Overview

Maximizing the efficiency of centrifugal fans is essential for optimal performance in various industrial applications. This can be achieved through:

- Strategic design choices

- Regular maintenance

- Appropriate fan selection tailored to specific application requirements

Understanding impeller design is crucial, as it directly impacts airflow dynamics. Furthermore, maintaining optimal airflow and implementing preventive maintenance practices are vital for enhancing both performance and longevity. By focusing on these elements, industry professionals can ensure that centrifugal fans operate at peak efficiency, ultimately leading to improved operational outcomes.

Introduction

Centrifugal fans are integral to numerous industrial applications, ranging from HVAC systems to manufacturing processes, where efficient airflow management is paramount. For engineers, grasping the mechanics and various types of these fans is crucial for optimizing performance and minimizing energy consumption. Yet, numerous factors influence fan efficiency, presenting a significant challenge: how can engineers effectively select and maintain the appropriate centrifugal fan to satisfy specific operational requirements? This article explores essential strategies for maximizing centrifugal fan efficiency, offering valuable insights that can lead to improved performance and substantial cost savings.

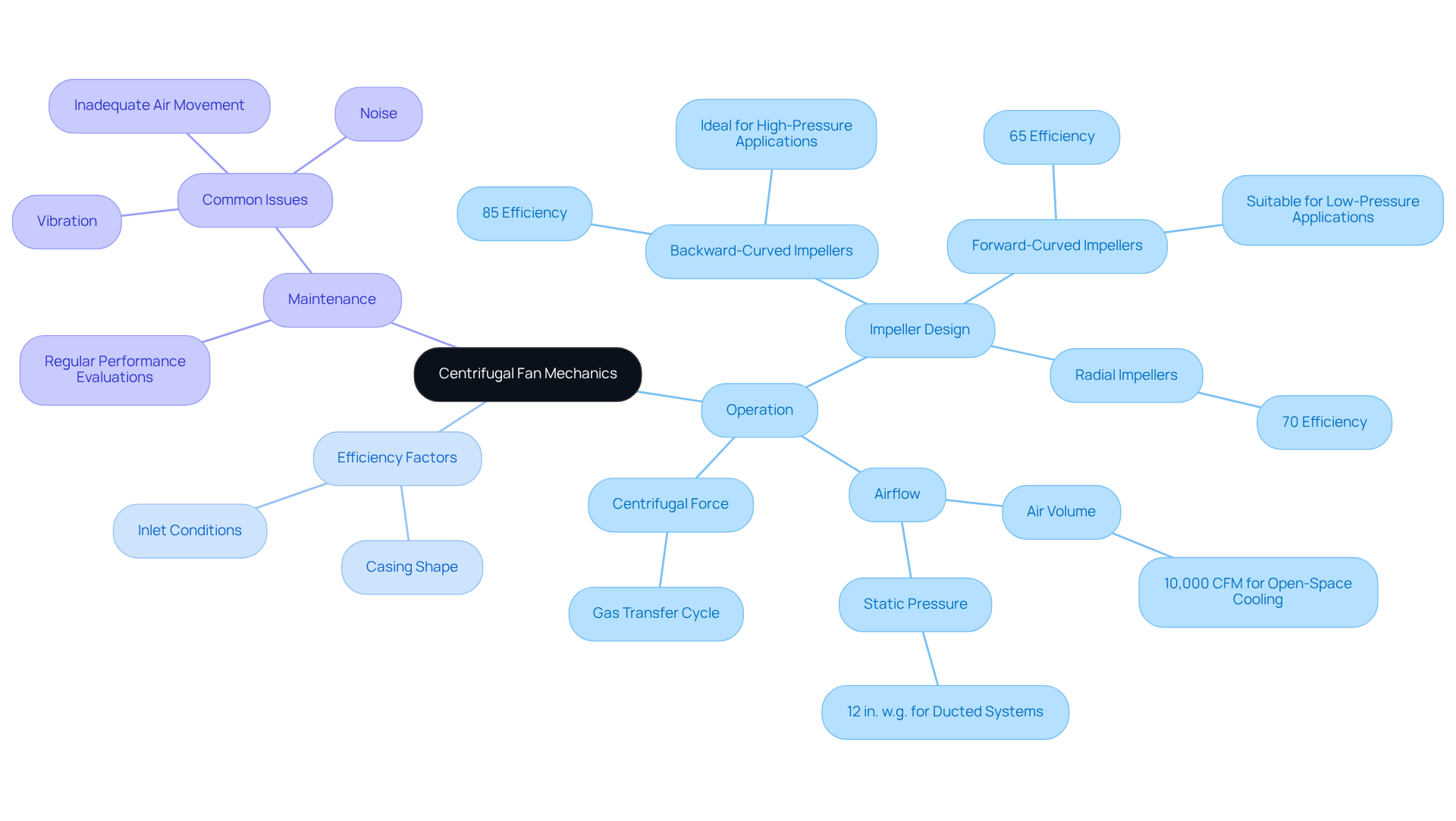

Understand Centrifugal Fan Mechanics

Centrifugal fans operate by utilizing a rotating impeller to increase the velocity of an airstream. As air enters the fan, it is drawn into the impeller’s center and propelled outward by centrifugal force, effectively converting kinetic energy into potential energy and elevating air pressure. Several critical factors influence centrifugal fan efficiency, such as impeller design, casing shape, and inlet conditions. Engineers must prioritize achieving uniform airflow at the fan’s inlet, minimizing turbulence to enhance performance.

For instance, backward-curved impellers can achieve up to 85% aerodynamic efficiency, making them ideal for high-pressure applications. Understanding these mechanics is essential for troubleshooting and optimizing systems to improve centrifugal fan efficiency across a variety of applications, from HVAC to industrial processes.

Regular maintenance and performance evaluations are crucial for addressing common issues such as vibration, inadequate air movement, and noise, ensuring that centrifugal blowers operate at peak capacity and positively impact energy management in industrial environments.

