Overview

The primary focus of this article is the optimization of fan RPM to enhance the performance of electronics. It highlights the critical importance of achieving the right balance of fan speed, which is essential for effective cooling while simultaneously minimizing noise and energy consumption. This assertion is supported by data indicating that even minor adjustments in RPM can lead to significant improvements in airflow and overall system efficiency.

Introduction

Understanding the delicate balance between cooling efficiency and operational noise is essential in the realm of electronics performance. Fan RPM, or revolutions per minute, plays a pivotal role in this equation, influencing everything from airflow to energy consumption. As engineers strive to optimize fan settings, the challenge lies in identifying the ideal RPM that maintains peak performance without compromising on noise levels or efficiency. To navigate this intricate landscape effectively, it is crucial to explore and employ various strategies that ensure electronic systems operate smoothly and efficiently.

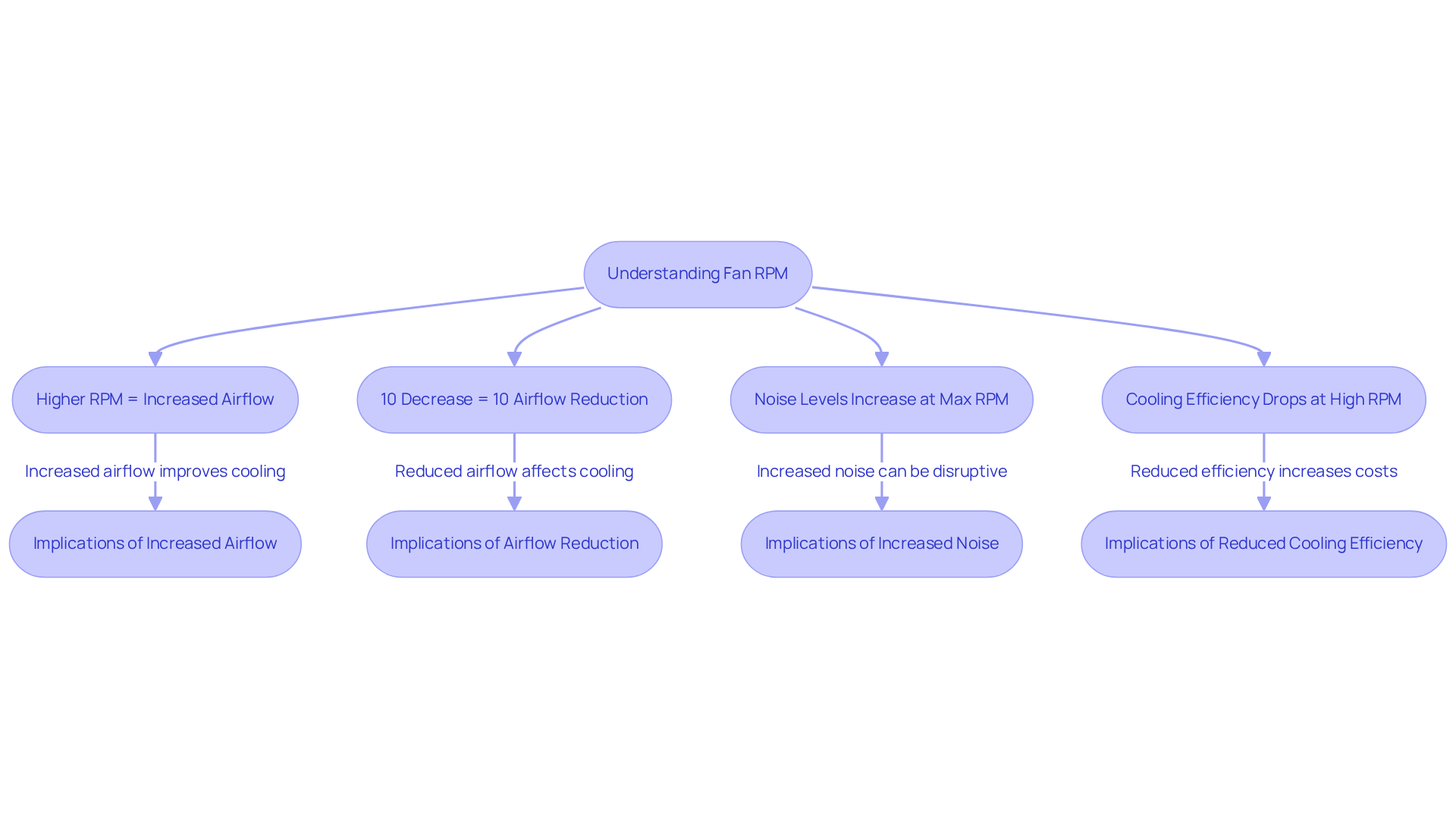

Understand Fan RPM and Its Impact on Electronics Performance

The fan RPM, or revolutions per minute, is a crucial metric that reflects the speed at which the fan operates. Higher fan RPM generally translates to increased airflow, which is vital for effectively cooling electronic components. For instance:

