Overview

This article presents an overview of eight essential benefits of high-pressure centrifugal fans for engineers, highlighting their efficiency, durability, and versatility across various industrial applications. The discussion begins by identifying the challenges faced in these sectors, followed by a detailed examination of how these fans address those challenges. Each benefit is substantiated by compelling evidence, including:

- Significant energy savings derived from advanced designs

- Lower maintenance costs

- Enhanced safety features

This evidence clearly illustrates the contribution of high-pressure centrifugal fans to improved operational performance and cost-effectiveness in diverse settings, prompting engineers to consider their implementation in future projects.

Introduction

High pressure centrifugal fans are emerging as indispensable tools in modern engineering, owing to their remarkable ability to enhance performance across a multitude of industrial applications. With the global market projected to expand significantly, these fans present engineers with a wealth of benefits, including:

- Energy efficiency

- Cost savings

- Durability

- Versatility

However, as industries strive for optimization, a crucial question arises: how can engineers leverage the latest advancements in fan technology to not only meet operational demands but also ensure safety and sustainability in their projects?

Gagner-Toomey Associates: Expert Solutions for High Pressure Centrifugal Fans

Gagner-Toomey Associates stands out in delivering inventive solutions for powerful fans, emphasizing cooling, power management, and interconnect technologies. Their expert team is dedicated to providing engineers with customized solutions that address the unique challenges of the electronics sector, significantly enhancing performance across various applications.

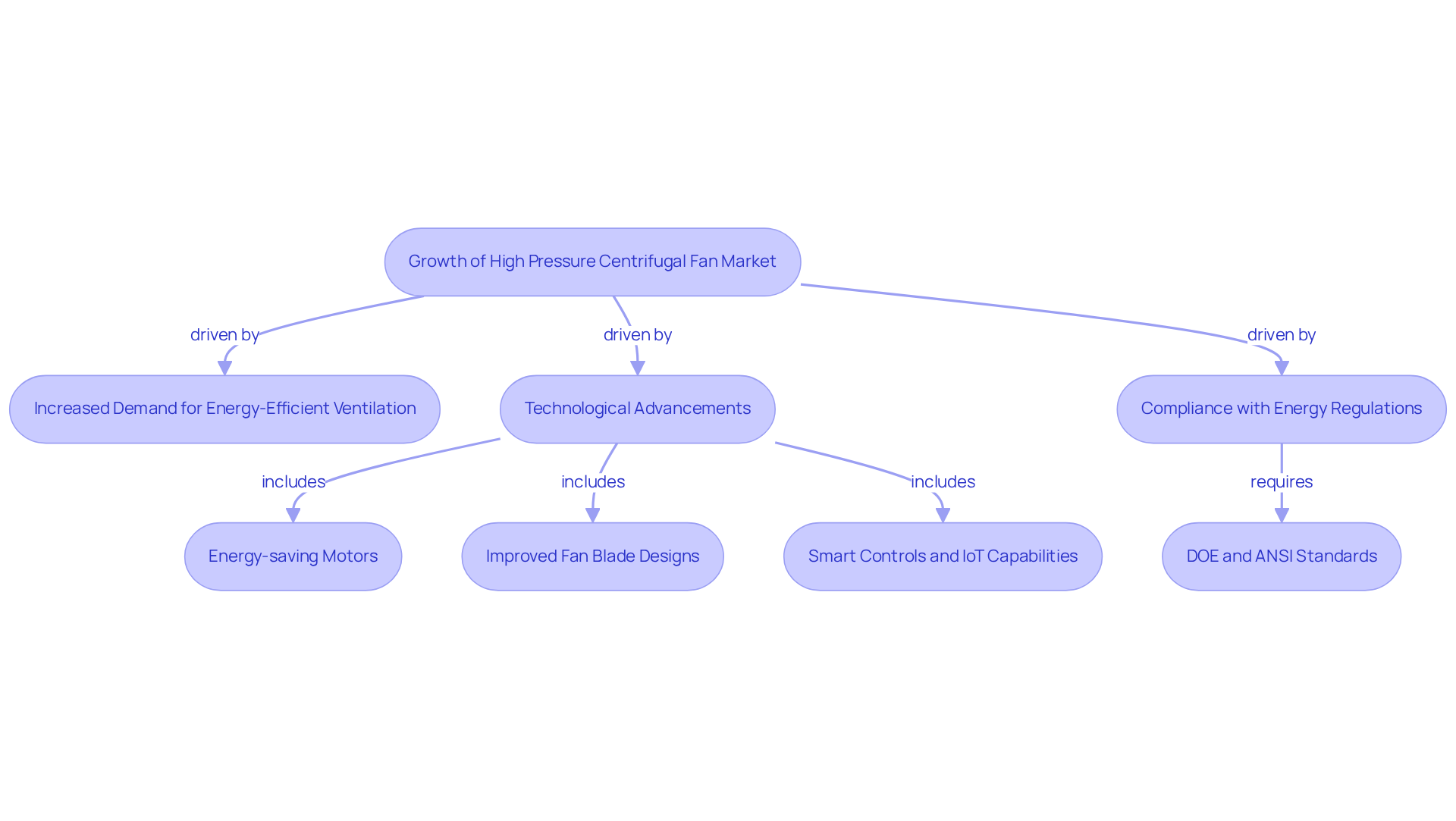

Notably, recent statistics reveal that the global market for high pressure centrifugal fans is expected to grow from USD 1.5 billion in 2023 to USD 2.5 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.5%. This expansion is fueled by the rising demand for energy-efficient ventilation solutions, particularly within industrial sectors.

Furthermore, advancements in fan technology, including energy-saving motors and improved fan blade designs, are elevating the operational performance of these systems. Industry leaders underscore the importance of complying with evolving energy conservation regulations, such as those set forth by the DOE and ANSI, which further emphasizes the significance of Gagner-Toomey’s tailored solutions in meeting these standards.