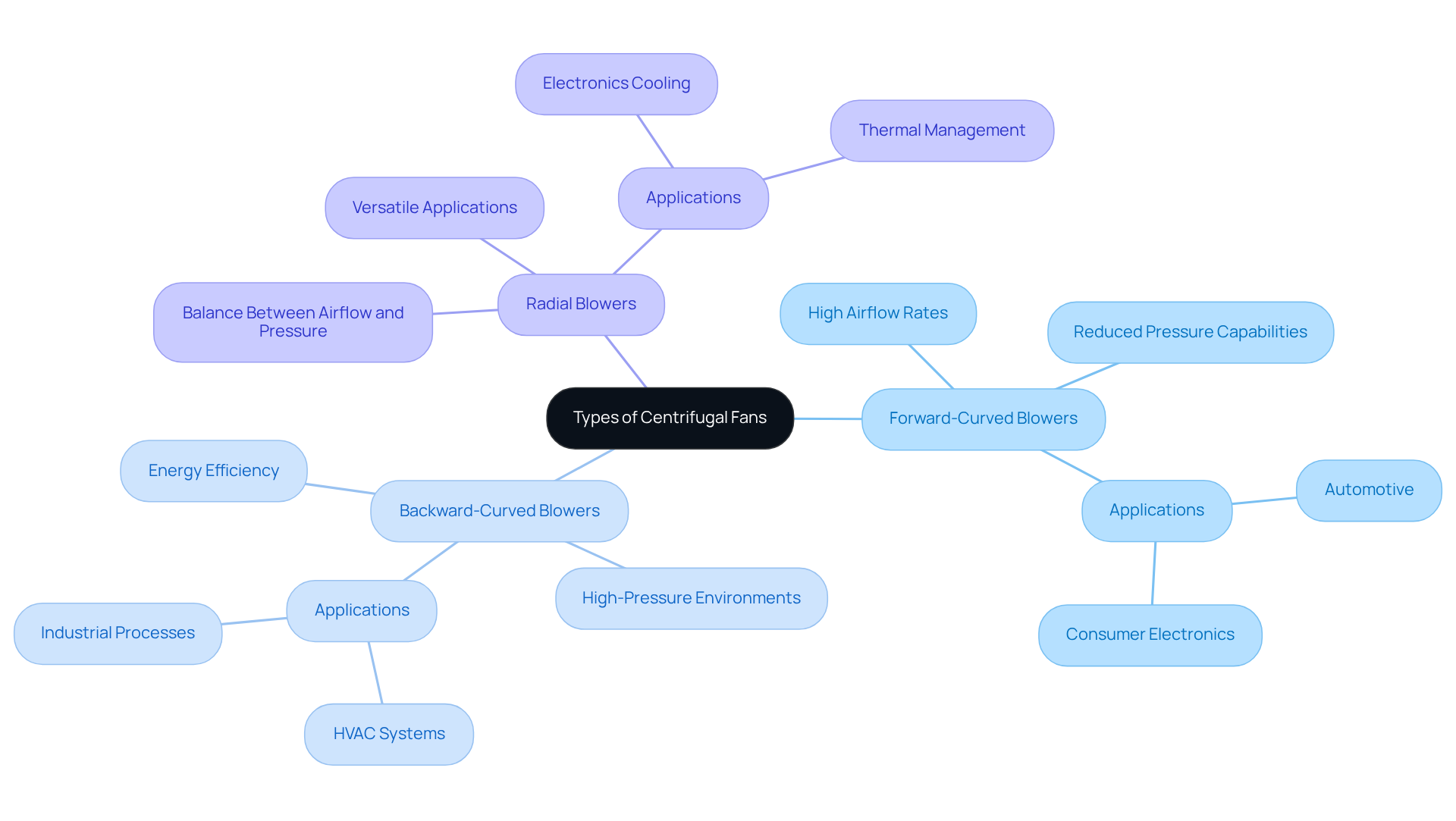

Identify Types of Centrifugal Fans

Centrifugal blowers can be classified into various types based on their blade design and air movement characteristics. Gagner-Toomey Associates offers an extensive selection of centrifugal blowers engineered for performance and centrifugal fan efficiency, making them suitable for diverse industrial applications. The three principal types include:

-

Forward-Curved Blowers: These devices are distinguished by their high airflow rates and reduced pressure capabilities, making them ideal for applications requiring substantial air volumes at lower pressures. Gagner-Toomey’s forward-curved blowers are meticulously designed to meet the demands of various sectors, including automotive and consumer electronics.

-

Backward-Curved Blowers: Known for their energy efficiency, backward-curved blowers excel in high-pressure environments. Commonly utilized in HVAC systems and industrial processes, centrifugal fan efficiency ensures reliable performance in demanding conditions. Gagner-Toomey’s backward-curved models are designed to improve centrifugal fan efficiency while ensuring optimal air movement.

-

Radial Blowers: Striking a balance between airflow and pressure, radial blowers are versatile for numerous applications. Gagner-Toomey’s radial devices are tailored to address the specific needs of electronics cooling, ensuring effective thermal management in critical systems.

Understanding these classifications enables engineers to effectively align fan characteristics with system requirements, thereby ensuring optimal centrifugal fan efficiency in their applications.

