Overview

The article delineates ten pivotal benefits of heat exchanger systems for electronics engineers, underscoring their essential role in augmenting energy efficiency, optimizing thermal management, and bolstering overall system reliability. It elaborates on how these systems effectively reduce operational costs, prolong equipment lifespan, and enhance air quality, thereby illustrating their indispensable significance in contemporary electronic applications.

Introduction

The role of heat exchanger systems in modern engineering is becoming increasingly vital, particularly for electronics engineers who are tasked with optimizing performance and efficiency. These systems not only enhance energy efficiency but also play a crucial role in thermal management, ultimately extending the lifespan of electronic components. However, with the myriad of options available, how can engineers determine the most effective heat exchanger solutions for their specific applications? This article explores ten compelling benefits of heat exchanger systems, providing insights designed to empower engineers in making informed decisions regarding their designs and operations.

Gagner-Toomey Associates: Innovative Cooling Solutions for Heat Exchanger Systems

Gagner-Toomey Associates stands at the forefront of providing cutting-edge cooling solutions tailored for thermal transfer units. By leveraging a diverse portfolio of manufacturers, the company guarantees that engineers have access to advanced technologies that significantly enhance thermal management in electronic applications. This commitment to excellence is reflected not only in their exceptional customer service but also in the superior quality of the products they represent. As a trusted partner for engineers in the electronics industry, Gagner-Toomey Associates exemplifies reliability and expertise.