As the market continues to evolve, Gagner-Toomey Associates remains at the forefront, ensuring that engineers have access to the latest technological advancements, strategic partnerships, and insights related to high pressure centrifugal fan technology.

Energy Efficiency: Reduce Operational Costs with High Pressure Centrifugal Fans

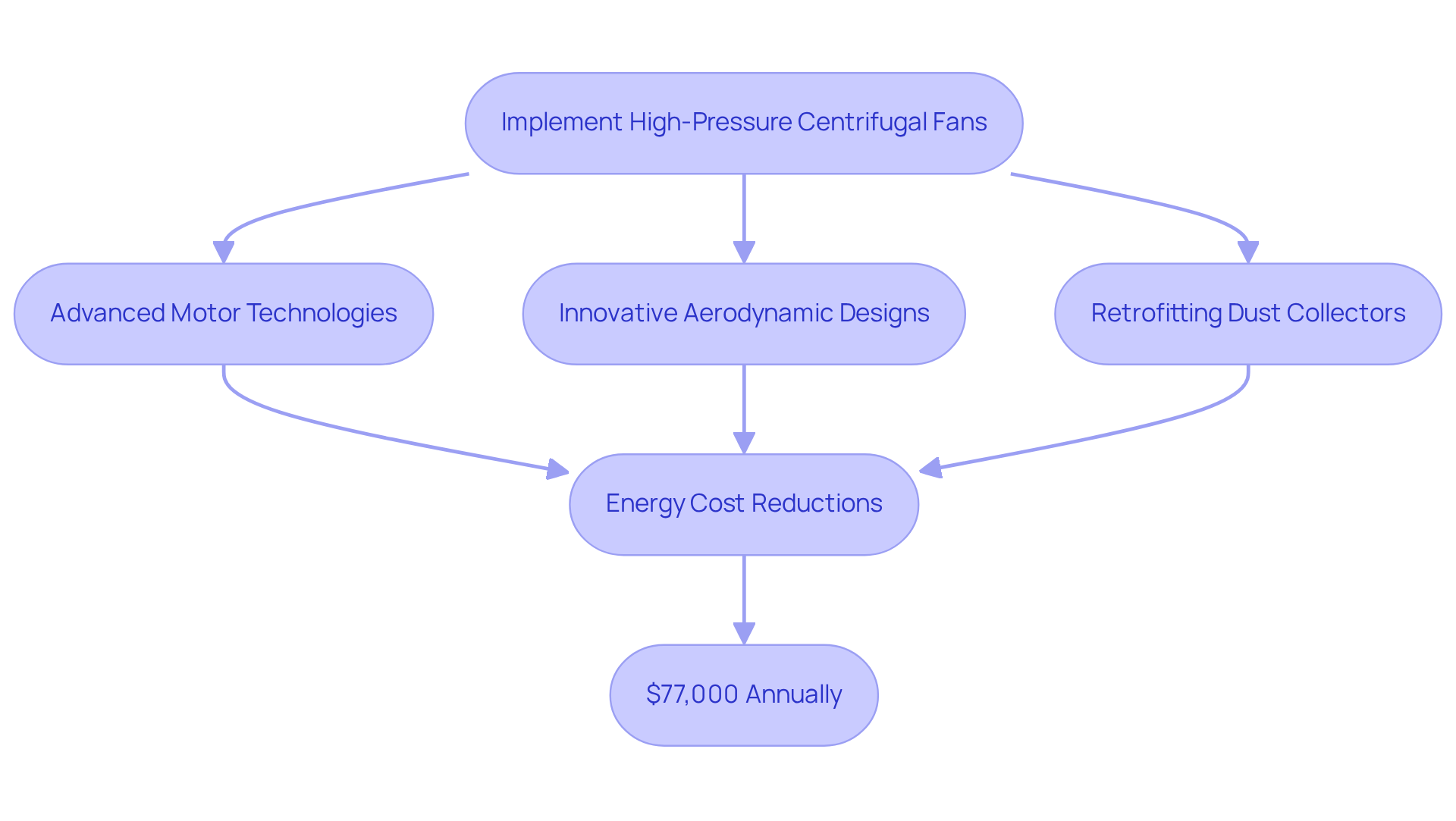

High-pressure rotating blowers are engineered for optimal performance, often consuming less energy than conventional models. By leveraging advanced motor technologies alongside innovative aerodynamic designs, these devices can lead to substantial energy cost reductions, thereby decreasing operational expenses over time.

In large-scale industrial settings, where energy consumption plays a pivotal role, the advantages become even more pronounced. For instance, a facility that retrofitted its dust collectors with hydroentangled filter media reported potential annual savings exceeding $77,000, underscoring the significant financial implications of such enhancements. This facility operates continuously—24 hours a day, 7 days a week, for 51 weeks each year—highlighting the operational significance of these savings.

Furthermore, while a 20% increase in fan speed can yield a 40% rise in static pressure, it necessitates a careful equilibrium; a 20% increase in airflow demands a 73% increase in power requirements to avert excessive energy costs. Ultimately, the adoption of high pressure centrifugal fans not only enhances energy efficiency but also leads to long-term cost reductions.

