Overview

This article delves into the design, applications, and insights surrounding forward curve fans—specialized centrifugal blowers recognized for their exceptional efficiency in delivering high airflow at low pressure. It elucidates their critical characteristics, including blade shape and impeller design, while exploring their diverse applications across sectors such as electronics cooling and HVAC systems. Furthermore, it evaluates the advantages and disadvantages of these fans, providing engineers with the necessary insights to select the most suitable fan for specific engineering challenges.

Introduction

Forward curve fans, recognized for their exceptional efficiency and versatility, are integral to a variety of engineering applications, spanning from HVAC systems to electronics cooling. This article explores the intricate design principles, operational mechanics, and diverse applications of these centrifugal blowers, providing engineers with essential insights to optimize their utilization.

However, as with any technology, it is imperative to understand the trade-offs between performance and efficiency, raising critical questions:

- Are forward curve fans genuinely the optimal choice for every scenario?

- Do their limitations necessitate a more nuanced approach?

Define Forward Curve Fans: Principles and Functionality

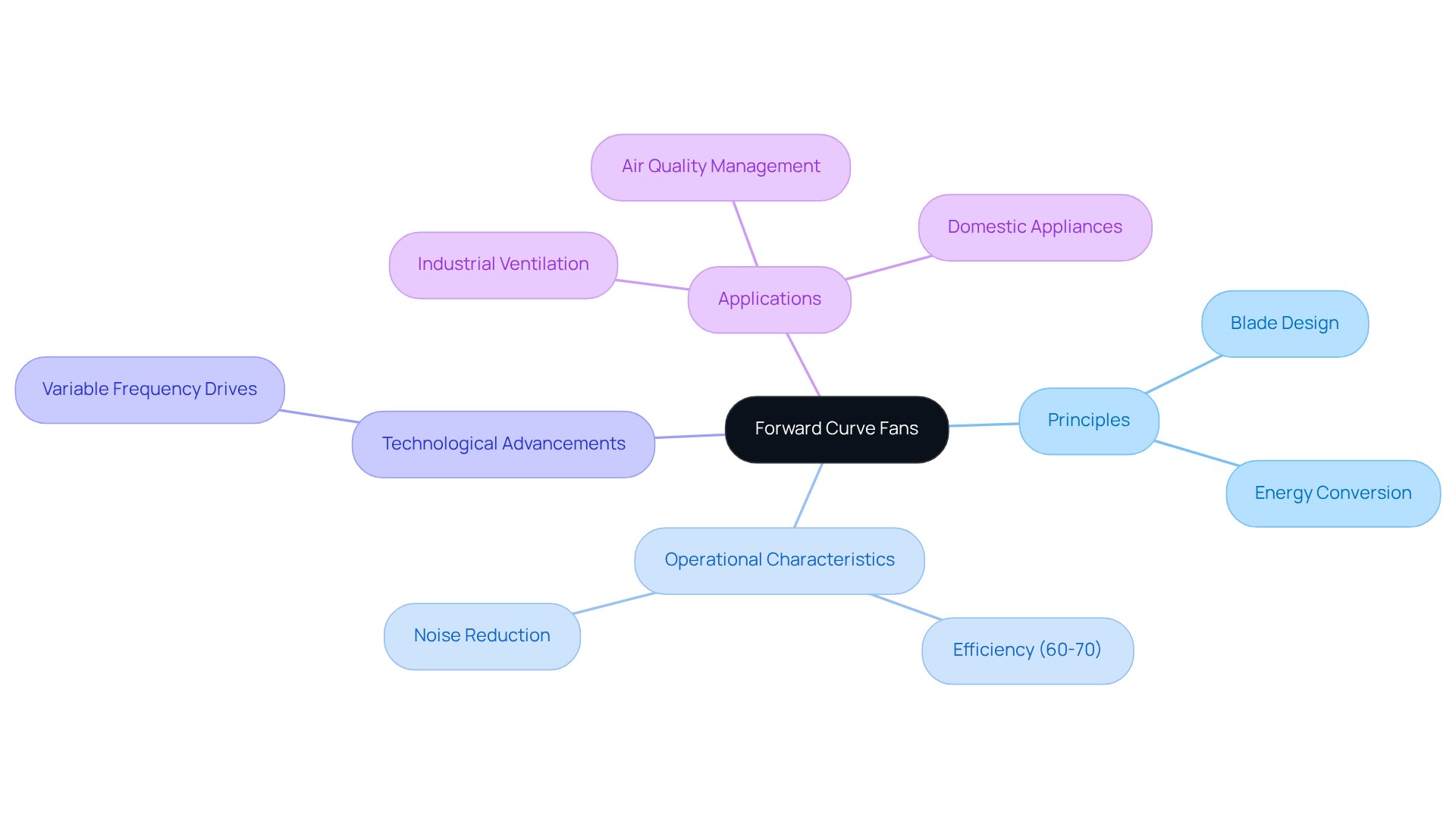

Forward blades enthusiasts, commonly referred to as centrifugal blowers, are characterized by blades that bend in the direction of rotation. This distinctive design allows for the effective conversion of rotational energy into kinetic energy, leveraging centrifugal force to draw air into the fan and expel it at an increased velocity.

Typically employed in scenarios necessitating , these devices excel in ventilation and cooling systems. Their operational efficiency is remarkable, boasting an efficiency range of 60-70%, which renders them suitable for various engineering applications.

Furthermore, aerodynamic devices are meticulously engineered to operate silently and effectively at reduced speeds, thereby enhancing their practicality in environments where noise minimization is paramount.

Recent advancements in centrifugal fan technology, particularly the integration of variable frequency drives (VFDs), facilitate precise control of fan speed and airflow rates, optimizing energy consumption and enhancing overall system performance.

The practical applications of airflow devices extend to industrial ventilation, air quality management, and domestic appliances, underscoring their flexibility and efficiency in addressing diverse engineering requirements.

