Overview

The article presents a compelling overview of the numerous benefits of maglev fans for electronics engineers, underscoring their:

- Energy efficiency

- Noise reduction

- Durability

- Compact design

- Versatility across various applications

These advantages are substantiated by data demonstrating significant energy savings, reduced operational noise, and enhanced performance. Consequently, maglev fans are becoming an increasingly popular choice within the electronics industry, reflecting a shift towards more efficient and reliable cooling solutions.

Introduction

The rapid evolution of technology in the electronics sector has ushered in a new era of cooling solutions. Magnetic levitation (maglev) fans have emerged as a game-changer for engineers, addressing critical challenges in this domain.

These innovative devices promise enhanced performance and energy efficiency, while also tackling issues such as noise reduction and space optimization.

As the demand for quieter, more reliable, and sustainable cooling solutions continues to grow, a pivotal question arises:

- How can maglev fans revolutionize temperature management in electronic applications?

- What specific benefits do they offer to engineers navigating this complex landscape?

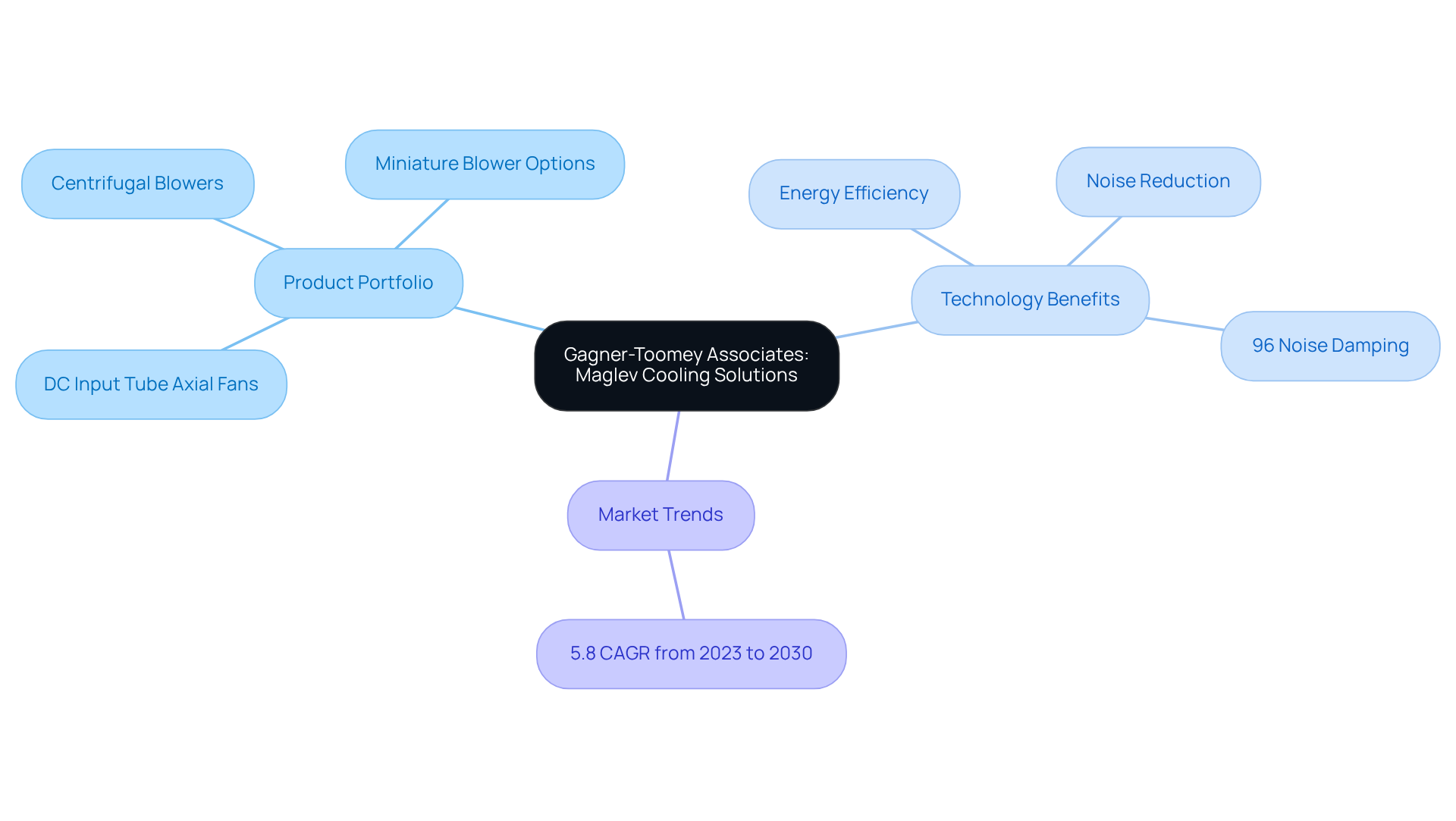

Gagner-Toomey Associates: Leading Provider of Maglev Cooling Solutions

Gagner-Toomey Associates stands at the forefront of innovative temperature regulation methods, meticulously tailored to meet the unique demands of engineers in the electronics industry. As the world’s largest manufacturer of both standard and custom air-movers, Gagner-Toomey boasts an extensive portfolio that includes:

- DC input tube axial fans, ranging from 15 to 280mm

- Centrifugal blowers

- Miniature blower options

All optimized for peak performance, efficiency, and minimal noise. Leveraging cutting-edge magnetic levitation technology, the company provides temperature regulation solutions for maglev fans that markedly enhance thermal management, alongside advancements in superconducting magnets. This technology not only boosts energy efficiency but also significantly mitigates operational noise, featuring advanced noise-dampening buffers capable of diminishing tunnel boom intensity by as much as 96%, rendering it ideal for sensitive electronic applications.

