Overview

The classification of motor technologies in engineering is essential for optimizing performance and efficiency across a wide array of applications, including automation and robotics. Understanding these classifications—such as DC, AC, stepper, and servo motors—empowers engineers to select the most suitable systems for specific tasks. This knowledge ultimately enhances energy efficiency and operational effectiveness in contemporary engineering practices, paving the way for improved outcomes in various projects.

Introduction

Understanding the intricate world of motor technologies is essential for engineers, as these systems serve as the backbone of countless machines and devices that drive modern society. The classification of these technologies not only elucidates their operational principles but also underscores their critical role in enhancing efficiency, precision, and sustainability across diverse applications. As the landscape of engineering evolves, it is imperative to consider how these classifications adapt to address the pressing challenges of innovation and environmental responsibility.

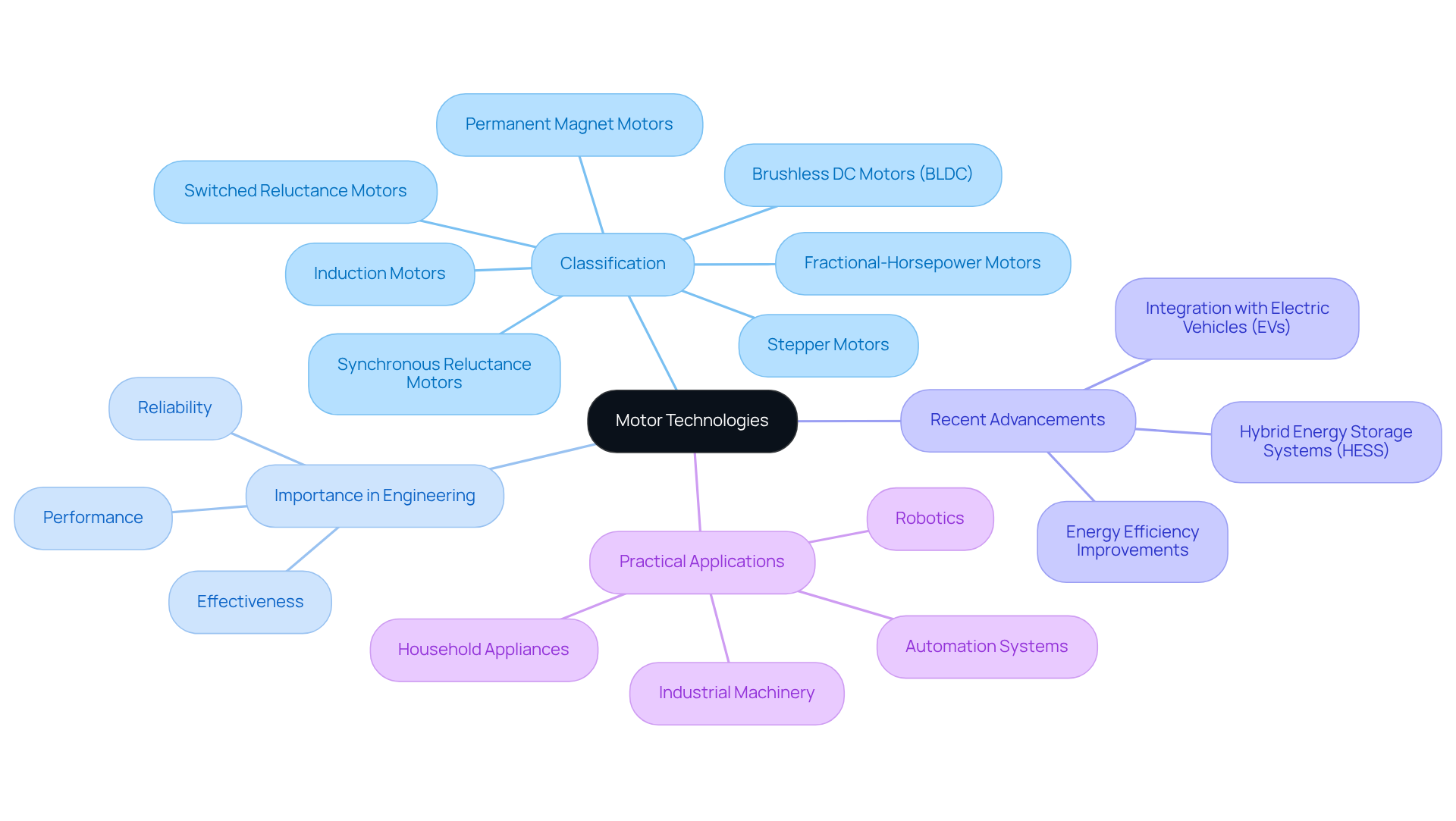

Define Motor Technologies and Their Importance in Engineering

The classification of motor methods represents the various structures and mechanisms that convert electrical energy into mechanical energy, enabling movement in machines and devices. These innovations are pivotal in engineering, driving a diverse range of applications, from household appliances to industrial machinery. Understanding the is essential for engineers, as these advancements significantly enhance performance, effectiveness, and reliability within electronic frameworks. The classification of motor systems emphasizes their importance, which transcends mere functionality; they are integral to , robotics, and energy conservation, establishing their role as a cornerstone of modern engineering practices.

Recent advancements in have led to improved and functionality, particularly in electric vehicles (EVs) and automation systems. For instance, the integration of (HESS) with permanent magnet and induction drives has yielded promising results in boosting efficiency and performance. Experts assert that these are not only vital for traditional applications but are also instrumental in the evolution of , where precision and reliability are paramount.

In practical applications, drive innovations across multiple industries, including manufacturing, transportation, and consumer electronics. Their contribution to automation and robotics is especially noteworthy, as they facilitate that enhance operational efficiency while reducing energy consumption. As the engineering field continues to evolve, the significance of propulsion systems remains foundational to contemporary engineering methodologies, shaping the future of sustainable and efficient design.

