Overview

This article identifies seven leading manufacturers of heat pipes specifically designed for electronics cooling solutions. It highlights their innovative technologies and tailored designs, showcasing their commitment to addressing the growing demands for effective thermal management as electronic devices continue to shrink in size and increase in power. As the landscape of electronics evolves, the need for efficient thermal solutions becomes paramount, positioning these manufacturers at the forefront of industry advancements.

Introduction

As electronic devices become increasingly compact and powerful, the demand for effective thermal management solutions has reached a critical juncture. This article delves into the leading heat pipe manufacturers that are pioneering innovation in electronics cooling, showcasing their unique technologies and significant contributions to the industry. Given the plethora of options available, engineers are faced with the challenge of selecting the most effective solutions to address the evolving demands of heat management in high-performance applications.

Gagner-Toomey Associates: Leading Provider of Innovative Cooling Solutions

Gagner-Toomey Associates stands as a distinguished sales organization, dedicated to delivering innovative cooling products tailored for the electronics industry. By addressing complex challenges in power and temperature management, Gagner-Toomey effectively represents a diverse array of manufacturers. This ensures that engineers gain access to cutting-edge technologies that significantly enhance the performance and efficiency of electronic components.

As the demand for effective thermal management solutions continues to escalate—particularly with the increasing miniaturization of devices and advancements in high-power electronics—Gagner-Toomey’s unwavering commitment to excellence establishes it as a vital partner among heat pipe manufacturers in the development of electronics cooling.

This foundation paves the way for a closer examination of the top thermal conductors, which play an essential role in providing efficient cooling methods for electronic applications.

