Overview

The article emphasizes the critical selection and evaluation steps for axial cooling fans, spotlighting essential criteria such as:

- Airflow requirements

- Static pressure

- Noise levels

- Size

- Power consumption

- Durability

These criteria are vital for ensuring optimal performance and reliability across various applications. It is underscored that a comprehensive evaluation and comparison of specifications, manufacturer reputation, and real-world testing are imperative for identifying the most appropriate fan tailored to specific thermal management needs.

Introduction

Understanding the intricacies of axial cooling fans is crucial for enhancing the performance and longevity of electronic systems. These fans, engineered to move air parallel to their axis, provide a distinctive solution for diverse applications, including HVAC systems and industrial processes. However, the selection of the appropriate axial cooling fan necessitates navigating a complex web of specifications and criteria. Engineers must consider several essential factors to ensure optimal performance and reliability in their cooling solutions.

Understand Axial Cooling Fans: Basics and Functionality

Axial cooling fans are engineered to move air parallel to the axis of rotation, which enables them to efficiently manage high volumes of air at low pressure. This design makes them particularly suitable for applications such as the refrigeration of electronic components, ventilation, air circulation, and the implementation of an axial cooling fan. The essential components of an axial cooling fan include the motor, blades, and housing. Upon activation, the motor spins the blades, generating a pressure differential that draws air into the fan and expels it in the same direction. This principle is crucial for evaluating their performance in electronics cooling systems that utilize an axial cooling fan, where maintaining optimal temperatures is vital for the longevity and efficiency of components.

