Overview

The article delves into the intricacies of fan blade design and its pivotal role in optimizing electronics cooling efficiency. It asserts that an optimal fan blade design—incorporating critical factors such as shape, pitch, and material—can significantly enhance airflow, reduce energy consumption, and minimize noise. This, in turn, ensures effective thermal management and bolsters the reliability of electronic systems.

Introduction

The intricate world of electronics cooling hinges significantly on the design of fan blades, where even minor variations can dramatically influence performance. A well-optimized fan blade design not only enhances airflow and reduces noise but also plays a crucial role in energy efficiency, particularly in high-density environments like data centers.

However, with numerous design options available—from straight to airfoil shapes—engineers face the challenge of determining the most effective configuration for their specific cooling needs.

Exploring the nuances of fan blade design reveals the key to unlocking superior thermal management and reliability in electronic systems.

Define Fan Blade Design and Its Role in Electronics Cooling

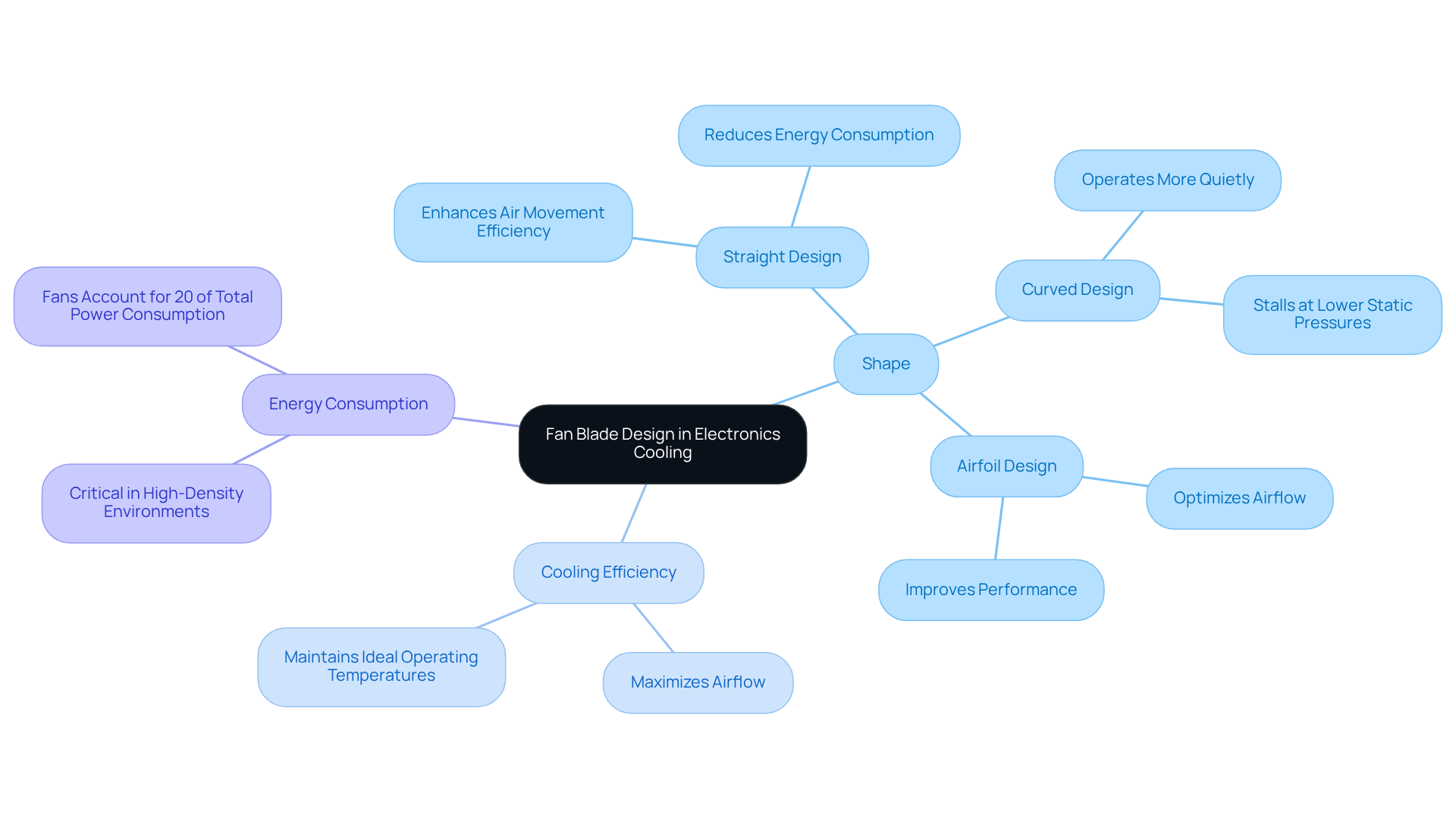

The structure of fan components, including the fan blade design, encompasses the specific shape, size, and arrangement of parts utilized in cooling fans, which are vital for effective heat dissipation in electronic devices. This layout significantly influences air movement patterns, cooling efficiency, and noise levels. In the domain of electronics cooling, an optimal fan blade design is crucial for sustaining ideal operating temperatures, thereby enhancing the performance and longevity of electronic components.

Various shapes of cutting instruments, such as straight, curved, and airfoil designs, each uniquely affect the dynamics of air movement. For instance, straight edges with triangular extensions near the leading edge have been shown to enhance movement efficiency and reduce energy consumption. Conversely, while curved edges tend to operate more quietly, they often stall at lower static pressures, impacting overall performance.

An effective fan blade design maximizes airflow while also minimizing energy usage, a critical consideration in high-density environments such as data centers, where fans can account for approximately 20% of total power consumption. By understanding and implementing advanced fan blade design, engineers can significantly improve thermal management and the overall reliability of systems.