As the demand for state-of-the-art thermal management escalates, Gagner-Toomey remains steadfast in its commitment to delivering the latest innovations in magnetic levitation technology that cater to maglev fans, ensuring clients benefit from improved performance and reliability. The adoption of maglev fans within the electronics sector is witnessing a notable uptick, with projections suggesting a compound annual growth rate exceeding 5.8% from 2023 to 2030. This trend reflects the broader expansion of the market for maglev fans and the growing acknowledgment of their benefits among engineers. Gagner-Toomey’s unwavering dedication to excellence positions it as a trusted partner for those seeking effective and pioneering temperature control solutions.

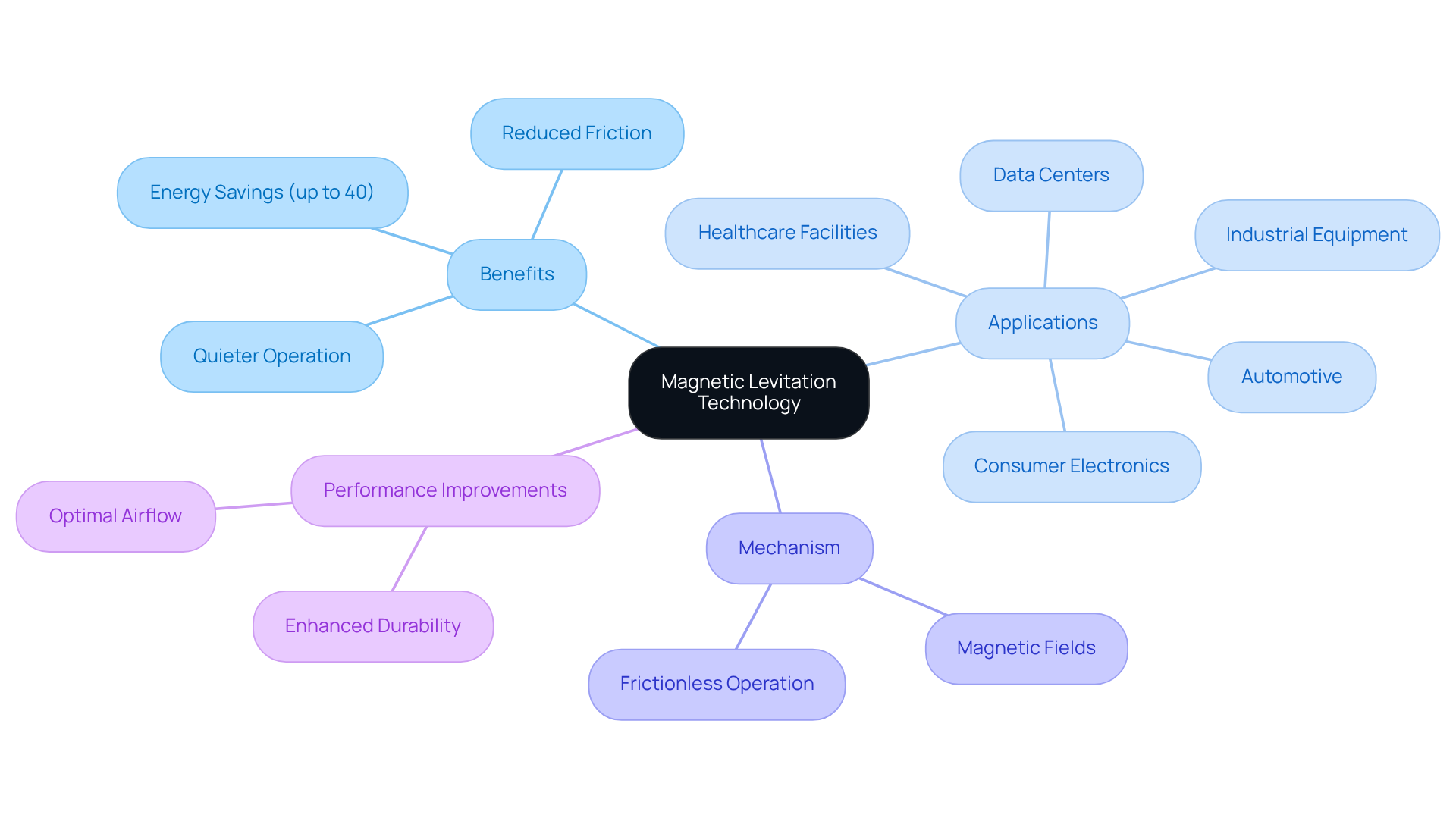

Magnetic Levitation Technology: Enhancing Cooling Efficiency

Maglev fans utilize magnetic levitation technology, which employs magnetic fields to suspend the fan blades, effectively eliminating physical contact with bearings. This groundbreaking method drastically reduces friction, resulting in superior cooling efficiency. By minimizing energy loss, maglev fans maintain optimal airflow while consuming less power, making them particularly suitable for high-performance electronic systems.

Engineers have observed that this frictionless operation not only enhances the durability of the devices but also contributes to quieter performance, which is essential in noise-sensitive environments. Studies indicate that magnetic levitation supporters can achieve energy savings of up to 40%, as evidenced by research from industry specialists like Cherish Cai, underscoring their capacity to significantly improve cooling efficiency across various applications.

Furthermore, the adaptability of maglev fans extends to consumer electronics, automotive, and industrial equipment, making them a valuable option across diverse sectors. The compact design of maglev chillers facilitates easy installation, optimizing space in various settings. The integration of this technology in electronics not only boosts performance but also aligns with the industry’s growing demand for energy-efficient solutions.

