Overview

Heat pipe cooling operates on the principle of phase change, efficiently transferring thermal energy through the utilization of a working fluid that evaporates and condenses within a sealed metal vessel. This technology is particularly effective in electronics cooling, significantly enhancing performance and reliability by managing heat dissipation.

Furthermore, it showcases remarkable adaptability and recent advancements that improve efficiency and reduce space requirements. Such developments not only underscore the importance of heat pipe cooling in modern applications but also prompt consideration for its implementation in future designs.

Introduction

In an increasingly technology-dependent world, efficient temperature control is paramount, especially within electronics, where overheating can significantly undermine both performance and longevity. Heat pipe cooling systems present a groundbreaking solution, employing the principles of phase change to transfer thermal energy with remarkable efficiency. As these systems gain traction across diverse applications, it is essential to consider the true benefits and limitations of this innovative technology. Furthermore, how can we optimize its application in various environments?

Define Heat Pipes: Principles and Functionality

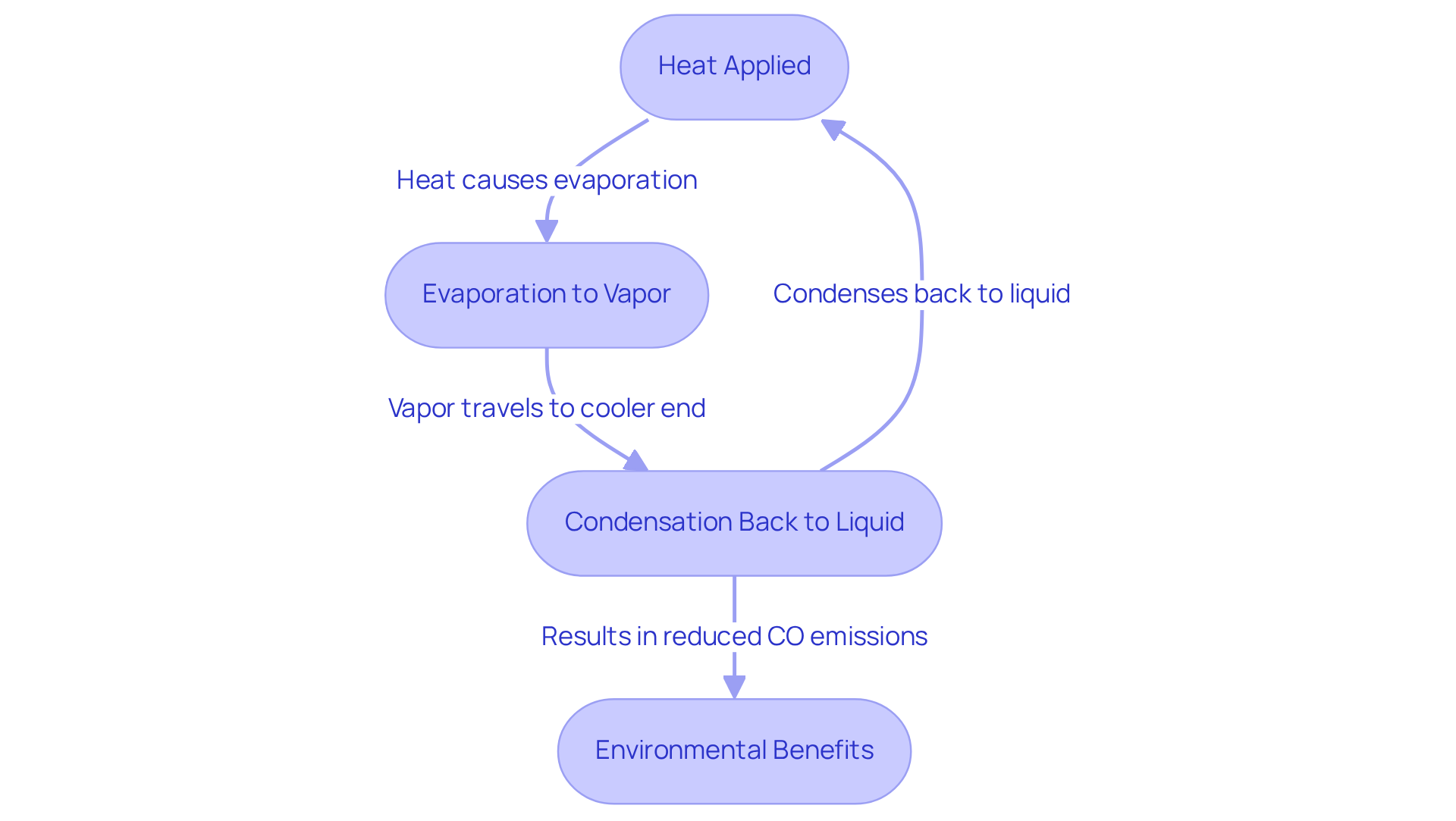

represent a cutting-edge solution for , designed to transfer energy with remarkable efficiency. These tools operate on the principle of phase change, utilizing a working fluid that evaporates at elevated temperatures and condenses at lower temperatures. The fundamental structure of a consists of a sealed metal vessel containing a small amount of liquid. When heat is applied to one end of the tube, the , creating vapor that travels to the cooler end, where it condenses back into liquid. This continuous cycle facilitates efficient energy transfer with minimal temperature difference, rendering thermal conduits highly effective in managing .

The superior conductivity of is particularly beneficial in electronic cooling applications, where is crucial for maintaining optimal operating temperatures. A recent case study of a solar prosumer residence demonstrated that the integration of a thermal radiator system resulted in a remarkable 96.8% reduction in total CO emissions responsibility, underscoring the environmental benefits of .

Recent advancements in thermal conductors have significantly improved their performance. Innovations such as the Enover Radiator prototype, which utilizes 3-phase refrigerant-filled wickless conduits, exhibit reduced oversizing requirements compared to traditional radiators. This not only conserves space and materials but also presents a feasible retrofit option for existing systems. Experts in temperature control emphasize that the adaptability of conduits to operate at low supply temperatures—down to 35 °C for heating and 17 °C for cooling—positions them as vital components in modern .

In conclusion, heat pipe cooling embodies a pivotal technology in , particularly within the electronics sector, where its ability to efficiently transfer thermal energy can significantly enhance performance and sustainability.