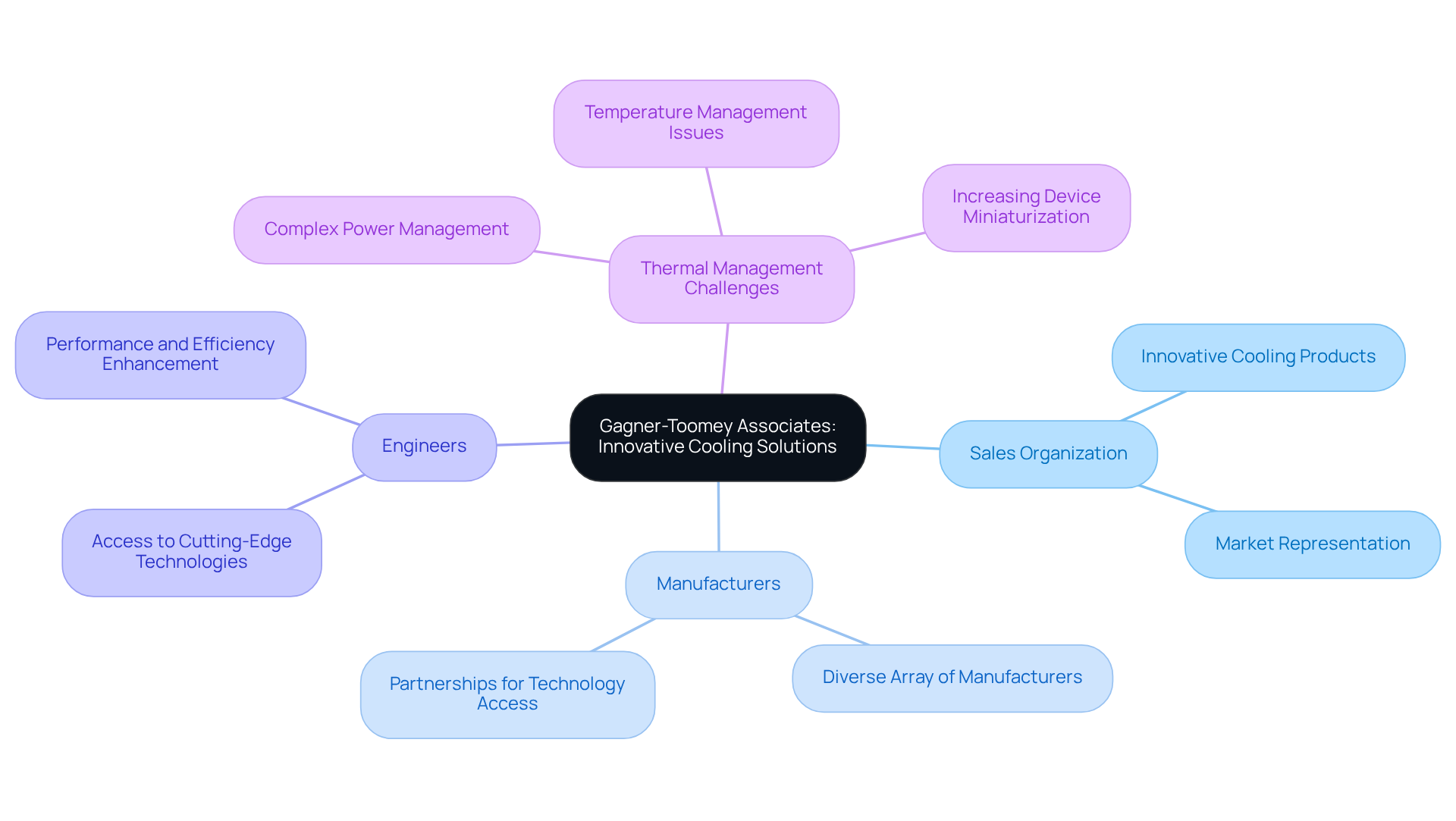

Thermal Management Technologies: Pioneering Heat Pipe Solutions for Electronics

Thermal Management Technologies is recognized as a pioneer in thermal conductors tailored for the electronics industry. Their innovative designs focus on maximizing energy efficiency while minimizing spatial requirements. By utilizing advanced materials and manufacturing techniques, alongside rigorous quality assurance processes, they produce thermal conduits that effectively transfer heat away from critical components, ensuring optimal performance and reliability.

Recent breakthroughs in heat pipe technology by heat pipe manufacturers, including ultra-thin gas-filled enclosures that achieve heat conductivities of up to 12032 W/(m⋅K) and energy savings of up to 75% in cooling applications, highlight their dedication to research and development. This positions them as a leader among heat pipe manufacturers in the heat management sector, tackling the evolving cooling challenges faced by high-performance electronics.

Furthermore, the importance of testing and validation for temperature control systems is crucial to confirm that these solutions function as intended under real-world conditions.