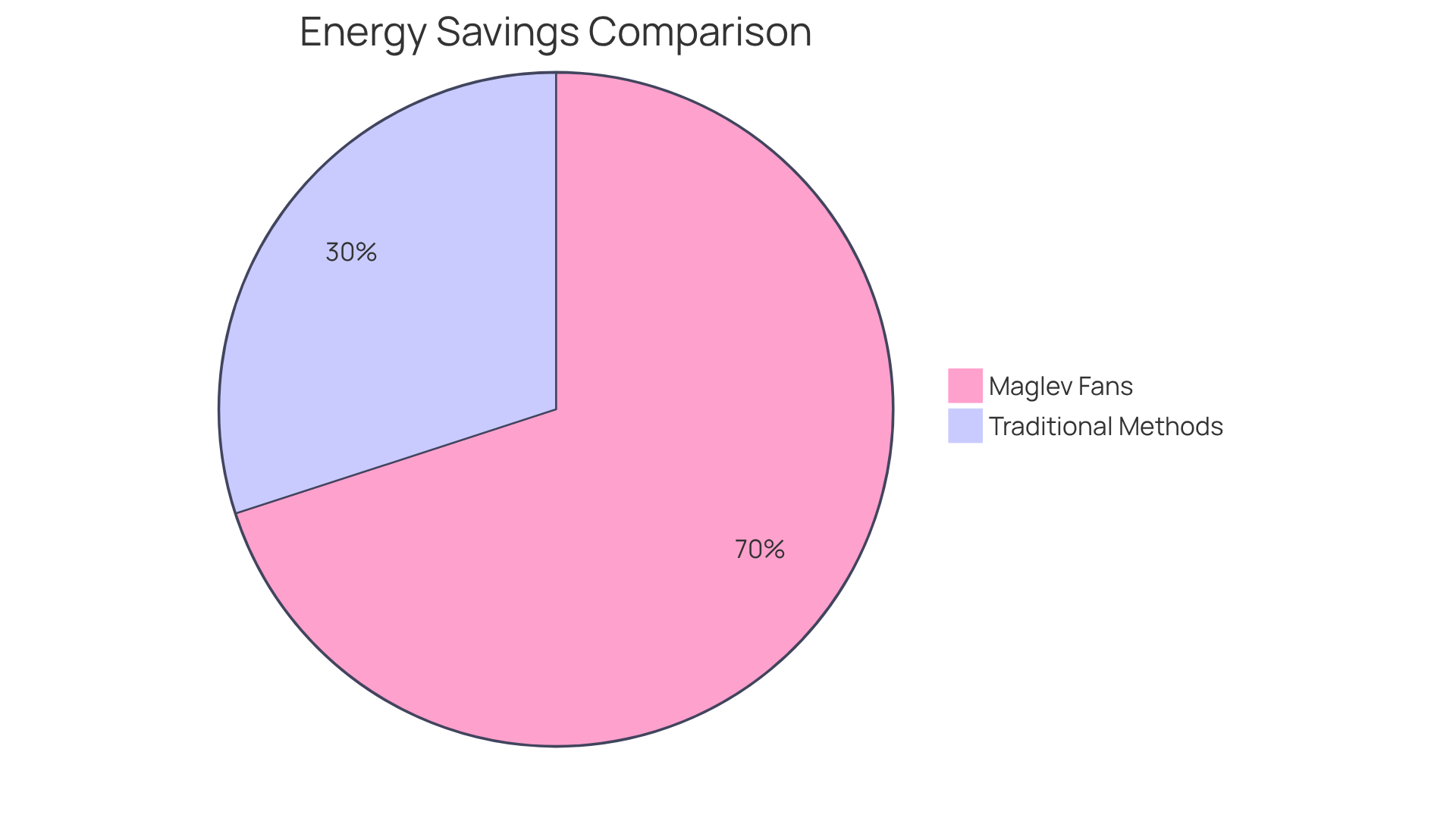

Energy Efficiency: Reducing Power Consumption with Maglev Fans

Maglev devices stand out for their exceptional energy efficiency, significantly reducing power usage compared to traditional temperature regulation methods. These devices leverage advanced magnetic levitation technology, often associated with brushless DC motors, allowing them to operate effectively at lower energy levels. This innovation not only leads to substantial operational cost savings but also fosters a sustainable approach to electronic temperature management.

Research indicates that enthusiasts of magnetic levitation can achieve up to a 70% reduction in energy consumption, translating into lower electricity costs and a diminished ecological footprint. As sustainability advocates champion environmentally friendly temperature regulation technologies, the integration of maglev fans aligns seamlessly with the industry’s shift toward more sustainable practices, addressing the increasing demand for energy-efficient solutions in electronics applications.

Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, offers a comprehensive range of DC input devices and centrifugal blowers, available in sizes from 15 to 280mm, all optimized for performance and efficiency.

Engineers must carefully consider application requirements, climate conditions, and energy costs when selecting cooling solutions, ensuring their choices are informed and tailored to meet specific needs.

Noise Reduction: Achieving Silent Operation with Maglev Fans

Maglev fans are distinguished by their exceptional silent operation, a vital characteristic in environments where noise reduction is paramount. By eliminating mechanical contact among moving parts, these devices substantially reduce vibrations and noise, setting them apart from traditional designs. This capability makes maglev fans ideally suited for applications such as data centers, where maintaining a quiet atmosphere is essential for optimal equipment performance and user comfort.

Although specific data on noise reduction were not available, the silent functionality of magnetic levitation devices is increasingly leveraged in medical equipment and consumer electronics, which maglev fans appreciate, where noise can impede both functionality and user experience.