Explain Heat Transfer Mechanisms in Heat Pipes

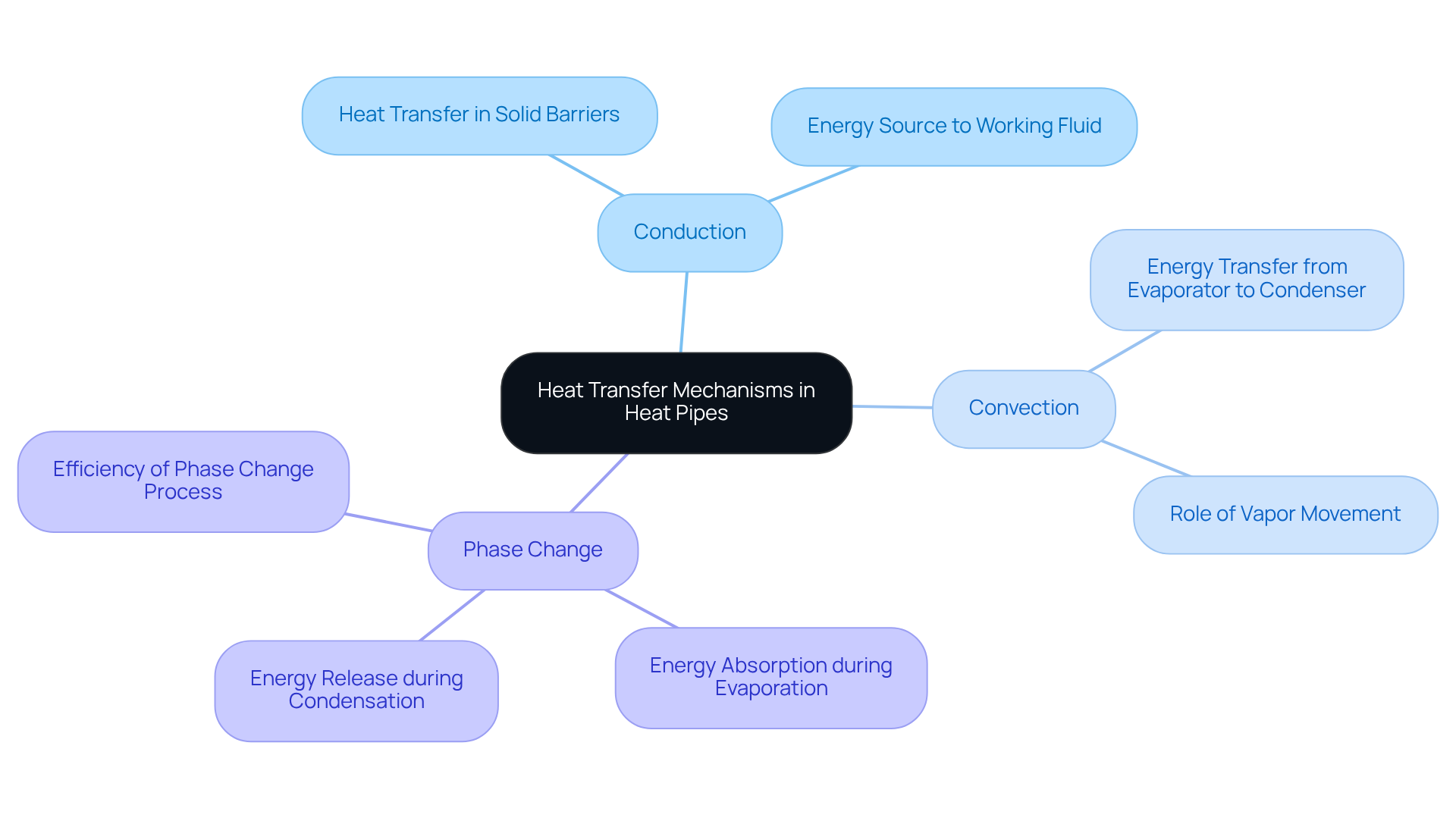

Thermal movement within conduits is facilitated by three primary processes: conduction, convection, and phase change.

- Conduction occurs within the solid barriers of the thermal conduit, enabling the from the energy source to the .

- As vapor traverses the conduit, convection is crucial for transferring energy from the evaporator area to the condenser area.

- However, the most significant mechanism is phase change, where the working fluid absorbs energy during evaporation and releases it during condensation.

This is remarkably efficient, allowing to transport substantial amounts of energy with minimal temperature differentials. Notably, the typical lifespan of is at least 20 years, underscoring their reliability in various applications.

The performance and efficiency of are heavily influenced by its design, particularly the wick structure and the choice of working fluid, which enhance . Moreover, the effective pairing of evaporators and condensers with thermal sources and sinks is vital in , particularly in heat pipe cooling, ensuring optimal across diverse applications.