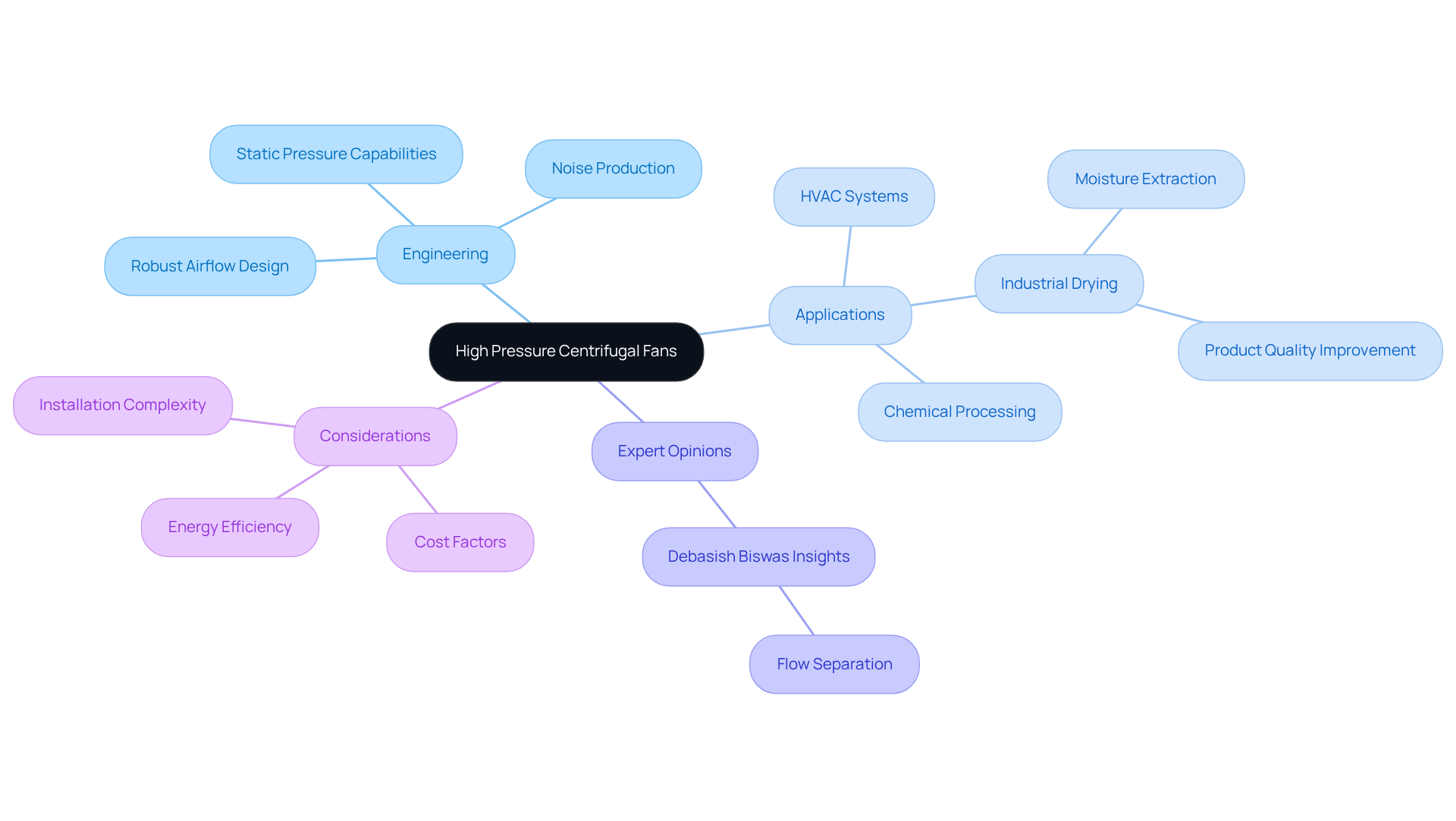

Enhanced Airflow: Improve Process Efficiency with High Pressure Centrifugal Fans

High pressure centrifugal fans are meticulously engineered to deliver robust airflow, which is essential for processes requiring consistent air movement. Their capacity to overcome elevated static pressures with a high pressure centrifugal fan ensures effective air circulation throughout systems, significantly enhancing cooling and ventilation. This capability is particularly crucial in applications such as HVAC systems, industrial drying, and chemical processing, where a high pressure centrifugal fan is vital for maintaining optimal airflow and operational efficiency.

For instance, in industrial drying procedures, these devices facilitate swift moisture extraction, thereby enhancing product quality and reducing drying durations. HVAC experts underscore that the efficiency of rotating air devices can lead to energy conservation and improved system reliability, establishing them as a preferred choice for modern industrial applications.

As HVAC specialist Debasish Biswas notes, “No flow separation occurred for the movement along the blade surfaces,” highlighting the effectiveness of rotating devices in maintaining airflow. Furthermore, while these blowers excel in elevated pressure settings, they tend to produce more noise than conventional models, a significant consideration for noise-sensitive applications.

As industries continue to evolve into 2025, the role of the high pressure centrifugal fan in optimizing airflow and enhancing process efficiency remains indispensable.

Durability and Reliability: Ensure Long-Term Performance with High Pressure Centrifugal Fans