Trace the Evolution of Fan Blade Design in Electronics

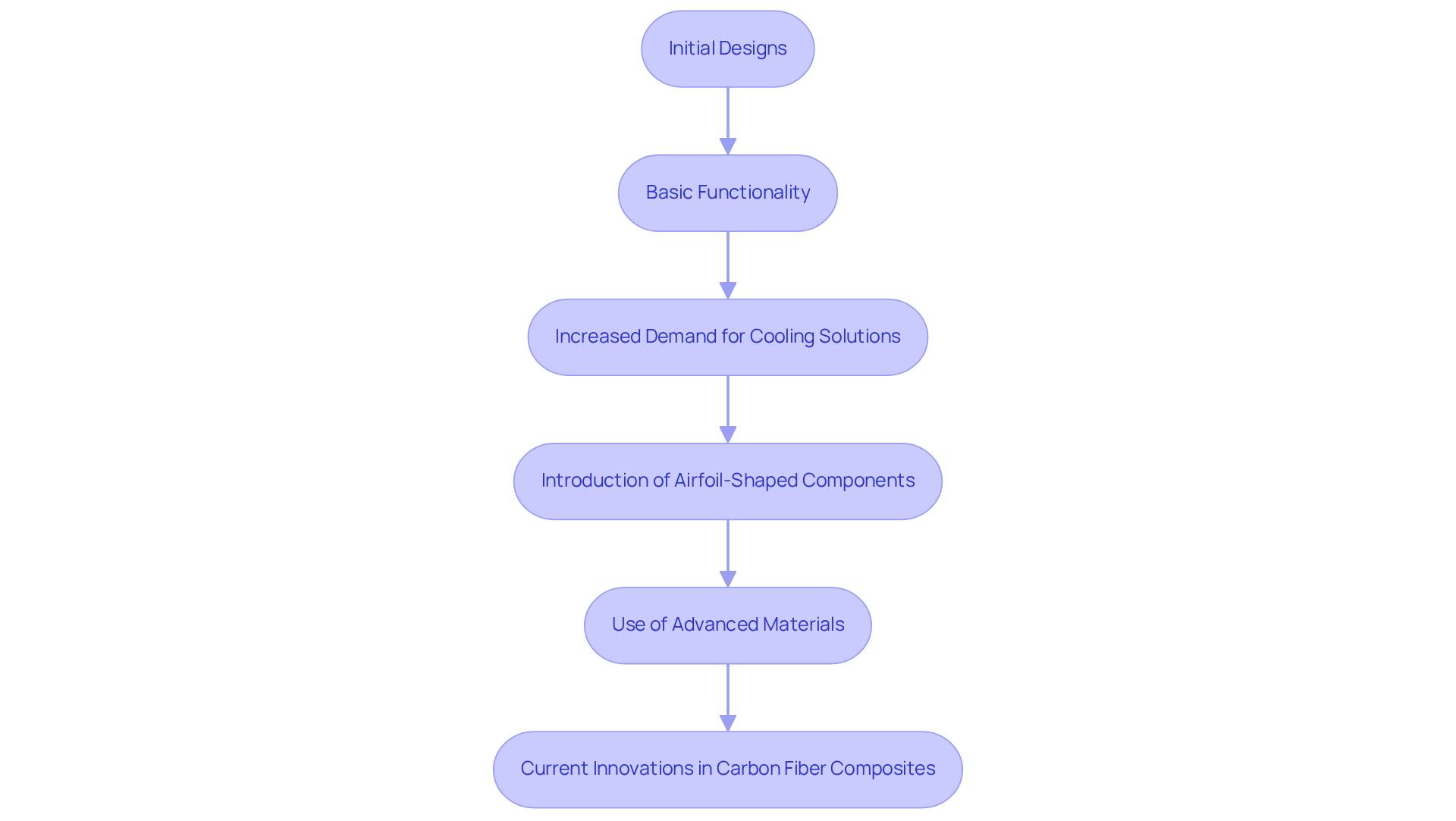

The evolution of electronics has seen remarkable technological advancements in fan blade design. Initially, designs were rudimentary, focusing primarily on basic functionality rather than efficiency. However, as the demand for compact and powerful electronic devices surged, the need for enhanced cooling solutions became increasingly evident.

The introduction of airfoil-shaped components in the late 20th century marked a pivotal shift, significantly improving airflow and reducing noise levels. Recent innovations have embraced advanced materials, such as composites, which not only enhance durability and performance but also reduce weight.

For instance, the application of carbon fiber composites has led to the development of fans that are both lighter and stronger, effectively addressing the growing thermal management challenges faced in contemporary electronics. This evolution highlights a broader trend towards optimizing cooling solutions, driven by the imperative for greater efficiency and effectiveness in managing heat dissipation, particularly through innovative fan blade design within high-performance electronic systems.