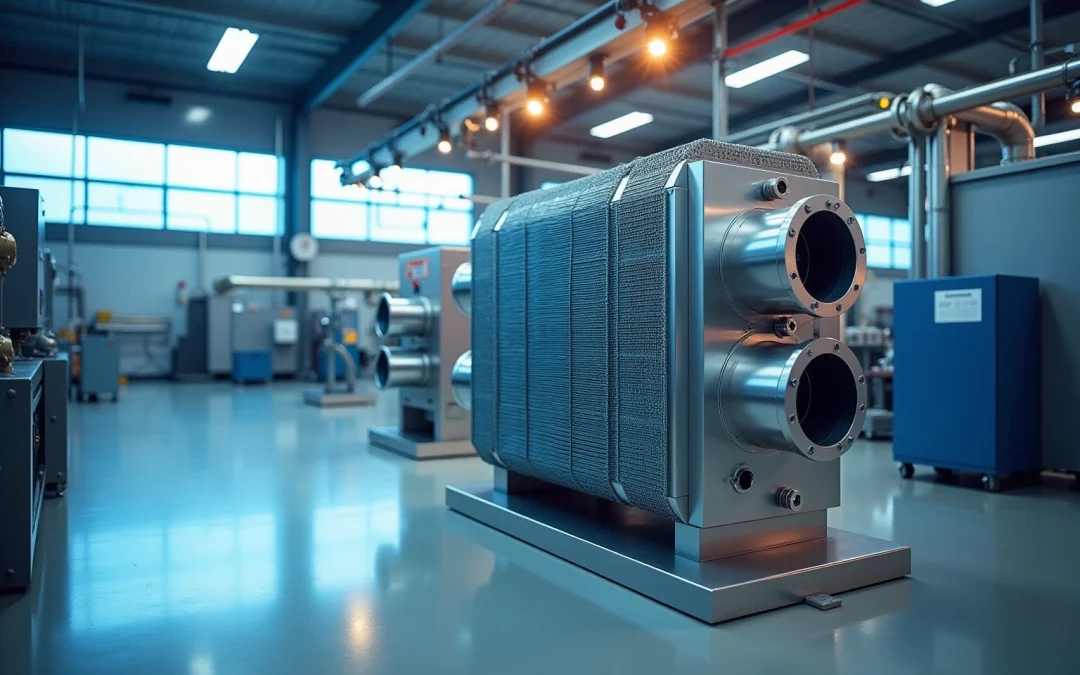

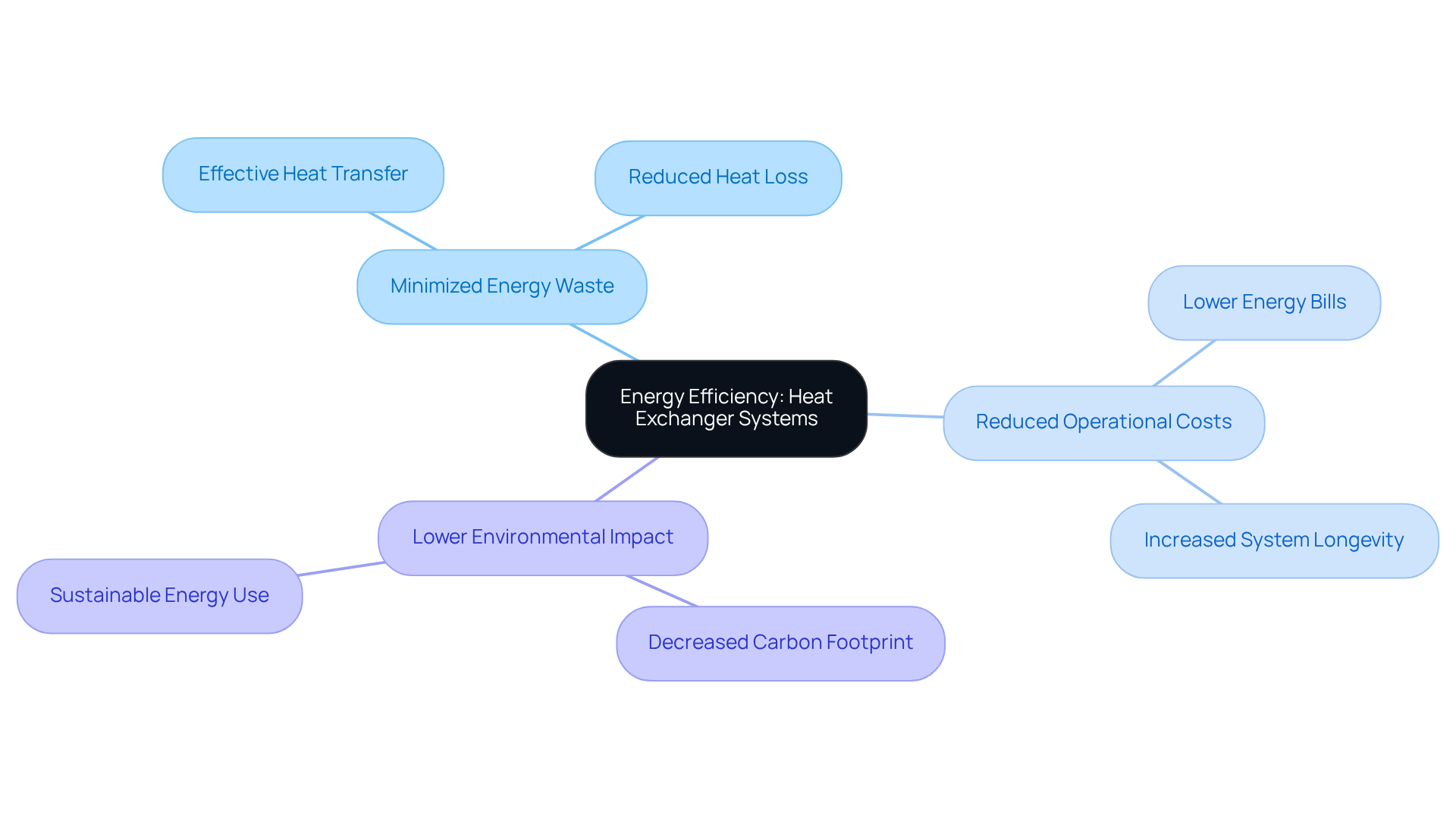

Energy Efficiency: Maximizing Performance with Heat Exchanger Systems

A heat exchanger system is designed to significantly enhance energy efficiency by effectively transferring heat between liquids. This process not only minimizes energy waste but also leads to reduced operational costs and a lower environmental impact. By optimizing the thermal transfer procedure in the heat exchanger system, engineers can ensure that it operates at peak performance, which is crucial in applications where energy consumption is a primary concern.