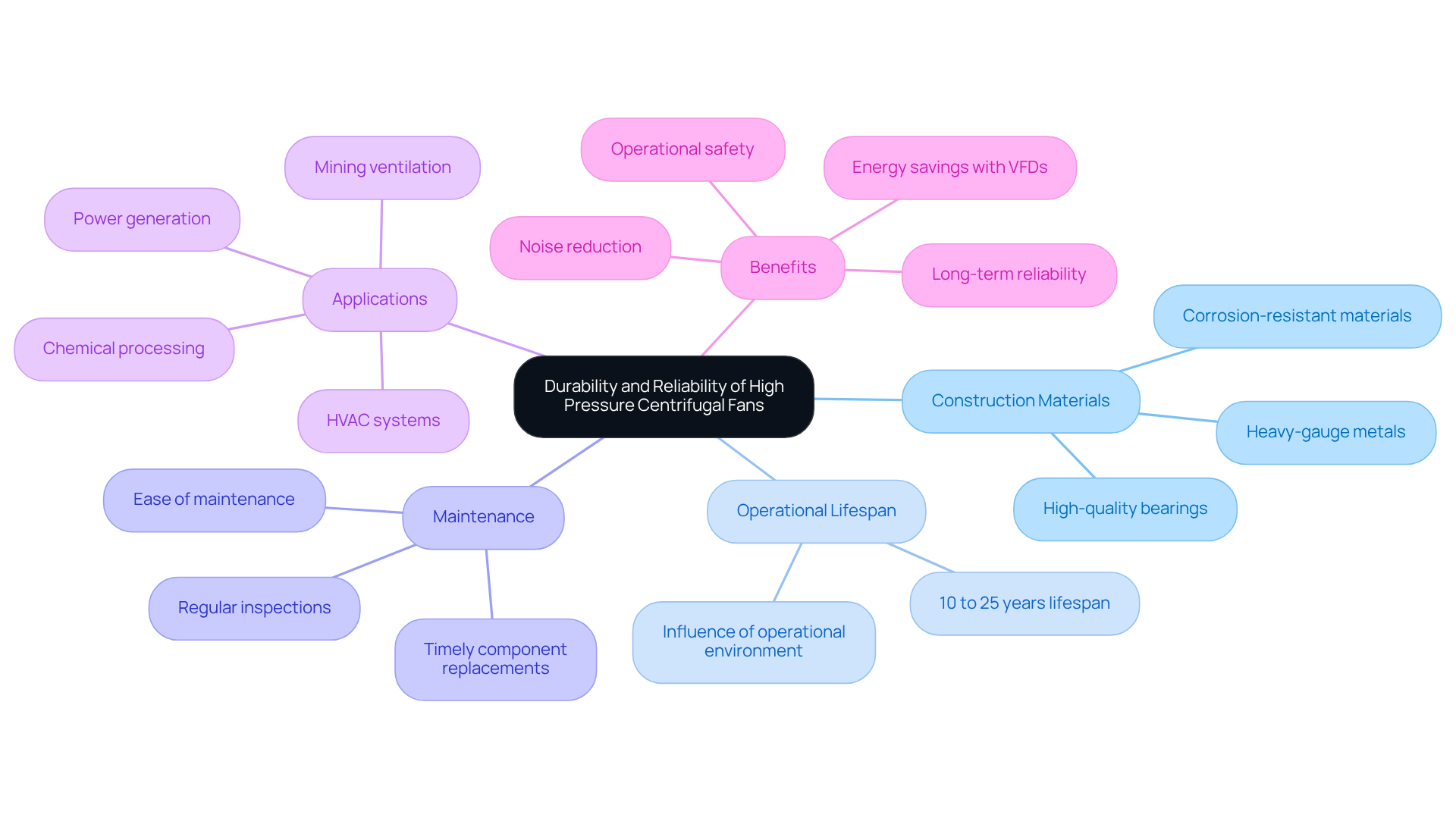

High-pressure centrifugal fans are constructed with durable materials and innovative designs that ensure long-term performance, even in the most challenging environments. Their capacity to function under significant stress without failure makes them indispensable in industrial applications where reliability is critical.

These devices, specifically high pressure centrifugal fans, are engineered to produce elevated static pressures, crucial for surpassing friction losses in systems such as HVAC and mining, where air quality and ventilation are vital.

Regular maintenance, including inspections and timely component replacements, coupled with high-quality construction, significantly extends their operational lifespan, typically ranging from 10 to 25 years, minimizing the frequency of replacements. This reliability is further supported by the integration of advanced control systems, such as variable frequency drives (VFDs), which enhance energy savings by enabling units to operate at speeds that match real-time load requirements.

In settings like power generation and chemical processing, where operational safety and energy efficiency are essential, high pressure centrifugal fans play a critical role in ensuring optimal conditions while sustaining low failure rates. Their durability not only contributes to operational excellence but also represents a critical investment in industrial infrastructure.

Furthermore, the simplicity of upkeep and sound reduction characteristics of these devices are important benefits, especially in delicate settings such as offices and hospitals.

Versatility: Adapt High Pressure Centrifugal Fans for Various Industrial Applications

High-pressure rotary blowers are distinguished for their versatility, making them ideal for a wide range of industrial applications, including ventilation, cooling, and material handling. Their inherent design facilitates extensive customization in size, airflow capacity, and pressure ratings, catering to both small-scale operations and expansive industrial facilities. Engineers have successfully modified these devices to meet specific requirements, such as enhancing air quality in manufacturing environments or optimizing cooling systems in data centers.

Statistics indicate that the market for personalized high-capacity rotary blowers is on the rise, with an anticipated growth rate of 6% from 2025 to 2033, according to Verified Market Reports. This growth underscores the increasing demand for customized solutions, which encompass various sizes and configurations tailored to meet unique operational needs. As one engineer noted, “the capacity to adjust specifications of the blower greatly enhances system effectiveness and performance,” highlighting the crucial role of high-pressure rotary blowers in modern industrial applications.

With the ability to achieve up to 84% static efficiency, these devices not only enhance operational effectiveness but also contribute to energy savings, making them a preferred choice across diverse sectors. The continuous advancements in fan technology, propelled by stringent environmental regulations, further facilitate the development of specialized solutions, ensuring that engineers can consistently identify the right fan to address their specific challenges.

Low Maintenance: Minimize Downtime with High Pressure Centrifugal Fans

High-pressure rotating blowers are engineered for minimal upkeep, presenting a substantial advantage for industrial operations. Their robust construction and efficient design significantly mitigate wear and tear, leading to fewer breakdowns and less frequent servicing. This reliability empowers companies to maintain continuous operations, thereby boosting productivity and minimizing costs linked to downtime.

For instance, organizations utilizing these devices can experience a reduction in unexpected interruptions, with predictive maintenance strategies correlating with a decrease in downtime by as much as 44%. In contrast, companies dependent on reactive maintenance face 3.3 times more downtime, highlighting the critical nature of proactive maintenance approaches.