Identify Key Characteristics and Components of Effective Fan Blade Design

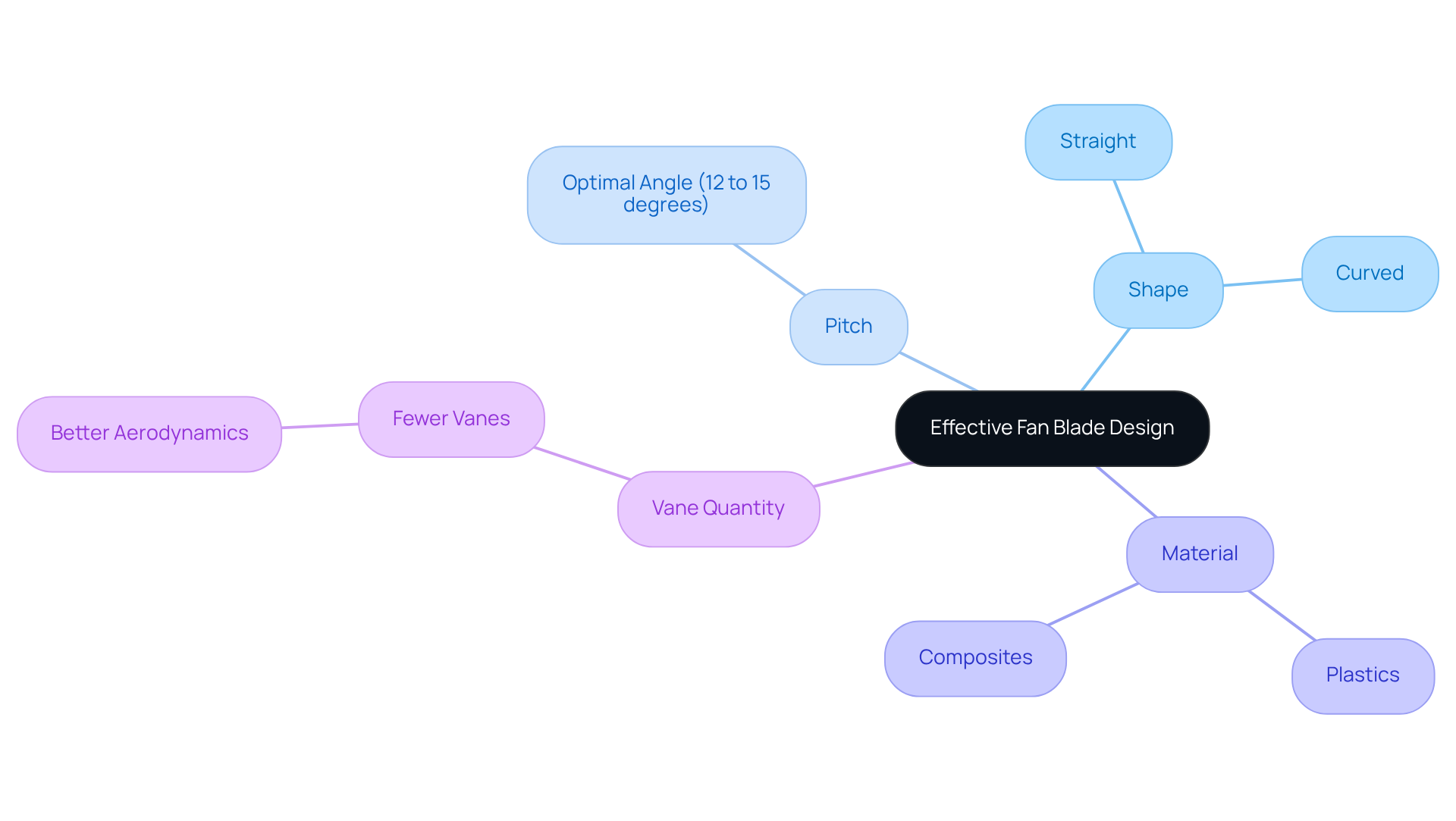

Effective fan blade design relies on several key characteristics: shape, pitch, and material. The arrangement of the blades—whether straight or curved—directly influences air movement, significantly impacting cooling efficiency. For instance, propellers with a greater pitch angle can shift more air per rotation, thereby improving overall circulation. Research indicates that an optimal pitch angle of 12 to 15 degrees maximizes airflow while minimizing energy usage.

Additionally, the choice of material is crucial; lightweight options such as plastics or composites not only enhance efficiency by reducing operational energy demands but also contribute to the durability of the fan. Engineers must carefully consider these factors to enhance cooling solutions in electronic applications, as the right fan blade design and pitch combination can lead to substantial advancements in thermal management and energy efficiency.

Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, offers an extensive product line of DC input Tube Axial fans ranging from 15 to 280mm and Centrifugal Blowers from 15 to 225mm, all designed to meet diverse industrial needs.

Furthermore, the quantity of vanes on a fan can influence efficiency; typically, fewer vanes lead to a more aerodynamic structure that reduces noise and drag. This comprehensive approach ensures that Gagner-Toomey Associates delivers optimal cooling solutions tailored to various applications.