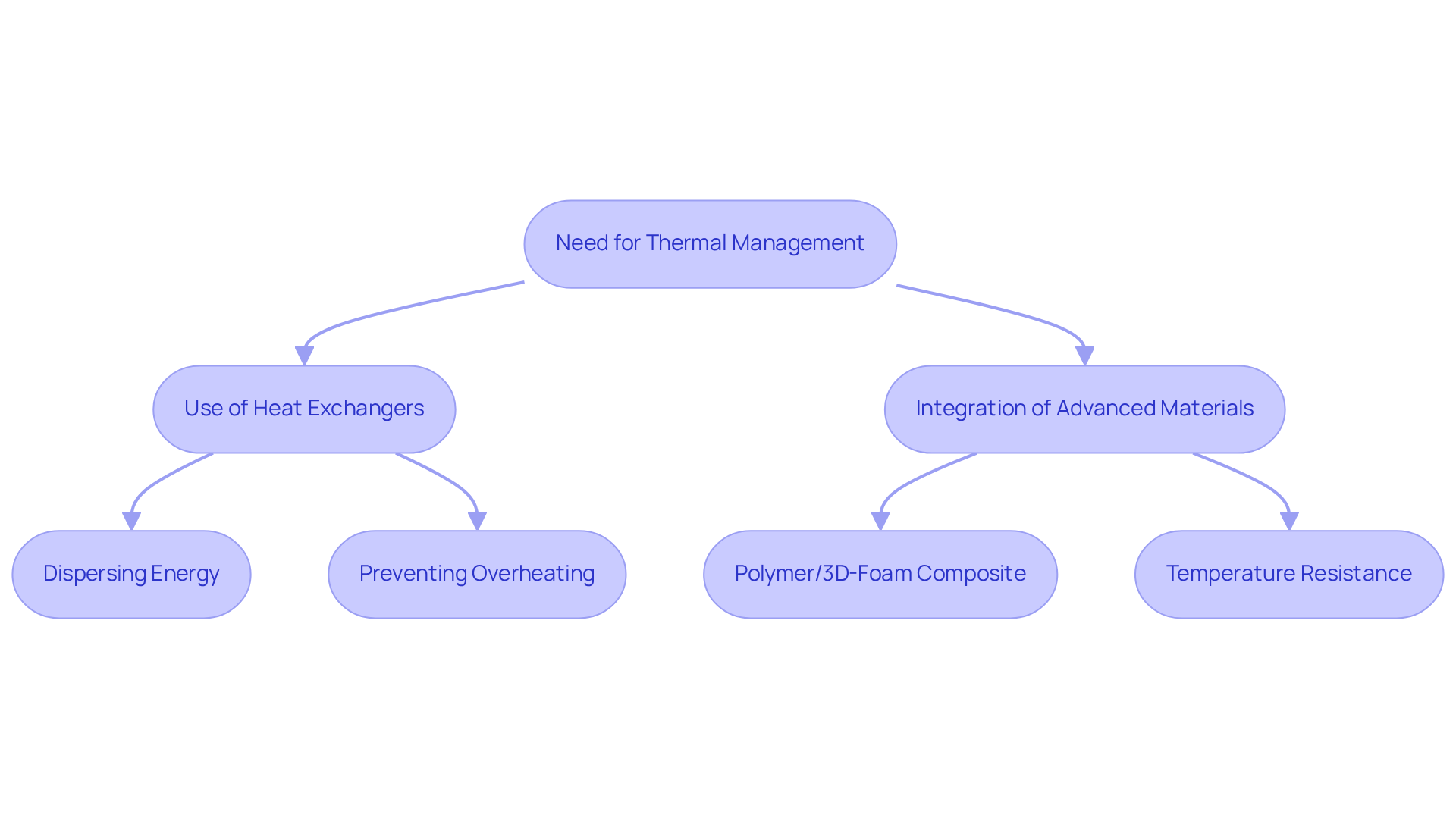

Enhanced Thermal Management: Protecting Electronics with Heat Exchangers

Thermal devices are crucial in temperature control, effectively dispersing energy generated by electronic components. This function is vital for preventing overheating, which can lead to significant degradation of components and potential system failures. Research reveals that overheating can diminish the average lifespan of electronic components by as much as 50%, as highlighted in a study published in June 2017. This underscores the necessity of maintaining optimal operating temperatures. By employing thermal transfer devices, engineers can ensure that sensitive electronics remain within safe temperature limits, thereby enhancing reliability and extending operational lifetimes.

For instance, a newly developed polymer/3D-foam composite has been engineered to maintain heat conductivity between 62-86 W m⁻¹ K⁻¹ while withstanding temperatures up to 330 °C. This innovation exemplifies how advanced materials in thermal devices can mitigate overheating in demanding environments, such as automotive and avionics applications.

Electronics engineers have expressed strong support for the integration of a heat exchanger system in design frameworks, emphasizing that effective temperature management is essential for the durability and functionality of electronic systems. Manuela Loeblein notes that heat management in electronics operating in harsh environments has emerged as a critical issue, highlighting the challenges faced in these applications. Engineers assert that proper temperature control not only diminishes risks associated with overheating but also enhances the overall efficiency of electronic assemblies. By utilizing temperature transfer devices, engineers can significantly reduce the risk of material degradation due to thermal stress, ensuring that electronic components operate reliably under challenging conditions.

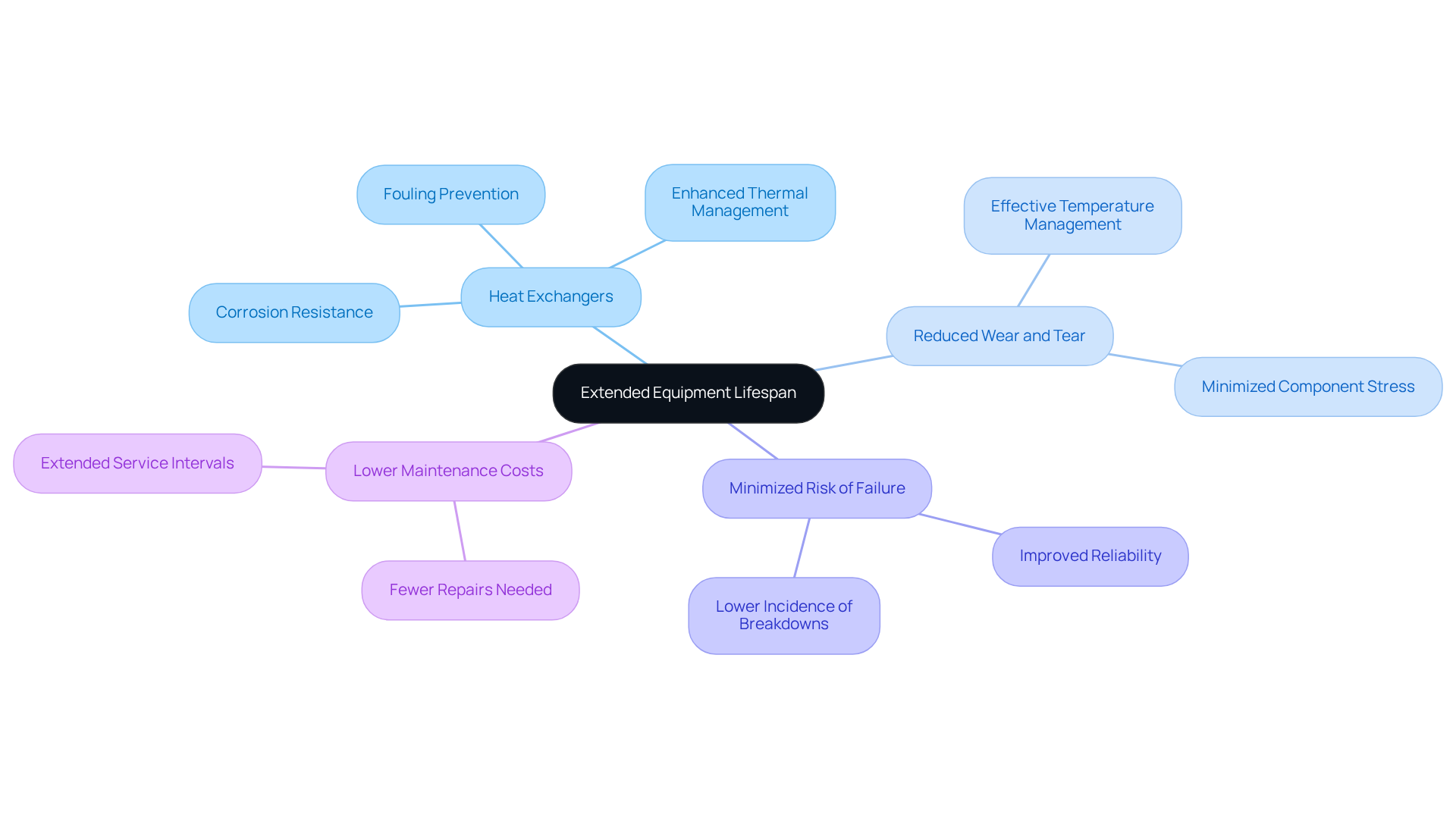

Extended Equipment Lifespan: How Heat Exchangers Contribute to Durability

By effectively managing temperature, thermal devices significantly extend the lifespan of electronic equipment. This crucial aspect of thermal management diminishes wear and tear on components, thereby minimizing the risk of failure and the necessity for expensive replacements. Such durability is especially vital in sectors where equipment reliability is essential, facilitating uninterrupted operations and lowering maintenance costs.