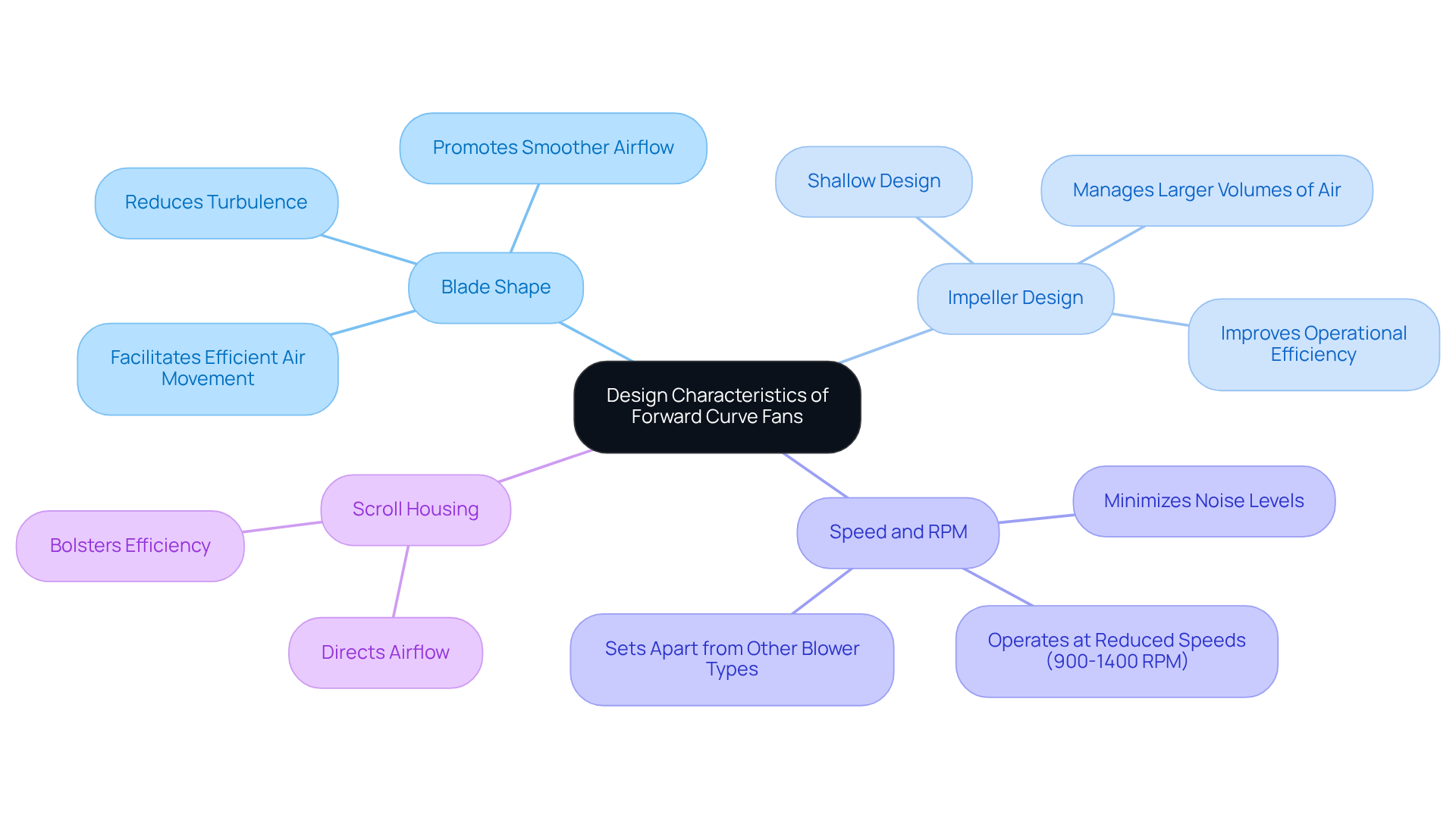

Explore Design Characteristics and Mechanics of Forward Curve Fans

The design of forward curve fans includes several pivotal characteristics that are essential for optimal performance.

- Blade Shape: The blades are shaped as a forward curve fan, facilitating efficient air movement. This innovative design not only promotes smoother airflow but also significantly reduces turbulence, enhancing overall effectiveness.

- Impeller Design: Typically, the impeller is shallow, which plays a crucial role in the fan’s capacity to manage larger volumes of air at lower pressures, thereby improving its operational efficiency.

- Speed and RPM: Forward curve fans generally operate at reduced speeds, ranging from 900 to 1400 RPM. This characteristic is instrumental in minimizing noise levels, setting them apart from other blower types.

- Scroll Housing: Often, the fan is encased in a scroll housing that directs airflow and bolsters efficiency.

Understanding these is vital for engineers when selecting a fan for specific applications, as they directly influence both performance and efficiency.