Examine the Importance of Fan Blade Design for Cooling Efficiency

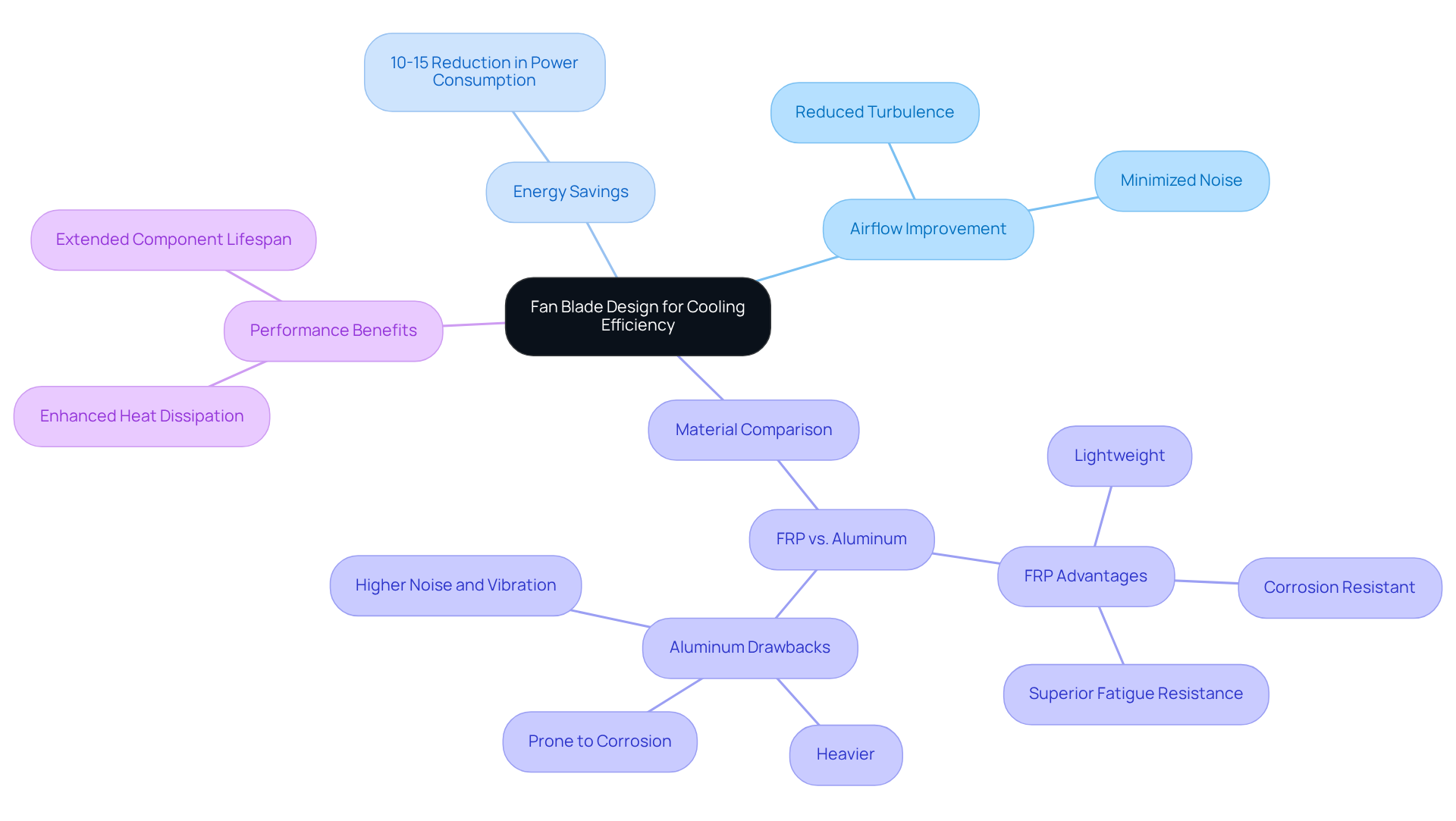

The fan blade design is crucial for optimizing the cooling efficiency of electronic systems. The fan blade design of well-designed components significantly improves air movement, reduces turbulence, and minimizes noise, all essential for effective thermal regulation. For example, components crafted with a fan blade design exhibit superior airflow characteristics compared to traditional designs, facilitating enhanced heat dissipation.

Research indicates that refining the fan blade design can lead to energy savings of 10-15%, as fans operate more efficiently, consuming less power while delivering effective cooling. This efficiency is particularly critical in high-performance electronics, where an effective fan blade design can prevent overheating, thereby avoiding component failure and extending lifespan.