For electronics engineers considering the integration of magnetic levitation blowers, it is prudent to evaluate the specific noise requirements of their applications and select devices that meet or exceed these criteria. The adoption of maglev systems not only enhances operational efficiency but also aligns with the growing demand for quieter, more reliable electronic systems.

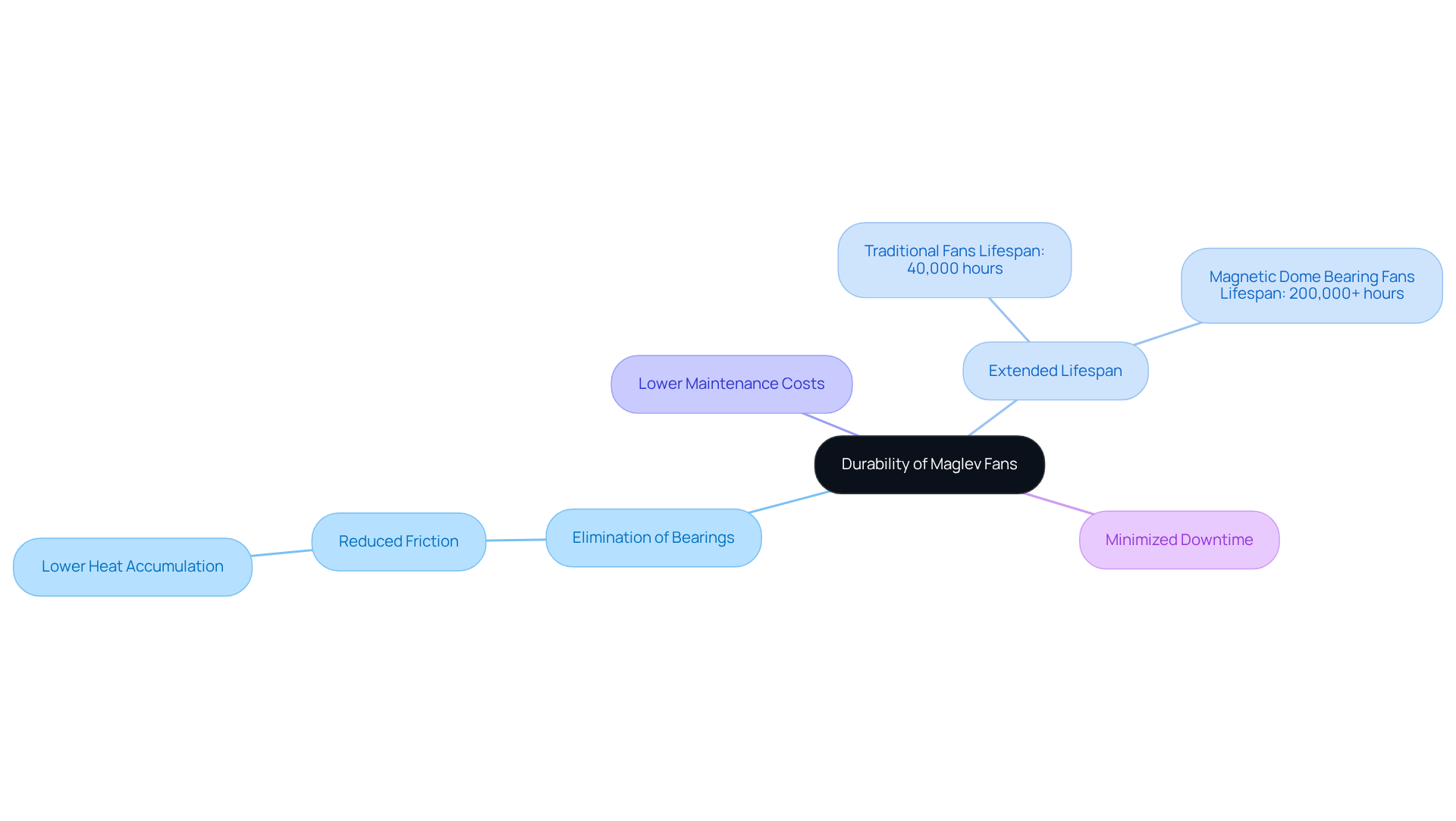

Longevity and Reliability: The Durability of Maglev Fans

Maglev fans are meticulously engineered for durability, thanks to their distinctive design that minimizes wear and tear. By eliminating conventional bearings, maglev fans significantly reduce friction and heat accumulation, leading to an extended operational lifespan. This reliability is paramount for engineers who demand components capable of withstanding rigorous conditions without frequent replacements, thereby minimizing maintenance costs and downtime.

As a leading supplier of advanced temperature control technologies, Gagner-Toomey Associates offers a comprehensive range of ventilators and blowers designed for optimal performance and efficiency. This ensures that engineers have access to reliable components that meet the stringent requirements of electronics applications.