Cost Savings: Reducing Operational Expenses with Heat Exchanger Systems

Installing a heat exchanger system presents a significant opportunity for cost reductions by achieving substantial decreases in energy usage and operational expenses. By optimizing the heat exchanger system for thermal transfer, companies can achieve energy cost reductions of up to 30%, while concurrently minimizing the frequency of maintenance interventions.

A recent implementation of a waste energy recovery system in a refinery exemplifies this, yielding annual savings of $216,770, thereby highlighting the financial benefits associated with efficient thermal transfer solutions. This aligns with the broader context of thermal recovery in refineries, where the heat exchanger system plays a critical role in enhancing energy efficiency. Such savings can be strategically reinvested into other vital operational areas, thereby bolstering overall business efficiency and sustainability.

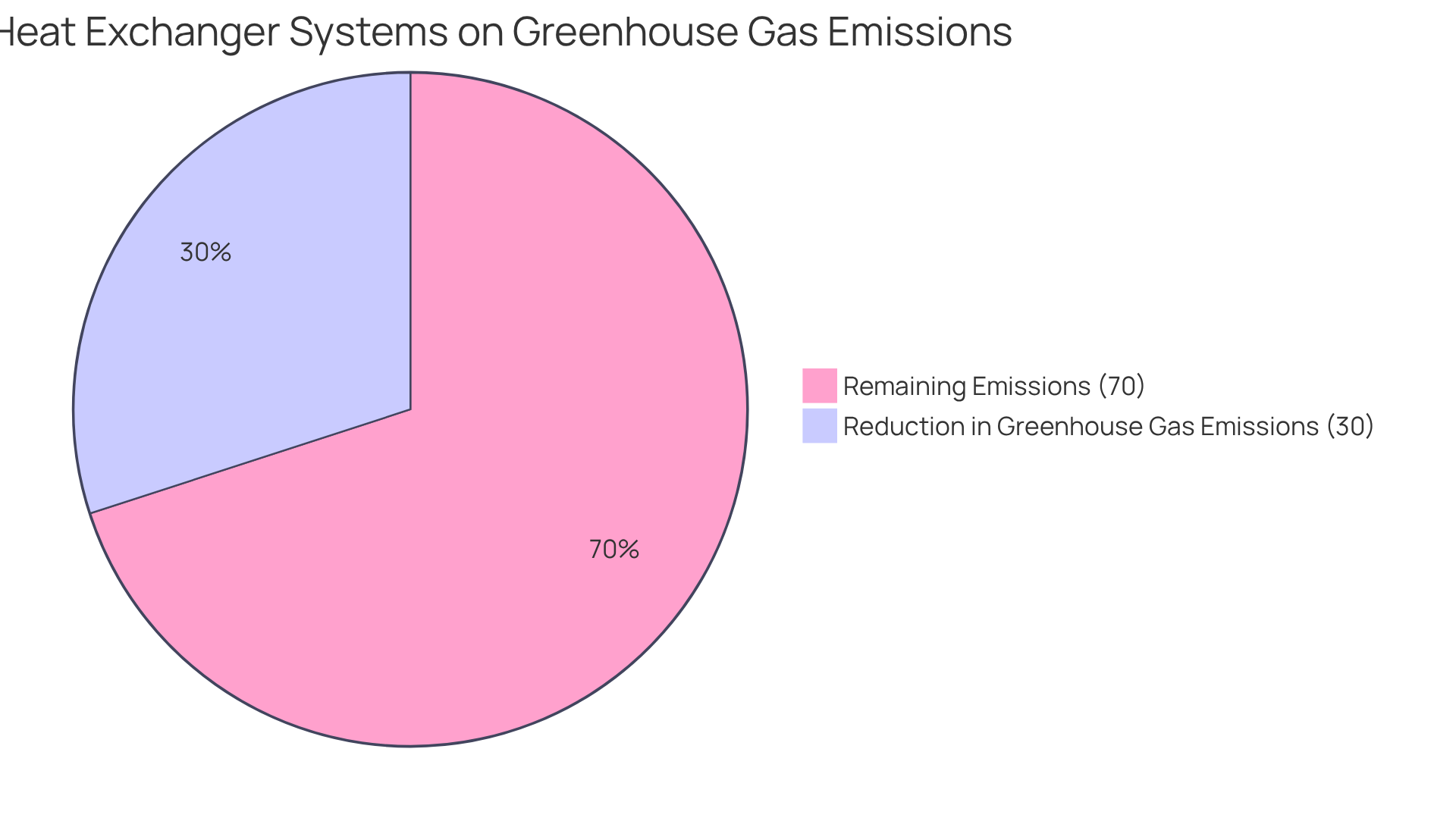

Furthermore, thermal transfer devices are crucial in mitigating energy loss; research indicates that improvements in their efficiency can lead to a reduction in greenhouse gas emissions, in line with contemporary environmental regulations. For instance, refining thermal system design and dimensions is essential for maximizing performance and energy efficiency, which also contributes to lowering operational costs.

Therefore, the integration of a heat exchanger system not only facilitates a reduction in operational expenses but also fosters a more sustainable and financially viable business model.

Improved Air Quality: The Environmental Benefits of Heat Exchanger Systems

The heat exchanger system is essential in enhancing air quality by effectively managing thermal processes and significantly reducing emissions associated with energy consumption. Research indicates that the adoption of an effective heat exchanger system can lead to a reduction of up to 30% in greenhouse gas emissions, reflecting the industry’s increasing focus on sustainability.