Furthermore, advanced structures, such as those made from fiberglass reinforced plastic (FRP), increase durability and lower maintenance needs, contributing to long-term energy efficiency and operational reliability. In contrast to aluminum components, which are heavier and prone to stress risers that may elevate failure rates, FRP options offer enhanced fatigue resistance and corrosion resistance, rendering them a more reliable choice for engineers focused on improving cooling solutions.

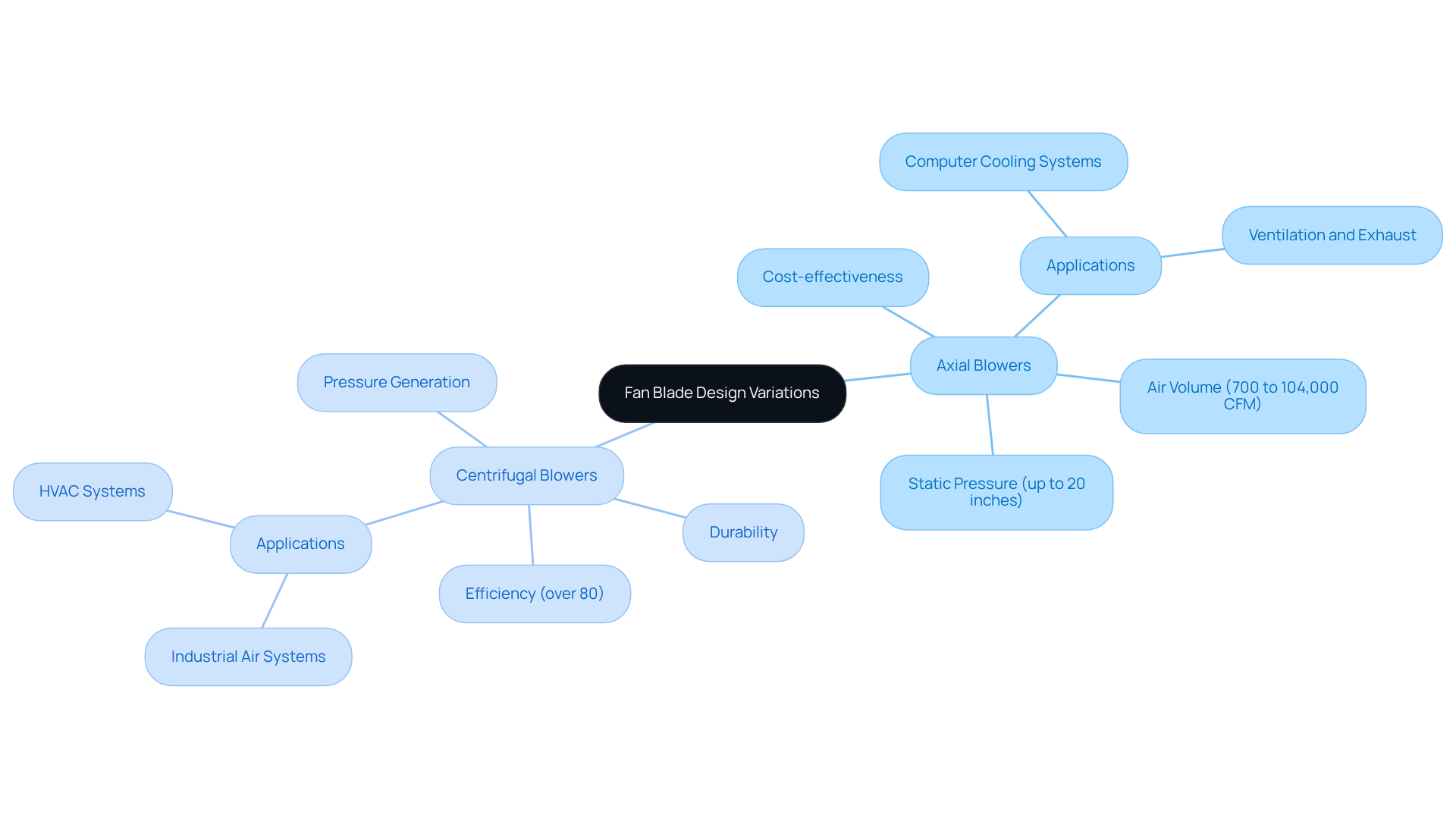

Explore Variations in Fan Blade Design for Different Applications

The design of fan blades plays a crucial role in addressing the specific cooling requirements of various applications. Axial blowers, characterized by blades that rotate around an axis, excel in scenarios demanding a high volume of air at low pressure. This makes them particularly suitable for computer cooling systems. They can deliver air volumes ranging from 700 to 104,000 CFM, with static pressure capabilities reaching up to 20 inches or more. Available in wheel diameters from 12 to 66 inches, axial devices are generally more cost-effective than centrifugal systems, further enhancing their appeal in commercial settings.

Conversely, centrifugal blowers utilize blades that push air outward, generating higher pressure at the expense of air movement. This design is especially effective in HVAC systems, where it is vital to maintain consistent airflow under varying pressure conditions. Renowned for their durability, centrifugal blowers often operate in challenging environments and can achieve peak efficiencies exceeding 80%, making them advantageous for large-scale air systems.

Tailored configurations, such as backward-curved edges, are employed in applications where noise reduction is paramount. These fans produce a steadier airflow and are less prone to overload, rendering them ideal for settings that necessitate quiet operation. By comprehending the distinctions in fan blade design, engineers can make informed decisions tailored to their unique cooling challenges, thereby ensuring optimal performance and efficiency in their systems.

Conclusion

The significance of fan blade design in electronics cooling is paramount. An optimized design not only enhances airflow but also plays a critical role in maintaining the performance and longevity of electronic components. By focusing on the shape, pitch, and material of fan blades, engineers can devise solutions that effectively manage heat dissipation, ensuring devices operate within their ideal temperature ranges.