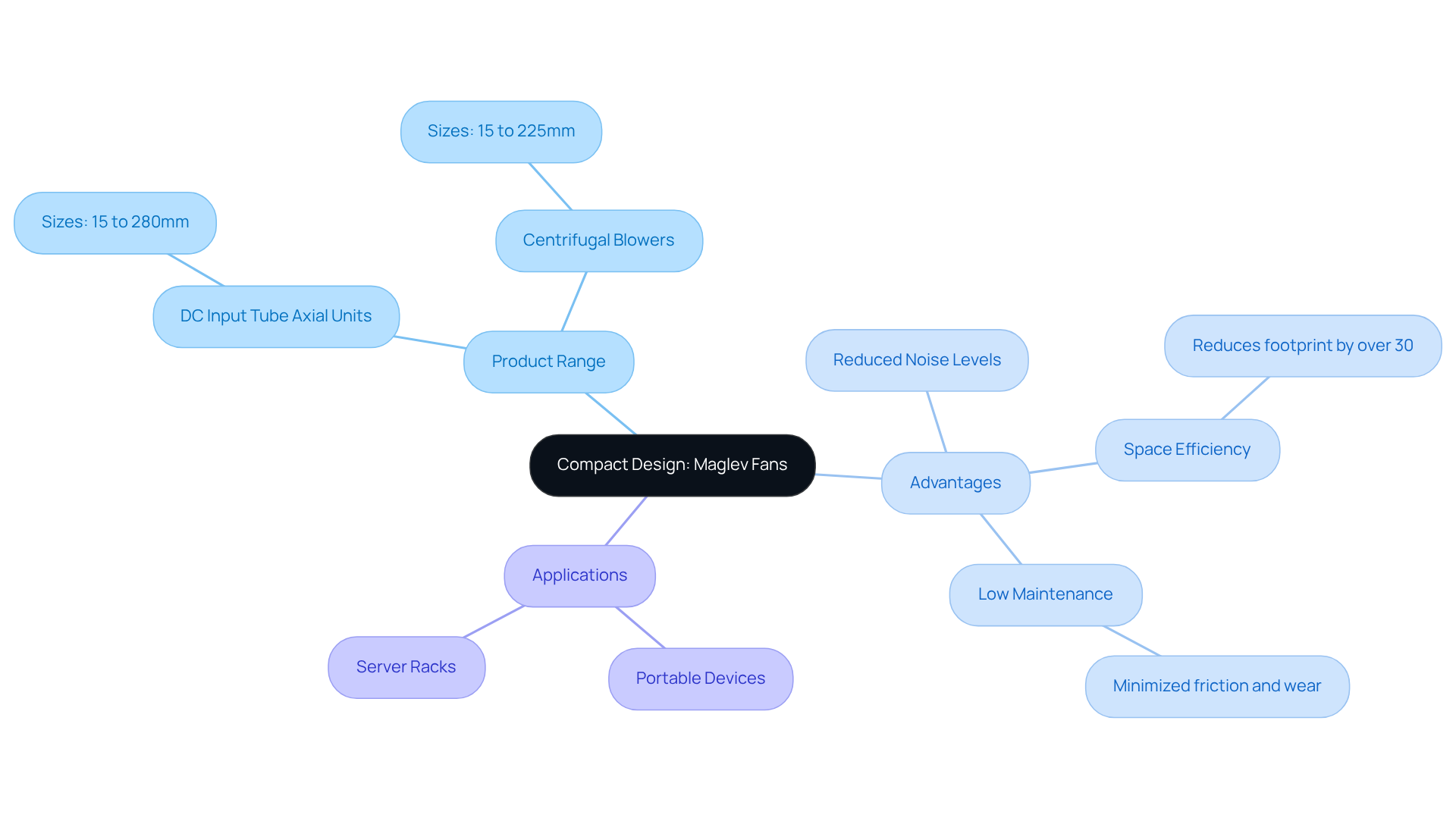

Compact Design: Space-Saving Solutions with Maglev Fans

Maglev devices are meticulously engineered with a compact design that optimizes space utilization within electronic systems. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers for temperature regulation, offers a diverse array of innovative options. Their product line includes:

- DC input Tube Axial units ranging from 15 to 280mm

- Centrifugal Blowers from 15 to 225mm

All designed to enhance performance while significantly reducing noise levels. The minimized footprint of these devices allows engineers to seamlessly incorporate them into confined spaces without compromising functionality. This characteristic is particularly advantageous for applications such as portable devices and densely populated server racks, where maximizing available space is essential for improving overall system efficiency.

Notably, research indicates that employing magnetic levitation technology, a preferred choice among maglev fans, can lead to substantial space reductions, often exceeding 30% compared to conventional refrigeration methods. Furthermore, the lightweight nature of magnetic levitation devices is appreciated by maglev fans as it facilitates easier installation and integration, making them an optimal choice for modern electronic systems that demand both performance and space efficiency.

Additionally, the contactless operation of magnetic levitation is appreciated by maglev fans for reducing friction and wear, thereby lessening maintenance requirements—an especially critical factor in industries with stringent hygiene standards. As Stephen Hayes, Managing Director at Beckhoff Automation UK, aptly remarks, “Unlike Marty McFly’s hoverboard, magnetic levitation technology has proven to be more than just a futuristic concept, with tangible benefits across diverse manufacturing industries.”

This statement underscores the practical advantages of maglev devices in enhancing operational efficiency, aligning seamlessly with Gagner-Toomey Associates’ dedication to providing advanced temperature control solutions.

Versatility: Adapting Maglev Fans for Diverse Applications

Maglev devices exemplify remarkable versatility, positioning them as ideal solutions for a diverse array of applications, spanning from consumer electronics to industrial machinery. Their inherent ability to provide effective temperature regulation across various environments allows engineers to integrate them into multiple projects, significantly enhancing design adaptability. In sectors such as telecommunications, automotive, and medical devices, magnetic levitation blowers can be meticulously customized to meet specific cooling requirements, demonstrating their pivotal role in advancing technological innovation.