By reusing energy and minimizing waste, the heat exchanger system not only mitigates the environmental impact of electronic operations but also enhances indoor air quality. This is accomplished through a heat exchanger system that provides precise temperature control, which prevents overheating and maintains optimal conditions for equipment, thereby lowering the release of harmful pollutants.

Furthermore, incorporating a heat exchanger system into designs fosters environmentally friendly practices by enhancing energy efficiency and promoting operational sustainability. Thus, heat exchanger systems are more than just devices for temperature regulation; they play a crucial role in promoting a cleaner, healthier environment in engineering applications.

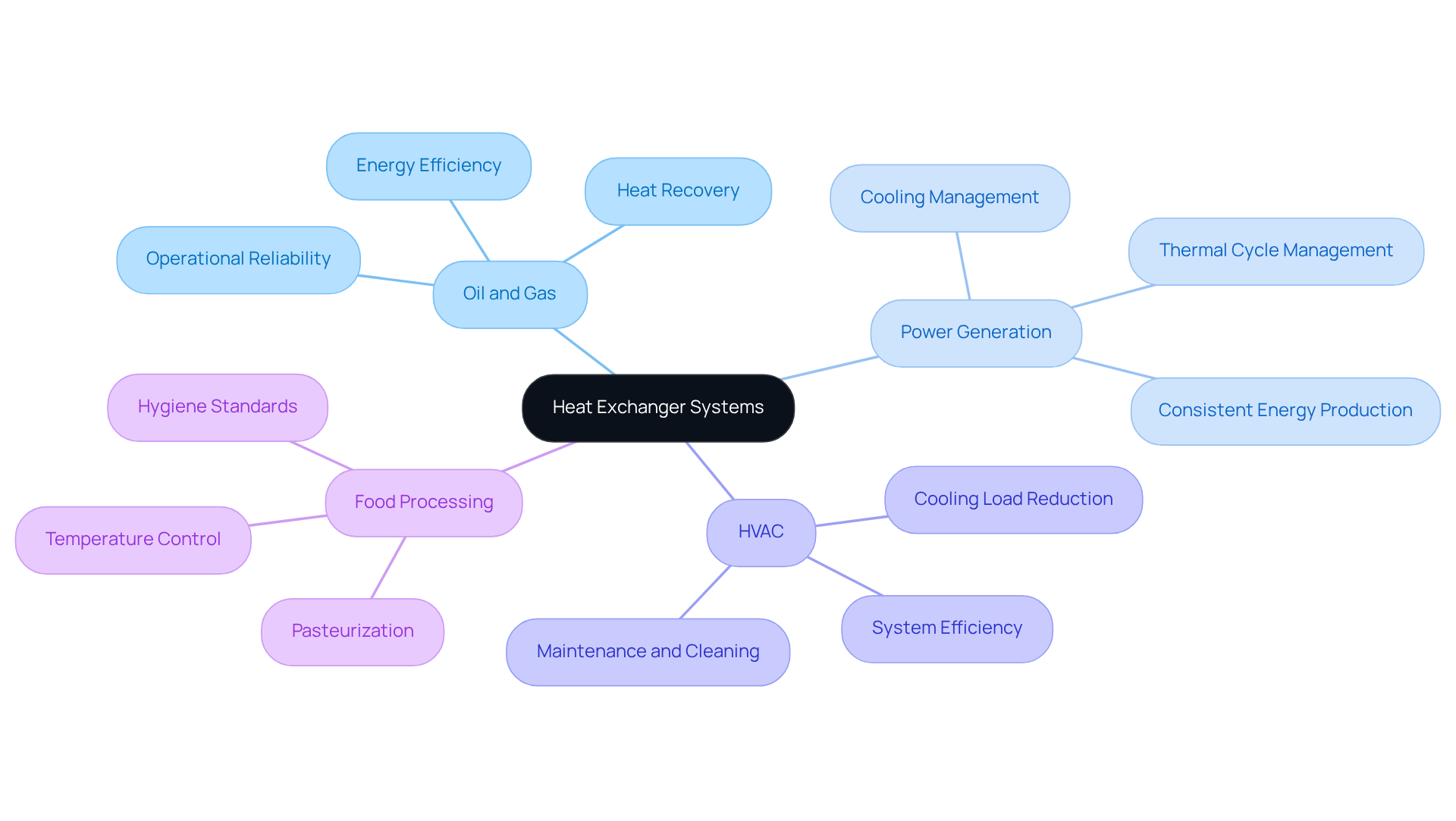

Versatility: Adapting Heat Exchanger Systems for Diverse Engineering Applications

The heat exchanger system demonstrates remarkable adaptability, making it essential across numerous engineering applications, from cooling electronic components to optimizing heat management in industrial environments. Their design facilitates the efficient handling of diverse fluids and temperature ranges, which is crucial for effective temperature regulation in the heat exchanger system. For instance, in the oil and gas industry, thermal devices enhance process recovery, significantly boosting energy efficiency and reducing operational costs. In power generation, these devices are vital for cooling turbine condensers and managing thermal cycles, ensuring consistent energy production.

Data show that thermal devices contribute to lowering greenhouse gas emissions by improving energy utilization, underscoring their significance in sustainable engineering practices. In HVAC systems, the heat exchanger system utilizes gasket plate thermal devices to connect chillers and boilers, effectively minimizing the cooling load and enhancing overall system efficiency. Notably, these gasket plate thermal devices can be disassembled for cleaning and maintenance, increasing their versatility and reducing long-term operational costs.

Moreover, their adaptability is highlighted in applications such as food processing, where a heat exchanger system with sanitary designs is paramount for upholding hygiene standards during pasteurization. The ability to adjust heating and cooling capacities by adding or removing internal plates allows engineers to tailor thermal devices to specific project needs, thereby enhancing their performance across various industries. This adaptability not only addresses diverse engineering requirements but also bolsters operational reliability and environmental compliance, establishing thermal transfer devices as a pivotal component in modern engineering solutions.