Explore Applications of Heat Pipes in Electronics Cooling

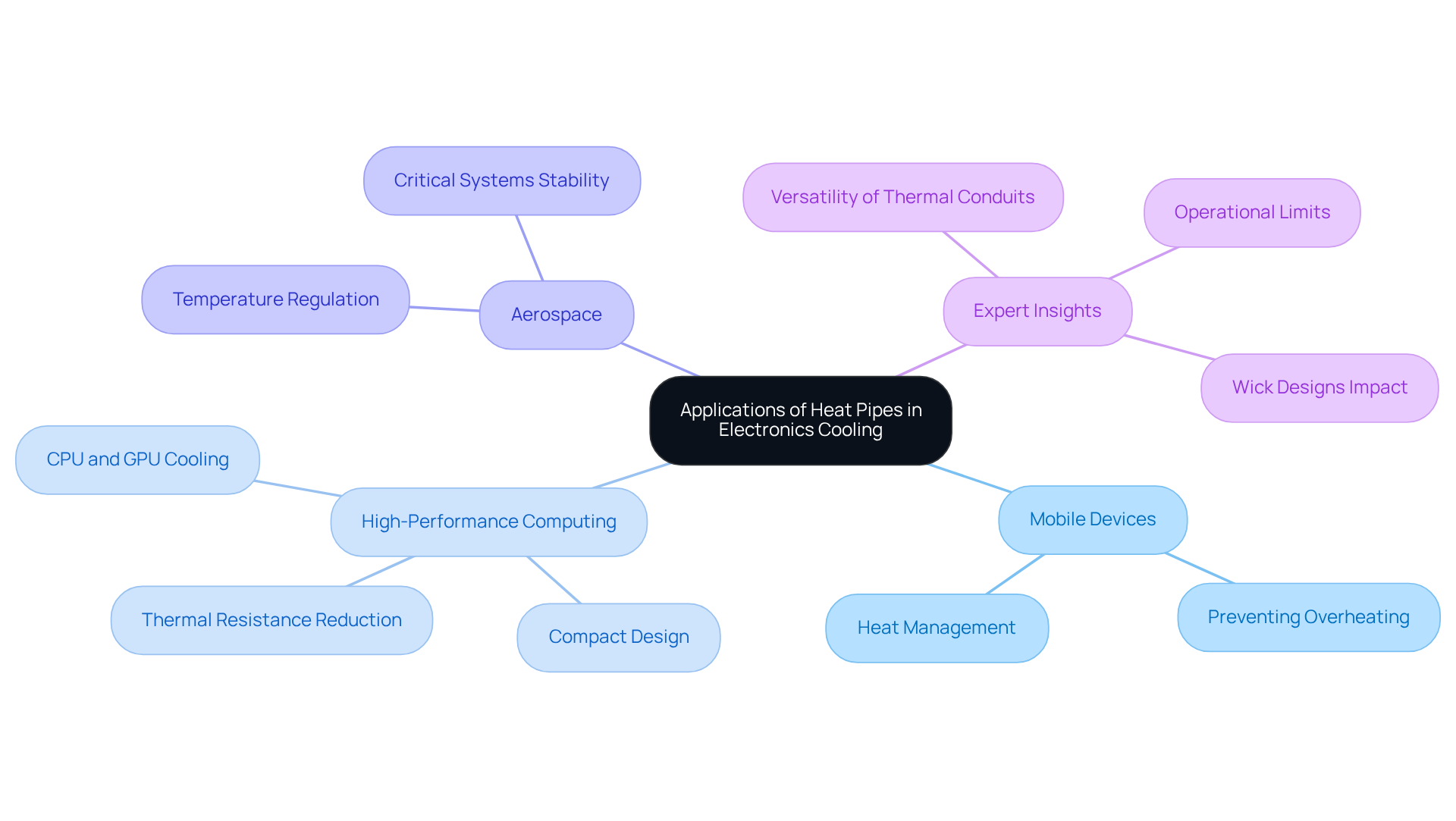

are essential in for electronics, especially in managing the heat produced by CPUs and GPUs. The efficiency of in dissipating heat is essential for maintaining performance stability and extending the lifespan of . In mobile devices, thermal conduits adeptly transport heat away from processors, preventing overheating and ensuring optimal functionality. Notably, case studies illustrate their effective application across various electronic systems, demonstrating significant reductions in thermal resistance and .

In high-performance computing environments, for instance, heat pipe cooling has been employed to manage the thermal output of CPUs and GPUs, allowing for compact designs that do not compromise on performance. Their lightweight and space-efficient nature makes them ideal for modern electronics, including LED lighting systems and telecommunications devices, where is paramount.