Furthermore, the average cost of downtime across industries can soar to $260,000 per hour, underscoring the financial advantages of investing in low-maintenance fan technologies. Additionally, rotating blowers typically have a lifespan of 15 to 20 years, further enhancing their long-term reliability and economic efficiency. Certain models even incorporate self-cleaning capabilities, which bolster their low-maintenance feature.

By employing high pressure centrifugal fans, organizations can enhance operational performance while also promoting long-term sustainability through optimized resource utilization and reduced disruptions.

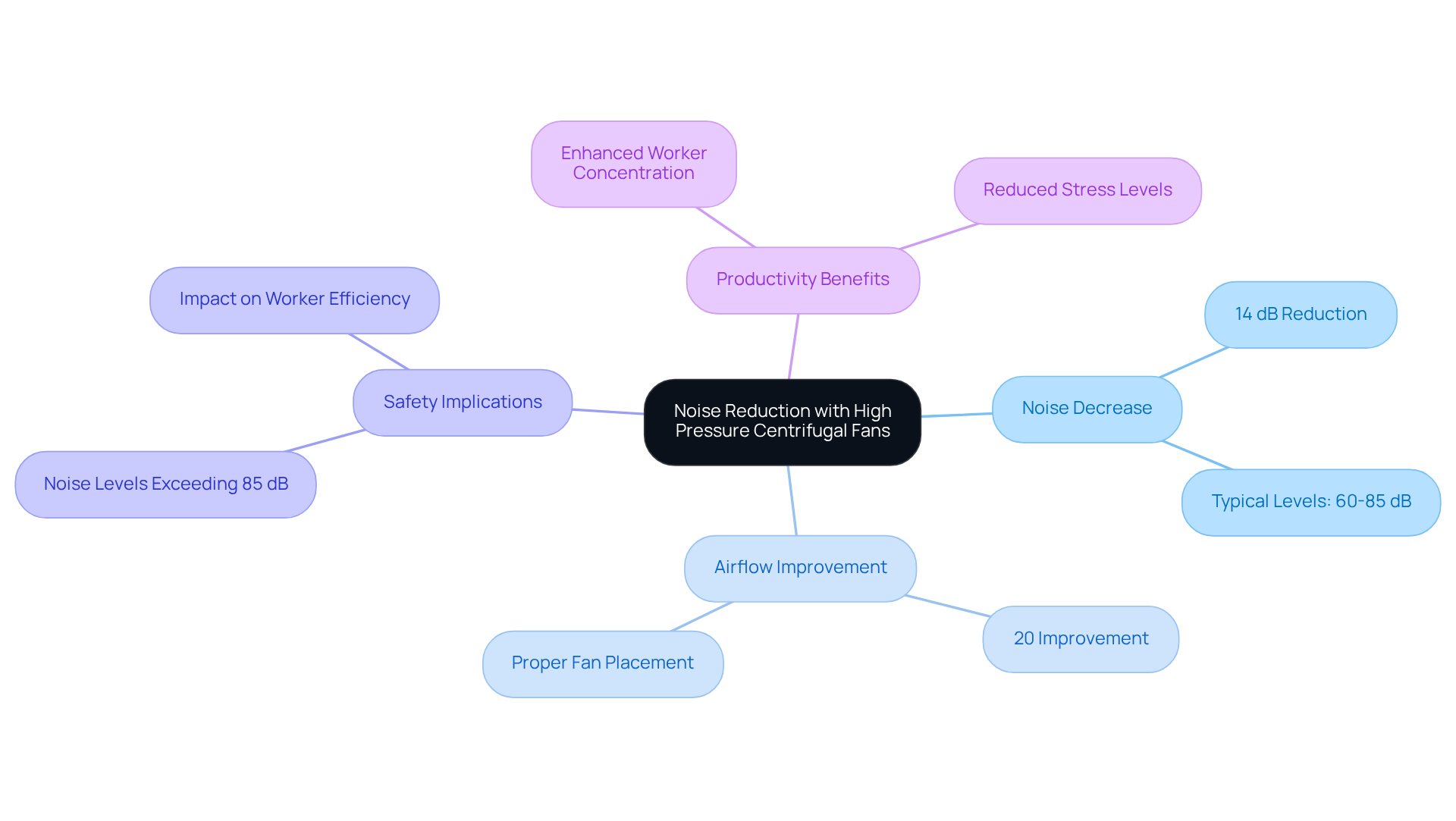

Noise Reduction: Create a Quieter Work Environment with High Pressure Centrifugal Fans

High pressure centrifugal fans are designed with a primary focus on reducing noise. Their enclosed housing and optimized blade designs significantly minimize operational noise, fostering a quieter work environment. This is especially vital in industrial settings, where excessive noise can distract workers and pose safety risks.

A revamp of a ventilation system in a Philippine auto plant, for instance, resulted in a significant 14 dB noise decrease while enhancing airflow performance by 20%. Such improvements not only enhance comfort but also boost productivity, allowing employees to concentrate on their tasks without the disruptive hum of loud machinery.

Safety professionals emphasize that maintaining acceptable noise levels is essential for a productive workplace, as noise levels exceeding 85 dB can lead to decreased efficiency and increased stress among workers. Furthermore, industrial blowers typically generate noise levels ranging from 60-85 dB at a distance of 3 feet, underscoring the significance of choosing quieter technologies.

By emphasizing quiet functionality, high pressure centrifugal fans contribute to creating a safer and more efficient working atmosphere. Engineers should consider these noise levels when selecting ventilation devices, as proactive measures in noise management can significantly enhance workplace safety and productivity.