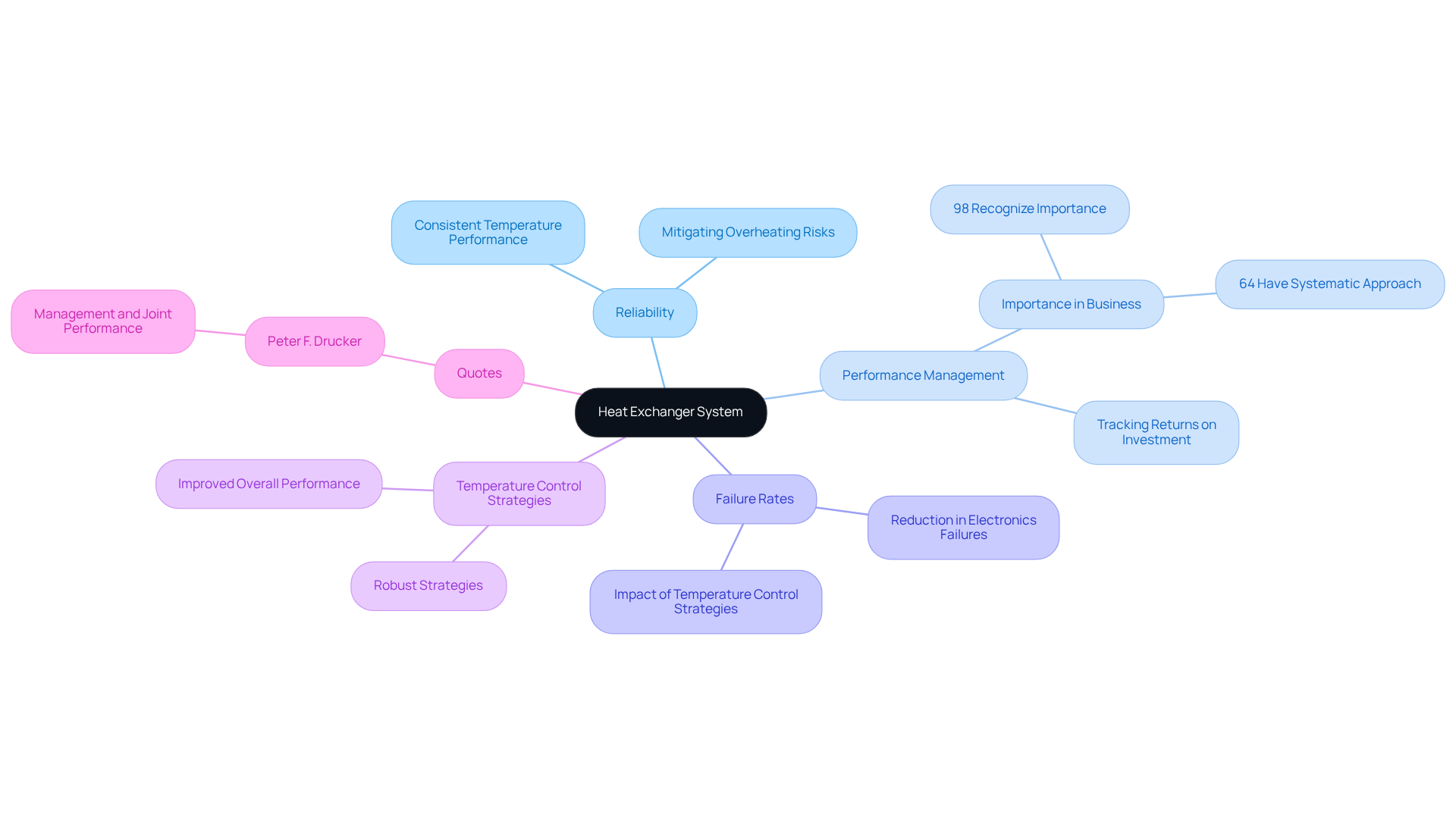

Increased System Reliability: Ensuring Consistent Performance with Heat Exchangers

The heat exchanger system is pivotal in enhancing reliability by guaranteeing consistent temperature performance across diverse operating conditions. By adeptly managing heat, the heat exchanger system mitigates the risk of overheating and subsequent failures, thereby facilitating uninterrupted operations. This reliability is particularly vital in critical applications, where consistent performance is not merely advantageous but essential for success.

Research indicates that 98% of companies recognize the importance of performance management, with an efficient heat exchanger system significantly reducing failure rates in electronics, underscoring the importance of these systems in maintaining operational integrity. For instance, companies implementing robust temperature control strategies report a notable decline in equipment failures, leading to improved overall performance and reduced downtime.

As Peter F. Drucker aptly stated, ‘The fundamental task of management remains the same: to make people capable of joint performance through common goals,’ which reinforces the importance of consistent temperature performance in electronics. Consequently, the heat exchanger system emerges as a vital component in the design and operation of electronic systems.

