Overview

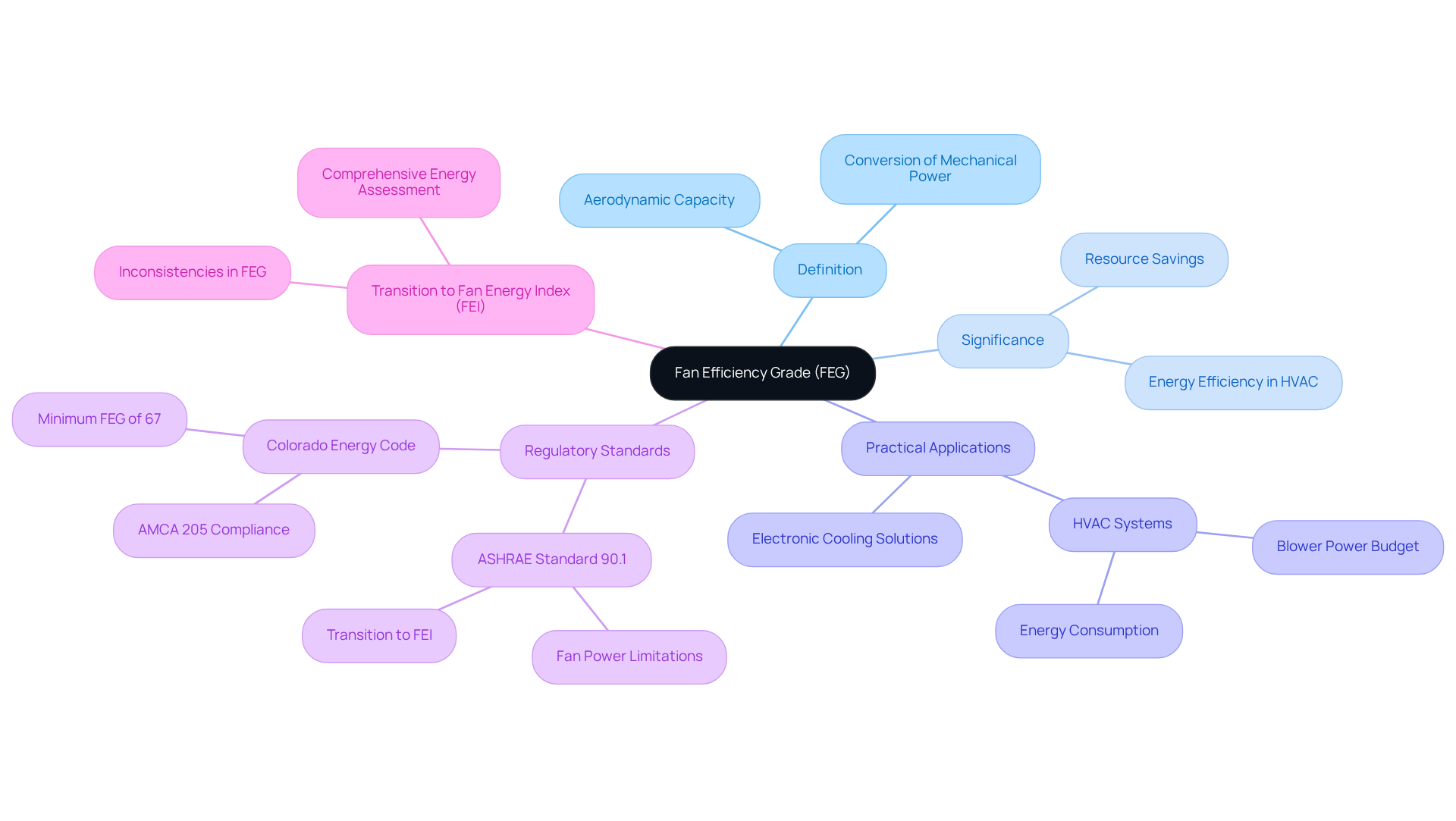

The fan efficiency grade (FEG) plays a pivotal role in assessing the performance of fans in converting mechanical power into airflow, which directly influences energy consumption in applications such as HVAC systems. A higher FEG not only leads to substantial resource savings but also aligns with regulatory standards. Therefore, it is essential for engineers to select fans that optimize performance while promoting sustainability.