Expert insights underscore the versatility of thermal conduits, highlighting their applicability in diverse contexts. In aerospace, for example, thermal conduits are utilized to maintain stable temperatures in critical systems, underscoring their importance in scenarios where effective temperature regulation is vital. Furthermore, understanding the operational limits of thermal conduits, such as their and the potential risks of dry-out or flooding, is essential for engineers. The choice of wick designs, including sintered powder wicks, significantly influences thermal device performance by enhancing capillary action and thermal transfer efficiency.

In conclusion, the implementation of heat pipe cooling systems in electronics not only boosts performance but also contributes to the durability and reliability of electronic devices.

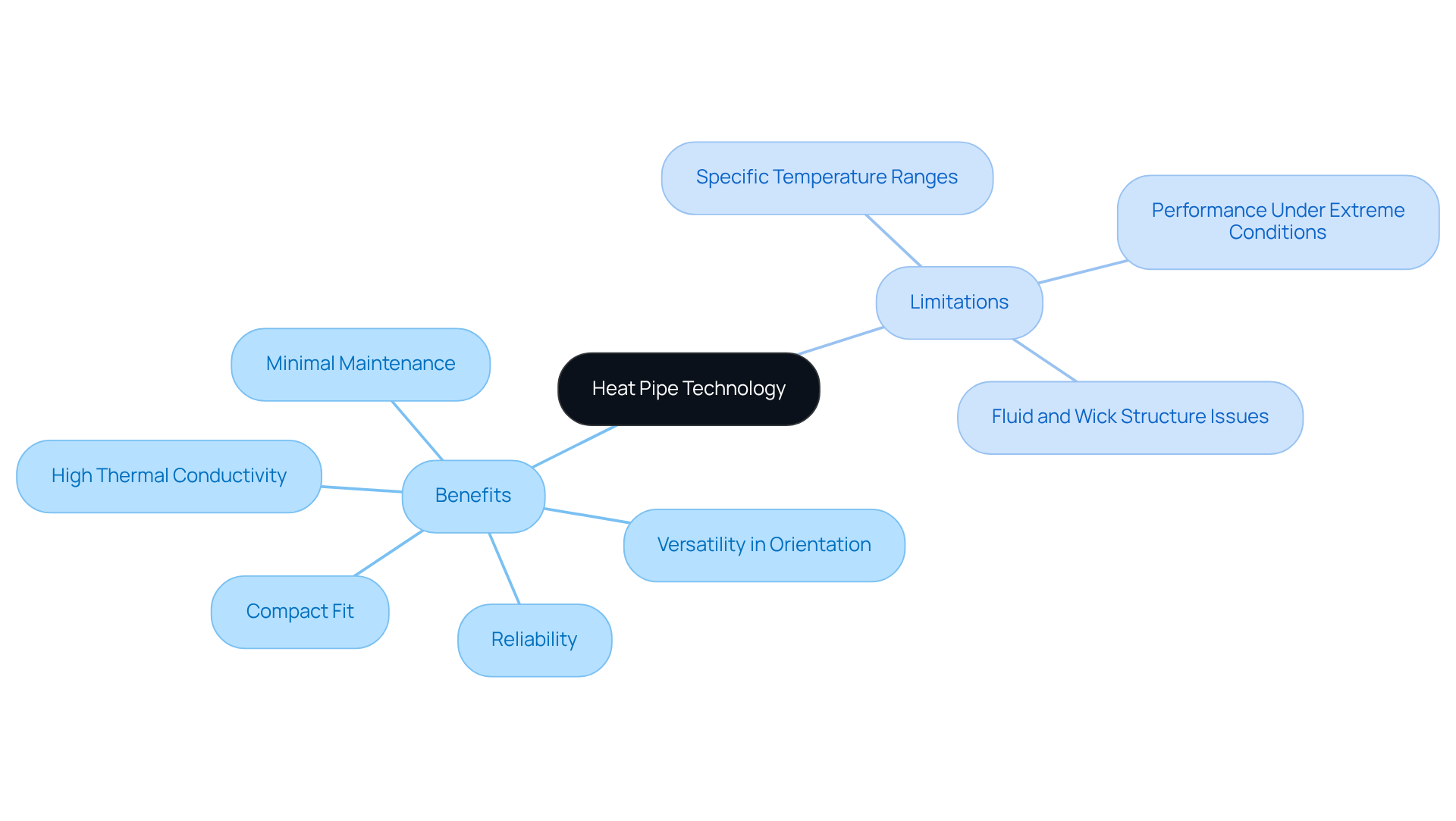

Evaluate Benefits and Limitations of Heat Pipe Technology

Heat transfer technology offers significant advantages, including , reliability, and versatility in orientation. These systems require minimal maintenance and can be tailored to fit compact spaces, making them particularly suitable for modern electronics.

However, it is crucial to recognize the limitations associated with these technologies. Heat transfer devices typically operate within and may struggle under extreme conditions. Furthermore, their performance can be affected by the selection of . Understanding these factors is essential for engineers and designers when selecting .

In conclusion, while serves as a powerful tool for , it is imperative to carefully evaluate its limitations to ensure optimal performance.

Conclusion

Heat pipe cooling technology represents a transformative approach to thermal management, particularly in the realm of electronics. By leveraging the principles of phase change and efficient heat transfer mechanisms, heat pipes facilitate effective thermal regulation, ensuring optimal performance and sustainability in various applications.

Key aspects of heat pipe functionality include the essential processes of conduction, convection, and phase change that enable efficient energy transfer. The versatility of heat pipes is showcased through their applications in electronics, where they play a critical role in managing the heat generated by high-performance components. Furthermore, the benefits of heat pipe technology, such as high thermal conductivity and minimal maintenance requirements, are examined alongside the importance of understanding their limitations and operational constraints.