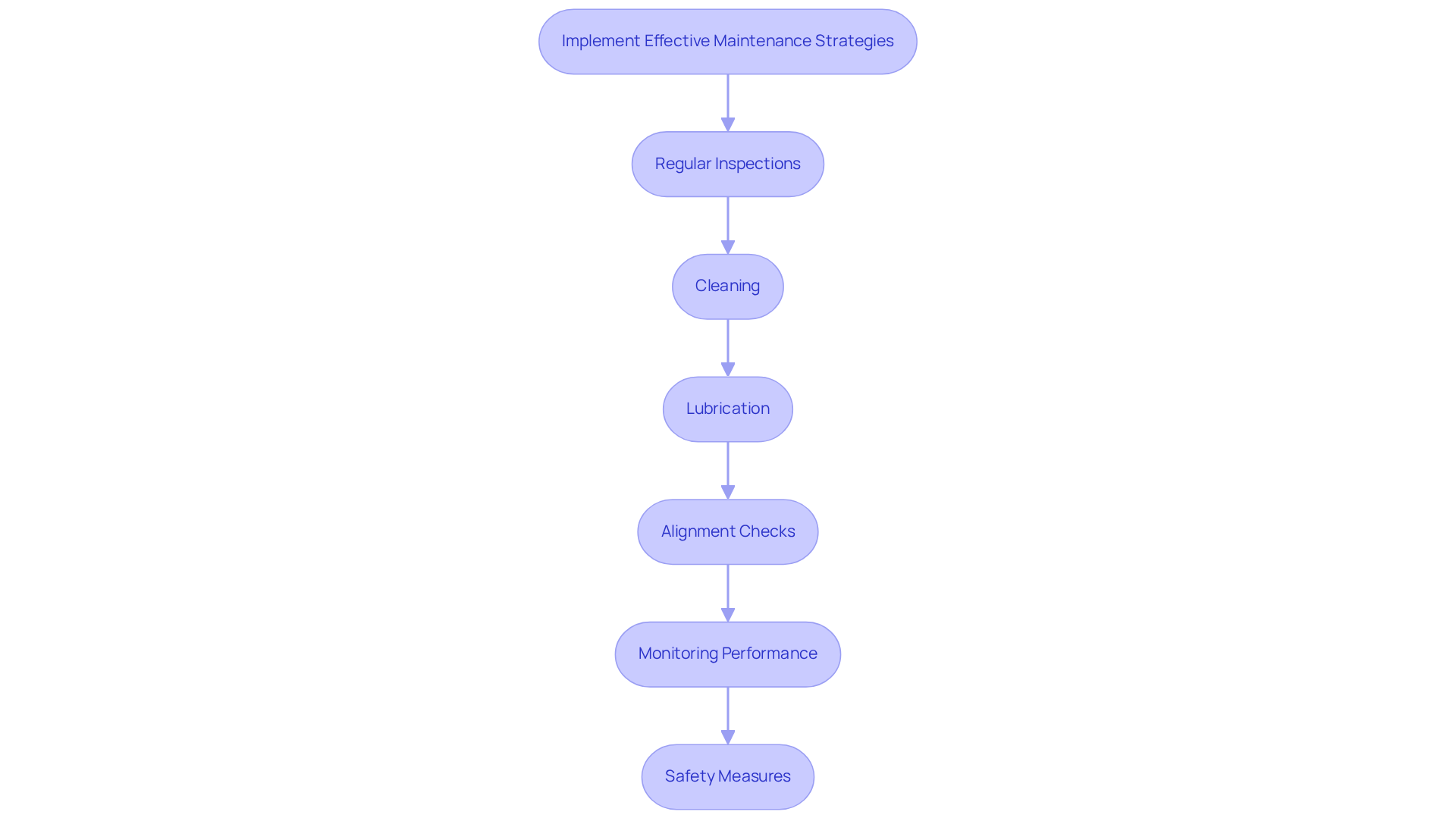

Implement Effective Maintenance Strategies

To ensure the effective maintenance of centrifugal fans, engineers should implement the following strategies:

-

Regular Inspections: Conduct routine checks for signs of wear and tear, focusing on critical components such as the impeller and motor. Regular inspections can significantly extend the lifespan of centrifugal fans, with well-maintained units lasting between 10 to 20 years or 20,000 to 40,000 hours of operation. Additionally, it is essential to check for air leaks around seals or gaskets to sustain performance.

-

Cleaning: The buildup of dust and debris on fan blades and inside the housing can significantly decrease performance. Establishing a consistent cleaning routine is crucial to eliminate accumulation and ensure optimal circulation.

-

Lubrication: Proper lubrication of bearings and moving parts is vital to minimize friction and wear. Adhering to manufacturer specifications for lubrication frequency—typically every 2 to 3 months—ensures smooth operation and prolongs equipment life.

-

Alignment Checks: Misalignment can lead to increased vibration and premature wear. Consistently inspecting and adjusting the alignment of the motor and impeller is essential to avoid these problems and sustain operational effectiveness.