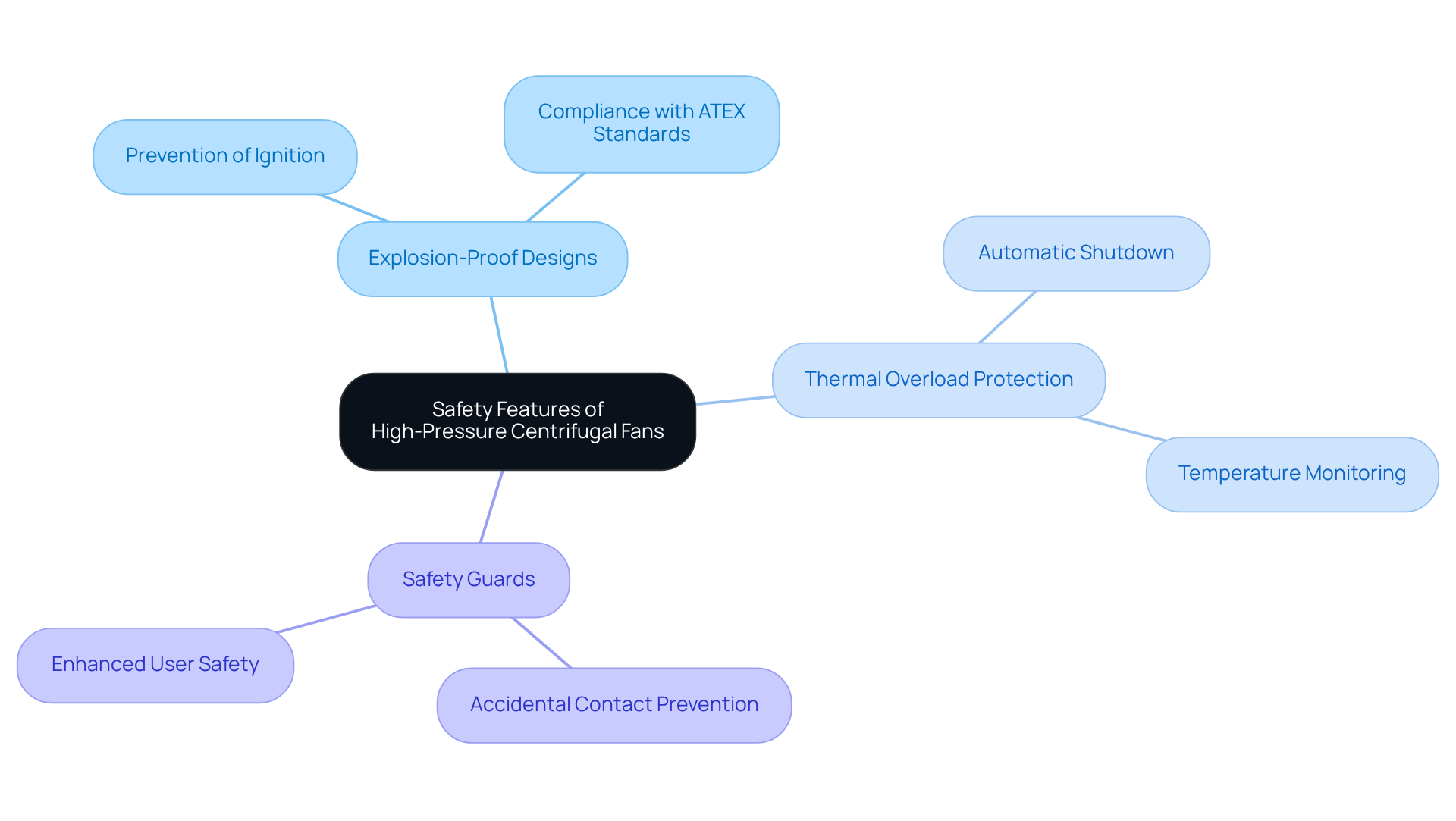

Safety Features: Protect Workers with High Pressure Centrifugal Fans

High-pressure rotating blowers play a critical role in ensuring workplace safety, equipped with an array of safety features designed to protect workers and comply with industry regulations. These features include:

- Explosion-proof designs

- Thermal overload protection

- Safety guards that prevent accidental contact with moving parts

By prioritizing safety, these devices not only contribute to a safer working environment but also significantly reduce the risk of accidents and injuries. Implementing such robust safety measures is essential for fostering a culture of safety in the workplace.