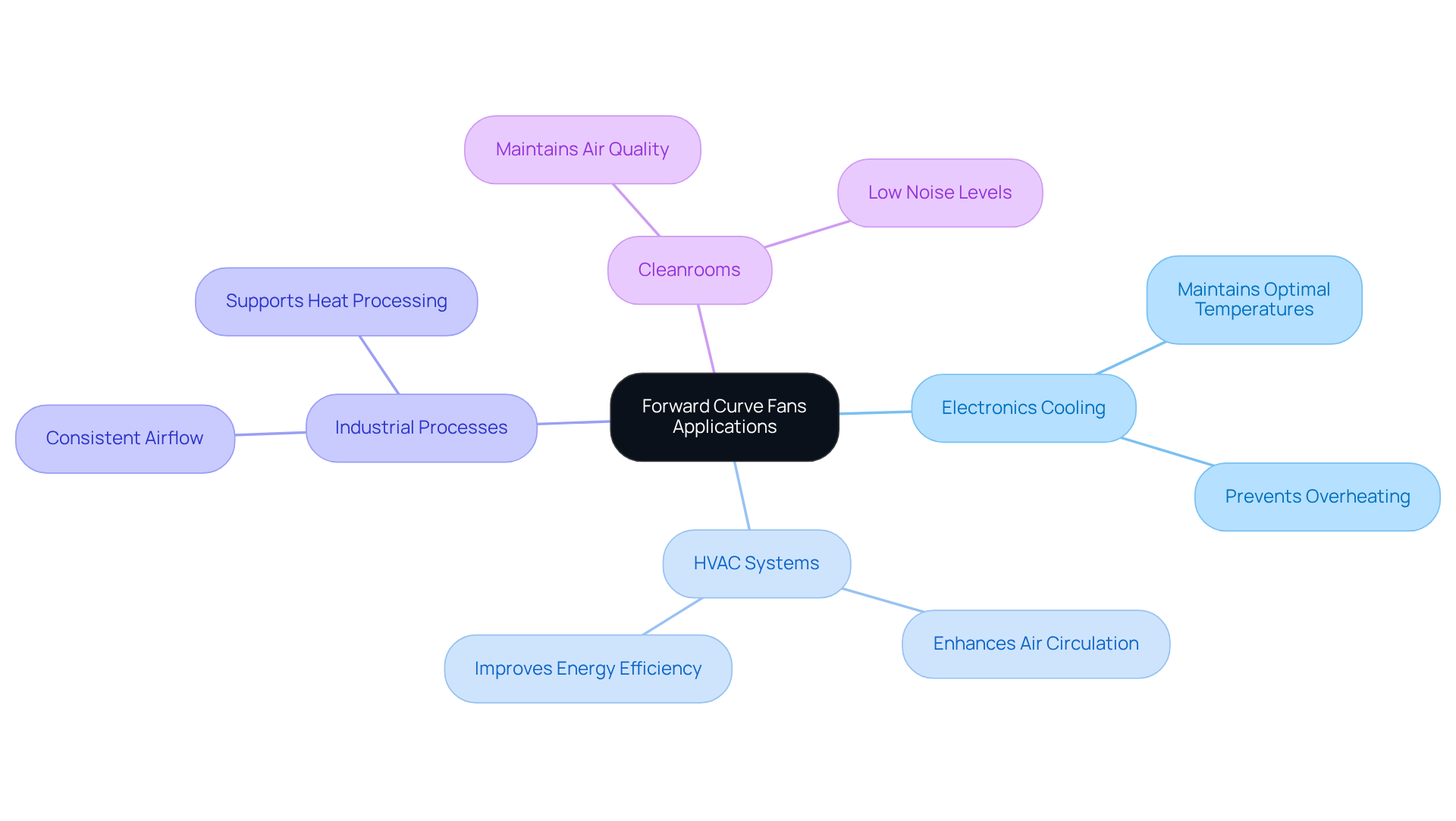

Identify Applications of Forward Curve Fans in Electronics and Beyond

Forward projections are extensively utilized across multiple sectors due to their efficiency and effectiveness. Key applications include:

- Electronics Cooling: Commonly employed in electronic devices, these projections help maintain optimal operating temperatures, particularly in server enclosures and data centers.

- HVAC Systems: In heating, ventilation, and air conditioning systems, propeller-style blowers play a crucial role in effectively circulating air, thereby enhancing overall system performance.

- Industrial Processes: These devices are integral to industrial ovens, furnaces, and other heat-processing equipment, where consistent airflow is critical.

- Cleanrooms: Their low noise levels and efficient airflow render them suitable for cleanroom environments, where maintaining air quality is essential.

Understanding these applications empowers engineers to utilize effectively in their designs.