Introduction

The efficiency of fans is paramount in determining energy consumption and operational costs, especially within the HVAC and electronics sectors. Recognizing the significance of the Fan Efficiency Grade (FEG) not only assists engineers in selecting optimal cooling solutions but also aligns with sustainability objectives through the maximization of power usage. As standards evolve and energy demands escalate, it becomes imperative for engineers to evaluate how they can make informed decisions in fan selection that satisfy both performance metrics and regulatory requirements.

Define Fan Efficiency Grade (FEG)

The Efficiency Grade (FEG) represents a vital numerical rating that evaluates devices based on their aerodynamic capacity to convert mechanical shaft power into air power. Established by the Air Movement and Control Association (AMCA) in standard AMCA 205, the fan efficiency grade (FEG) acts as a benchmark for assessing a fan’s efficiency at its optimal performance point. This rating is crucial for engineers and designers selecting devices that not only meet operational requirements but also maximize power usage. A higher fan efficiency grade indicates a more efficient fan, potentially resulting in significant resource savings across various applications, particularly within HVAC systems and electronic cooling solutions.

In practice, HVAC systems account for a substantial portion of a commercial building’s power budget, with blowers consuming approximately 1.25 quads annually. The Colorado Commercial Energy Code mandates a minimum fan efficiency grade of 67, highlighting the significance of efficient fans in reducing the overall power expenditures of commercial structures. By adhering to these standards, engineers can ensure that their fan selections contribute to enhanced resource conservation and sustainability. As Joe Hullebusch articulates, “The FEG measures the fan ability to convert its shaft or impeller power into air power.”

Moreover, the peak total performance on the FEG Curve occurs at the apex of the bell-shaped effectiveness curve, which is essential for understanding how FEG is determined. Additionally, the transition from FEG to the Fan Energy Index (FEI) metric in ASHRAE Standard 90.1-2022 reflects the evolving criteria in fan performance and its implications for power usage.