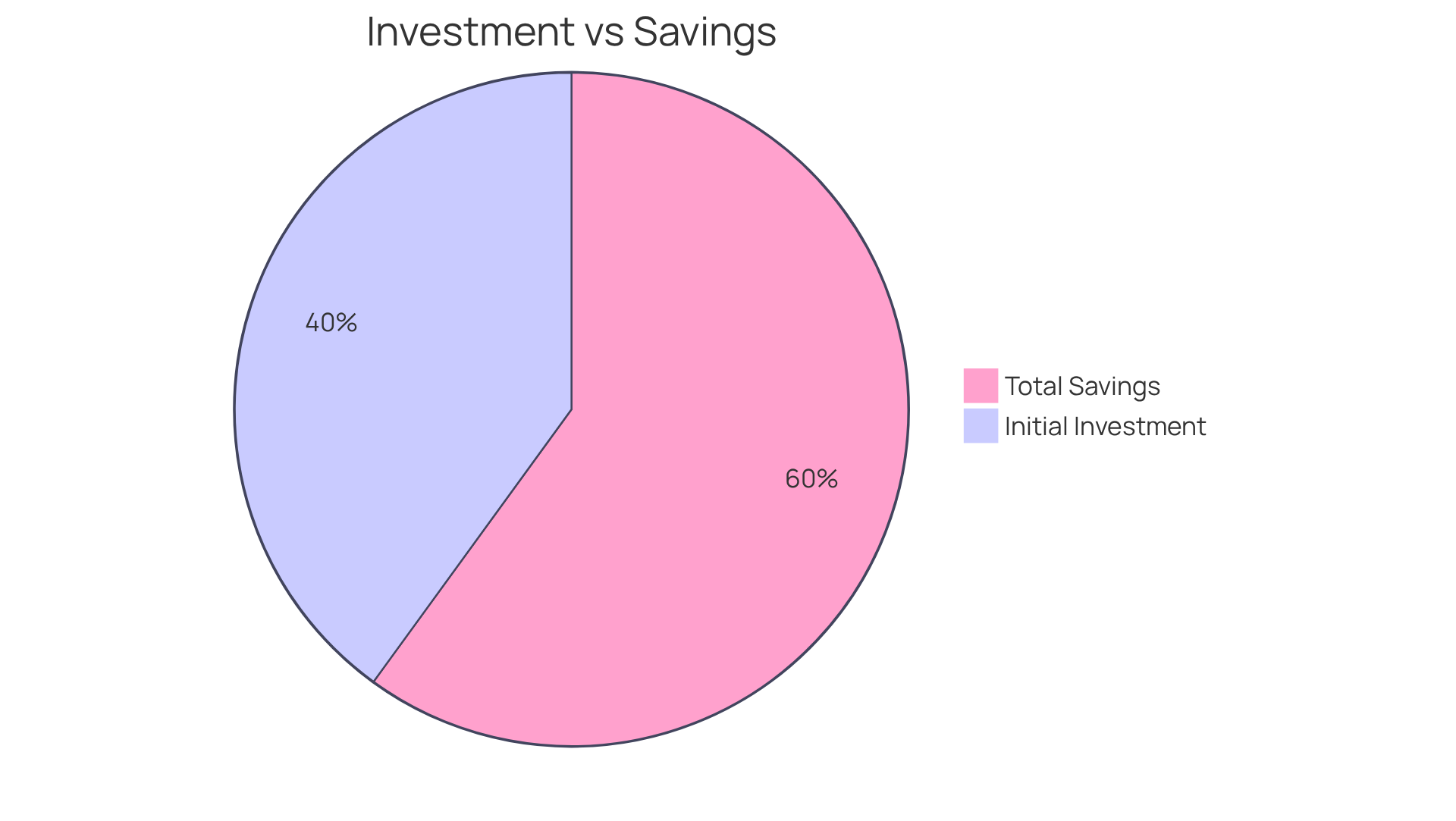

Cost-Effectiveness: Maximize ROI with High Pressure Centrifugal Fans

Investing in high pressure centrifugal fans presents a significant opportunity for cost savings over time. Their energy efficiency, minimal maintenance requirements, and robust durability contribute to a strong return on investment (ROI). By reducing operational expenses and minimizing downtime, these devices emerge as a cost-effective solution for diverse industrial applications, making them a prudent choice for engineers and facility managers.

A comprehensive ROI analysis indicates that the initial investment in high pressure centrifugal fans can be recouped within a few years through lower energy costs and reduced maintenance expenses. Facility managers have noted that these units not only enhance operational efficiency but also yield long-term savings, thereby reinforcing their value in industrial settings.

With the market for high-speed blowers projected to grow at a CAGR of 5.6% from 2025 to 2030, the demand for energy-efficient solutions is expected to rise, positioning these devices as a strategic investment for the future. In summary, powerful rotating blowers represent a smart choice for engineers and facility managers seeking to optimize ROI while ensuring operational effectiveness.