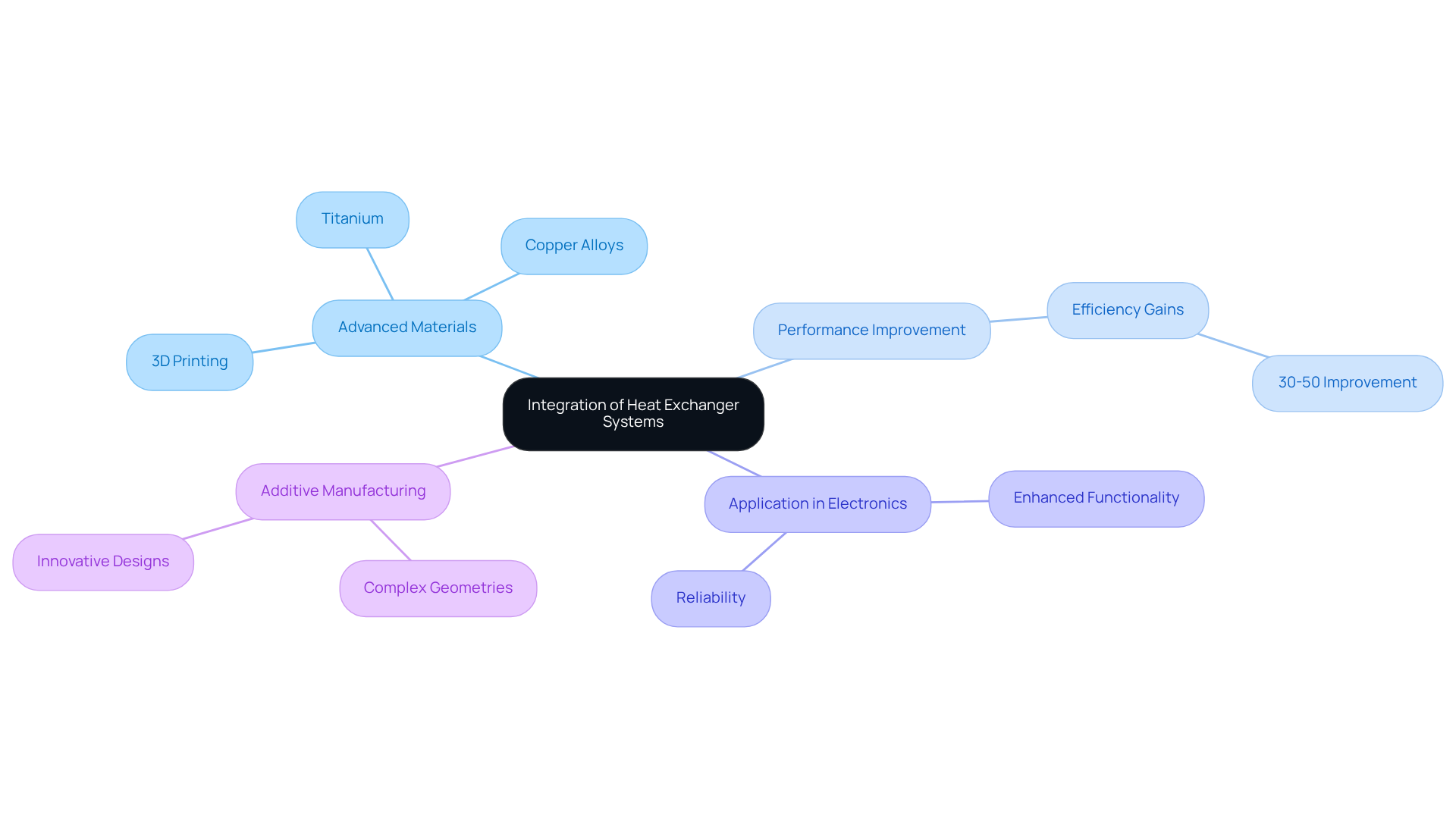

Integration: Incorporating Heat Exchanger Systems into Modern Electronics

Incorporating thermal transfer devices into modern electronics is essential for effective temperature control. These systems can be seamlessly integrated into various designs, significantly boosting the performance of electronic devices. Advanced materials, such as titanium and copper alloys used in 3D printed thermal devices, allow for intricate shapes that enhance temperature transfer efficiency by 30% to 50% compared to conventional designs. This innovation addresses the stagnation in thermal device design that has persisted for decades, as noted by Bill King, a leading authority in the field.

By leveraging these sophisticated materials and technologies, engineers can ensure that thermal devices not only improve the functionality of contemporary electronics but also contribute to enhanced efficiency and reliability. The integration of the heat exchanger system is vital for optimizing energy frameworks and meeting the demands of high-power devices in mobile applications.

To effectively incorporate thermal transfer devices into your designs, it is advisable to explore the latest advancements in additive manufacturing and the specific materials that enhance thermal performance.

