Overview

The article serves as a comprehensive guide for engineers aiming to master thermoelectric cooler (TEC) modules. It outlines essential steps in the selection, configuration, installation, and troubleshooting processes. Understanding the Peltier effect is crucial, as is the evaluation of module specifications. By addressing common issues, engineers can significantly enhance the reliability and efficiency of thermal management solutions across various electronic applications.

Introduction

Mastering the intricacies of thermoelectric cooler modules is essential for engineers aiming to enhance thermal management across diverse applications. These innovative devices leverage the Peltier effect to transfer heat efficiently, rendering them indispensable in electronics where precise temperature control is paramount. Yet, with a myriad of specifications and potential challenges, how can engineers ensure they select, configure, and integrate these modules effectively to maximize performance? This guide delves into the essential steps and considerations for mastering thermoelectric coolers, equipping engineers with the knowledge to address common issues and optimize their systems.

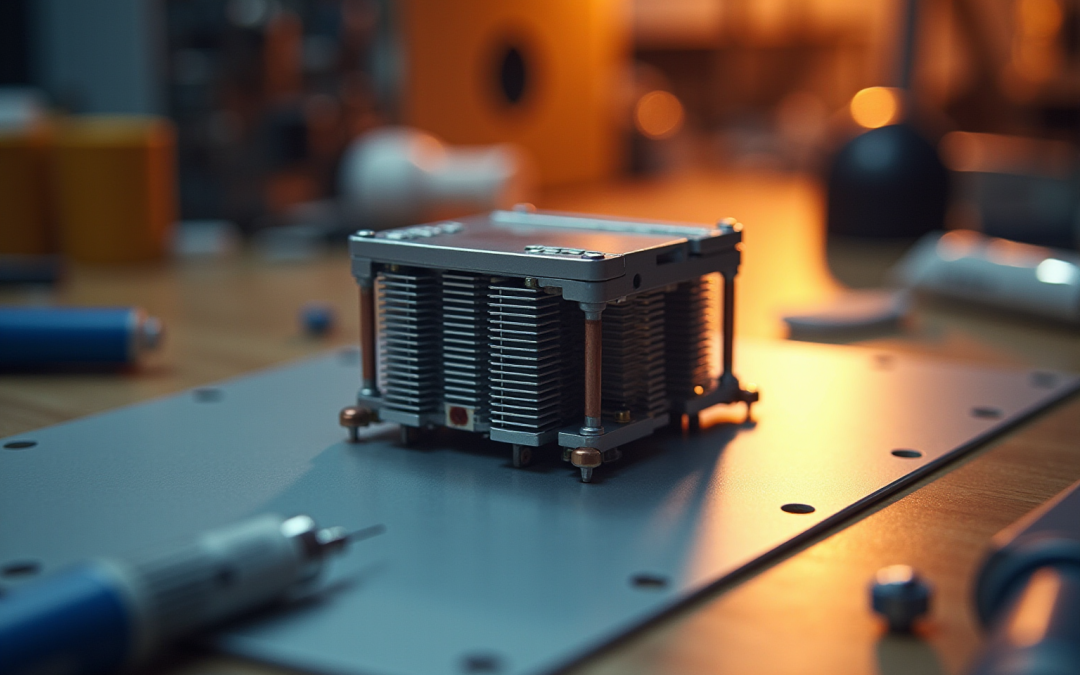

Understand the Basics of Thermoelectric Coolers

Thermoelectric coolers leverage the Peltier effect, wherein an electric current traversing two distinct conductors generates a temperature differential. This principle enables to proficiently transfer heat from one side to another, resulting in a cooling effect on one side and heating on the other.

Principles of Operation: Thermoelectric coolers function by employing semiconductor materials that display a temperature difference when an electric current is applied. Heat absorption occurs at the cold side, while the hot side dissipates heat into the environment. This characteristic renders the thermoelectric cooler module particularly suitable for applications necessitating precise thermal management. Gagner-Toomey Associates, recognized as the leading supplier of thermal management solutions for electronics globally, offers a comprehensive range of thermoelectric cooler modules designed for optimal effectiveness and efficiency.