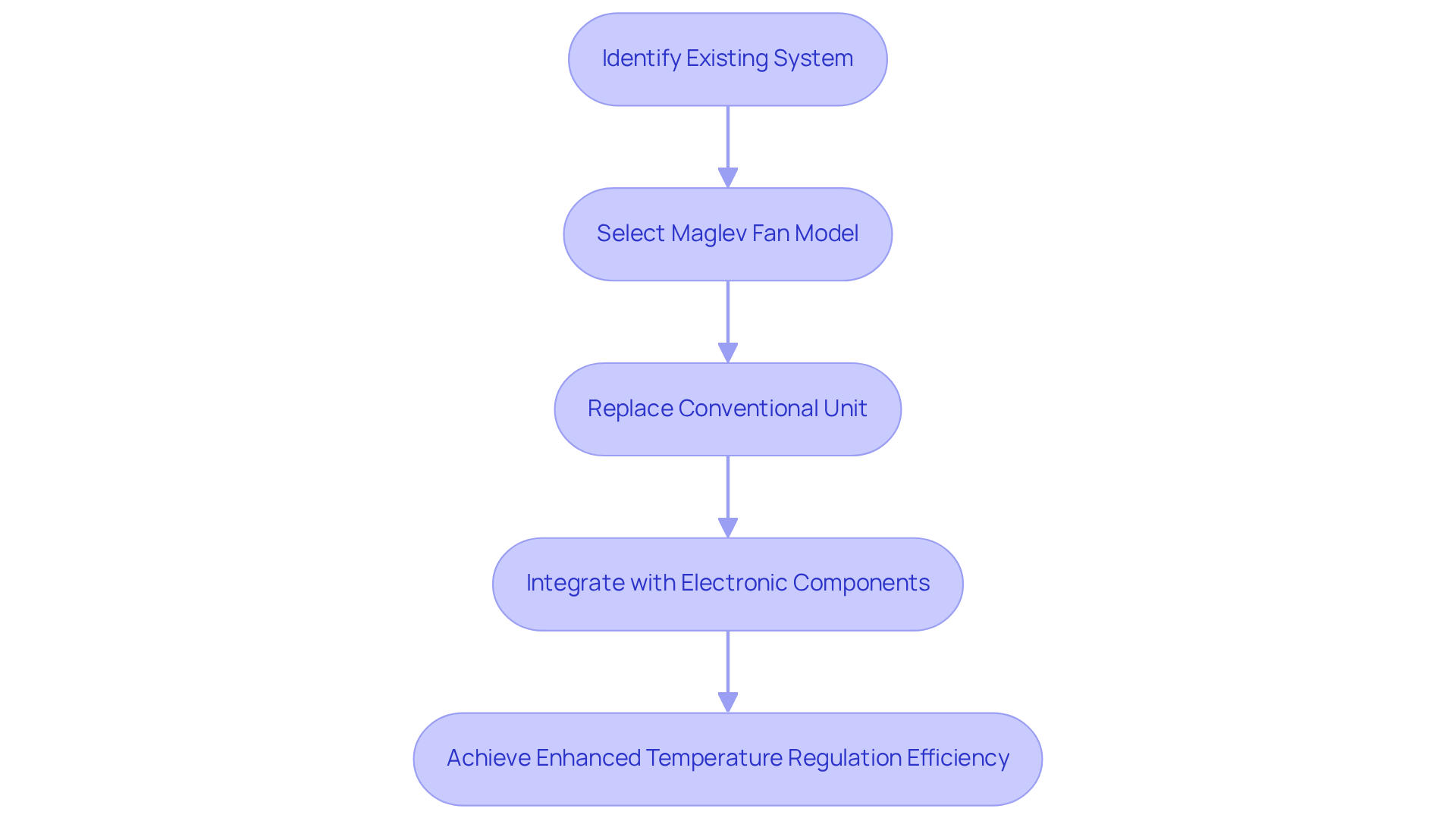

Ease of Integration: Simplifying Upgrades with Maglev Fans

Incorporating magnetic levitation blowers into existing systems presents a straightforward solution, owing to their standardized designs and compatibility with various electronic components. Engineers can seamlessly replace conventional units with maglev fan alternatives, facilitating upgrades without extensive redesigns. This seamless integration not only conserves valuable time but also enables rapid performance enhancements in temperature regulation efficiency.