Trace the Evolution of Motor Technology Classifications

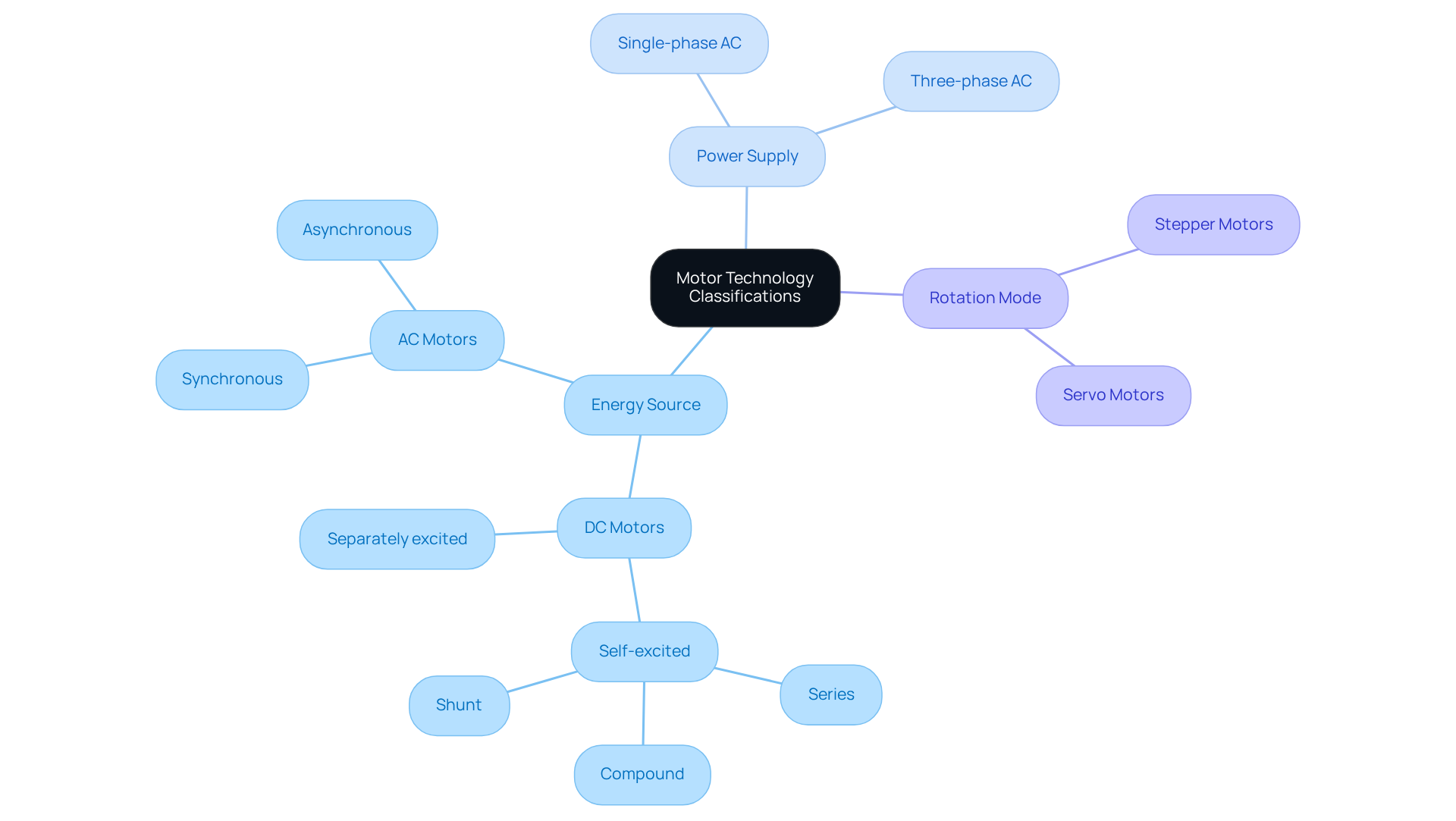

The categorization of machinery has advanced significantly since the advent of in the early 19th century. Initially, devices were primarily classified based on their energy source, such as and types. As technology progressed, the classification of motor systems became more nuanced, encompassing , along with like stepper and servo systems.

Furthermore, the can be done by into DC, single-phase AC, and three-phase AC types. Within the domain of DC devices, distinctions arise between , which further refine the classification of motor types. This evolution in categorization mirrors the increasing complexity and diversity of applications for engines, driven by the demand for , precision, and control in engineering systems.

Additionally, classification by rotation mode highlights factors affecting rotating speed or reverse rotation, adding another layer to the understanding of engine systems. Historical milestones, such as Nikola Tesla’s creation of the in 1888, signify pivotal moments in this evolution. The introduction of various specialized engines, including direct drive systems and linear units, underscores the comprehensive range of advancements in engines available today.