Contextualize the Importance of FEG for Electronics Engineers

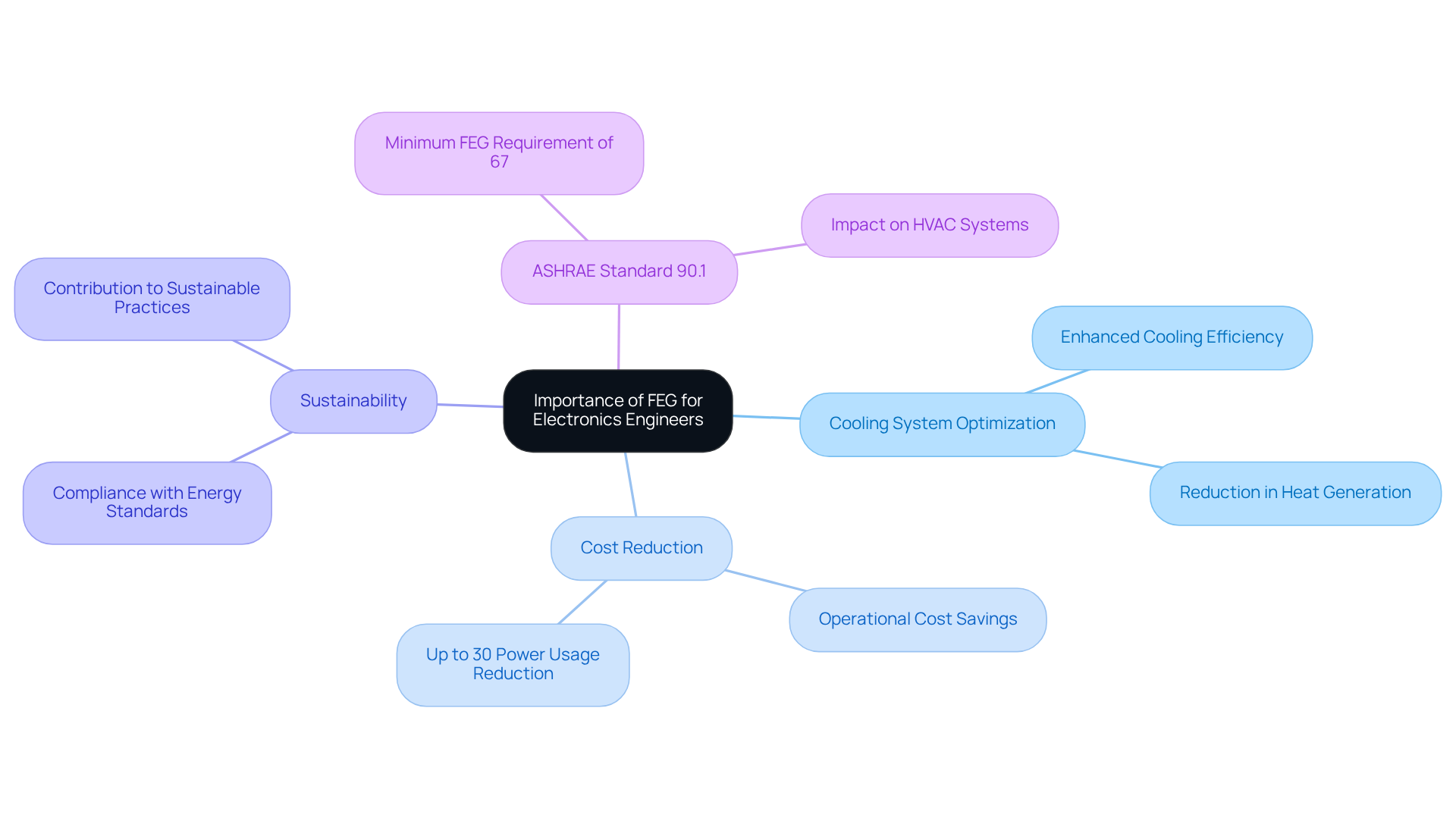

For electronics engineers, understanding the fan efficiency grade is essential for optimizing cooling system performance. Electronic devices generate significant heat; thus, selecting cooling systems with a high fan efficiency grade can substantially reduce power usage and operational costs.

Fans that meet or exceed the ASHRAE Standard 90.1 requirement of a minimum fan efficiency grade of 67 not only enhance cooling efficiency but also contribute to the sustainability of electronic systems. In data centers, where numerous servers operate concurrently, the savings from employing high-FEG fans can be considerable, often leading to consumption reductions of up to 30%.

This highlights the fan efficiency grade (FEG) as a vital component in system design and component selection, enabling engineers to deliver efficient and cost-effective solutions while adhering to contemporary power standards.