-

Monitoring Performance: Utilizing sensors and monitoring systems to track performance metrics allows for proactive maintenance. Regularly assessing the movement of air and pressure can assist in recognizing potential issues before they escalate, ensuring that the fan operates within design specifications. Furthermore, performing vibration analysis is crucial to detect potential issues before they develop into major problems.

-

Safety Measures: During inspections, it is important to wear personal protective equipment (PPE) and follow lockout/tagout procedures to ensure safety.

-

Maintenance Logs: Keeping detailed maintenance logs to record inspections, maintenance activities, and parts replaced is crucial for trend analysis and systematic maintenance.

Incorporating these best practices into a preventive maintenance program not only enhances centrifugal fan efficiency but also reduces downtime and maintenance costs, ultimately leading to improved performance and longevity.

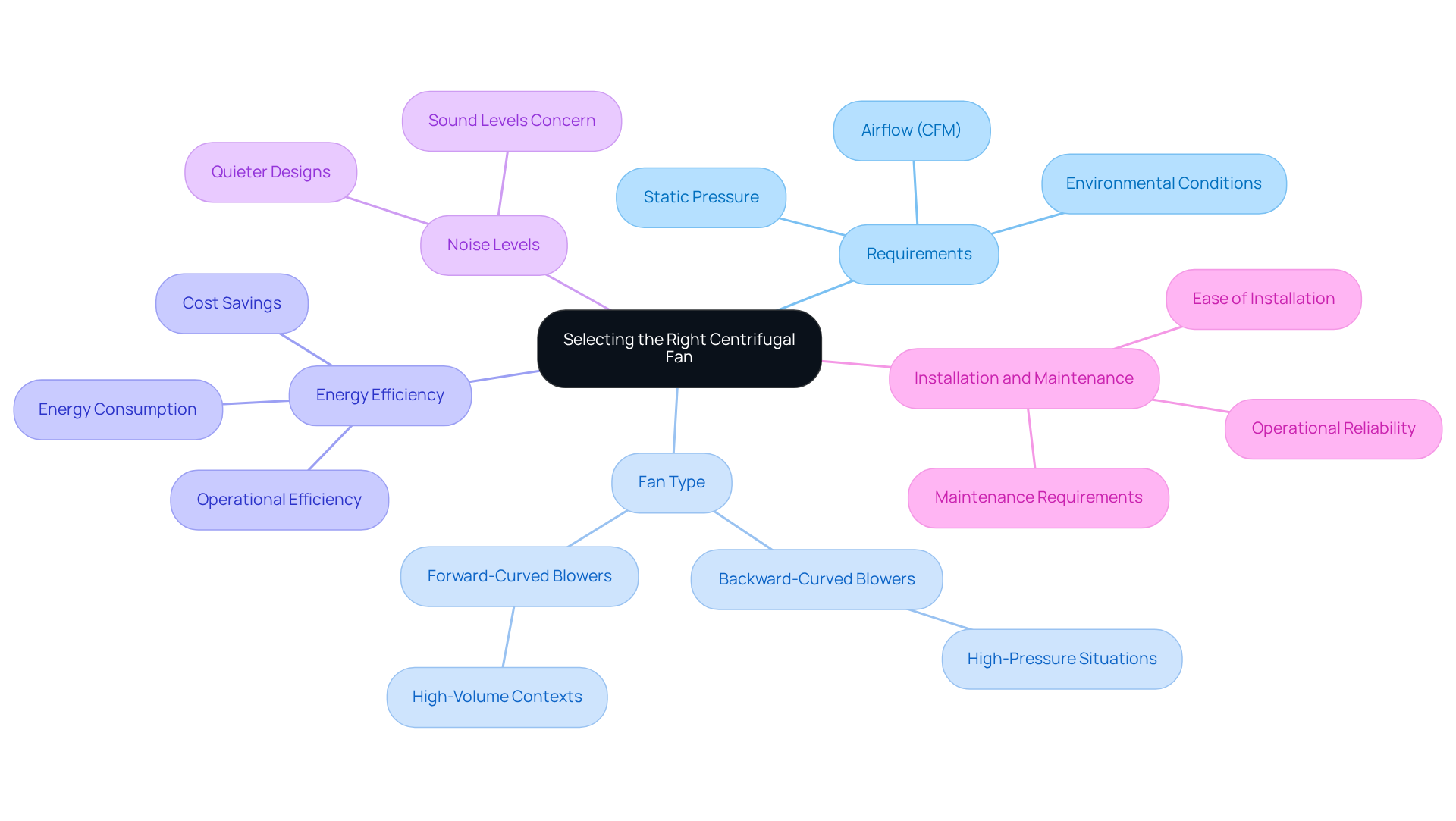

Select the Right Centrifugal Fan for Your Application

When selecting a centrifugal fan, engineers must consider several critical factors:

- Requirements: It is essential to evaluate the specific needs of the system, including necessary airflow (CFM), static pressure, and environmental conditions that may impact performance.

- Fan Type: Selecting the appropriate fan type is crucial for meeting usage requirements. For instance, backward-curved blowers are ideal for high-pressure situations, whereas forward-curved blowers are more effective in high-volume contexts.

- Energy Efficiency: Assessing the energy consumption of various fan models is vital. Choosing energy-efficient fans can lead to significant cost savings over time while also improving centrifugal fan efficiency and enhancing overall operational efficiency.

- Noise Levels: The noise generated by the fan must be taken into account, particularly in applications where sound levels are a concern. Certain fan designs are inherently quieter, which can be a decisive factor in selection.

- Installation and Maintenance: It is important to ensure that the chosen fan can be easily installed and maintained, as this will directly influence long-term operational efficiency and reliability.

Conclusion

Maximizing the efficiency of centrifugal fans is essential for engineers focused on optimizing performance across diverse applications. A thorough understanding of the mechanics of centrifugal fans, particularly the importance of impeller design and airflow dynamics, establishes a solid foundation for effective system performance. By selecting the right fan type and implementing comprehensive maintenance strategies, engineers can significantly enhance operational efficiency and reduce energy costs.