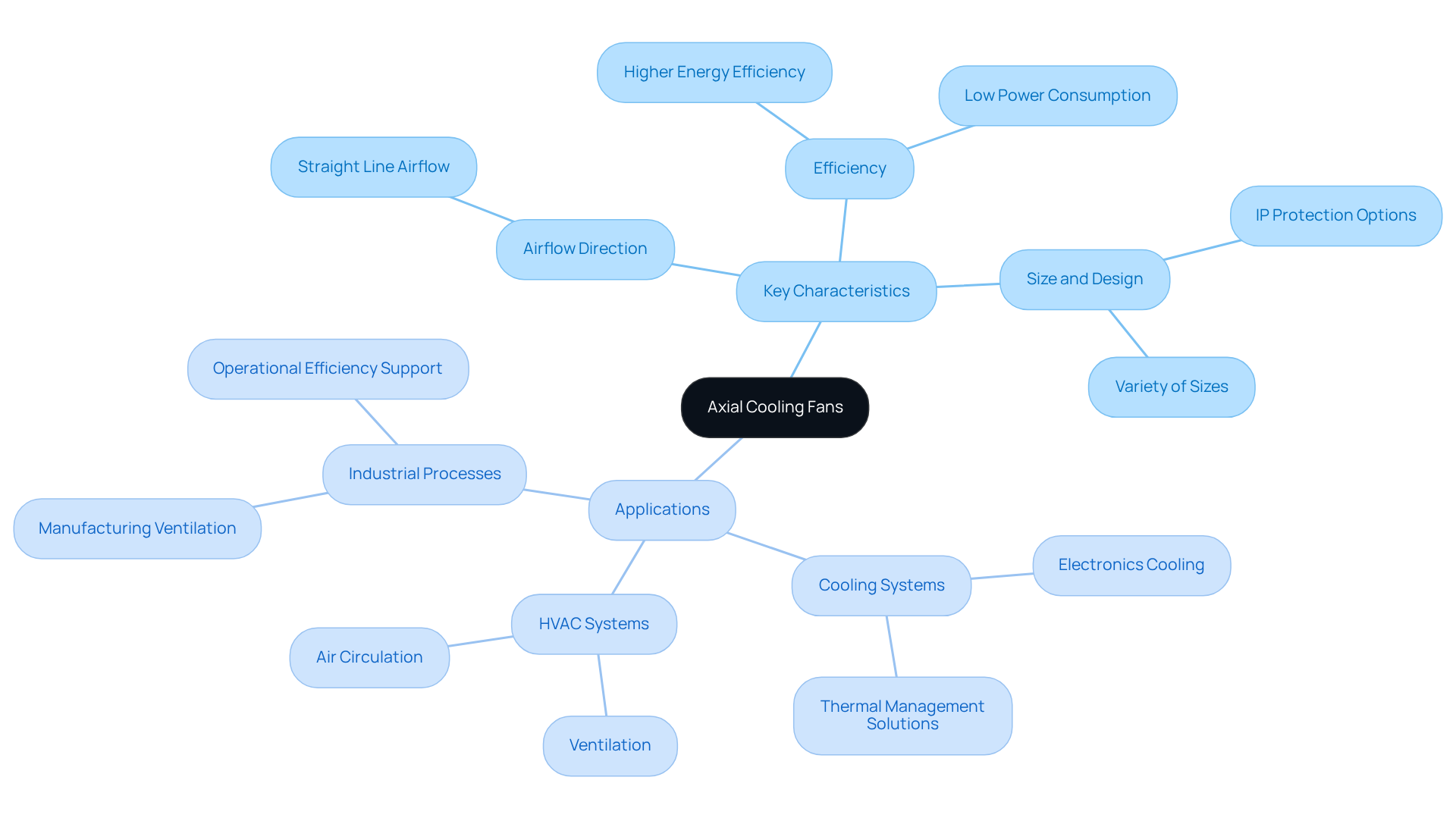

Key Characteristics of Axial Fans

- Airflow Direction: Air is directed in a straight line, making axial fans ideal for applications requiring focused airflow.

- Efficiency: Axial cooling fans typically exhibit higher energy efficiency than centrifugal devices in high-volume, low-pressure scenarios.

- Size and Design: Axial blowers are available in various sizes, allowing customization to meet specific spatial and operational requirements. Most models also offer IP protection upon request, enhancing their adaptability for diverse environments.

Applications

Axial fans are extensively utilized in:

- Cooling Systems: Effectively dissipating heat from electronic devices to ensure optimal performance, leveraging Gagner-Toomey’s comprehensive portfolio of thermal management solutions, including centrifugal blowers and heat sinks.

- HVAC Systems: Facilitating ventilation and air circulation in residential and commercial settings using an axial cooling fan.

- Industrial Processes: Maintaining necessary ventilation in manufacturing environments through the use of an axial cooling fan to support operational efficiency.

By comprehending these fundamentals, engineers can more accurately evaluate the suitability of axial devices for their specific projects, thereby ensuring effective thermal management and system reliability.

Identify Key Selection Criteria for Axial Cooling Fans

When selecting axial cooling fans, several key criteria must be considered to ensure optimal performance, particularly when leveraging the innovative solutions offered by Gagner-Toomey Associates, a leading provider of cooling solutions for electronics and beyond:

Airflow Requirements

- CFM (Cubic Feet per Minute): Determine the required airflow for your application. Higher CFM ratings signify greater ventilation capacity, which is crucial for cooling high-power electronics. For instance, a system dissipating 200W requires 0.5 m³/min of air movement to maintain a maximum temperature rise of 20 °C. Furthermore, a fan generating 5 CFM can ventilate a 5 ft x 5 ft x 5 ft enclosure in roughly 25 minutes, emphasizing the significance of sufficient circulation in maintaining optimal temperatures. It’s also important to select a fan that can produce double the required airflow to account for real-world conditions, as noted by Johann Tang.

Static Pressure

- Pressure Ratings: Understand the static pressure requirements of your system. Axial blowers excel in low-pressure applications, but if your system demands higher static pressure, alternative types may be necessary. Gagner-Toomey’s extensive portfolio includes DC input axial cooling fans that are optimized for performance, ensuring that you can find a suitable solution for your specific setup. It’s essential to choose a fan that can overcome the resistance faced in your particular setup, as incorrect selection can result in insufficient temperature management. The case study “Understanding Airflow Requirements and Static Pressure” emphasizes the importance of calculating airflow requirements based on cooling needs.

Noise Levels

- Decibel Ratings: Consider the noise output of the fan, especially in environments where noise reduction is critical. Search for devices with lower dB ratings for quieter operation, which is particularly crucial in environments like home theaters or audio equipment. Gagner-Toomey’s devices are created with low noise levels considered, making them suitable for sensitive applications.

Size and Form Factor

- Dimensions: Ensure the fan fits within the designated space. Measure the available area and compare it with the fan’s dimensions to avoid compatibility issues that could hinder performance. Gagner-Toomey provides a wide range of products including ventilation devices from 15 to 280mm and DC input blowers from 15 to 225mm, addressing diverse size needs.