Trace the Origins and Development of FEG

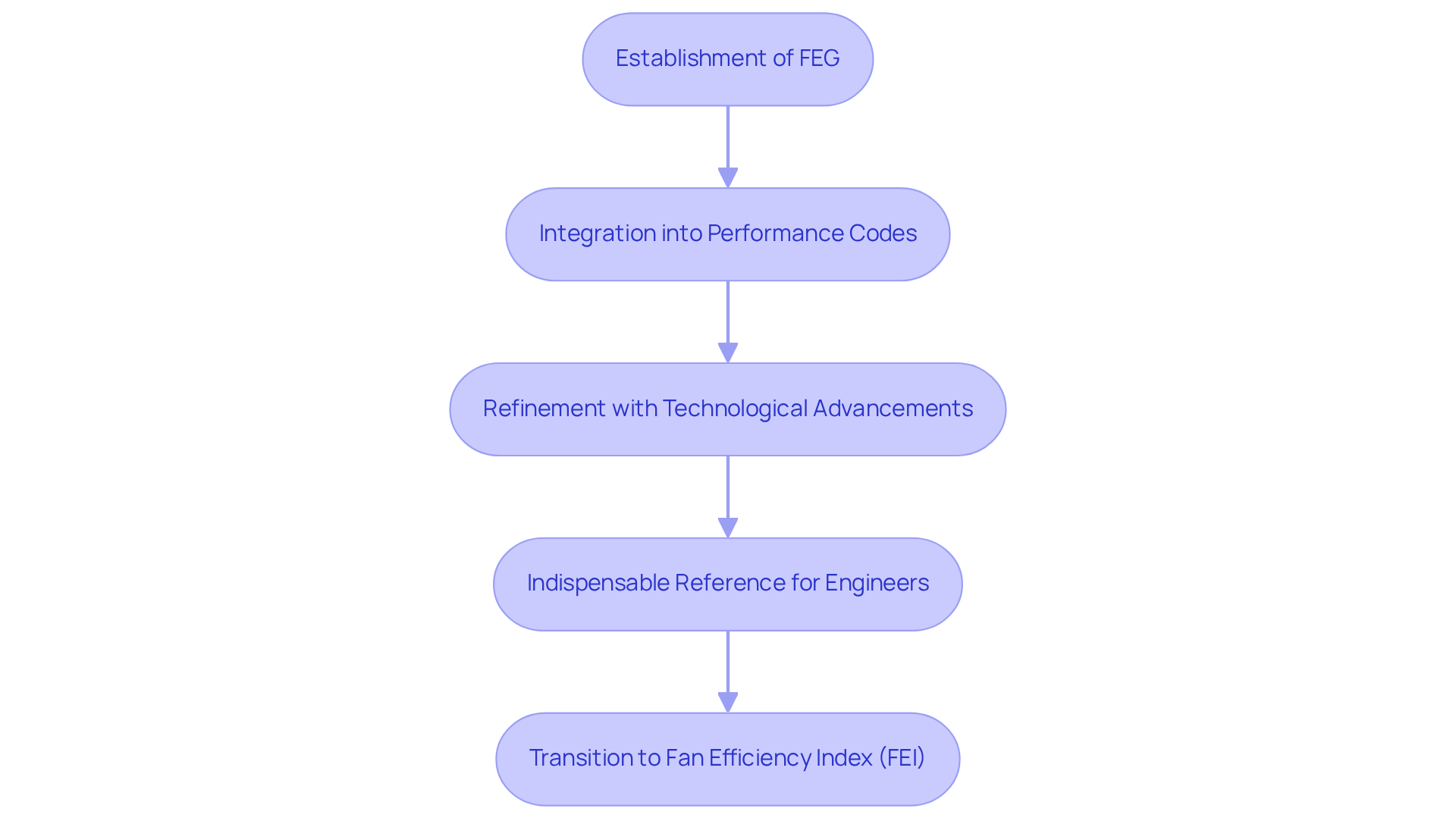

The fan efficiency grade (FEG) was established in response to escalating power consumption and the pressing need for standardized metrics to assess fan performance. The Air Movement and Control Association (AMCA) introduced the fan efficiency grade in the early 2010s as part of its initiative to create a clear and consistent framework for rating fan performance. Over the years, the refinement of the fan efficiency grade (FEG) has aligned with technological advancements and evolving regulatory requirements. Its incorporation into performance codes, such as ASHRAE 90.1, underscores its pivotal role in fostering efficient practices within the HVAC and electronics sectors.

As power efficiency standards continue to evolve, the fan efficiency grade (FEG) remains an indispensable reference for engineers and manufacturers, guiding the selection and design of efficient fan systems. Case studies illustrate the successful application of FEG across various sectors, demonstrating its effectiveness in enhancing conservation efforts. The transition from FEG to the Fan Efficiency Index (FEI) further exemplifies the ongoing commitment to optimizing resource savings and streamlining compliance for industry professionals.