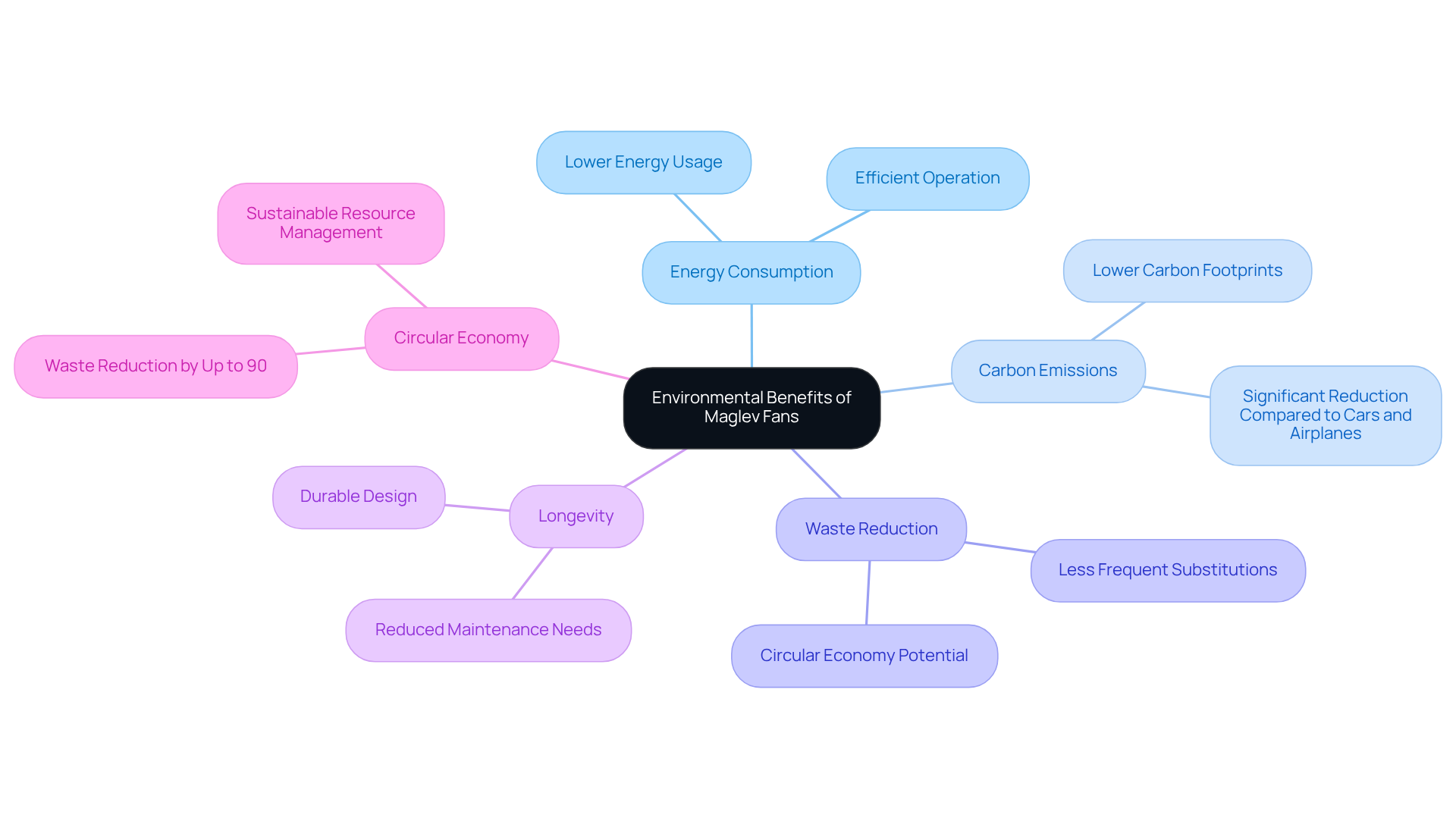

Environmental Benefits: Eco-Friendly Cooling with Maglev Fans

Maglev fans are crucial in promoting environmental sustainability by significantly reducing energy consumption and minimizing waste. The advanced design of maglev fans allows for efficient operation, which translates to lower carbon footprints—making them an ideal eco-friendly choice for cooling solutions in electronics.

Magnetic levitation trains, employing similar technology, emit between 66 and 75 percent fewer carbon emissions compared to cars and airplanes, underscoring the substantial environmental benefits of adopting such technologies. Furthermore, the longevity of magnetic levitation devices means they require less frequent substitutions, thus reducing waste and fostering a more eco-friendly approach to electronic design.

As sustainability advocates emphasize, every minor action contributes to a greater effect; embracing environmentally friendly technologies such as maglev fans is essential for a greener future. Incorporating such approaches aligns with the industry’s transition toward sustainability and supports the broader aim of minimizing environmental harm, which jeopardizes the livelihoods of billions worldwide, including those who are maglev fans.

Additionally, embracing a circular economy can reduce waste by up to 90%, further reinforcing the sustainability message. The case study on land use comparison of high-speed trains illustrates how this technology aids wildlife conservation and diminishes habitat destruction, making it a compelling option for environmentally friendly alternatives.

As Richard Rogers stated, ‘The only way forward, if we are going to improve the quality of the environment, is to get everybody involved,’ emphasizing the importance of collective action in adopting eco-friendly technologies.