Applications of the thermoelectric cooler module are widespread in electronics, especially for cooling critical components such as CPUs, lasers, and sensors. Their capacity to maintain narrow temperature ranges is vital for applications in telecommunications and medical devices, where overheating can precipitate performance degradation or failure. For example, in high-performance computing, a thermoelectric cooler module is employed to cool processors, thereby ensuring optimal operation and longevity. Furthermore, Gagner-Toomey Associates provides an array of temperature regulation solutions, including heatsinks, liquid temperature control systems, and CPU coolers, to meet diverse thermal management requirements.

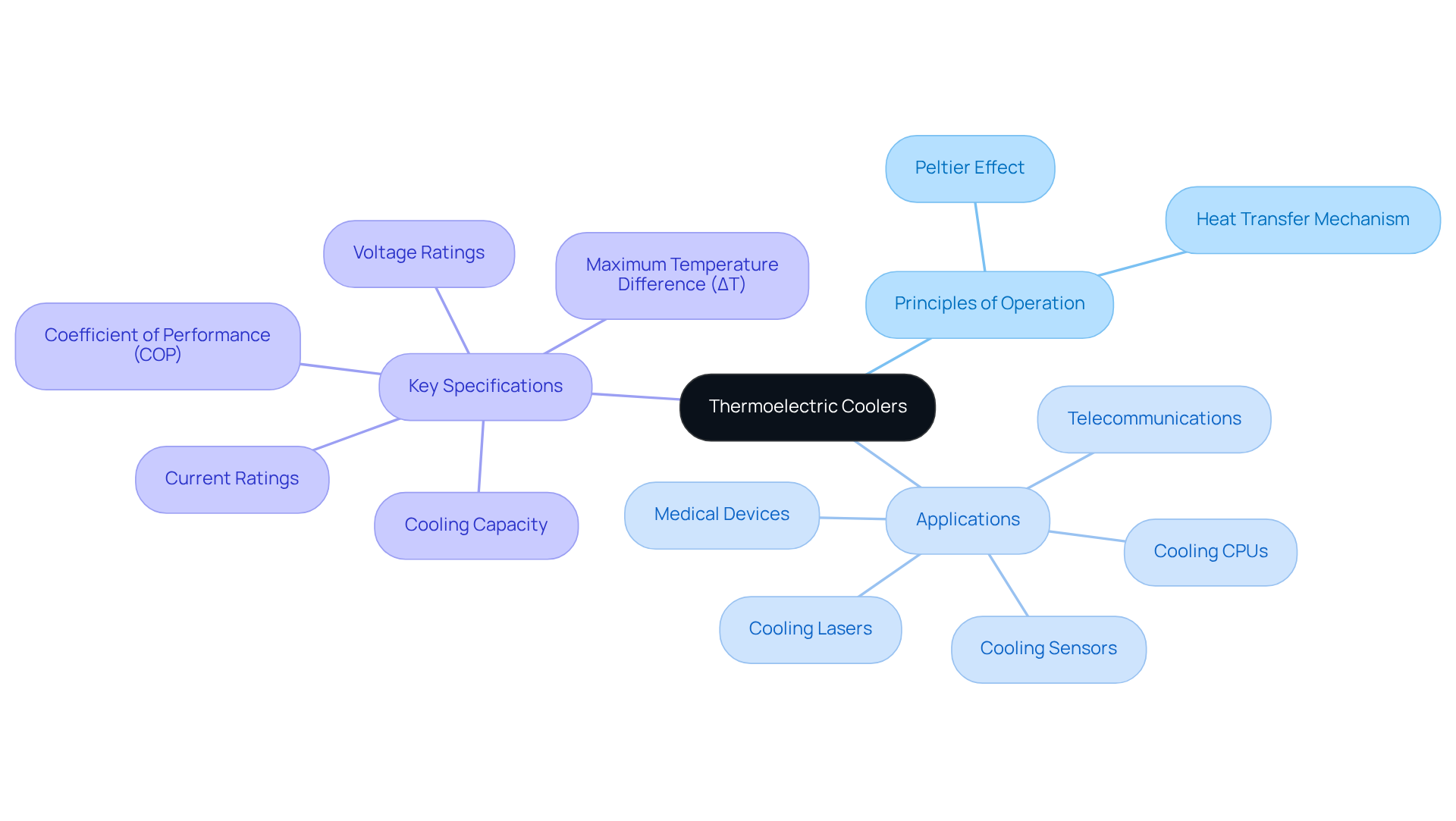

Key Specifications: Engineers must consider several specifications when selecting a thermoelectric cooler module, including cooling capacity, voltage, and current ratings. These parameters significantly influence the effectiveness and appropriateness of a thermoelectric cooler module for specific applications. A thorough understanding of the coefficient of performance (COP) and the maximum temperature difference (ΔT) that a thermoelectric cooler module can sustain is crucial for effective integration into electronic systems. Gagner-Toomey Associates supplies detailed product specifications for their technical equipment, ensuring engineers can select the most suitable solution for their projects.

By mastering these concepts and remaining attuned to the evolving market dynamics, engineers can make informed decisions when integrating technology into their projects, thereby enhancing the reliability and efficiency of electronic devices.

Select and Configure Your Thermoelectric Cooler Module

