Overview

This article delves into the critical distinctions between heat pipes and vapor chambers, emphasizing their operational mechanisms, thermal performance, advantages, and disadvantages for engineers. It underscores that both devices proficiently transfer heat through the processes of evaporation and condensation.

However, heat pipes are particularly adept at point-to-point thermal transfer, whereas vapor chambers excel in providing uniform heat distribution across larger surfaces. This characteristic makes vapor chambers particularly suitable for high-performance electronics, where consistent thermal management is paramount.

Introduction

Thermal management is a critical aspect of engineering, especially as technology advances and components become increasingly compact. Among the various tools available for optimizing heat dissipation, heat pipes and vapor chambers are particularly noteworthy for their efficiency and effectiveness across a range of applications. This article examines the fundamental differences between these two thermal conduits, investigating their operational mechanisms, performance metrics, and the distinct advantages and disadvantages they offer. As engineers seek to improve thermal efficiency in their designs, the pertinent question arises: which solution—heat pipe or vapor chamber—delivers superior performance for specific applications?

Define Heat Pipes and Vapor Chambers

Heat exchangers serve as passive two-phase thermal transfer devices, adeptly transferring energy through the processes of evaporation and condensation of a working fluid. Typically constructed from , these devices incorporate a wick structure alongside a working fluid that evaporates at the hot end and condenses at the cooler end. This operational mechanism facilitates efficient , rendering essential in a multitude of applications, including high-performance computing and aerospace systems. Notably, loop thermal conduits possess the capability to function against gravity, providing flexibility in challenging installations, whereas diode thermal systems are specifically engineered for temperature management in spacecraft and electronics, effectively preventing reverse thermal flow.

In contrast, specialized flat thermal conduits are meticulously designed to distribute energy across a broader surface area. They operate on the same principles as conventional thermal pipes but feature a significantly larger surface area, which is critical for applications requiring uniform temperature distribution. This characteristic makes thermal enclosures particularly effective in regulating heat from various sources, such as high-performance electronics like GPUs and CPUs, where minimizing temperature variations across surfaces is vital for optimal performance.

Recent advancements in in 2025 have focused on enhancing such as copper and aluminum, which significantly improve transfer performance. These innovations are further complemented by the development of compact designs that enable seamless integration into contemporary electronic devices, addressing the escalating demand for efficient in an increasingly miniaturized market. The thermal conduit market is projected to expand from USD 3.5 billion in 2024 to USD 5.8 billion by 2033, indicating substantial growth and significance within the sector. Emerging economies in the Asia-Pacific region, particularly China and India, present considerable growth opportunities for thermal conduits. As the thermal transfer market continues to evolve, understanding the key characteristics and applications of is imperative for engineers aiming to enhance in their designs.