The significance of heat pipe technology cannot be overstated. As the demand for efficient thermal management solutions continues to grow, embracing the capabilities of heat pipes can lead to enhanced performance and reliability across a myriad of industries. Engineers and designers are encouraged to explore the potential of heat pipe systems, carefully considering both their advantages and limitations to optimize their application in future innovations.

Frequently Asked Questions

What are heat pipes and how do they function?

Heat pipes are thermal conductors designed to transfer energy efficiently using the principle of phase change. They contain a sealed metal vessel with a small amount of liquid that evaporates at high temperatures and condenses at lower temperatures, creating a continuous cycle that facilitates energy transfer.

What is the structure of a heat pipe?

The structure of a heat pipe consists of a sealed metal vessel containing a working fluid. When heat is applied to one end, the liquid evaporates and the vapor travels to the cooler end, where it condenses back into liquid.

What are the benefits of heat pipe cooling systems in electronic applications?

Heat pipe cooling systems provide superior conductivity, which is crucial for effective energy dissipation in electronics, helping to maintain optimal operating temperatures and enhance performance.

How do heat pipes contribute to environmental sustainability?

A case study showed that integrating a thermal radiator system in a solar prosumer residence resulted in a 96.8% reduction in total CO emissions, highlighting the environmental benefits of advanced thermal management solutions.

What advancements have been made in thermal conductors recently?

Recent advancements include innovations like the Enover Radiator prototype, which uses 3-phase refrigerant-filled wickless conduits, reducing oversizing requirements and conserving space and materials.

What temperature ranges can heat pipes operate at?

Heat pipes can operate at low supply temperatures down to 35 °C for heating and 17 °C for cooling, making them vital components in modern energy-efficient systems.

Why are heat pipes considered pivotal in thermal regulation?

Heat pipes are pivotal in thermal regulation, especially in the electronics sector, due to their ability to efficiently transfer thermal energy, significantly enhancing performance and sustainability.