Power Consumption

- Voltage and Current Ratings: Evaluate the power requirements of the fan. Selecting a fan with appropriate voltage and current ratings is crucial for compatibility with your system, ensuring efficient operation without overloading your power supply. Gagner-Toomey’s fans are optimized for efficiency, helping to minimize power consumption.

Durability and Reliability

- Material and Build Quality: Assess the materials used in the fan’s construction. Fans constructed from premium materials typically exhibit longer lifespans and superior operation under stress, which is crucial for ensuring reliability in challenging applications. Gagner-Toomey’s dedication to quality guarantees that their temperature control solutions are built to last, with options for custom designs available.

By thoughtfully evaluating these criteria and utilizing the extensive services from Gagner-Toomey Associates, engineers can select axial cooling fans that effectively satisfy their particular thermal requirements and operational limitations, ensuring optimal performance and durability of electronic systems.

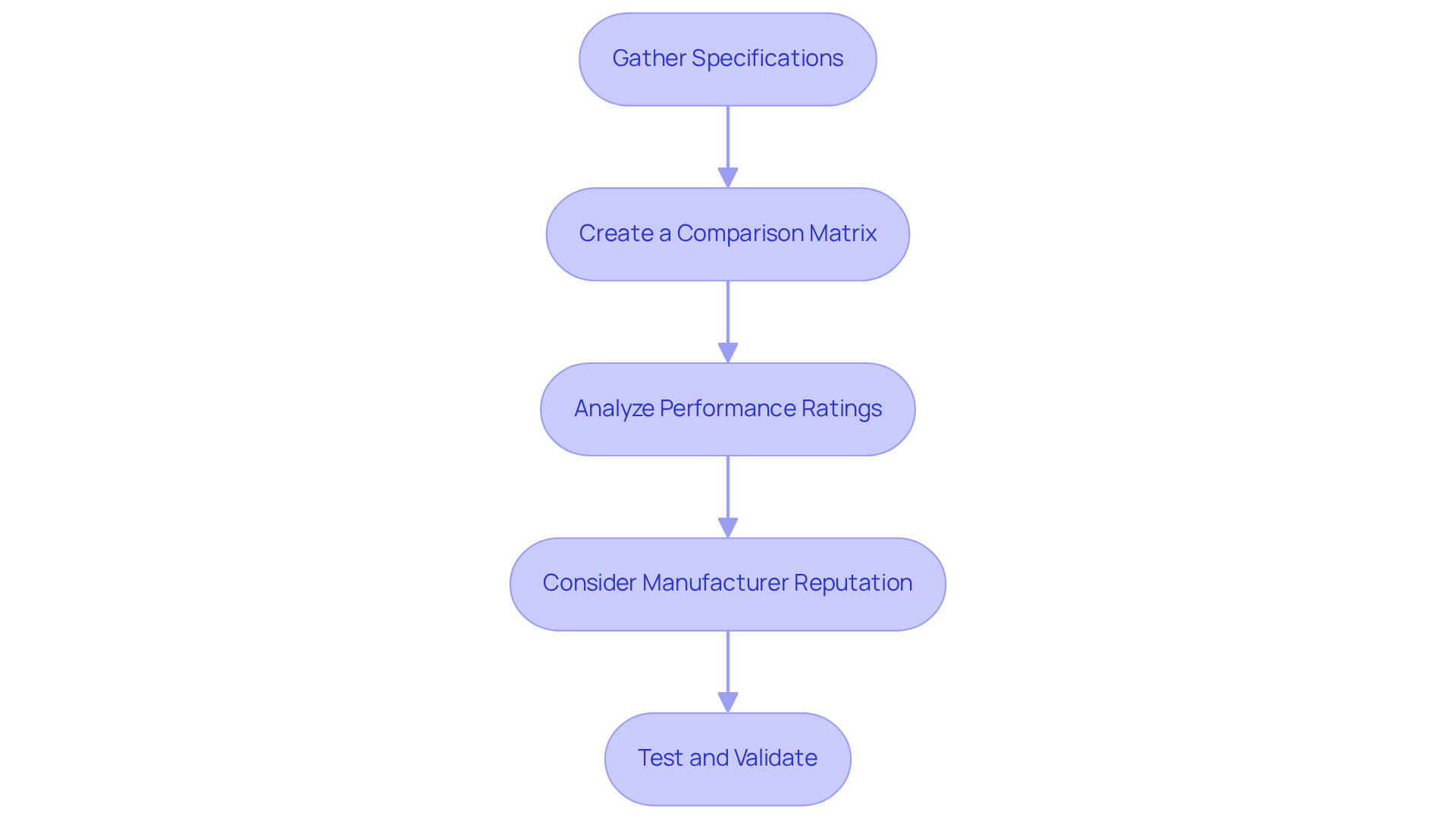

Evaluate and Compare Axial Cooling Fan Options

After you have identified the key selection criteria, the next step is to evaluate and compare various options for the axial cooling fan. Here’s how to approach this process:

Gather Specifications

- Datasheets: Collect datasheets from manufacturers for the fans you are considering. These documents offer crucial details on air movement, pressure ratings, noise levels, and power consumption.

Create a Comparison Matrix

- Matrix Setup: Create a table to compare the specifications of each fan side by side. Include columns for airflow (CFM), static pressure, noise level (dB), size, power consumption, and price.

Analyze Performance Ratings

- Performance Metrics: Look for performance ratings and reviews from other users. This information can offer insights into the reliability and efficiency of the devices in practical applications. User feedback is crucial as it highlights potential issues or advantages based on practical experiences.

Consider Manufacturer Reputation

- Brand Reliability: Research the manufacturers of the fans. Established brands often have a track record of quality and customer service, which can be crucial for long-term support. Understanding the reputation of manufacturers can guide you in selecting reliable products.

Test and Validate

- Prototype Testing: If possible, test the fans in your specific application. This hands-on evaluation can reveal how well the fan performs under actual operating conditions. Implementing a comprehensive testing protocol, as recommended by industry standards such as those from the Air Movement and Control Association (AMCA), ensures that the fans meet performance expectations and comply with quality assurance measures.