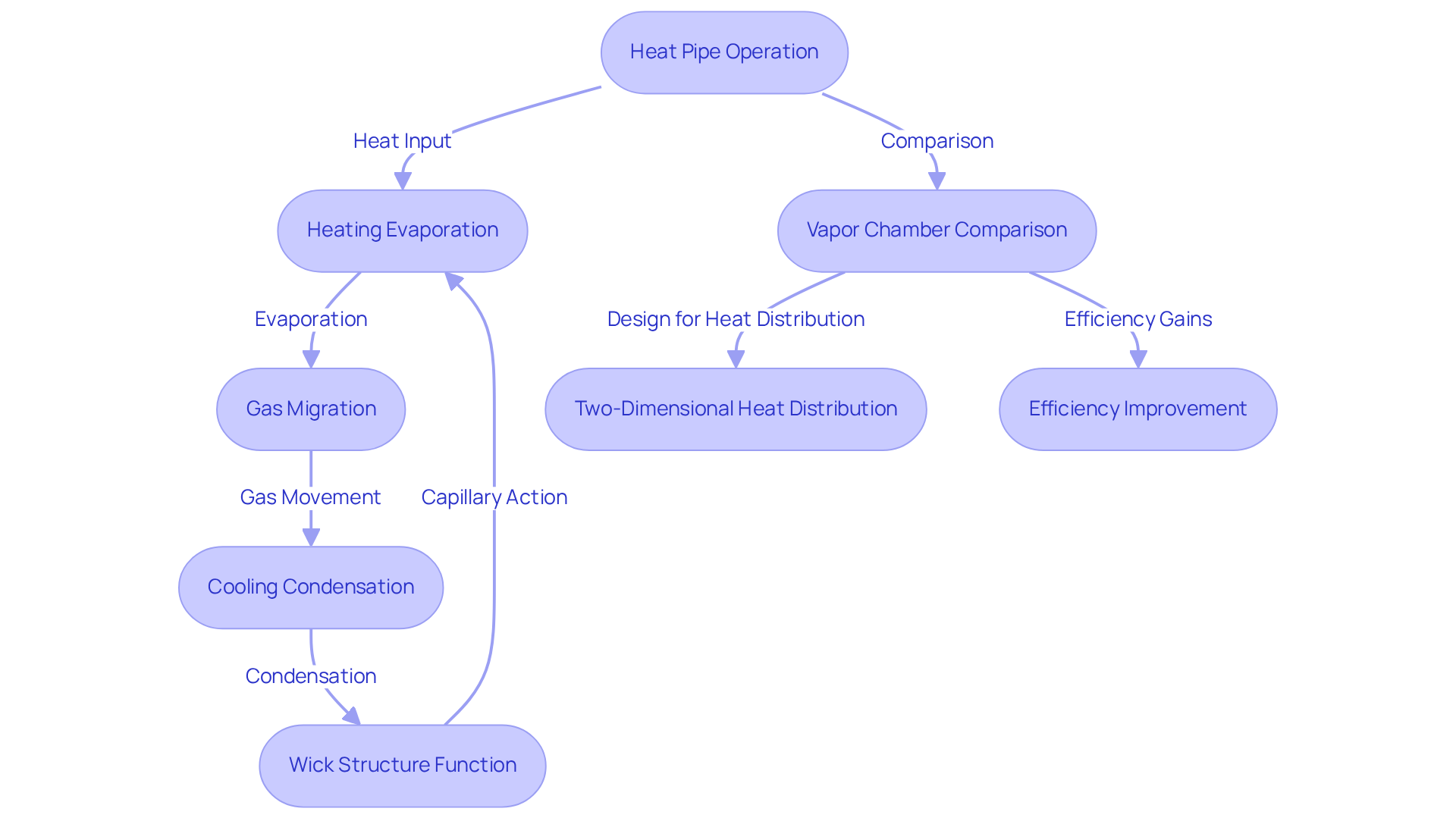

Explain Operational Mechanisms

Heat pipes function by utilizing a working fluid that evaporates upon heating, generating gas that migrates to the cooler end of the pipe, highlighting the differences between . The vapor subsequently condenses back into liquid, releasing heat in the process. This continuous cycle is facilitated by a wick structure that draws the liquid back to the energy source through , ensuring uninterrupted operation.

The comparison of heat pipe vs shows that they operate similarly but are designed to distribute heat across two dimensions. They incorporate a ; however, their flat configuration allows for uniform heat distribution over a larger surface area. This characteristic is particularly beneficial in scenarios requiring simultaneous management of multiple thermal sources, as fluid-filled devices effectively mitigate hotspots and maintain consistent temperatures. Notably, the comparison of heat pipe vs vapor chamber devices shows that they can transfer thermal energy 10 to 50 times more efficiently than solid metal structures, significantly enhancing their performance metrics.

For instance, a fluid-filled sink can achieve a temperature difference (ΔT) of merely 3°C from the center to the outer edge, exemplifying remarkable . Additionally, studies indicate that evaporation units can result in a 5°C reduction in temperature for the System on a Chip (SoC) compared to conventional copper base heat sinks, emphasizing the advantages of heat pipe vs vapor chamber in real-world applications. Furthermore, gas-filled enclosures can improve by 20-30% relative to traditional pipes under similar conditions, making them an appealing option for thermal control.

The practical applications of are evident in various electronics, such as gaming laptops and tablets, where they have been extensively employed to enhance cooling efficiency. In 2024 alone, over 12 million vaporization units were deployed globally, highlighting their growing importance in modern . Importantly, when comparing heat pipe vs vapor chamber, the latter can provide up to 20 years of consistent, passive temperature transfer without a decline in thermal performance, emphasizing their .