Explore Key Classifications of Motor Technologies

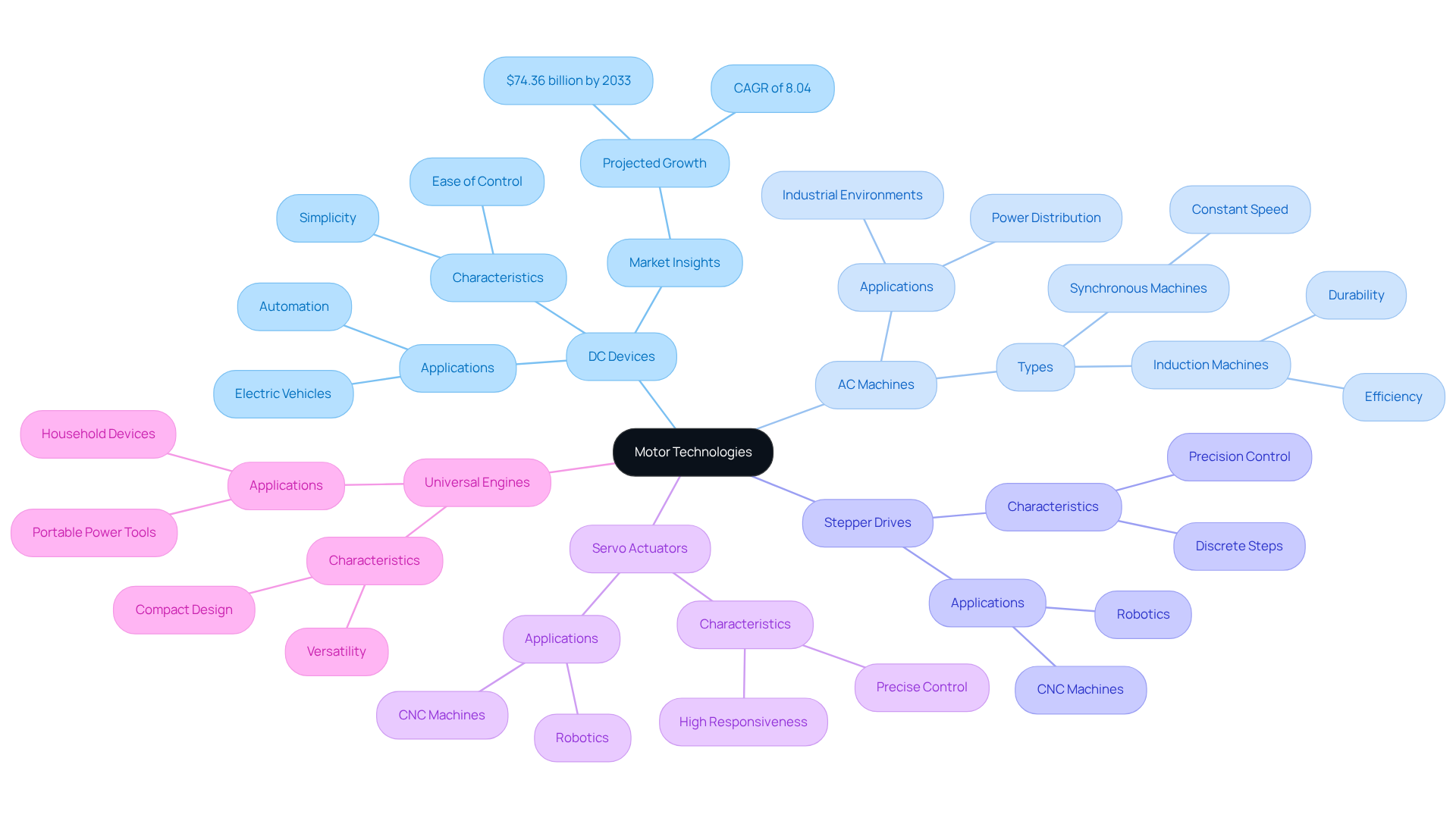

Motor technologies can be included in the classification of motor, which is broadly based on their operational principles and applications. The primary classifications include:

- : Functioning solely on direct current, these devices are acknowledged for their simplicity and ease of control. They excel in applications requiring variable speed and torque, making them a logical choice for many industries. The global DC engine market is expected to expand considerably, attaining $74.36 billion by 2033, fueled by rising demand in electric vehicles and automation, with a CAGR of 8.04% throughout the projection period 2023-2033.

- : AC machines are further classified into synchronous and asynchronous (induction) types. Synchronous machines maintain a constant speed regardless of load, making them ideal for applications requiring precision, such as clocks and power distribution systems. In contrast, induction machines are widely utilized for their durability and efficiency, especially in industrial environments, where they represent a significant share of applications due to their low cost and high dependability.

- : These devices divide a full rotation into discrete steps, allowing for precise control of angular position. Stepper devices are essential in robotics and automation, where precision is paramount. Their ability to move in fixed increments makes them ideal for applications like 3D printers and CNC machines, where precise positioning is critical.

- : Designed for precise control of angular or linear position, velocity, and acceleration, [servo actuators](https://mdpi.com/1996-1073/16/6/2555) are crucial in high-performance applications such as CNC machines and robotics. Their enable them to achieve high accuracy and responsiveness, making them indispensable in modern engineering.

