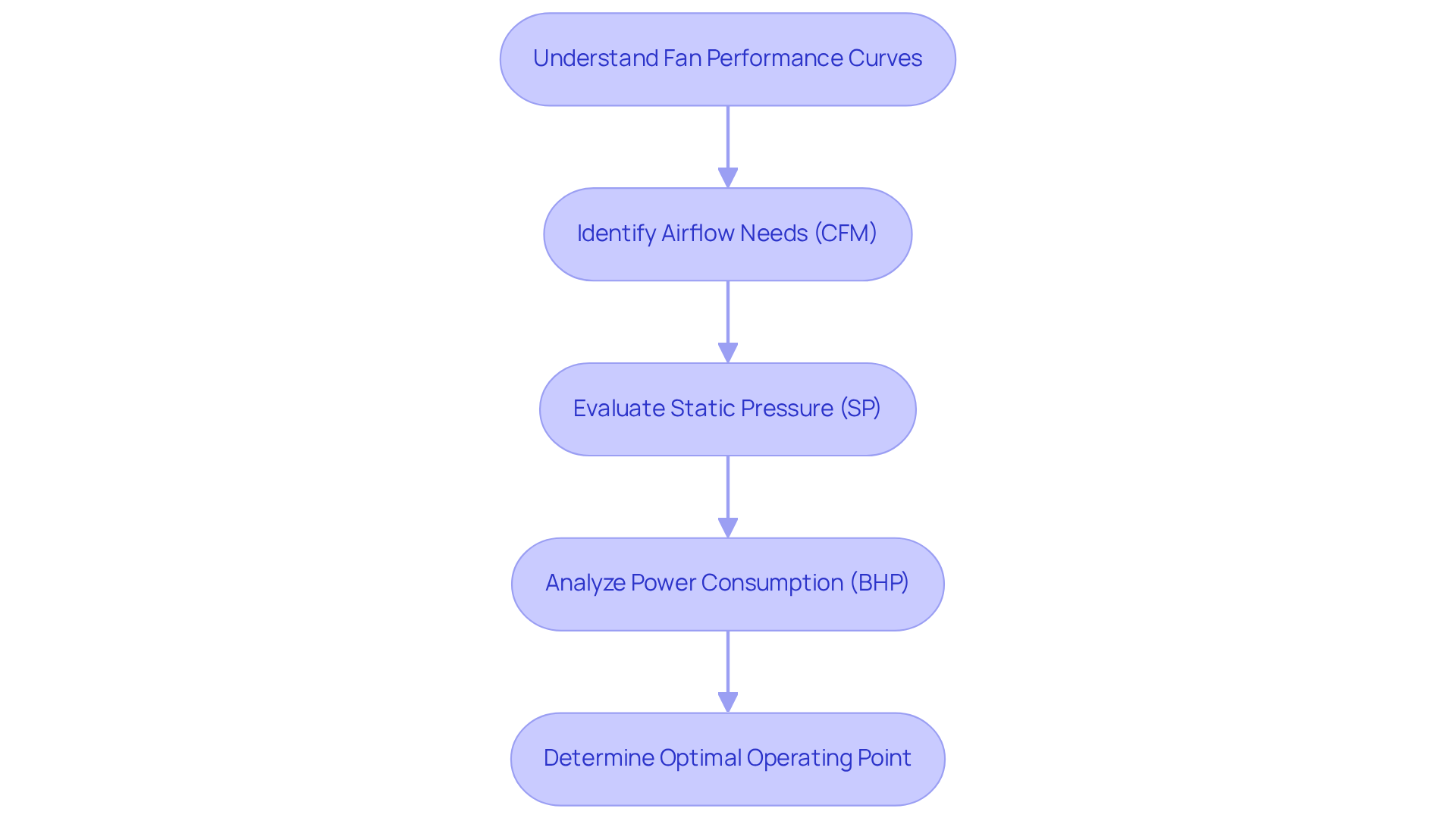

Define Fan Performance Curves and Their Importance

Performance graphs serve as vital tools that visually illustrate the intricate relationship between airflow (CFM), static pressure (SP), power consumption (BHP), and the fan performance curve for specific units. These graphs are essential instruments for engineers, enabling them to predict the fan performance curve under various operating conditions. A comprehensive understanding of the fan performance curve is crucial for selecting fans that align with system requirements, thereby enhancing efficiency and reliability in electronic systems. By meticulously analyzing the fan performance curve, engineers can pinpoint the optimal operating point for a fan, achieving a delicate balance between air movement and noise levels. This equilibrium is particularly critical in applications where effective thermal management is essential.