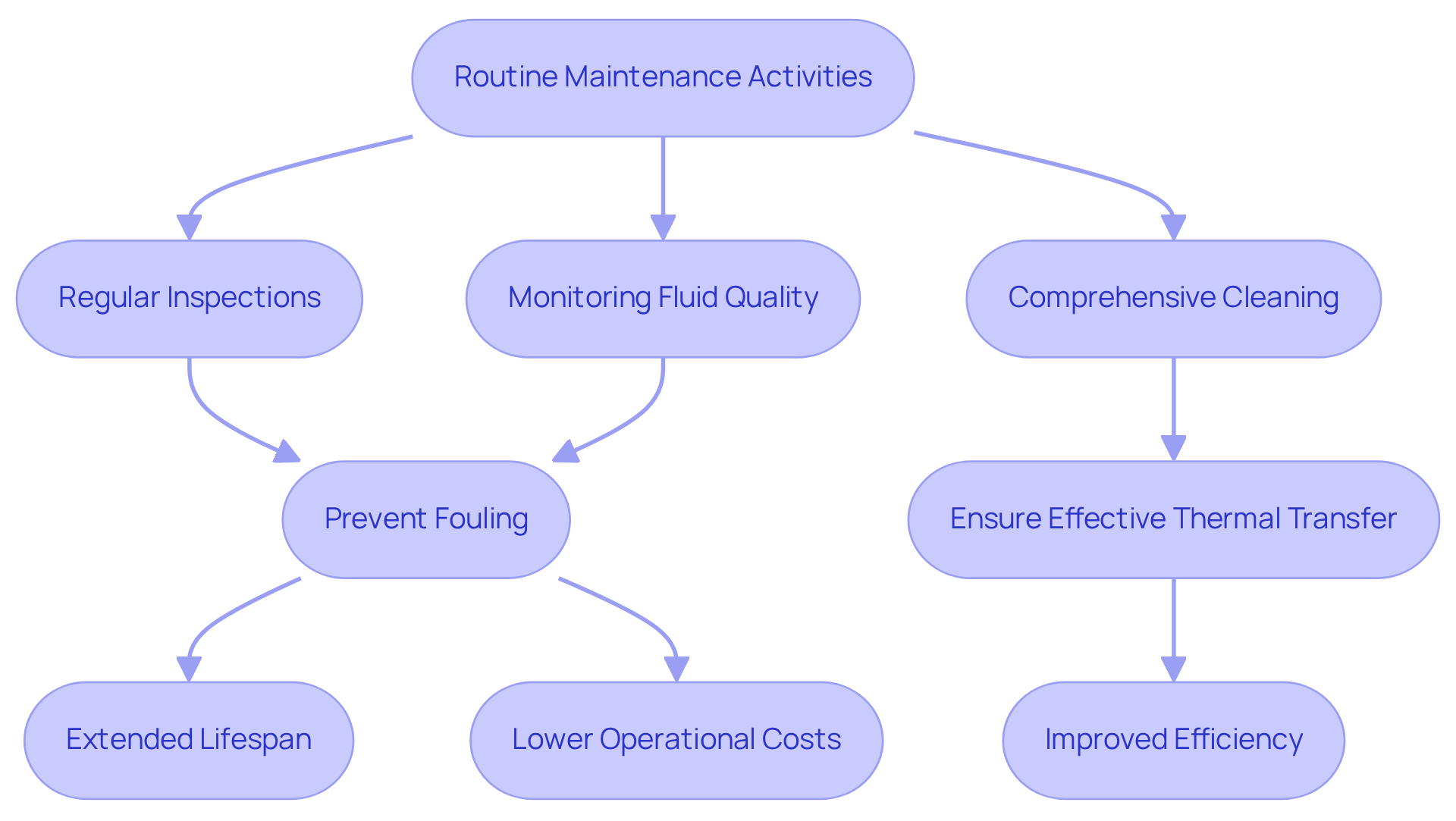

Maintenance Matters: Ensuring Optimal Performance of Heat Exchanger Systems

Routine upkeep is essential for enhancing the efficiency and lifespan of the heat exchanger system. This involves conducting regular inspections, comprehensive cleaning, and meticulous monitoring of fluid quality to prevent fouling and ensure effective thermal transfer. Proactive maintenance programs can significantly extend the lifespan of thermal devices.

A notable case study illustrates this:

- A Type 304L stainless steel unit in a rendering plant improved operational efficiency by effectively condensing gases and heating water.

- By adhering to best practices—such as utilizing molybdenum-based lubricants to reduce friction and enhance efficiency—engineers can achieve superior performance and lower operational costs.

The impact of diligent maintenance on the heat exchanger system performance is profound; it not only safeguards the equipment but also contributes to overall system reliability and efficiency in the electronics industry.

Conclusion

The integration of heat exchanger systems in electronic engineering is not merely a trend; it is a necessity that significantly enhances performance, efficiency, and sustainability. These systems play a pivotal role in managing heat, ensuring that electronic components operate within safe temperature limits—an essential factor for maintaining reliability and extending the lifespan of equipment.

Key benefits highlighted throughout the article include:

- Improved energy efficiency

- Enhanced thermal management

- Substantial cost savings

- Notable environmental advantages

The versatility of heat exchangers allows for their application across various industries, adapting to the specific needs of different applications—from electronics to HVAC systems. Moreover, the importance of routine maintenance cannot be overstated, as it is vital for ensuring optimal performance and longevity of these systems.

Ultimately, the adoption of heat exchanger technology is essential for engineers aiming to enhance their designs and operational efficiency. By prioritizing effective thermal management, engineers can not only improve the reliability and durability of their electronic systems but also contribute to a more sustainable future. Embracing these advanced cooling solutions will pave the way for innovative designs that meet the growing demands of modern technology while minimizing environmental impact.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in providing innovative cooling solutions tailored for thermal transfer units, focusing on advanced technologies that enhance thermal management in electronic applications.

How does Gagner-Toomey Associates support engineers in the electronics industry?

The company supports engineers by offering a diverse portfolio of manufacturers, exceptional customer service, and superior quality products, ensuring they have access to cutting-edge cooling solutions.

What is the primary function of a heat exchanger system?

The primary function of a heat exchanger system is to enhance energy efficiency by effectively transferring heat between liquids, minimizing energy waste, reducing operational costs, and lowering environmental impact.

Why is thermal management important for electronics?

Thermal management is crucial for preventing overheating in electronic components, which can lead to significant degradation and potential system failures. Maintaining optimal operating temperatures is essential for enhancing reliability and extending the lifespan of electronic devices.

What impact can overheating have on electronic components?

Overheating can diminish the average lifespan of electronic components by as much as 50%, highlighting the necessity of effective thermal management to ensure their durability.

What advancements have been made in thermal devices for managing heat?

A newly developed polymer/3D-foam composite has been engineered to maintain heat conductivity between 62-86 W m⁻¹ K⁻¹ while withstanding temperatures up to 330 °C, showcasing innovations that help mitigate overheating in demanding environments.

What do electronics engineers think about integrating heat exchanger systems?

Electronics engineers strongly support the integration of heat exchanger systems in design frameworks, emphasizing that effective temperature management is essential for the durability and functionality of electronic systems, especially in harsh environments.

How do temperature transfer devices benefit electronic assemblies?

Temperature transfer devices help reduce the risk of material degradation due to thermal stress, ensuring that electronic components operate reliably under challenging conditions and enhancing overall efficiency.