Selecting the appropriate thermoelectric cooler (TEC) module necessitates a systematic approach that ensures optimal performance and efficiency:

- Determine Temperature Control Needs: Start by assessing the heat load of your application to identify the required temperature regulation capacity. This foundational step is critical, as the of thermoelectric coolers can vary significantly based on specific thermal requirements.

- Evaluate Module Specifications: Examine the TEC’s specifications, including dimensions, voltage, and current ratings. It is vital that these parameters align with your system’s requirements to prevent inefficiencies. For instance, voltage ratings for power supplies used with TECs typically range from 12 to 24 volts; therefore, it is advisable to select a power supply rated at 1.3 times the TEC’s rated power to guarantee optimal operation.

- Consider Environmental Factors: Assess the operating environment, including ambient temperature and humidity levels. These factors can substantially influence the cooler’s performance. For example, keeping ambient humidity below 80% is essential to prevent condensation, which is crucial for maintaining system integrity.

- Configuration Options: Investigate various configurations, such as series or parallel connections, to optimize efficiency according to your specific requirements. Proper configuration can significantly enhance the TEC system’s efficiency, ensuring effective heat dissipation and stable operation.

By meticulously selecting and configuring the thermoelectric cooler module, engineers can substantially enhance the efficiency and reliability of their temperature management solutions, paving the way for innovative applications in electronics.