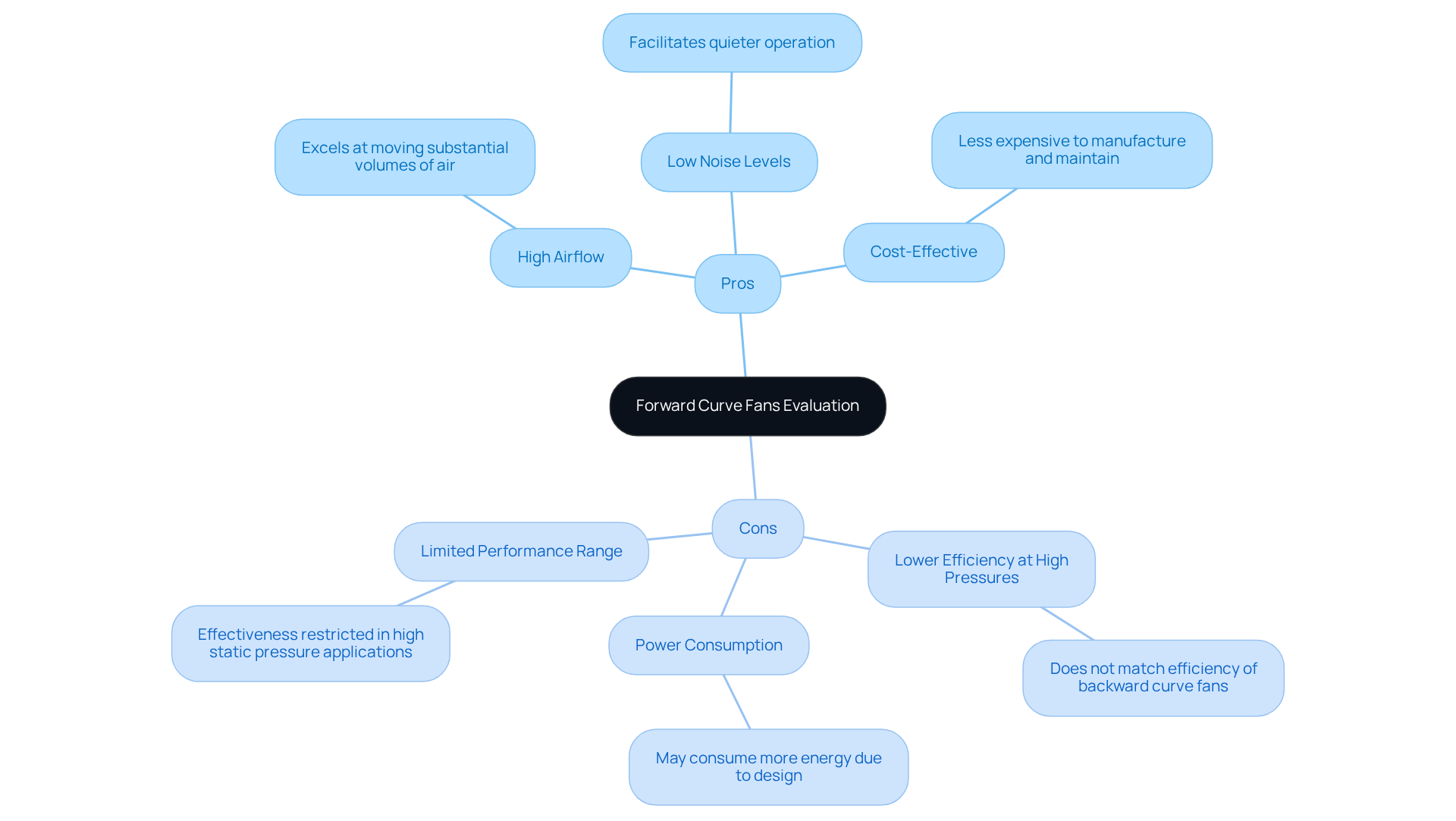

Evaluate Pros and Cons of Forward Curve Fans for Engineering Solutions

When evaluating the , it is crucial to assess them carefully.

Pros:

- High Airflow: These fans excel at moving substantial volumes of air, rendering them suitable for a variety of applications.

- Low Noise Levels: Their design facilitates quieter operation compared to other fan types, a significant advantage in noise-sensitive environments.

- Cost-Effective: Typically, forward airflow devices are less expensive to manufacture and maintain than alternative options.

Cons:

- Lower Efficiency at High Pressures: In scenarios requiring elevated pressure, they do not match the efficiency of backward curve fans.

- Power Consumption: Due to their design prioritizing airflow over efficiency, forward airflow devices may consume more energy.

- Limited Performance Range: Their effectiveness can be restricted in applications that demand high static pressure.

By carefully evaluating these factors, engineers can assess the suitability of forward curve fans for their specific engineering solutions.

Conclusion

The exploration of forward curve fans underscores their pivotal role in various engineering applications, characterized by unique design and operational efficiency. These centrifugal blowers, with blades curving in the direction of rotation, effectively convert rotational energy into kinetic energy, making them indispensable in scenarios requiring high airflow at low pressure. Their ability to operate quietly and efficiently positions them as the preferred choice in environments where noise control is essential.

This article examined key aspects such as design characteristics, practical applications, and the pros and cons of forward curve fans. The design elements—blade shape, impeller design, and scroll housing—are crucial in determining performance and efficiency. Moreover, their applications span electronics cooling, HVAC systems, and industrial processes, showcasing their versatility. While these fans offer significant benefits, including high airflow and low noise levels, potential drawbacks such as lower efficiency at high pressures and increased power consumption must also be considered.