This article has presented key insights that highlight the evolution of fan blade technology, the importance of specific design characteristics, and the impact of these factors on cooling efficiency. The transition from basic designs to advanced airfoil shapes, along with the integration of lightweight materials such as carbon fiber composites, exemplifies the strides made in this field. Furthermore, differentiating between axial and centrifugal blowers underscores the tailored approaches required for various applications, showcasing how fan blade design directly influences cooling effectiveness.

In conclusion, understanding and implementing effective fan blade design is essential for optimizing thermal management in electronic systems. As technology continues to advance, the demand for efficient cooling solutions will only escalate. Engineers and manufacturers must prioritize innovative designs that not only meet the demands of modern electronics but also contribute to energy efficiency and sustainability. By embracing these advancements, the industry can ensure the reliability and performance of electronic devices for years to come.

Frequently Asked Questions

What is fan blade design and why is it important in electronics cooling?

Fan blade design refers to the specific shape, size, and arrangement of parts used in cooling fans. It plays a crucial role in effective heat dissipation in electronic devices, influencing air movement patterns, cooling efficiency, and noise levels. An optimal design helps maintain ideal operating temperatures, enhancing the performance and longevity of electronic components.

How do different fan blade shapes affect performance?

Different fan blade shapes, such as straight, curved, and airfoil designs, uniquely affect air movement dynamics. Straight edges with triangular extensions improve movement efficiency and reduce energy consumption, while curved edges operate more quietly but may stall at lower static pressures, impacting overall performance.

What are the energy considerations associated with fan blade design?

An effective fan blade design maximizes airflow while minimizing energy usage, which is critical in high-density environments like data centers, where fans can account for about 20% of total power consumption. Advanced designs can significantly improve thermal management and system reliability.

How has fan blade design evolved in electronics?

Fan blade design has evolved from rudimentary designs focused on basic functionality to more advanced solutions emphasizing efficiency. The introduction of airfoil-shaped components in the late 20th century improved airflow and reduced noise levels. Recent innovations include the use of advanced materials, like carbon fiber composites, which enhance durability, performance, and reduce weight.

What materials are being used in modern fan blade designs?

Modern fan blade designs often utilize advanced materials such as composites, including carbon fiber, which contribute to making fans lighter and stronger. This addresses the thermal management challenges in contemporary electronics, optimizing cooling solutions for greater efficiency and effectiveness.