For example, a case study involving a factory initially required 50,000 CFM for ten machines. However, after decommissioning five machines, the air volume demand was reduced to 25,000 CFM. This significant change necessitated a thorough evaluation of the fan’s performance characteristics to avert instability and ensure adequate ventilation. Furthermore, statistical data indicates that maintaining air speed above the minimum transport air velocity is crucial for preventing insufficient air movement, particularly in environments dealing with dust or particulates. Ultimately, is indispensable for engineers striving to optimize system design and enhance operational efficiency.

Explore the Three Fan Laws and Their Applications

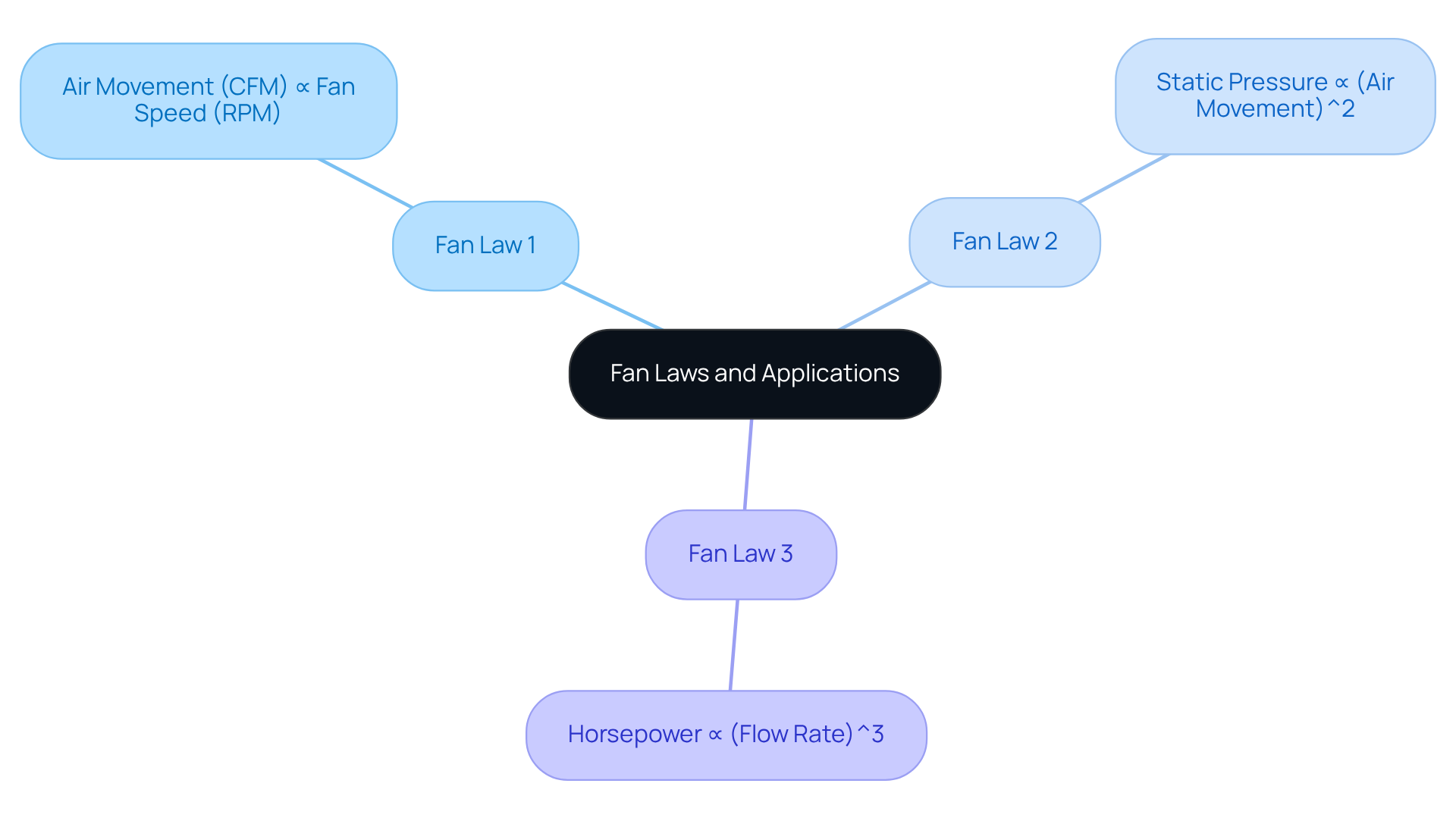

The three fan laws are critical to understanding fan performance:

- Fan Law 1 asserts that the movement of air (CFM) is directly proportional to the fan speed (RPM). This relationship indicates that an increase in the fan’s speed directly enhances the movement of air.