By following these steps, you can effectively evaluate and compare options for an axial cooling fan, ensuring that you select the best fan for your cooling needs.

Conclusion

Axial cooling fans are indispensable for maintaining optimal temperatures across diverse applications, ranging from electronics cooling to HVAC systems. Grasping their functionality and selection criteria is vital for effective thermal management. This article has presented a thorough guide to the fundamentals of axial fans, their essential characteristics, and the critical steps in selecting the appropriate fan for specific requirements.

The discussion has addressed pivotal factors, including:

- airflow requirements

- static pressure

- noise levels

- size

- power consumption

- durability

Each of these elements plays a crucial role in assessing the suitability of an axial cooling fan for any given application. By adhering to a systematic approach—gathering specifications, creating comparison matrices, and analyzing performance ratings—engineers can make informed decisions that bolster the reliability and efficiency of their systems.

Ultimately, the selection of the right axial cooling fan transcends immediate cooling needs; it is fundamental to ensuring long-term operational success and sustainability. By leveraging the insights and strategies delineated in this guide, stakeholders can optimize their cooling solutions, thereby enhancing the performance and longevity of their electronic systems. Embracing these best practices will lead to a more efficient and effective approach to thermal management across various industries.

Frequently Asked Questions

What are axial cooling fans designed to do?

Axial cooling fans are designed to move air parallel to the axis of rotation, efficiently managing high volumes of air at low pressure.

What are the main components of an axial cooling fan?

The essential components of an axial cooling fan include the motor, blades, and housing.

How does an axial cooling fan operate?

Upon activation, the motor spins the blades, generating a pressure differential that draws air into the fan and expels it in the same direction.

What are the key characteristics of axial cooling fans?

Key characteristics include directed airflow in a straight line, higher energy efficiency compared to centrifugal devices in high-volume, low-pressure scenarios, and availability in various sizes for customization.

In what applications are axial cooling fans commonly used?

Axial cooling fans are commonly used in cooling systems for electronic devices, HVAC systems for ventilation and air circulation, and industrial processes for maintaining ventilation in manufacturing environments.

Why is understanding axial cooling fans important for engineers?

Understanding axial cooling fans allows engineers to accurately evaluate their suitability for specific projects, ensuring effective thermal management and system reliability.