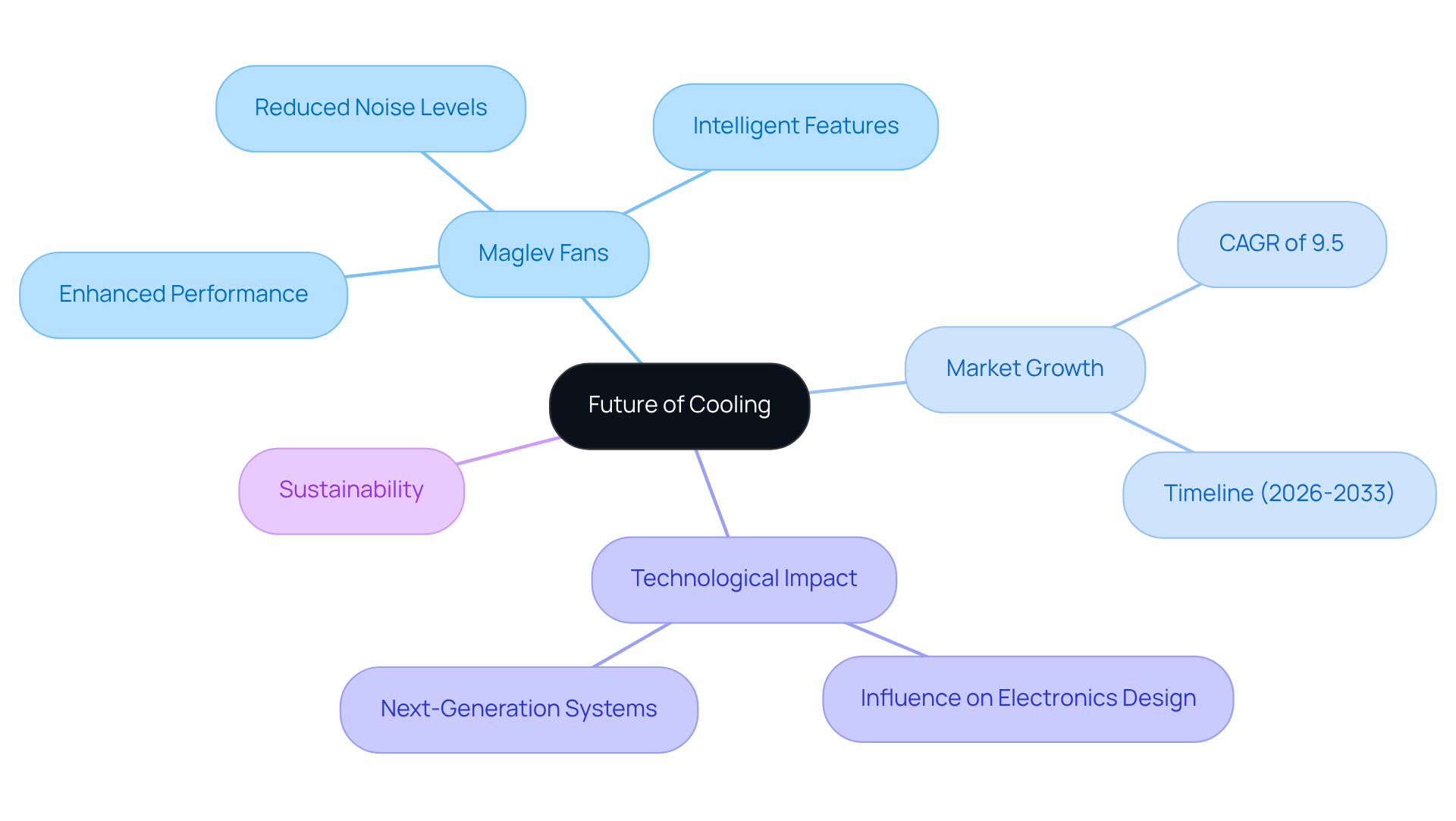

Future of Cooling: The Impact of Maglev Fans on Technology

The electronics sector is on the brink of a significant transformation, driven by the increasing adoption of maglev fans. These innovative temperature regulation methods not only enhance performance but also integrate intelligent features that meet the evolving demands for efficiency and sustainability.

Industry leaders recognize that advancing magnetic levitation technology is essential, with projections indicating a robust growth rate in adoption over the next decade. For instance, the fan market is anticipated to grow at a CAGR of 9.5% from 2026 to 2033, underscoring the rising demand for energy-efficient temperature regulation solutions.

This trend is expected to profoundly influence electronics design, as engineers seek to leverage the advantages of magnetic levitation devices, which include reduced noise levels and improved airflow efficiency.

As Chuck Campagna, CEO of Delta Intelligent Building Technologies, remarked, “The establishment of Delta Intelligent Building Technologies reflects our commitment to addressing evolving priorities in the North American building sector, where sustainability, energy efficiency, and smart technologies take center stage.”

As advancements progress, the role of maglev fans is set to become a critical element in the development of next-generation electronic systems, fundamentally shaping the future of cooling technology.

Conclusion

The adoption of maglev fans signifies a monumental advancement in cooling technology for electronics engineers, merging innovative design with superior performance. By harnessing magnetic levitation technology, these fans minimize friction and noise while delivering exceptional energy efficiency, establishing them as an optimal choice for a myriad of applications within the electronics sector.

In this examination of maglev fans, key advantages have been elucidated, including:

- Unparalleled cooling efficiency

- Diminished power consumption

- Impressive longevity

Their compact design facilitates seamless integration into existing systems, while their versatility allows adaptation to an extensive range of applications, from consumer electronics to industrial machinery. Moreover, the environmental benefits of utilizing maglev fans resonate with the industry’s increasing focus on sustainability, underscoring their contribution to a greener future.

As the electronics landscape continues to evolve, the integration of maglev fans is set to be pivotal in shaping the future of cooling technology. Engineers are urged to embrace these advanced solutions to enhance performance, lower operational costs, and foster a more sustainable approach to electronic design. The moment to acknowledge the advantages of maglev fans is now, as they stand at the forefront of innovation in the pursuit of efficient and reliable cooling solutions.

Frequently Asked Questions

What types of cooling solutions does Gagner-Toomey Associates provide?

Gagner-Toomey Associates offers a range of innovative temperature regulation solutions, including DC input tube axial fans (15 to 280mm), centrifugal blowers, and miniature blower options, all optimized for performance, efficiency, and minimal noise.

How does magnetic levitation technology enhance cooling efficiency?

Magnetic levitation technology suspends fan blades using magnetic fields, eliminating physical contact with bearings. This drastically reduces friction, leading to superior cooling efficiency, lower energy consumption, and quieter performance, making it ideal for high-performance electronic systems.

What are the energy savings associated with maglev fans?

Maglev fans can achieve energy savings of up to 40% compared to traditional cooling methods, with some research indicating reductions in energy consumption of up to 70%. This results in lower electricity costs and a smaller ecological footprint.

In which sectors can maglev fans be utilized?

Maglev fans are adaptable and can be used across various sectors, including consumer electronics, automotive, and industrial equipment, making them a valuable option for diverse applications.

What advantages do maglev fans offer for noise-sensitive environments?

The frictionless operation of maglev fans enhances durability and contributes to quieter performance, which is essential in environments where noise reduction is a priority.

What is the projected market growth for maglev fans in the electronics sector?

The adoption of maglev fans within the electronics sector is expected to grow at a compound annual growth rate exceeding 5.8% from 2023 to 2030.

How does Gagner-Toomey Associates ensure the quality of its products?

Gagner-Toomey Associates is committed to delivering the latest innovations in magnetic levitation technology, ensuring that their maglev fans provide improved performance and reliability for clients.