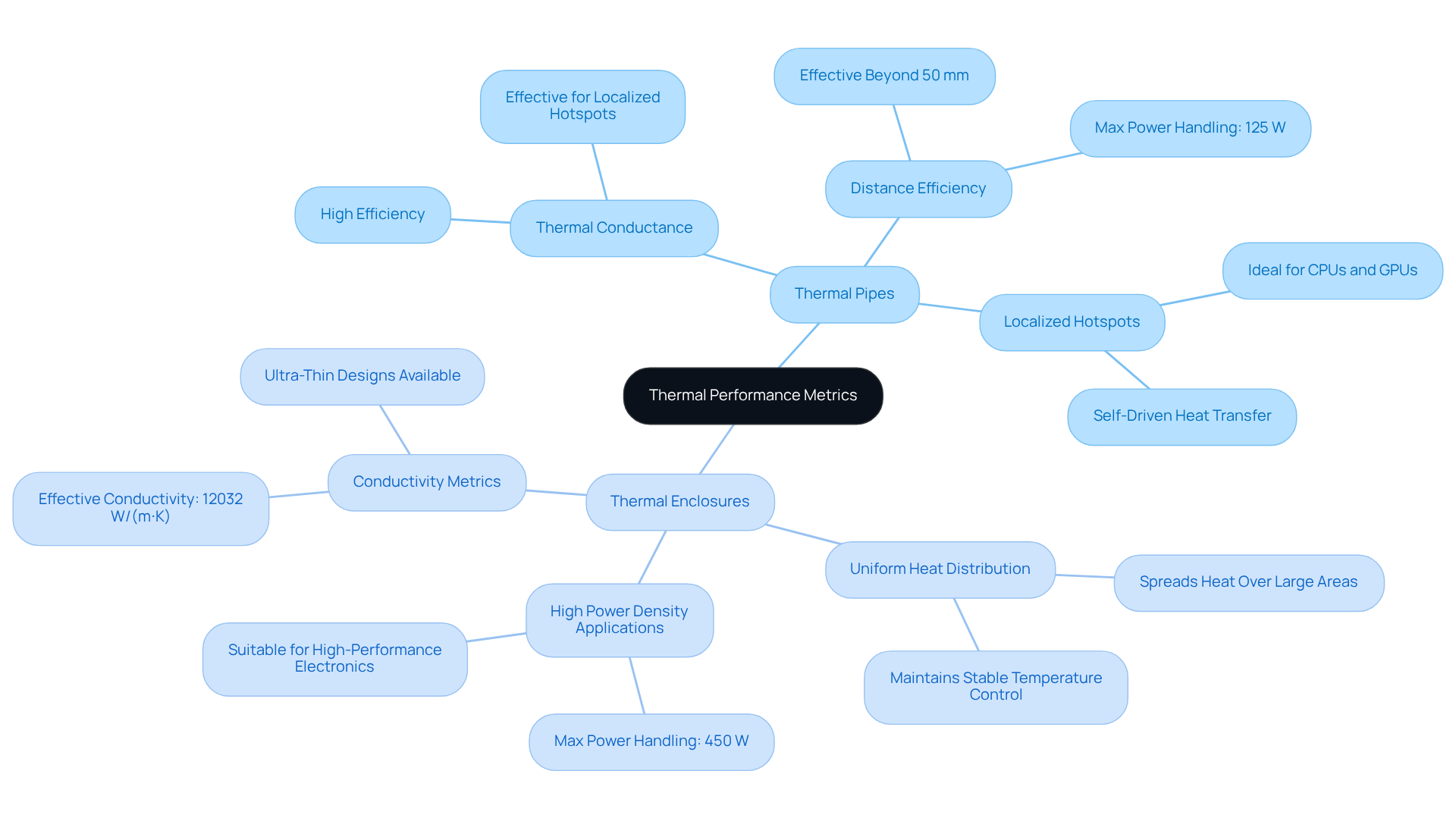

Compare Thermal Performance Metrics

Thermal pipes are renowned for their exceptional thermal conductance, facilitating with minimal temperature gradients. They are particularly effective in applications requiring point-to-point , especially over distances exceeding 50 mm. Their design allows for the efficient transfer of energy from localized hotspots, making them ideal for environments where space is constrained.