- A fan RPM of 2000 typically provides adequate airflow for standard applications.

- A fan RPM of 3000 may be necessary for high-performance systems under heavy loads.

Gagner-Toomey Associates, recognized as the largest producer of standard and custom air-movers globally, offers a wide range of DC input tube axial devices and centrifugal blowers, varying from 15 to 280mm in size, optimized for performance and efficiency across diverse applications, including electronics and automotive sectors.

However, consistently operating devices at their maximum fan RPM can lead to excessive noise and higher energy consumption. It’s important to recognize that cooling efficiency can diminish at very high fan RPM due to turbulence, disrupting airflow patterns. A 10% decrease in fan RPM can result in:

- A 10% reduction in airflow

- A 19% drop in static pressure (SP)

- A 27% cut in brake horsepower (BHP)

This underscores the necessity for careful optimization. Engineers frequently recommend balancing fan operation with noise levels; for example, configuring fans to operate at reduced rates until noise becomes a concern can enhance overall system performance.

Real-world applications demonstrate that (ITE) can reduce airflow by 57.2%, which highlights the practical challenges engineers face in optimizing fan placement and fan RPM. Furthermore, understanding fan efficiency metrics is essential, as they evaluate fan performance from an energy consumption perspective.

Adjusting the fan RPM not only enhances cooling efficiency but also reduces operational costs, making it imperative for engineers to identify the optimal fan RPM that maintains performance without compromising energy efficiency or introducing excessive noise. Additionally, many models offer IP protection upon request, ensuring reliability in various environments.

Explore Tools and Software for Fan RPM Control

To effectively optimize fan RPM, several tools and software options stand out in the electronics industry.

- SpeedFan is a freeware program that excels in monitoring fan speeds, temperatures, and voltages, allowing users to adjust fan speeds dynamically based on system temperatures. With a user satisfaction rating of 3.4, it reflects reliability among engineers.

- MSI Afterburner, while primarily known for GPU overclocking, offers robust fan control features. Users can set custom fan curves to adjust the fan rpm, enhancing cooling performance during demanding tasks. Its rating of 3.1 indicates effectiveness in real-world applications.

- FanControl is recognized for extensive customization options, enabling users to design complex fan curves based on readings from various sensors. This flexibility allows for precise adjustments tailored to specific cooling needs.

- Argus Monitor provides extensive fan control features, including automatic modifications based on heat levels. Its user-friendly interface simplifies the process of maintaining optimal cooling performance.

Each of these tools provides distinctive features that empower users to customize their fan rpm settings, ensuring optimal performance and efficiency in their electronic systems. User satisfaction ratings reflect the effectiveness of these programs, with many engineers praising SpeedFan and MSI Afterburner for their reliability and functionality in real-world applications. For instance, one user noted that via the ‘Q-Fan’ interface results in more stable fan behavior compared to other software solutions. Additionally, maintaining a balance between intake and exhaust airflow is crucial for effective cooling, as highlighted by various user experiences.