- : Capable of functioning on both AC and DC power, universal engines are frequently encountered in portable power tools and household devices. Their high speed and effectiveness make them suitable for applications where versatility and compact design are essential. However, they are less efficient than specialized devices and produce more heat, which can restrict their application in specific situations.

In conclusion, understanding the classification of motor systems and their uses is crucial for engineers aiming to enhance performance and effectiveness in their designs. The benefits of , including greater efficiency, extended lifespan, and lower maintenance, further enhance their significance in electric vehicles and automation. As electric vehicles play a vital role in decreasing CO2 emissions, the importance of these automotive advancements in the context of environmental impact cannot be disregarded.

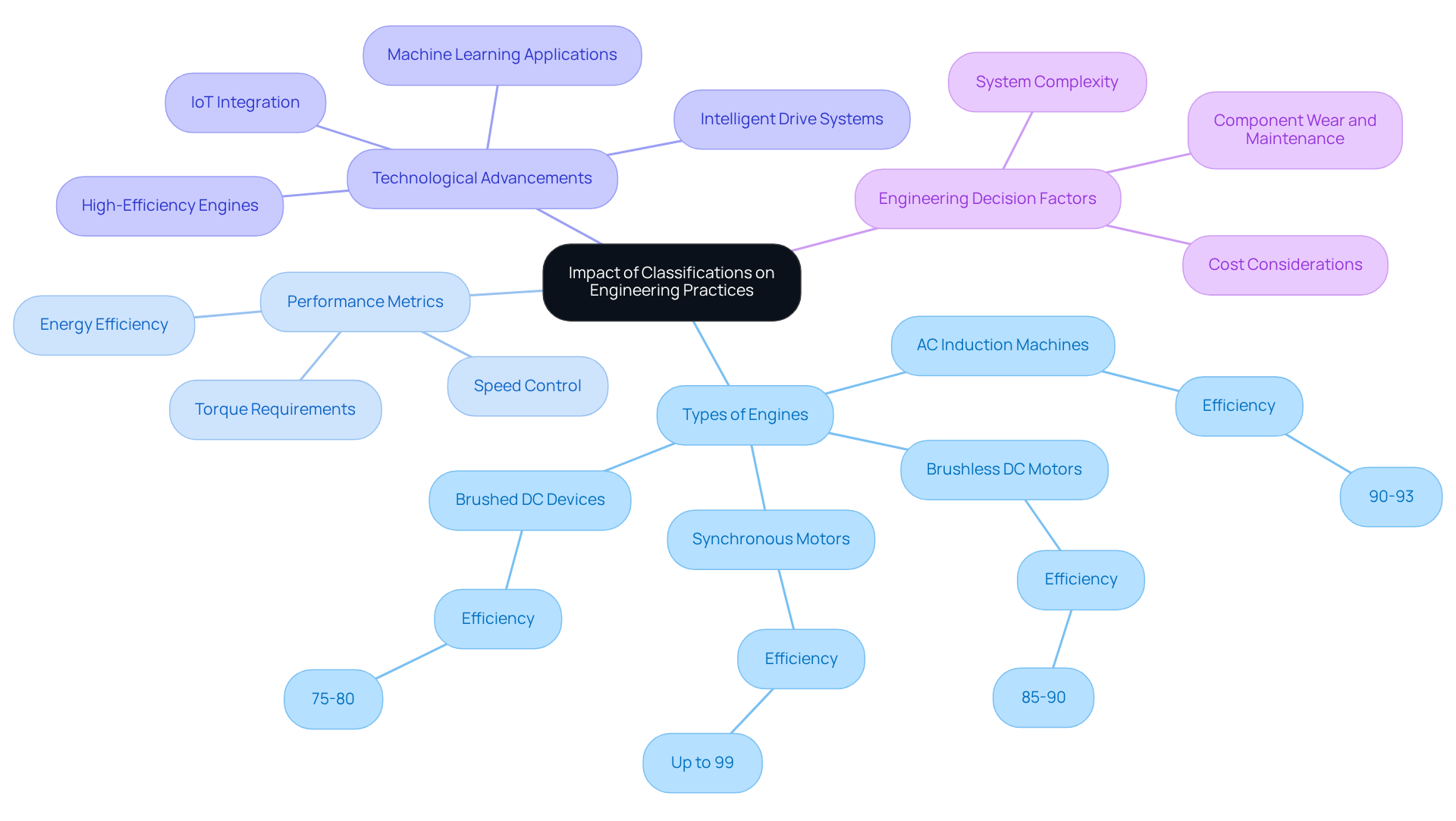

Analyze the Impact of Classifications on Engineering Practices

The categorization of mechanical technologies significantly influences engineering practices by determining the selection of . For instance, the choice between a DC unit and an AC unit can profoundly impact the overall performance, cost, and complexity of a system. Engineers must evaluate factors such as torque requirements, speed control, and when choosing types of engines. Notably, ranging from 90% to 93%, whereas brushed DC devices convert only 75% to 80% of electrical power into mechanical energy. This disparity underscores the critical importance of selecting the right type for .

Recent advancements in propulsion technologies, including the rise of and , are transforming engineering practices. Pelonis Technologies emphasizes that represent one of the largest contributors to energy consumption in electromechanical systems, highlighting the urgent need for efficient designs. The integration of IoT and machine learning into vehicle mechanisms further enhances their capabilities, enabling predictive maintenance and improved performance tracking. As Sam Pelonis notes, not only boosts efficiency but also protects various components from excessive wear and potential system failures. Consequently, a is vital for engineers aiming to innovate and optimize their designs, ensuring they can adeptly navigate the complexities of contemporary engineering challenges.

Conclusion

Understanding the classification of motor technologies is essential for grasping their profound impact on engineering and design. These classifications enhance the efficiency and functionality of machines and play an integral role in advancing automation and robotics. By effectively categorizing motor systems, engineers can navigate the complexities of modern engineering challenges, ensuring they select the most suitable technologies for specific applications.