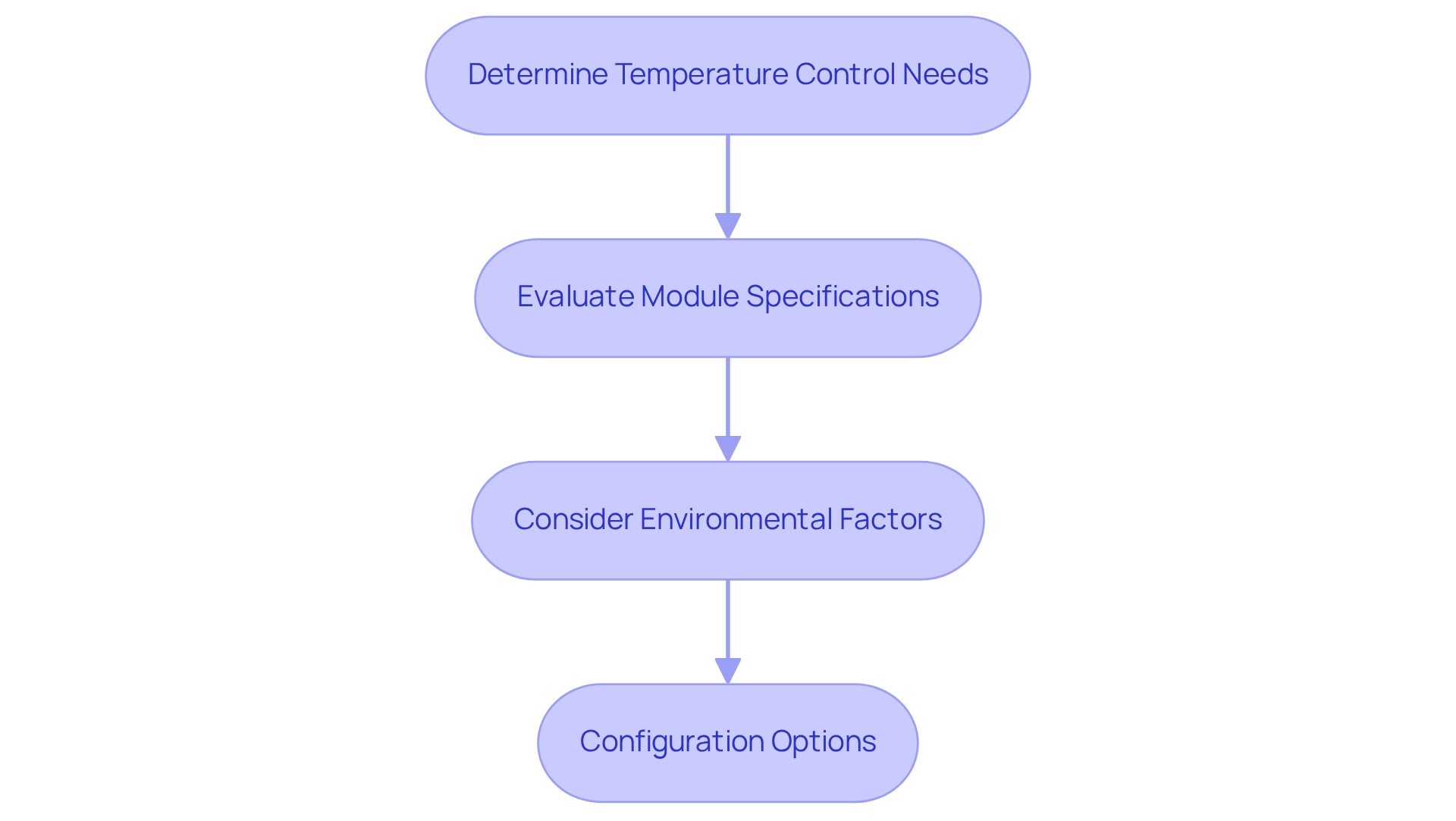

Install and Integrate the Thermoelectric Cooler Module

To effectively install and integrate your thermoelectric cooler (TEC) module, adhere to the following steps:

- Prepare the Mounting Surface: Ensure the surface where the TEC will be mounted is clean and exhibits a flatness of at least 0.05mm over 100mm. This preparation promotes optimal thermal contact and enhances heat transfer efficiency.

- Apply Thermal Interface Material: Select an appropriate thermal interface material (TIM) to fill microscopic gaps between the TEC and the components it cools. This selection is crucial, as TIMs significantly improve , with ratings ranging from 1.0 to 6.0 W/m*K, ensuring efficient heat dissipation and preventing thermal bottlenecks. As Ryan Smoot states, “A Thermal Interface Material (TIM) is what makes certain that these other heat management methods perform at their highest efficiency.”

- Secure the Module: Attach the TEC firmly with screws or clamps, ensuring correct alignment to prevent mechanical stress that could jeopardize functionality. Utilizing captive screws or serrated washers can prevent loosening over time, maintaining effective cooling.

- Connect Electrical Leads: Carefully connect the electrical leads to the power supply, ensuring correct polarity to avoid damage. Common incoming DC power connections typically operate at 12V or 24V, with 48V options available.

- Test the Installation: Power on the system and monitor the temperature to confirm that the TEC is functioning as intended. Efficient heat removal from the hot side is crucial; ensure that the assembly has sufficient clearance of 20-40mm around it for optimal heat dissipation. Additionally, avoid mounting the cold side upwards to prevent condensation issues.

By following these steps, you will facilitate a successful installation and integration of the thermoelectric cooler module, which enhances the overall thermal management of your system.