Set Up and Calibrate Fan RPM for Optimal Performance

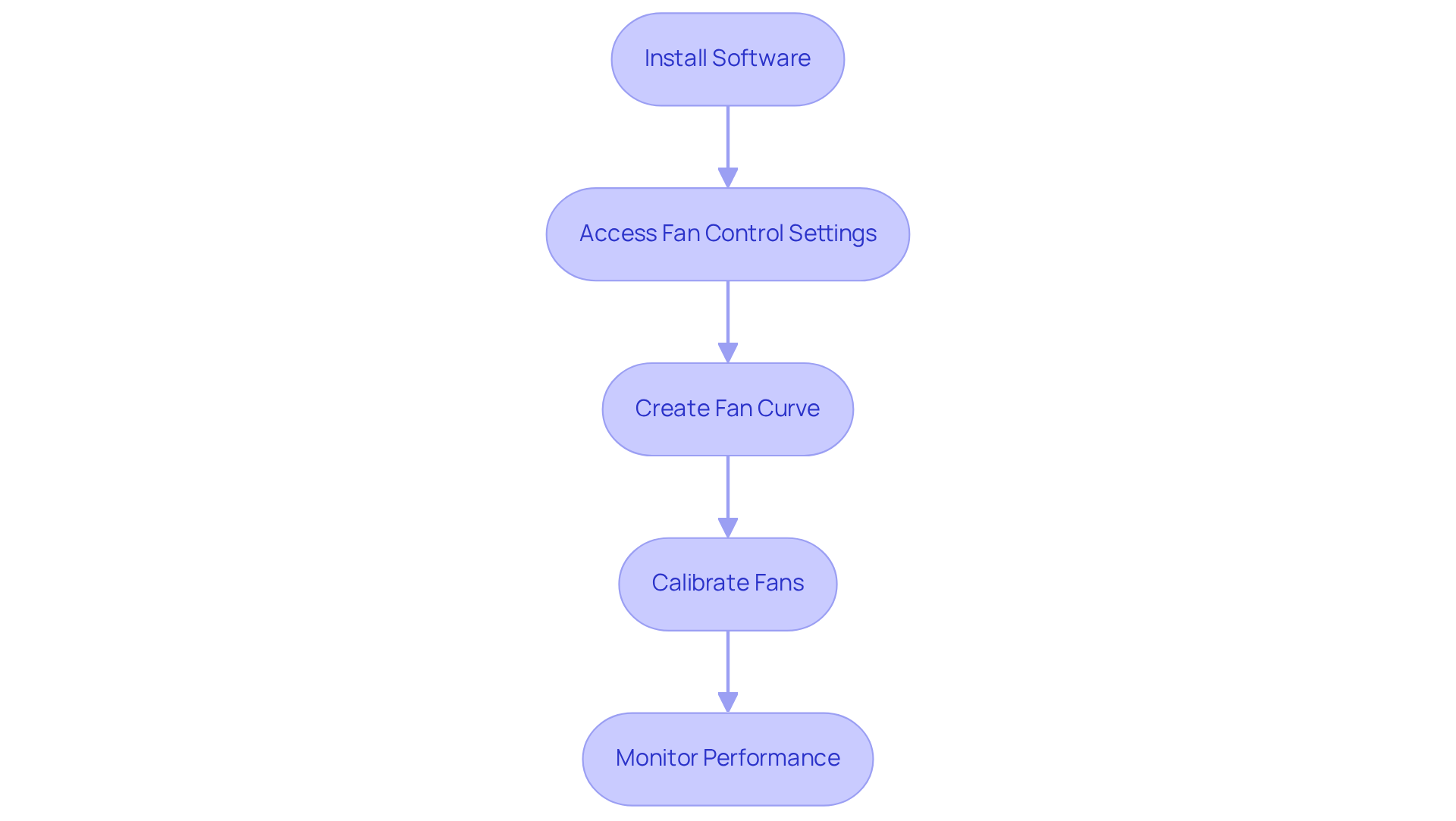

To effectively set up and calibrate fan RPM, follow these steps:

- Install the Chosen Software: Begin by downloading and installing your preferred fan control software, such as SpeedFan or MSI Afterburner, which facilitates detailed fan management.

- Access Fan Control Settings: Launch the software and navigate to the fan control settings. Here, you can view the current fan RPM readings and adjust various parameters to suit your needs.

- Create a Fan Curve: Establish a fan curve that modifies the fan rate according to temperature. For example, configure the fan to operate at 30% capacity when the temperature reaches 30°C, increasing to 100% at 70°C. This strategy helps maintain while minimizing noise.

- Calibrate the Fans: Conduct a calibration test by setting the fans to 100% for a brief period to record the maximum RPM. Subsequently, gradually decrease the pace to determine the optimal RPM for your system’s cooling requirements. It is important to note that fan rotations can differ by 5% to 10% due to manufacturing variations, and can fluctuate up to 20% as a result of aging and other factors. Additionally, testing has shown that 8 seconds per 10% increments is sufficient for calibration purposes.