Outline Key Characteristics of FEG

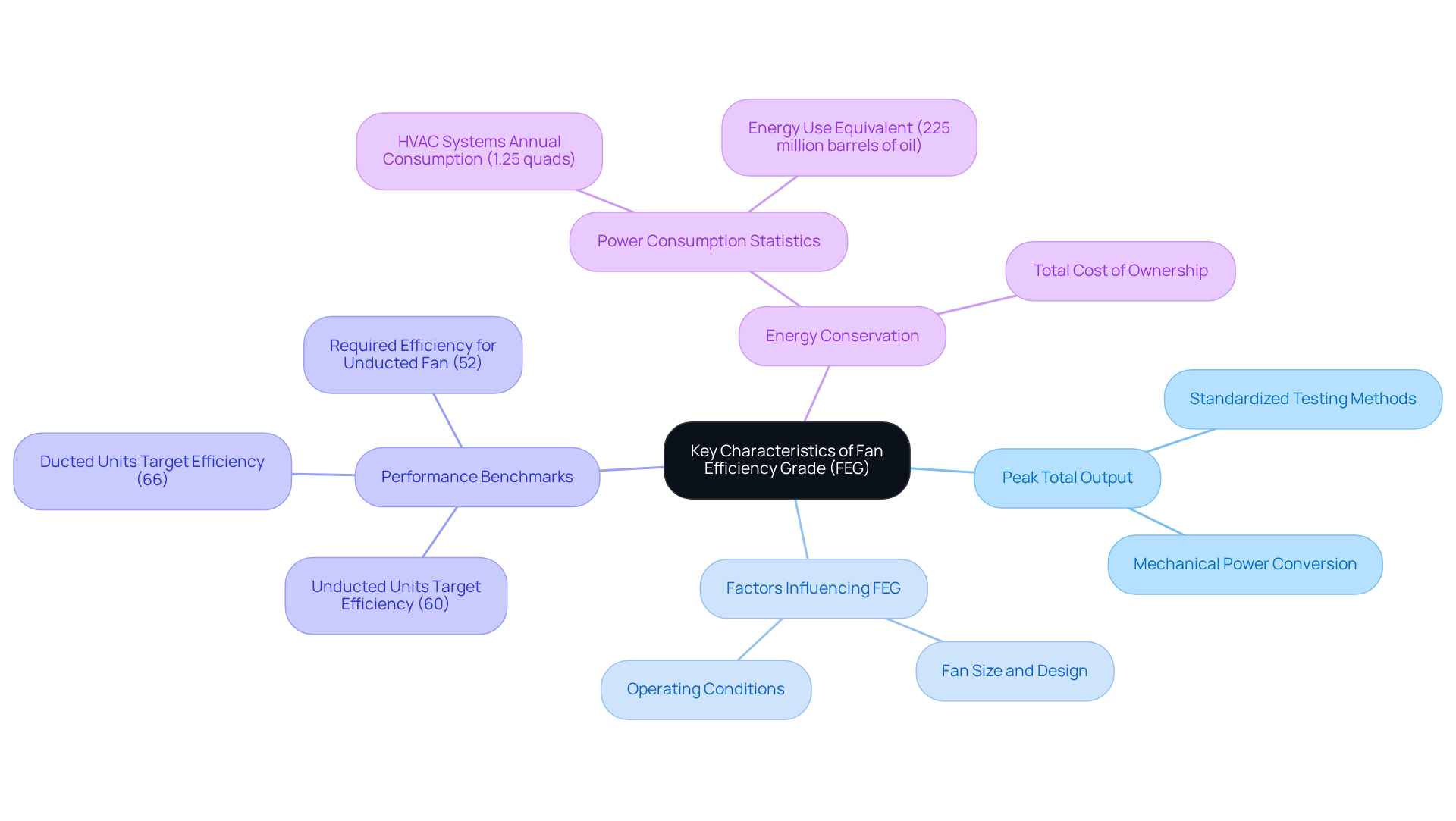

The key traits of fan efficiency grade are fundamentally tied to its dependence on peak total output, which is rigorously assessed through standardized testing methods. The fan’s ability to convert mechanical power into airflow against static pressure determines its fan efficiency grade (FEG) ratings. Notably, factors such as fan size, design, and operating conditions play a critical role in influencing the fan efficiency grade.