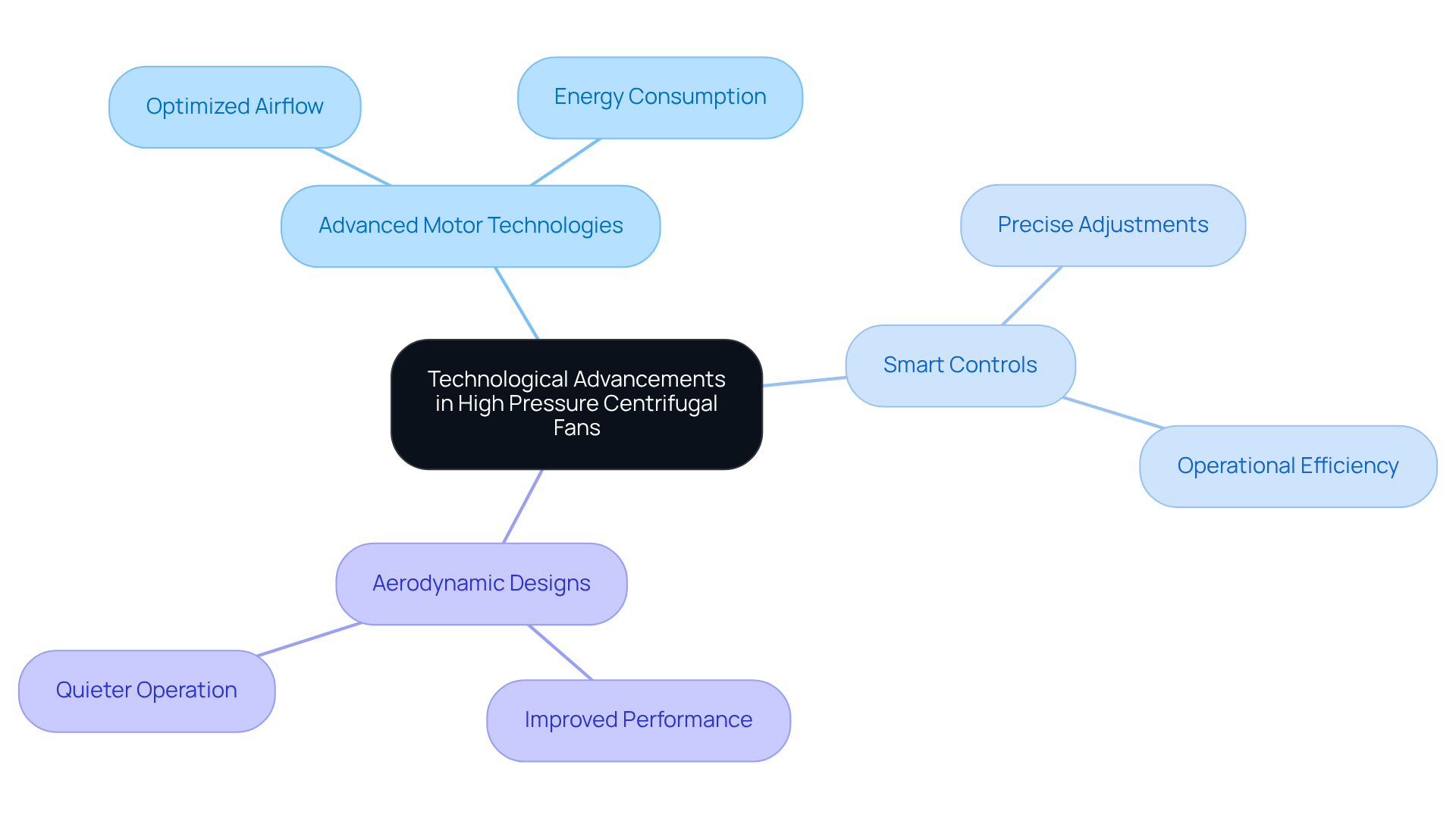

Technological Advancements: Leverage Innovations in High Pressure Centrifugal Fans

Recent advancements in high pressure centrifugal fan technology have significantly enhanced their performance, effectiveness, and reliability. Innovations such as advanced motor technologies and smart controls are revolutionizing fan operation, enabling precise adjustments that optimize airflow and energy consumption. Furthermore, enhanced aerodynamic designs contribute to improved performance, allowing these fans to operate efficiently across various applications, including HVAC, chemical processing, and power generation.

For instance, the introduction of mixed flow wheel technology in products like the RSQ hooded rooftop fan exemplifies how these advancements lead to quieter operation and superior performance. As highlighted by Greenheck Fan Corporation, this technology boasts improved airflow and higher efficiency within a compact design. By leveraging these innovations, engineers can ensure they are utilizing the most effective solutions available, ultimately enhancing system performance while reducing operational costs.

Moreover, the high pressure centrifugal fan market is projected to reach approximately $2.5 billion by 2033, highlighting the increasing importance of these innovations in today’s environmentally conscious landscape.

Conclusion

High pressure centrifugal fans are an essential asset for engineers aiming to enhance operational efficiency and reduce costs across diverse industrial applications. These robust devices deliver not only exceptional airflow and energy efficiency but also durability, versatility, and low maintenance requirements, making them a wise investment for modern facilities.

Key insights from the article underscore the myriad benefits these fans offer, including:

- Significant energy savings

- Improved process efficiency

- Enhanced worker safety through innovative designs and safety features

Their capability to minimize operational noise and maintenance downtime further emphasizes their value in fostering a productive work environment. As the market for high pressure centrifugal fans continues to expand, the necessity of leveraging technological advancements becomes ever more evident.

In conclusion, the adoption of high pressure centrifugal fans signifies a strategic initiative for engineers and facility managers seeking to optimize performance and maximize return on investment. By embracing these innovative solutions, industries can not only comply with stringent energy regulations but also cultivate safer, quieter, and more efficient operational environments. The future of industrial ventilation and airflow management rests with those who recognize the transformative potential of high pressure centrifugal fans.

Frequently Asked Questions

What services does Gagner-Toomey Associates provide?

Gagner-Toomey Associates offers inventive solutions for high pressure centrifugal fans, focusing on cooling, power management, and interconnect technologies, tailored to the unique challenges of the electronics sector.

What is the projected growth of the high pressure centrifugal fan market?

The global market for high pressure centrifugal fans is expected to grow from USD 1.5 billion in 2023 to USD 2.5 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.5%.

What factors are driving the growth of high pressure centrifugal fans?

The growth is driven by the rising demand for energy-efficient ventilation solutions, particularly in industrial sectors, as well as advancements in fan technology.

How do high pressure centrifugal fans contribute to energy efficiency?

High pressure centrifugal fans consume less energy than conventional models due to advanced motor technologies and innovative aerodynamic designs, leading to substantial energy cost reductions and lower operational expenses.

Can you provide an example of cost savings from using high pressure centrifugal fans?

A facility that retrofitted its dust collectors with hydroentangled filter media reported potential annual savings exceeding $77,000, highlighting the financial benefits of these enhancements.

What is the importance of maintaining a balance in fan speed and airflow?

A 20% increase in fan speed can yield a 40% rise in static pressure, but a 20% increase in airflow requires a 73% increase in power, which is crucial to avoid excessive energy costs.

How do high pressure centrifugal fans enhance process efficiency?

These fans provide robust airflow necessary for consistent air movement, effectively overcoming elevated static pressures, which is vital in applications like HVAC systems, industrial drying, and chemical processing.

What are the noise considerations associated with high pressure centrifugal fans?

While these fans excel in elevated pressure settings, they tend to produce more noise than conventional models, which is an important factor for noise-sensitive applications.

What role do high pressure centrifugal fans play in industrial drying processes?

They facilitate swift moisture extraction in industrial drying procedures, enhancing product quality and reducing drying durations.

How does Gagner-Toomey Associates ensure engineers have access to the latest technology?

Gagner-Toomey Associates remains at the forefront of the market by providing access to the latest technological advancements, strategic partnerships, and insights related to high pressure centrifugal fan technology.