- Monitor Performance: After calibration, continuously observe system heat levels and fan performance under various workloads. This ongoing assessment ensures that the settings remain effective. Adjust the fan curve as necessary based on measured heat levels and noise conditions, keeping in mind that a standard closed-loop fan control system can accommodate fan RPM rates ranging from approximately 500 to more than 15,000. The precision of thermal sensors in closed-loop fan control can vary from 1°C to 3°C, which is crucial to understand during calibration.

Real-world instances demonstrate that engineers frequently favor high-frequency PWM control due to its efficiency and reliability. PWM drive signals generally operate at frequencies exceeding 20 kHz, allowing fans to run at reduced rates while maintaining performance. Furthermore, feedback from users underscores the importance of precisely establishing thresholds for fan speed modifications to prevent excessive noise and energy consumption. As one engineer aptly noted, “It makes no sense to define a degree below the ambient level.

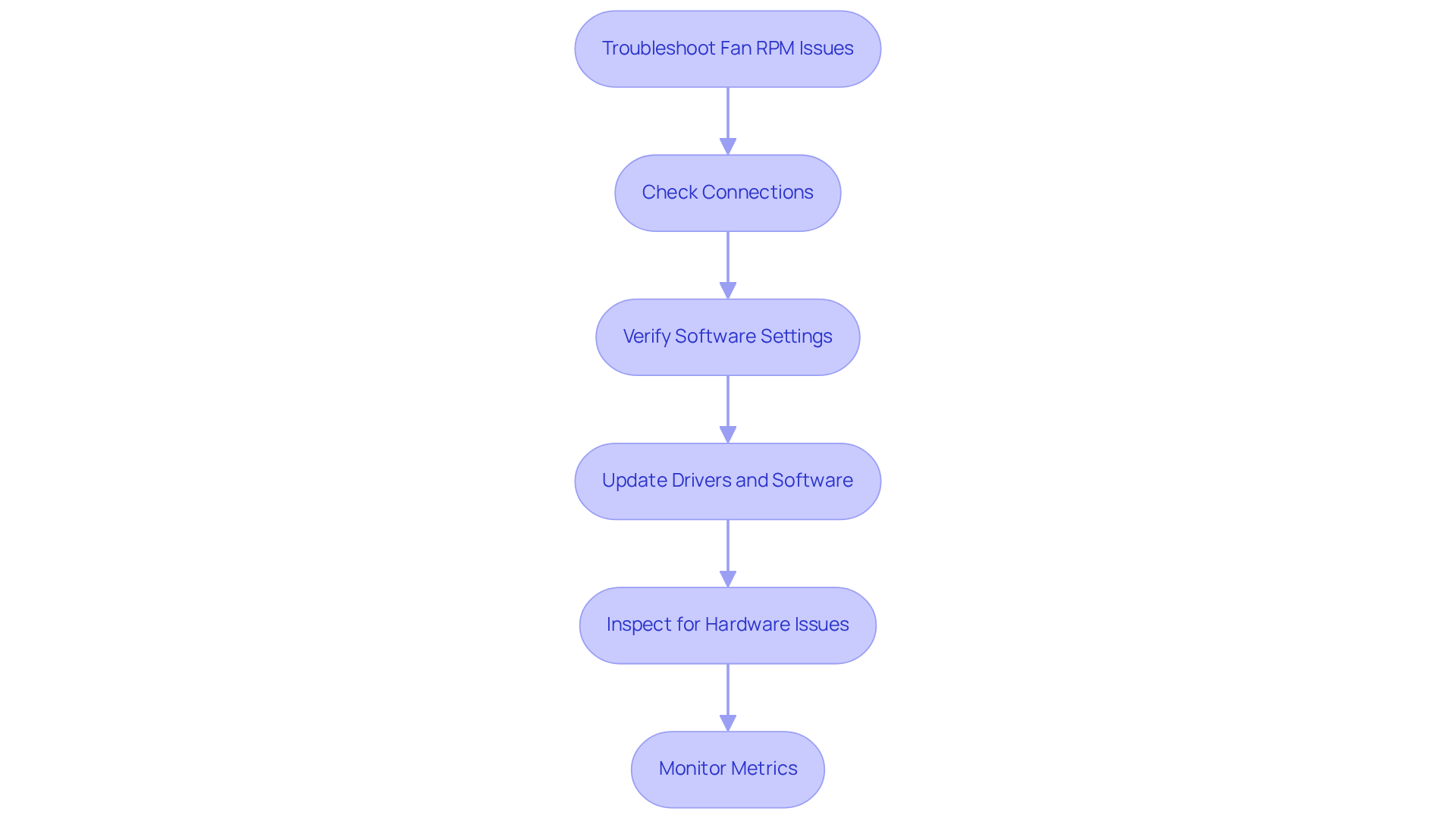

Troubleshoot Common Fan RPM Control Issues

Fan RPM control issues can significantly impact system performance, so it is essential to understand how to effectively troubleshoot fan RPM problems. To resolve common fan connection issues, consider the following steps:

- Check Connections: Ensure that all fans are securely connected to the motherboard or fan controller. Loose connections can disrupt power supply and control signals, leading to fan malfunctions.