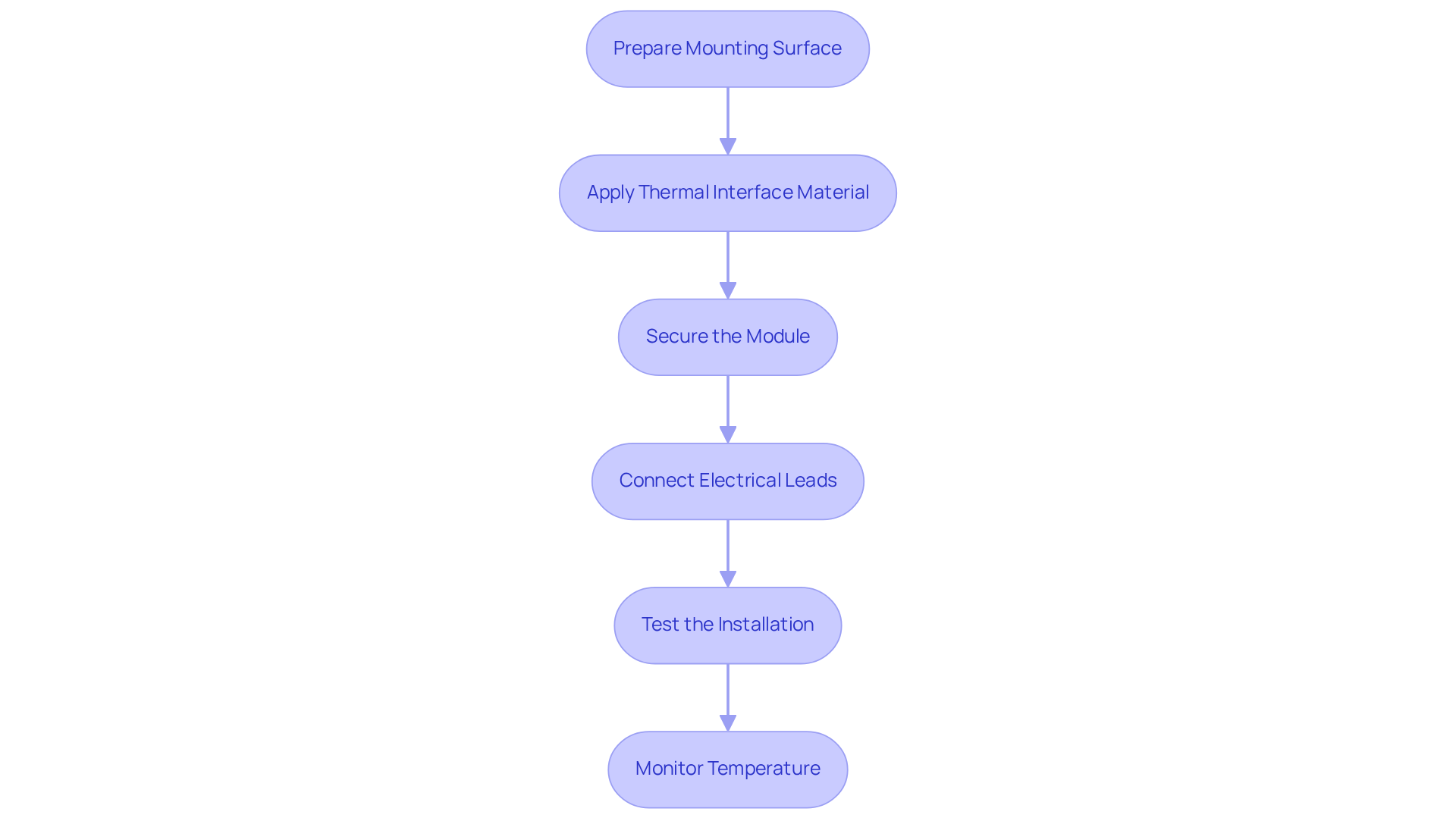

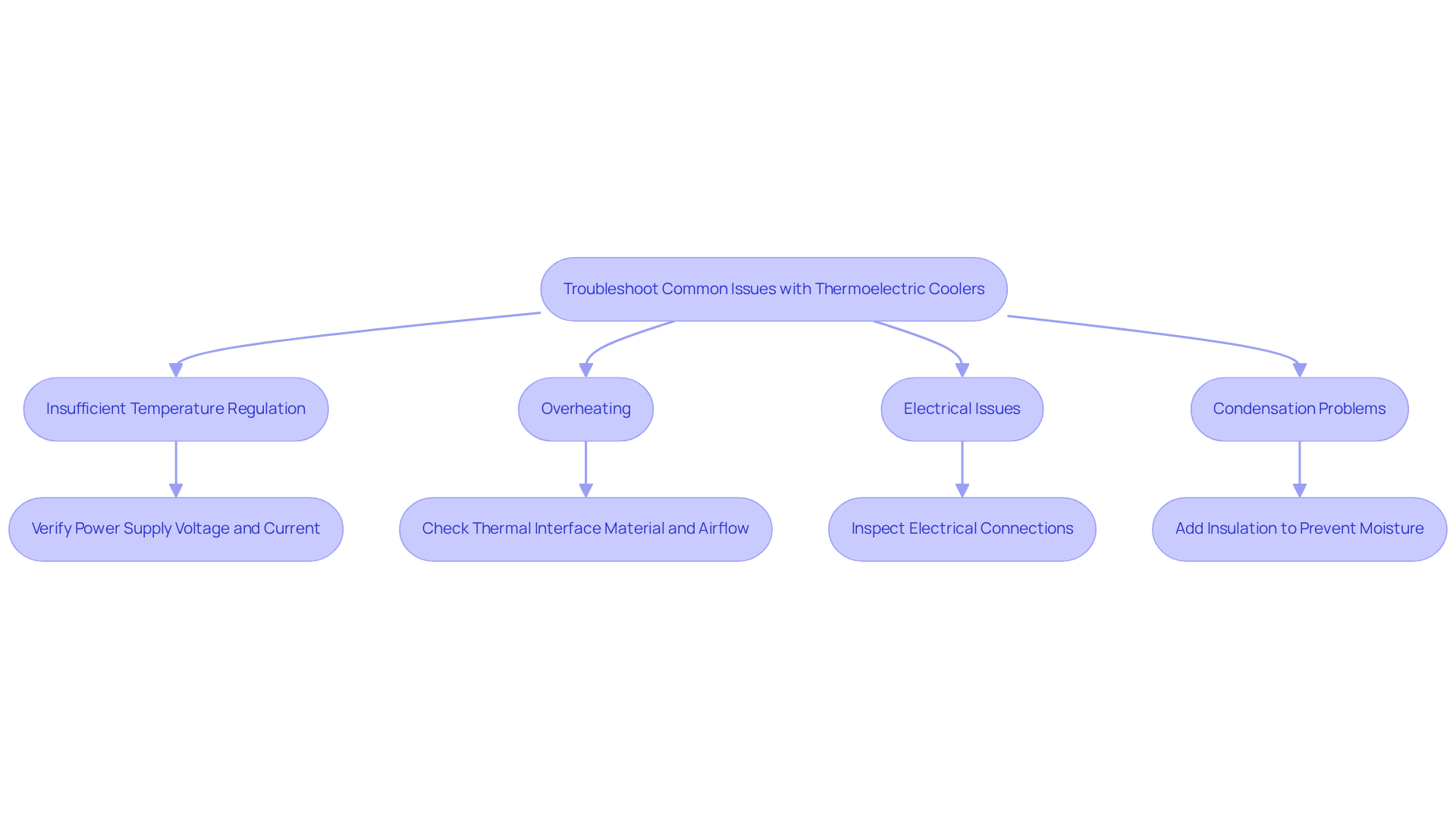

Troubleshoot Common Issues with Thermoelectric Coolers

Engineers working with thermoelectric cooler modules frequently encounter challenges that can impede performance. A structured approach to troubleshooting insufficient cooling in TECs is essential:

- Insufficient Temperature Regulation: When the TEC does not achieve the anticipated temperature reduction, it is imperative to first verify that the power supply voltage and current correspond with the module’s specifications. Research indicates that an inadequate power supply can lead to a significant decline in temperature regulation efficiency. The USDOE highlights that the extraction, processing, and transport of fuels in electricity generation could elevate life-cycle water consumption of coal-fired power plants by as much as 10%, underscoring the importance of efficient power management in thermal regulation systems.