Key insights include the classification of centrifugal fans into:

- Forward-curved

- Backward-curved

- Radial types

Each type is tailored for specific applications. Regular maintenance practices—such as inspections, cleaning, lubrication, and performance monitoring—are critical for sustaining fan efficiency and extending equipment lifespan. Moreover, careful selection based on system requirements, energy efficiency, and noise levels ensures that the most suitable fan is employed for optimal results.

Incorporating these strategies not only enhances centrifugal fan efficiency but also plays a vital role in overall energy management and cost savings within industrial environments. Engineers are urged to prioritize these best practices and considerations when working with centrifugal fans, as doing so will lead to improved performance, reliability, and sustainability in their operations.

Frequently Asked Questions

How do centrifugal fans operate?

Centrifugal fans operate by utilizing a rotating impeller to increase the velocity of an airstream. Air is drawn into the center of the impeller and propelled outward by centrifugal force, converting kinetic energy into potential energy and elevating air pressure.

What factors influence the efficiency of centrifugal fans?

Several critical factors influence centrifugal fan efficiency, including impeller design, casing shape, and inlet conditions. Achieving uniform airflow at the fan’s inlet and minimizing turbulence are essential for enhancing performance.

What type of impeller is considered highly efficient for high-pressure applications?

Backward-curved impellers can achieve up to 85% aerodynamic efficiency, making them ideal for high-pressure applications.

Why is understanding centrifugal fan mechanics important?

Understanding centrifugal fan mechanics is essential for troubleshooting and optimizing systems, which can improve centrifugal fan efficiency across various applications, including HVAC and industrial processes.

What maintenance practices are recommended for centrifugal fans?

Regular maintenance and performance evaluations are crucial for addressing common issues such as vibration, inadequate air movement, and noise, ensuring that centrifugal blowers operate at peak capacity.

How do centrifugal fans impact energy management in industrial environments?

Properly maintained centrifugal fans can positively impact energy management in industrial environments by operating efficiently and effectively, which helps reduce energy consumption.