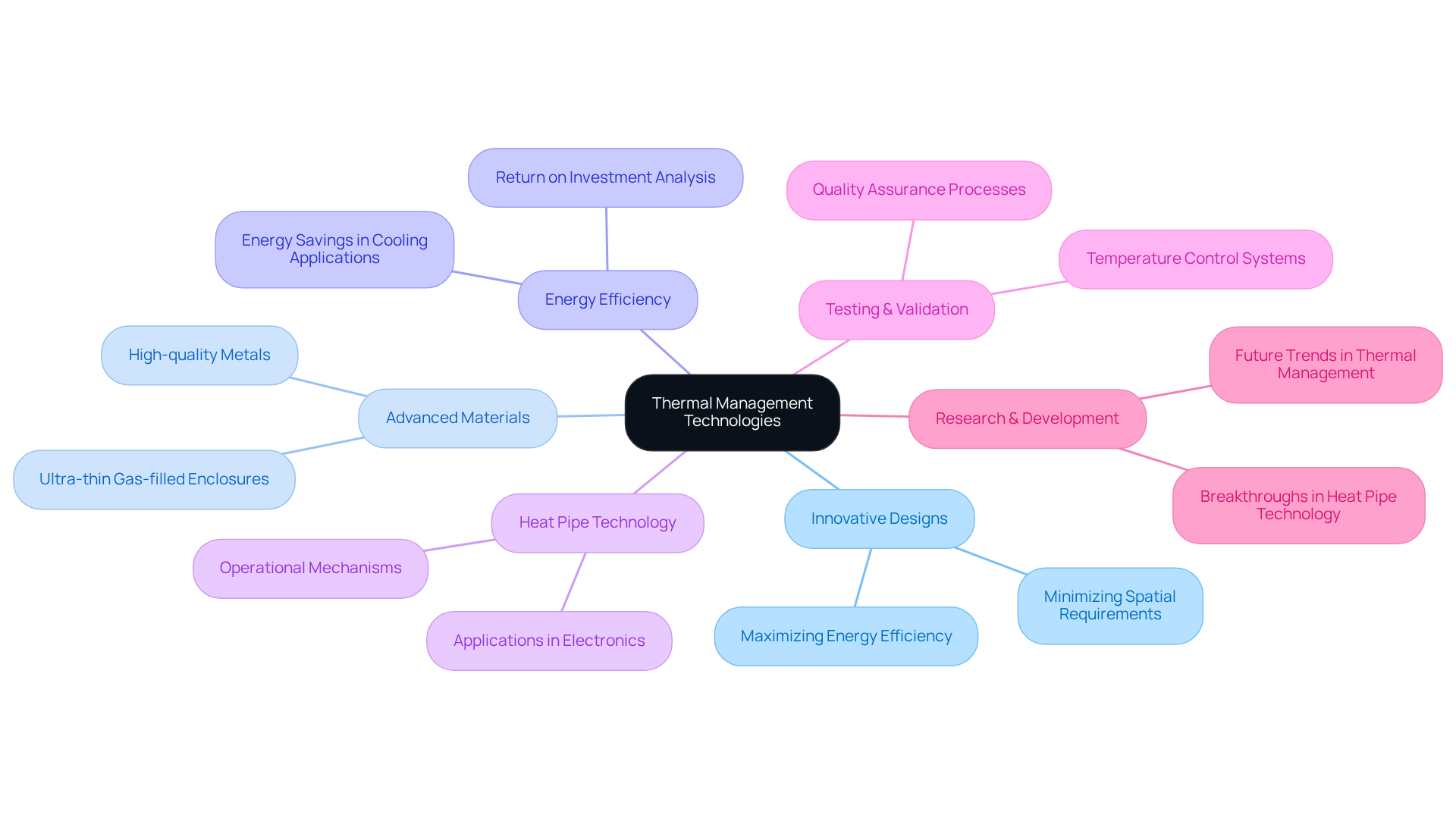

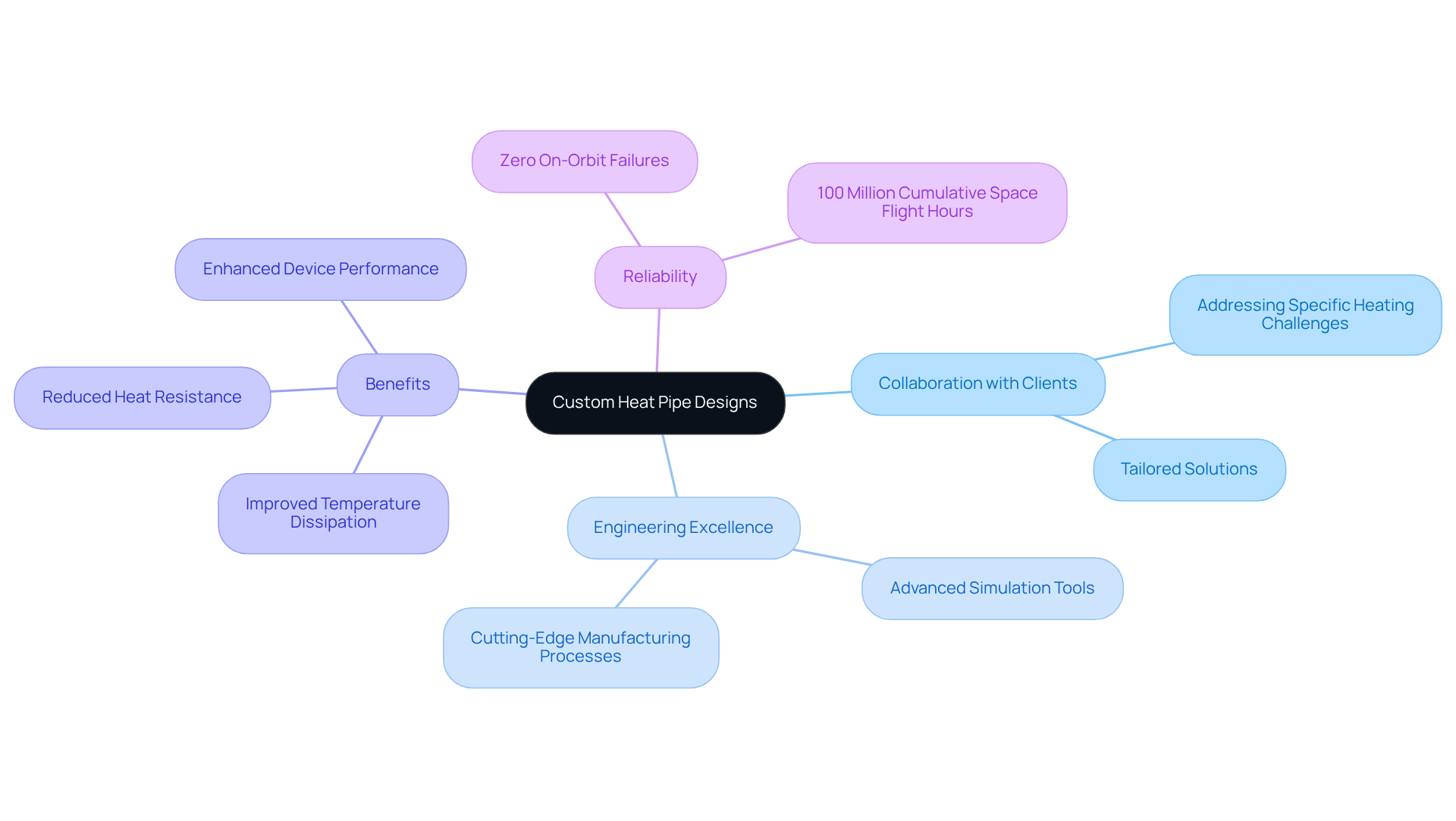

Advanced Cooling Technologies: Custom Heat Pipe Designs for Optimal Performance

Advanced Cooling Technologies excels in developing custom heat pipe designs that meet the distinct requirements of electronic applications, showcasing the expertise of heat pipe manufacturers. Their engineering group collaborates closely with clients to address specific heating challenges, ensuring that each solution is not only effective but also integrates seamlessly into existing systems.

By utilizing advanced simulation tools alongside cutting-edge manufacturing processes, they optimize both performance and reliability. This commitment to personalization leads to significant enhancements in heat control across a range of electronic devices, effectively meeting the industry’s growing demands in 2025 and beyond.

The advantages of such customized approaches include:

- Improved temperature dissipation

- Reduced heat resistance

- Enhanced overall device performance

These benefits make them indispensable in contemporary electronics. Industry specialists emphasize that the ability of heat pipe manufacturers to tailor heat management systems is crucial for addressing the evolving needs of high-performance electronics.

Furthermore, ACT’s heat pipes have achieved effective conductivities ranging from 50,000 to 200,000 W/mK, with the company boasting a proven track record of zero on-orbit failures, supported by 100 million cumulative space flight hours that underscore their reliability.

John Hartenstine, Vice President of Operations & Quality Assurance at ACT, states, “This milestone reflects ACT’s dedication to providing high-quality, flight-tested heating options to the space industry.” This underscores the critical role of personalization in heat management solutions.