In light of the insights presented, understanding the intricacies of forward curve fans is vital for engineers seeking effective airflow solutions in their designs. As technology evolves, staying informed about the latest trends and advancements in forward curve fan engineering empowers professionals to make informed decisions that enhance system performance and energy efficiency. Embracing these insights elevates engineering practices and contributes to sustainable, innovative solutions across various sectors.

Frequently Asked Questions

What are forward curve fans?

Forward curve fans, also known as centrifugal blowers, are fans with blades that bend in the direction of rotation, allowing them to convert rotational energy into kinetic energy effectively.

What is the primary function of forward curve fans?

The primary function of forward curve fans is to draw air into the fan and expel it at an increased velocity, making them suitable for applications requiring high airflow at low pressure.

What is the efficiency range of forward curve fans?

Forward curve fans have an operational efficiency range of 60-70%, making them effective for various engineering applications.

In what scenarios are forward curve fans typically used?

They are typically used in ventilation and cooling systems, as well as in industrial ventilation, air quality management, and domestic appliances.

How do forward curve fans minimize noise?

These fans are engineered to operate silently and effectively at reduced speeds, which is beneficial in environments where noise minimization is important.

What recent advancements have been made in centrifugal fan technology?

Recent advancements include the integration of variable frequency drives (VFDs), which allow for precise control of fan speed and airflow rates, optimizing energy consumption and improving overall system performance.