Conversely, in the discussion of , to distribute heat uniformly across a broader surface area, rendering them especially advantageous for . They can achieve that surpass those of copper, with some ultra-thin gas-filled enclosures exhibiting thermal conductivities of up to 12032 W/(m⋅K). This remarkable capability positions thermal units as particularly suitable for , such as CPUs and GPUs, where maintaining stable temperature control is critical.

Recent research underscores that even under elevated thermal loads, adeptly managing power densities of up to 50 W/cm². For instance, a cooling system designed for temperature regulation can accommodate up to 450 watts, significantly outperforming thermal conduits, which typically peak at approximately 125 watts in horizontal configurations. This makes the comparison of heat pipe vs vapor chamber crucial in applications where uniform thermal distribution is imperative, ensuring optimal performance and reliability in electronic devices.

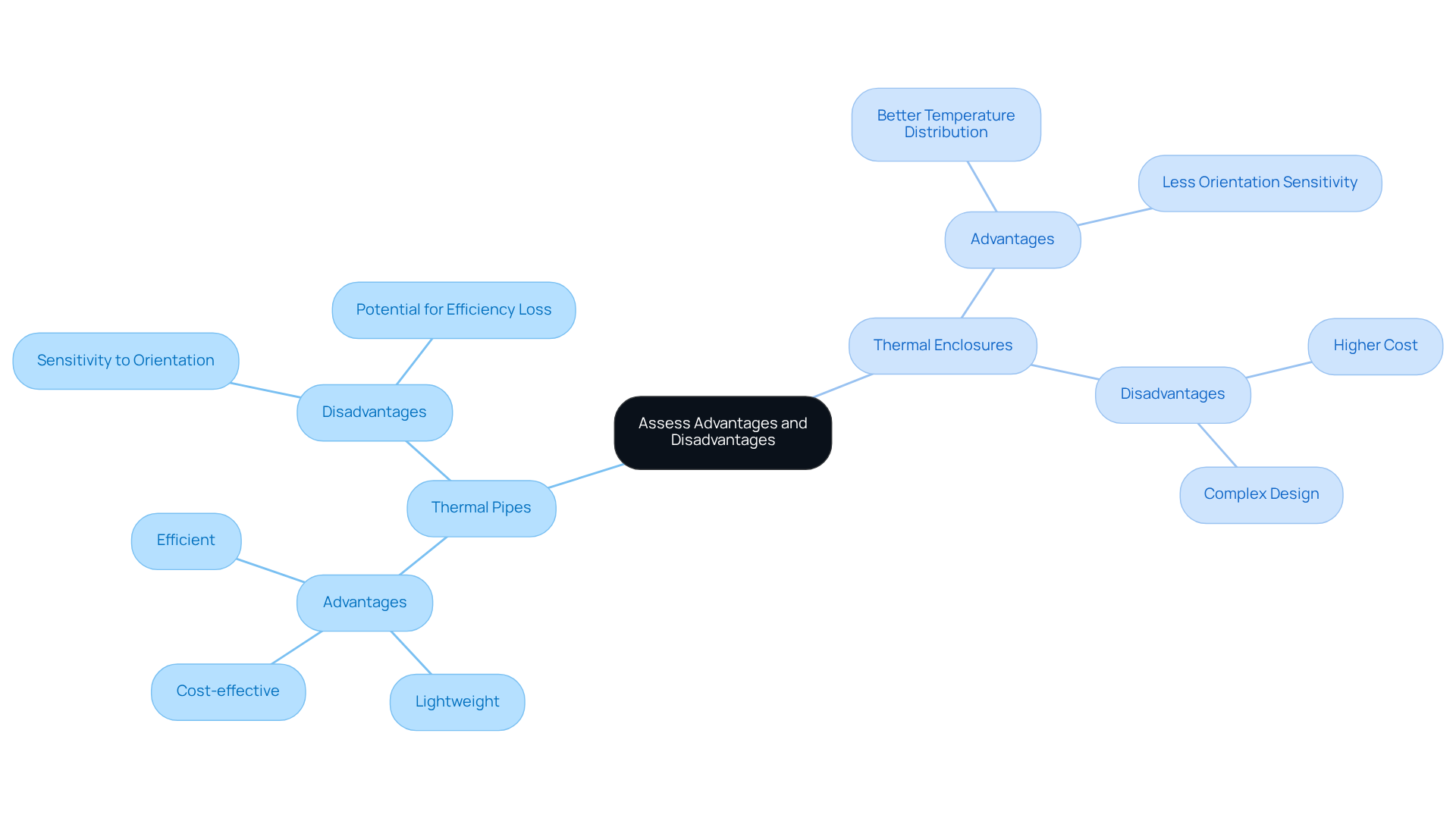

Assess Advantages and Disadvantages

Thermal pipes are celebrated for their cost-effectiveness, straightforward design, and exceptional efficiency in transferring warmth over considerable distances. Their —requiring no external power—render them suitable for a variety of applications, particularly in scenarios where space and weight constraints are paramount. However, they possess certain limitations. Their performance is sensitive to orientation, necessitating a specific elevation difference between the evaporator and condenser ends to function optimally. Excessive thermal input can lead to dry-out or flooding, significantly diminishing efficiency.

Conversely, thermal enclosures, while typically more expensive to produce, excel in their ability to distribute temperature and exhibit less sensitivity to orientation. This characteristic makes them particularly adept at managing various thermal sources and maintaining consistent temperatures, which is crucial in high-performance applications. Nevertheless, their and higher production costs can present challenges in specific contexts. For instance, in consumer electronics, although evaporation systems can enhance , their cost may not justify the benefits when simpler thermal solutions might suffice.

Expert opinions suggest that while steam enclosures offer superior , remain a more economical choice for numerous applications, especially where are a factor. Ultimately, the decision regarding should take into account , , and performance needs.

Conclusion

Understanding the distinctions between heat pipes and vapor chambers is crucial for engineers aiming to optimize thermal management in their designs. Both technologies serve as effective thermal transfer solutions, yet they cater to different needs and applications. Heat pipes excel in point-to-point thermal transfer, making them ideal for constrained spaces, while vapor chambers offer superior surface area coverage for uniform heat distribution, particularly in high-performance electronics.

Key points have been highlighted throughout this discussion, including:

- The operational mechanisms of each device

- Their thermal performance metrics

- The advantages and disadvantages associated with their use

Heat pipes are celebrated for their cost-effectiveness and simplicity, whereas vapor chambers shine in their ability to handle multiple thermal sources with consistent efficiency. The choice between the two ultimately hinges on specific application requirements, performance needs, and budget considerations.

As the demand for efficient thermal management solutions continues to rise, particularly in the electronics sector, understanding these technologies becomes increasingly vital. Engineers are encouraged to carefully assess their project needs and consider the unique benefits each system offers. By doing so, they can make informed decisions that not only enhance performance but also contribute to the longevity and reliability of their designs.

Frequently Asked Questions

What are heat pipes and vapor chambers?

Heat pipes and vapor chambers are passive two-phase thermal transfer devices that efficiently transfer energy through the processes of evaporation and condensation of a working fluid, typically within sealed metal tubes.

How do heat pipes operate?

Heat pipes operate by having a wick structure and a working fluid that evaporates at the hot end and condenses at the cooler end, facilitating effective thermal control.

In what applications are heat pipes commonly used?

Heat pipes are essential in various applications, including high-performance computing and aerospace systems.

What is the difference between loop thermal conduits and diode thermal systems?

Loop thermal conduits can function against gravity, providing flexibility in challenging installations, while diode thermal systems are designed specifically for temperature management in spacecraft and electronics, preventing reverse thermal flow.

How are specialized flat thermal conduits different from conventional thermal pipes?

Specialized flat thermal conduits are designed to distribute energy across a broader surface area, which is critical for applications that require uniform temperature distribution.

What advancements have been made in vapor chamber technology recently?

Recent advancements in vapor chamber technology have focused on enhancing thermal conductivity using superior materials like copper and aluminum, along with compact designs for better integration into modern electronic devices.

What is the projected growth of the thermal conduit market?

The thermal conduit market is projected to grow from USD 3.5 billion in 2024 to USD 5.8 billion by 2033.

Which regions present significant growth opportunities for thermal conduits?

Emerging economies in the Asia-Pacific region, particularly China and India, present considerable growth opportunities for thermal conduits.

Why is it important for engineers to understand heat pipes and vapor chambers?

Understanding the key characteristics and applications of heat pipes and vapor chambers is imperative for engineers aiming to enhance thermal efficiency in their designs.