Aavid Thermalloy: Comprehensive Heat Pipe Products for Electronics

Aavid Thermalloy stands out with its extensive selection of thermal transfer products specifically tailored for the electronics sector. Their offerings include a variety of designs, such as flat and tubular conduits, meticulously engineered to meet diverse temperature control needs. Aavid’s commitment to quality and innovation is underscored by an impressive portfolio of 33 patents, reflecting their dedication to advancing thermal transfer technology.

With effective conductivities ranging from 50,000 to 200,000 W/mK, their products are adept at managing significant thermal loads efficiently. Rigorous evaluation procedures confirm that Aavid’s thermal conduits maintain functionality under harsh conditions, including shock and vibration, with tests demonstrating durability through as many as 1,200 freeze-thaw cycles without distortion.

This reliability, combined with extensive industry experience and an average shipping time of 1-3 days, positions Aavid Thermalloy as a trusted partner for engineers seeking advanced cooling solutions in the rapidly evolving electronics landscape.

However, engineers must also consider potential limitations of thermal conduits, such as the capillary limit, which can impact performance in specific applications. Furthermore, integrating Gagner-Toomey Associates’ solenoid and rotary boost pumps into the thermal management strategy can significantly enhance cooling efficiency, offering a comprehensive approach to managing thermal loads in electronic systems.

Cooler Master: Innovative Heat Pipe Technology for Enhanced Cooling

Cooler Master has pioneered advancements in thermal management technology, particularly with the introduction of 3D conduits that significantly enhance cooling efficiency. This innovative design transforms traditional U-shaped thermal pipes into a trident configuration, thereby increasing the contact area with heatsink fins. As a result, both heat conductivity and dissipation are markedly improved, leading to lower CPU temperatures and enhanced performance.

For instance, the V-Series CPU Air Coolers, inspired by automotive design, utilize this 3DHP technology to deliver outstanding heat management while ensuring compatibility with the latest Intel and AMD processors. Notably, these coolers can accommodate thermal design power (TDP) ratings of up to 340W, demonstrating their proficiency in managing high-performance components effectively.

The V8 Ace cooler, featuring four 3D heatpipes, is anticipated to outperform the V4 series in cooling efficiency. Real-world applications of this technology have shown a reduction in hotspots and a more uniform heating across heatsink fins, optimizing cooling and prolonging the lifespan of critical electronic components. Additionally, the Hyper 411 Nano cooler employs direct contact technology for rapid temperature transfer, making it ideal for compact designs.

Cooler Master’s commitment to innovation in cooling technologies reinforces its position as a leader among heat pipe manufacturers in the electronics cooling market. As highlighted by Michael Pabia, ‘Cooler Master today announced its latest innovation: the V-Series CPU Air Coolers, featuring proprietary 3D Heat Pipe (3DHP) technology,’ which underscores the company’s dedication to merging performance with reliability, a commitment that reflects the standards set by heat pipe manufacturers. The anticipated commercialization of the 3DHP technology in 2025 further emphasizes the significance of these advancements.

Thermal Solutions, Inc.: Tailored Heat Pipe Solutions for Electronics

Thermal Solutions, Inc. is dedicated to delivering personalized designs that reflect the expertise of heat pipe manufacturers, tailored to the specific needs of electronic applications. Their engineering team collaborates closely with clients to identify unique heat-related challenges, ensuring that each design is meticulously optimized for superior performance.

By harnessing advanced materials and innovative manufacturing techniques, Thermal Solutions guarantees dependable and efficient cooling solutions. This commitment to personalization not only enhances the heat regulation of electronic devices but also yields significant performance improvements.

For instance, customized thermal conduit designs effectively manage temperature dissipation in high-performance components, such as CPUs and GPUs, thus ensuring optimal functionality and longevity.

As the demand for effective cooling solutions continues to escalate, particularly in 2025, the importance of tailored heat pipes from heat pipe manufacturers in electronics applications becomes increasingly critical, positioning Thermal Solutions as a preferred partner for engineers looking to tackle complex heat-related challenges.