- Verify Software Settings: Review the settings in your . Confirm that the correct fan headers are selected and that the fan control mode (PWM or DC) aligns with the fan rpm specifications.

- Update Drivers and Software: Keeping your motherboard drivers and fan control software up to date is crucial. Outdated software can cause compatibility issues, resulting in erratic fan behavior.

- Inspect for Hardware Issues: If a fan fails to respond, it may be defective. Testing the fan in another system or replacing it can help determine its functionality.

- Monitor Metrics: Utilize monitoring software to track system readings. If the conditions remain cool, the fan may not boost speed as required. Adjusting the fan rpm can ensure it responds appropriately to temperature fluctuations.

Real-world examples indicate that approximately 30% of users experience fan control problems, often stemming from improper connections or software settings. Engineers emphasize the importance of understanding these issues, as highlighted by Tim De Stasio, who states, “Ultimately, a service technician should understand the three fan laws to be more accurate when making airflow adjustments.” This understanding can prevent system inefficiencies and enhance overall performance.

Conclusion

Optimizing fan RPM is crucial for enhancing the performance and efficiency of electronic systems. Understanding the relationship between fan speed and airflow enables engineers to make informed decisions that effectively balance cooling effectiveness with energy consumption and noise levels. This meticulous calibration not only extends the lifespan of electronic components but also promotes a more sustainable approach to system design.

The article delineates four essential steps for optimizing fan RPM:

- Understanding fan performance metrics

- Utilizing specialized software for control

- Setting up and calibrating fan speeds

- Troubleshooting common issues

Each step highlights the significance of precision and adaptability in fan management, showcasing tools such as SpeedFan and MSI Afterburner that facilitate dynamic adjustments based on real-time system demands. Additionally, recognizing the impact of fan placement and airflow dynamics underscores the complexity of achieving optimal cooling solutions.

In conclusion, the importance of proper fan RPM optimization cannot be overstated. As electronic devices evolve and demand higher performance, leveraging these strategies will ensure systems operate efficiently while mitigating potential thermal issues. Engineers and technicians are urged to adopt these practices and tools, fostering a proactive approach to thermal management that enhances both performance and reliability in electronic applications.

Frequently Asked Questions

What does fan RPM stand for and why is it important?

Fan RPM stands for revolutions per minute, and it is a crucial metric that reflects the speed at which a fan operates. Higher fan RPM typically results in increased airflow, which is essential for effectively cooling electronic components.

What are the typical fan RPM requirements for different applications?

A fan RPM of 2000 generally provides adequate airflow for standard applications, while a fan RPM of 3000 may be necessary for high-performance systems under heavy loads.

What are the potential downsides of operating fans at maximum RPM?

Operating devices at their maximum fan RPM can lead to excessive noise and higher energy consumption. Additionally, cooling efficiency may decrease at very high fan RPM due to turbulence, which can disrupt airflow patterns.

How does a decrease in fan RPM affect airflow and performance?

A 10% decrease in fan RPM can lead to a 10% reduction in airflow, a 19% drop in static pressure (SP), and a 27% cut in brake horsepower (BHP).

What is the recommended approach for optimizing fan operation?

Engineers often recommend balancing fan operation with noise levels by configuring fans to operate at reduced rates until noise becomes a concern, which can enhance overall system performance.

What challenges do engineers face regarding fan placement and RPM?

Real-world applications show that placing the fan inside specific Information Technology Equipment (ITE) can reduce airflow by 57.2%, highlighting the practical challenges engineers encounter in optimizing fan placement and RPM.

Why is understanding fan efficiency metrics important?

Understanding fan efficiency metrics is essential as they assess fan performance from an energy consumption perspective, helping engineers to identify optimal fan RPM that maintains performance while minimizing energy use and noise.

Do fans come with any protective features?

Many fan models offer IP protection upon request, ensuring reliability in various environments.