- Fan Law 2 reveals that the total static pressure varies with the square of the air movement. Consequently, if the airflow doubles, the static pressure increases by a factor of four.

- Fan Law 3 states that the horsepower required to operate the fan varies with the cube of the flow rate. This implies that even a minor increase in airflow can result in a significant rise in power consumption.

Understanding these laws equips engineers with the ability to will affect performance, thereby facilitating the design of more efficient systems.

Interpret Fan Curves for Effective System Design and Troubleshooting

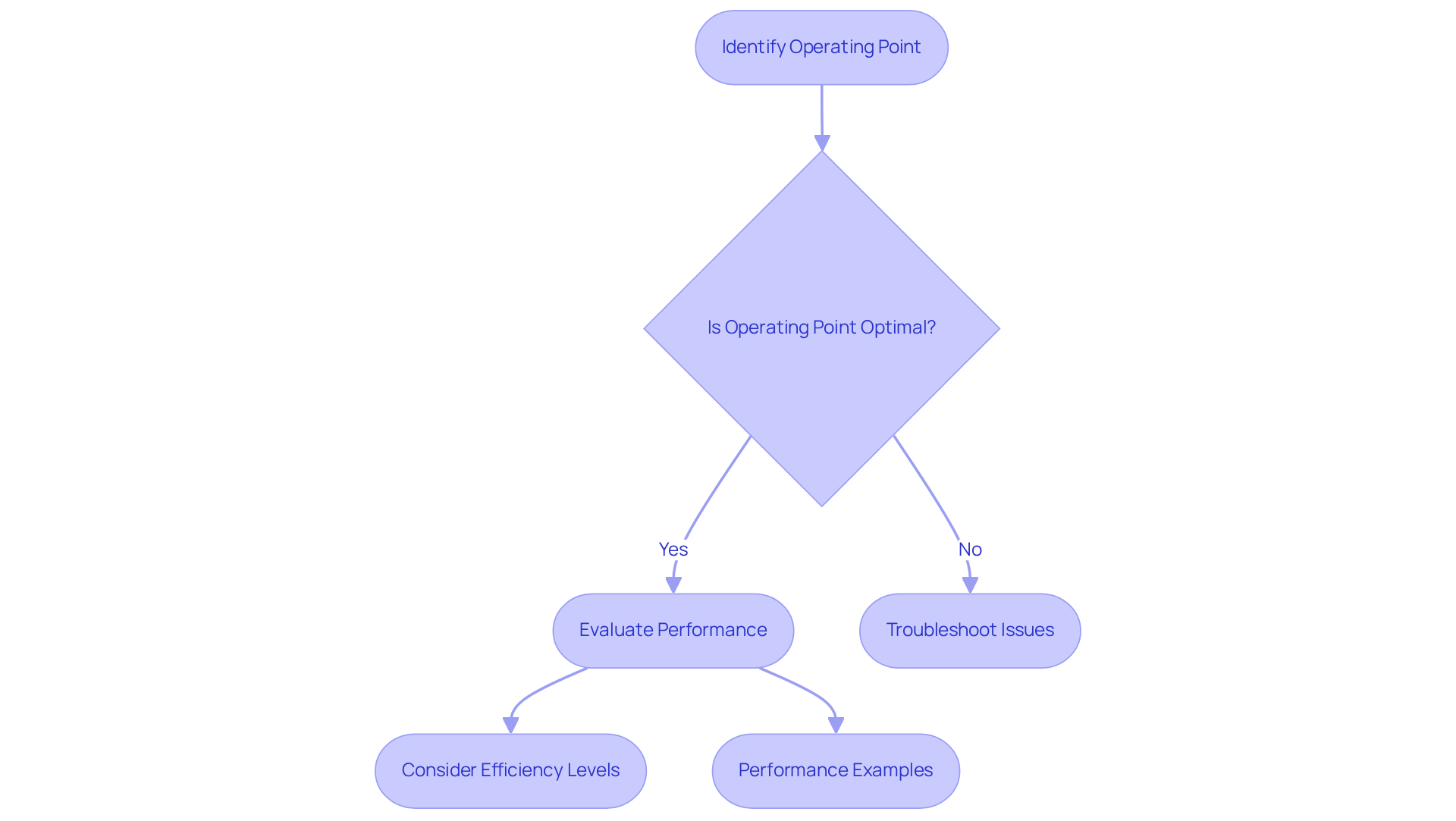

To effectively interpret fan curves, engineers must focus on several critical aspects:

- Identify the Operating Point: The operating point is defined by the intersection of the fan graph and the network graph, which indicates the actual airflow and static pressure the fan delivers within the network. Grasping this point is essential for evaluating system performance and ensuring stability.

- Evaluate Performance: Analyzing the form of the fan profile is vital for determining efficiency. Fans operating higher on the curve typically demonstrate enhanced performance and reduced noise levels. For example, at the operating point of 12,000 CFM, a fan’s static efficiency can achieve 81.1%, while total efficiency may reach as high as 86.8%. This underscores the significance of selecting fans that operate near their peak efficiency.

- Troubleshoot Issues: If the operating point deviates from expectations, it may signal underlying problems such as excessive resistance, improper fan selection, or . Common issues affecting fan performance include fan malfunctions, ductwork leaks, and incorrect fan speed settings. By systematically reviewing monitoring data and inspecting equipment, engineers can identify and rectify these issues, thereby enhancing system reliability and energy efficiency.

Practical instances underscore the importance of the fan performance curve analysis. A study conducted by the National Renewable Energy Laboratory revealed that optimizing the fan performance curve in commercial buildings can reduce energy consumption by an average of 12%. Furthermore, implementing strategies such as variable speed drives can yield energy savings of 20-50%, emphasizing the potential for improved efficiency through careful fan selection and configuration. Regular maintenance, including cleaning and inspecting fans, is also crucial for sustaining optimal performance and achieving significant energy savings.