Furthermore, with the advanced heat management materials market anticipated to expand substantially, the necessity for customized solutions is clearer than ever.

Engineers are also invited to attend the Thermal Live Fall 2025 event on October 7-8, where they can discover the latest advancements in thermal management.

Heat Pipe Technology, Inc.: High-Performance Heat Pipes for Electronics

Heat Transfer Technology, Inc. excels in providing high-performance thermal conduits tailored for the rigorous demands of modern electronics. Their advanced products are meticulously designed to ensure effective temperature transfer and reliable performance, even in the most challenging environments. Notably, the latest trends in heat pipe technology for 2025 emphasize how heat pipe manufacturers are integrating intelligent temperature management systems that adjust in real-time, enhancing energy efficiency and sustainability. This innovation is crucial as electronics continue to shrink, making efficient heat management increasingly complex.

In this context, Gagner-Toomey Associates distinguishes itself with its advanced solenoid and rotary boost pumps, engineered for precision applications in heat management. The solenoid pump, capable of operating up to 16 Bar, features a DC brushless motor and an EMI suppression circuit, ensuring precise control and low noise operation. Such inventive cooling methods enhance heat pipe technology, providing heat pipe manufacturers with a comprehensive range of air movers and temperature control solutions.

Gagner-Toomey Associates’ commitment to quality and innovation positions them as a reliable partner for engineers seeking advanced cooling options, adept at addressing the evolving challenges of thermal management in contemporary applications. Their solutions not only optimize performance but also bolster the overall reliability of electronic systems, establishing them as a trusted choice within the industry.

Conclusion

The exploration of leading heat pipe manufacturers reveals a dynamic landscape shaped by innovation and the pressing need for effective thermal management in electronics. Each of the highlighted companies, from Gagner-Toomey Associates to Thermal Solutions, Inc., showcases a commitment to developing cutting-edge solutions that cater to the increasing complexities of heat management in modern electronic devices.

Key insights from the article emphasize the importance of tailored designs, advanced materials, and innovative technologies that enhance cooling efficiency. Companies like Advanced Cooling Technologies and Cooler Master exemplify how customization and pioneering designs can significantly improve thermal performance. In contrast, Aavid Thermalloy and Heat Pipe Technology, Inc. demonstrate the reliability and durability required in high-performance applications. These manufacturers are not merely responding to current demands; they are also anticipating future challenges in the electronics sector.

As the industry continues to evolve, the significance of effective heat management solutions cannot be overstated. Engineers and manufacturers are encouraged to embrace these advancements, as they play a critical role in optimizing the performance and longevity of electronic components. Engaging with these leading companies will not only enhance product reliability but also drive the innovation necessary for the next generation of electronics. The ongoing developments in heat pipe technology underscore the necessity for collaboration and exploration in achieving superior thermal management solutions.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is a distinguished sales organization that provides innovative cooling products specifically tailored for the electronics industry, addressing complex challenges in power and temperature management.

How does Gagner-Toomey Associates support engineers?

Gagner-Toomey Associates represents a diverse array of manufacturers, ensuring that engineers have access to cutting-edge technologies that enhance the performance and efficiency of electronic components.

Why is thermal management increasingly important in electronics?

The demand for effective thermal management solutions is rising due to the increasing miniaturization of devices and advancements in high-power electronics.

What role does Thermal Management Technologies play in the electronics industry?

Thermal Management Technologies is recognized as a pioneer in thermal conductors for the electronics industry, focusing on maximizing energy efficiency while minimizing spatial requirements.

What advancements have been made in heat pipe technology?

Recent advancements include ultra-thin gas-filled enclosures that achieve heat conductivities of up to 12032 W/(m⋅K) and energy savings of up to 75% in cooling applications.

Why is testing and validation important for temperature control systems?

Testing and validation are crucial to ensure that temperature control solutions function as intended under real-world conditions, confirming their reliability and effectiveness.