The article delves into the evolution of motor classifications, highlighting key categories such as:

- DC machines

- AC machines

- Stepper drives

- Servo actuators

Each type offers unique advantages that cater to diverse industrial needs, from precision control in robotics to energy-efficient solutions in electric vehicles. The significance of these classifications is further emphasized by their influence on engineering practices, where the right choice of motor can lead to substantial improvements in performance and energy conservation.

As the engineering landscape continues to evolve, embracing advancements in motor technologies is increasingly vital. A commitment to understanding these classifications fosters innovation and paves the way for sustainable design practices. Engineers are encouraged to stay informed about the latest developments in motor technology to optimize their designs and contribute to a more efficient and environmentally friendly future.

Frequently Asked Questions

What are motor technologies?

Motor technologies refer to the various structures and mechanisms that convert electrical energy into mechanical energy, enabling movement in machines and devices.

Why are motor technologies important in engineering?

Motor technologies are crucial in engineering as they enhance performance, effectiveness, and reliability in electronic frameworks, driving applications from household appliances to industrial machinery.

How do motor technologies contribute to advancements in automation and robotics?

Motor technologies play a vital role in automation and robotics by providing the precision and reliability needed for sophisticated control systems, which enhance operational efficiency and reduce energy consumption.

What recent advancements have been made in motor technologies?

Recent advancements include improvements in energy efficiency and functionality, particularly in electric vehicles (EVs) and automation systems, such as the integration of hybrid energy storage systems (HESS) with permanent magnet and induction drives.

In which industries are motor technologies applied?

Motor technologies are applied across multiple industries, including manufacturing, transportation, and consumer electronics, driving innovations in these sectors.

What is the significance of propulsion systems in engineering?

Propulsion systems are foundational to contemporary engineering methodologies, shaping the future of sustainable and efficient design as the engineering field continues to evolve.