Integrate Fan Performance Data into Equipment Selection and System Design

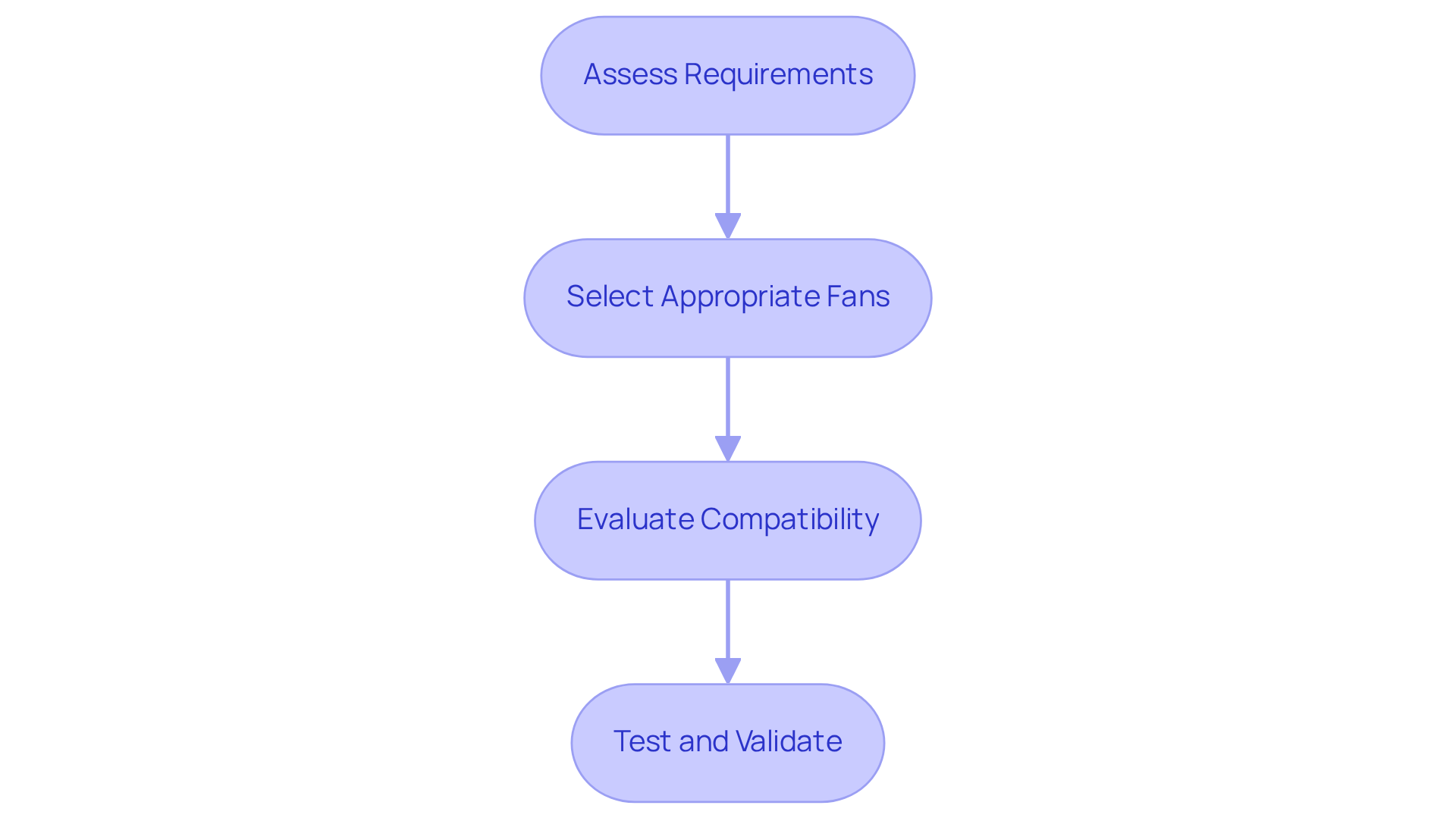

When incorporating the fan performance curve data into equipment selection and design, it is essential to follow these critical steps to ensure optimal outcomes:

- Assess Requirements: Begin by determining the airflow and static pressure needs of your setup based on the specific application.

- Select Appropriate Fans: Utilize the fan performance curve to identify fans that meet or exceed the required performance metrics. It is crucial to ensure that the selected fan operates efficiently within the desired range.

- Evaluate Compatibility: Confirm that the fan’s dimensions and mounting options align with your design specifications.

- Test and Validate: Following installation, it is imperative to observe the performance of the setup to verify that the fan functions as anticipated. Be prepared to make adjustments based on real-world conditions.

By adhering to these steps, engineers can guarantee that their systems are designed for optimal performance and reliability.

Conclusion

Mastering the intricacies of fan performance curves is essential for engineers dedicated to optimizing system design and enhancing operational efficiency. Understanding the interrelation of airflow, static pressure, and power consumption empowers professionals to select the most suitable fans for their applications, ensuring systems operate at peak performance while minimizing noise and energy usage.

Key insights from the article underscore the significance of the three fan laws, which provide a framework for predicting how changes in fan speed affect airflow, static pressure, and power requirements. Furthermore, interpreting fan curves enables engineers to identify operating points, evaluate performance, and troubleshoot potential issues, ultimately leading to more effective and reliable systems. Practical examples illustrate that optimizing fan performance can significantly reduce energy consumption, highlighting the value of thorough analysis and maintenance.

In conclusion, the mastery of fan performance curves transcends mere technical knowledge; it embodies a commitment to creating efficient, reliable, and sustainable systems. Engineers are urged to integrate these insights into their design processes, ensuring their selections not only meet current demands but also adapt to future challenges. By prioritizing fan performance analysis, the potential for enhanced energy efficiency and system reliability becomes a tangible reality.

Frequently Asked Questions

What are fan performance curves?

Fan performance curves are graphical representations that illustrate the relationship between airflow (CFM), static pressure (SP), and power consumption (BHP) for specific fan units.

Why are fan performance curves important?

They are essential tools for engineers to predict fan performance under various operating conditions, enabling the selection of fans that meet system requirements and enhance efficiency and reliability.

How do engineers use fan performance curves?

Engineers analyze the fan performance curve to identify the optimal operating point for a fan, balancing air movement and noise levels, which is critical for effective thermal management.

Can you provide an example of the importance of fan performance curves?

In a case study, a factory’s air volume demand decreased from 50,000 CFM to 25,000 CFM after decommissioning five machines. This required a thorough evaluation of the fan’s performance characteristics to ensure adequate ventilation and stability.

What is the significance of maintaining air speed above the minimum transport air velocity?

Maintaining air speed above this minimum is crucial for preventing insufficient air movement, especially in environments with dust or particulates.

How does mastering fan performance curves benefit engineers?

Mastering fan performance curves is vital for engineers to optimize system design and enhance operational efficiency in electronic systems.