For instance, while a fan may exhibit high peak performance, this does not necessarily guarantee reduced energy consumption unless it is appropriately aligned with its operational context. Statistics indicate that the required performance for an unducted fan at 10,000 cfm and 3.0-in. H2O static pressure is 52 percent, with target performance benchmarks set at 60 percent for unducted units and 66 percent for ducted units. This underscores the importance of selecting ventilators based on their specific applications to ensure optimal performance and energy conservation.

Practical assessments reveal that devices classified with a fan efficiency grade of FEG71, achieving a maximum overall performance of 69%, can significantly impact power consumption, particularly given that HVAC systems in the United States consume approximately 1.25 quads of power annually. Furthermore, fans that are part of equipment packages certified by third parties for air or energy performance are exempt from minimum fan efficiency grade and selection-window restrictions, which is a critical consideration for engineers.

Grasping these characteristics, along with the total cost of ownership, is essential for engineers striving to make informed fan selections that improve the fan efficiency grade and enhance overall system efficiency.

Conclusion

Understanding the Fan Efficiency Grade (FEG) is pivotal for optimizing system performance, particularly in HVAC and electronic cooling applications. The FEG acts as a benchmark for assessing how effectively a fan converts mechanical power into air power, significantly influencing energy consumption and operational costs. By selecting fans with a high FEG, engineers can ensure their designs not only meet performance requirements but also advance sustainability and resource conservation.

The article discussed several key insights, including the necessity of adhering to standards such as the ASHRAE Standard 90.1, which mandates a minimum FEG of 67. This standard holds particular significance for electronics engineers, as high-efficiency fans can yield substantial energy savings—often up to 30% in data centers. The evolution of the FEG, from its inception by the Air Movement and Control Association (AMCA) to its integration into performance codes, underscores the increasing emphasis on energy efficiency within engineering practices.

Given the rising demand for energy-efficient solutions, it is essential for engineers and designers to prioritize fan selection based on efficiency grades. The FEG not only enhances the performance of cooling systems but also plays a crucial role in minimizing overall energy consumption. As technology continues to advance, remaining informed about fan efficiency standards will be vital for fostering innovation and sustainability in engineering design. Embracing high FEG fans transcends technical necessity; it represents a commitment to a more energy-efficient future.

Frequently Asked Questions

What is the Fan Efficiency Grade (FEG)?

The Fan Efficiency Grade (FEG) is a numerical rating that evaluates devices based on their ability to convert mechanical shaft power into air power, as established by the Air Movement and Control Association (AMCA) in standard AMCA 205.

Why is the FEG important?

The FEG serves as a benchmark for assessing a fan’s efficiency at its optimal performance point, helping engineers and designers select devices that meet operational requirements while maximizing power usage.

What does a higher FEG indicate?

A higher Fan Efficiency Grade indicates a more efficient fan, which can lead to significant resource savings, especially in applications like HVAC systems and electronic cooling solutions.

How do HVAC systems relate to fan efficiency?

HVAC systems consume a substantial portion of a commercial building’s power budget, with blowers alone using approximately 1.25 quads annually. Efficient fans can help reduce overall power expenditures in these systems.

What is the minimum FEG mandated by the Colorado Commercial Energy Code?

The Colorado Commercial Energy Code mandates a minimum Fan Efficiency Grade of 67, highlighting the importance of efficient fans in reducing power costs in commercial buildings.

How is the FEG curve related to fan performance?

The peak total performance on the FEG curve occurs at the apex of the bell-shaped effectiveness curve, which is essential for understanding how the FEG is determined.

What is the relationship between FEG and the Fan Energy Index (FEI)?

The transition from FEG to the Fan Energy Index (FEI) in ASHRAE Standard 90.1-2022 reflects evolving criteria in fan performance and its implications for power usage.