- Overheating: Overheating poses a serious threat to the TEC’s functionality. It is crucial to ensure that the thermal interface material is properly applied and that there is adequate airflow surrounding the module. Insufficient airflow can result in elevated temperatures, which may induce thermal stress and potential failure. As noted by Shu-Yuan Pan, “Cooling systems are the most water-intensive part of the generation process, presenting significant opportunities to reduce the withdrawal and consumptive use of fresh water.”

- Electrical Issues: All electrical connections should be inspected for signs of damage or looseness. Defective connections can lead to erratic operation, resulting in temperature control inefficiencies. Regular maintenance checks are vital for identifying these issues before they escalate.

- Condensation Problems: The presence of condensation on the cooler necessitates the addition of insulation to prevent moisture from impacting the electronics. Moisture can lead to corrosion and short circuits, significantly diminishing the cooler’s lifespan. The significance of managing moisture in cooling systems is reinforced by findings from various case studies, which emphasize the necessity for .

By systematically addressing these prevalent issues, engineers can significantly enhance the reliability and efficiency of thermoelectric cooler modules, ensuring optimal performance across diverse applications.

Conclusion

In conclusion, thermoelectric cooler modules are indispensable for optimizing thermal management in electronic systems. By mastering their principles of operation and selecting appropriate specifications, engineers can significantly bolster the performance and reliability of their applications. This expertise not only ensures optimal temperature regulation but also fosters innovative advancements across diverse sectors, such as telecommunications and medical devices.

The article delineates essential steps for engineers, beginning with a solid understanding of thermoelectric coolers and progressing to the careful selection and configuration of modules. Critical considerations, including:

- Cooling capacity

- Environmental factors

- Installation techniques

are underscored as integral to achieving effective thermal management. Furthermore, addressing common troubleshooting issues empowers engineers to uphold the integrity and functionality of their systems, ultimately enhancing performance and longevity.

In an age where precision and efficiency reign supreme, the insights presented herein serve as a vital resource for engineers aspiring to implement thermoelectric cooling solutions. By embracing a systematic approach to selection, configuration, and maintenance, professionals can not only navigate challenges but also unlock the full potential of thermoelectric cooler modules. Adopting these practices will elevate individual projects while simultaneously advancing technology within the broader engineering landscape.

Frequently Asked Questions

What is the principle behind thermoelectric coolers?

Thermoelectric coolers operate based on the Peltier effect, where an electric current passing through two different conductors creates a temperature differential, allowing heat to be transferred from one side to another.

How do thermoelectric coolers function?

They use semiconductor materials that generate a temperature difference when an electric current is applied. Heat is absorbed at the cold side, while the hot side dissipates heat into the environment, making them suitable for precise thermal management.

What are the common applications of thermoelectric coolers?

Thermoelectric coolers are widely used in electronics for cooling critical components like CPUs, lasers, and sensors, especially in telecommunications and medical devices where maintaining narrow temperature ranges is essential.

What key specifications should engineers consider when selecting a thermoelectric cooler?

Engineers should consider cooling capacity, voltage, current ratings, the coefficient of performance (COP), and the maximum temperature difference (ΔT) that the cooler can sustain to ensure effective integration into electronic systems.

Who is Gagner-Toomey Associates, and what do they offer?

Gagner-Toomey Associates is a leading supplier of thermal management solutions for electronics, offering a range of thermoelectric cooler modules, heatsinks, liquid temperature control systems, and CPU coolers to meet various thermal management needs.

Why is it important to understand the specifications of thermoelectric coolers?

A thorough understanding of the specifications is crucial for selecting the most suitable thermoelectric cooler module for specific applications, thereby enhancing the reliability and efficiency of electronic devices.