Overview

This article provides essential insights for electronics engineers regarding master blower manufacturers and their products. It underscores the significance of comprehending various blower types, assessing manufacturer criteria, and ensuring adherence to safety standards. Such knowledge collectively empowers engineers to make informed decisions, optimizing performance in electronic applications.

Introduction

Blowers serve as indispensable components in electronics engineering, meticulously designed to enhance air movement and manage thermal dynamics within devices. As engineers navigate the complexities of airflow management, grasping the various types of blowers—such as centrifugal and positive displacement—becomes essential for optimizing performance and reliability in electronic applications.

Yet, amidst a multitude of manufacturers touting expertise and quality, how can engineers discern which blower suppliers genuinely meet their project demands while adhering to crucial safety and compliance standards?

This article delves into the fundamental concepts of blowers, evaluates key criteria for selecting trustworthy manufacturers, and underscores the significance of compliance in ensuring efficient and safe operations.

Explore the Fundamentals of Blowers in Electronics Engineering

Blowers serve as crucial mechanical devices engineered to move air or gas by augmenting its pressure and velocity. Operating on the principle of transforming mechanical energy into kinetic energy, they play a vital role in various electronic applications, including component cooling and airflow management.

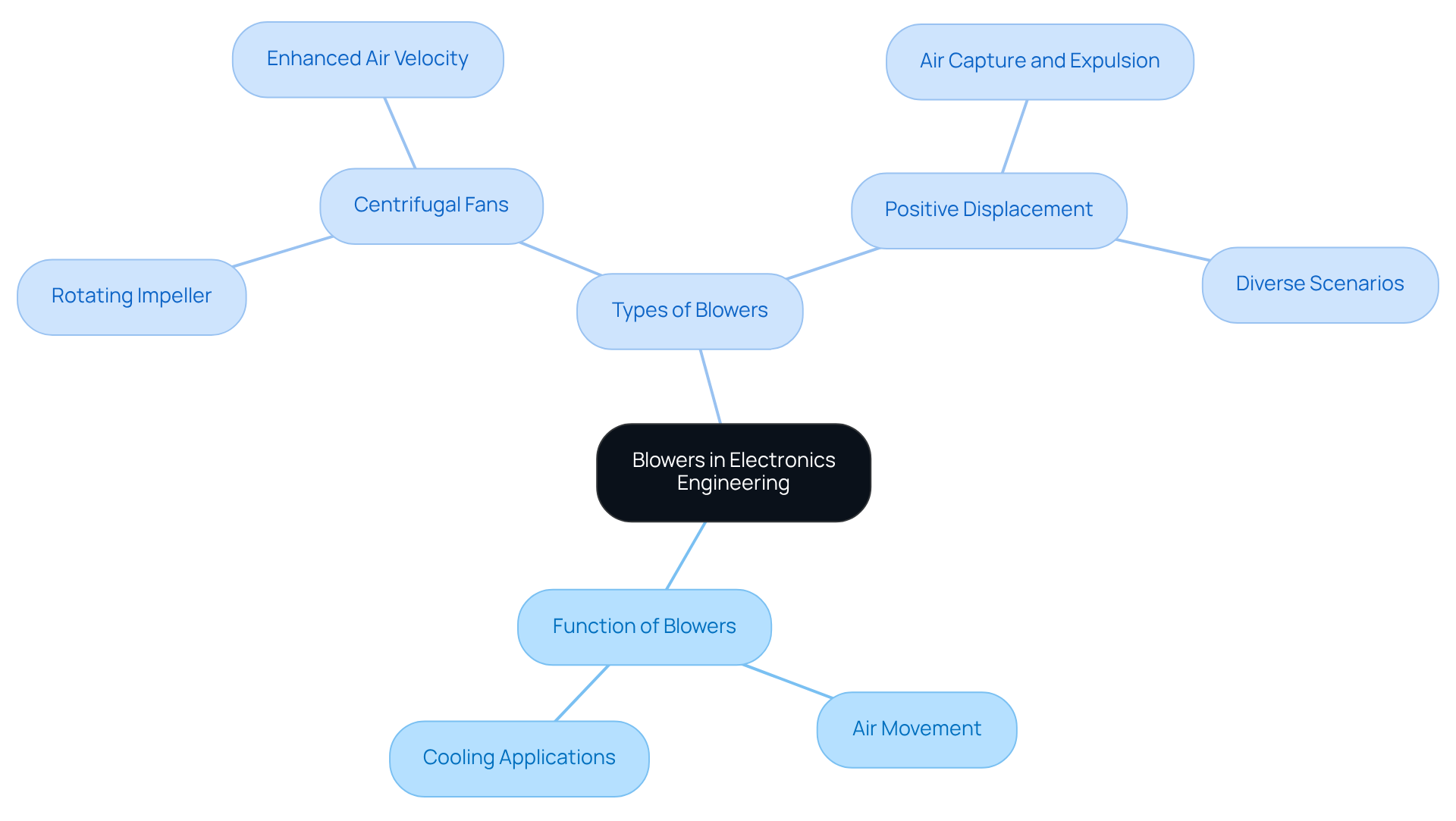

Understanding the different types of blowers, such as centrifugal and positive displacement, is essential for effective implementation:

- Centrifugal fans utilize a rotating impeller to significantly enhance air velocity.

- Positive displacement devices effectively capture and expel air, making them suitable for diverse scenarios in electronics engineering.

Familiarity with these foundational concepts empowers engineers to make informed decisions when integrating fans into their designs, ultimately optimizing performance and reliability.

Identify Different Types of Blowers and Their Applications

Gagner-Toomey Associates offers a diverse range of blowers, each tailored to meet specific needs and applications:

-

Centrifugal Blowers: These blowers are widely employed in cooling processes due to their ability to generate high pressure and airflow. Gagner-Toomey’s centrifugal fans excel in electronic cooling applications, particularly where space is limited. Available in sizes ranging from 15 to 225mm, these options are optimized for both performance and minimal noise, making them ideal for compact environments.

-

Positive Displacement Fans: Designed for applications requiring stable airflow, such as pneumatic transport systems in manufacturing, these fans are a key component of Gagner-Toomey’s extensive portfolio. Their efficiency in maintaining consistent airflow is paramount for operational success.

-

Axial Fans: Commonly used in ventilation systems, Gagner-Toomey’s axial fans move air parallel to the axis of the fan, which is particularly effective for substantial volume air movement. These fans come with options that enhance performance while minimizing noise, ensuring they meet the demands of various settings.

-

Regenerative Fans: Known for their efficiency, regenerative fans are frequently deployed in suction applications and can handle a wide range of gases. This versatility underscores Gagner-Toomey’s commitment to providing innovative solutions tailored to diverse operational requirements.

-

Mixed Flow Fans: Combining features of both centrifugal and axial fans, these versatile options can be utilized in numerous applications, including HVAC systems. This adaptability further illustrates Gagner-Toomey’s extensive capabilities as one of the leading blower manufacturers in the market.

Moreover, many models are available with IP protection upon request, ensuring reliability across various environments. Understanding these categories empowers engineers to select the most suitable fan for their specific project needs, thereby guaranteeing optimal performance across a range of applications.

Evaluate Criteria for Choosing Reliable Blower Manufacturers

When evaluating blower manufacturers, considering several key criteria is essential as they can significantly impact your project’s success.

-

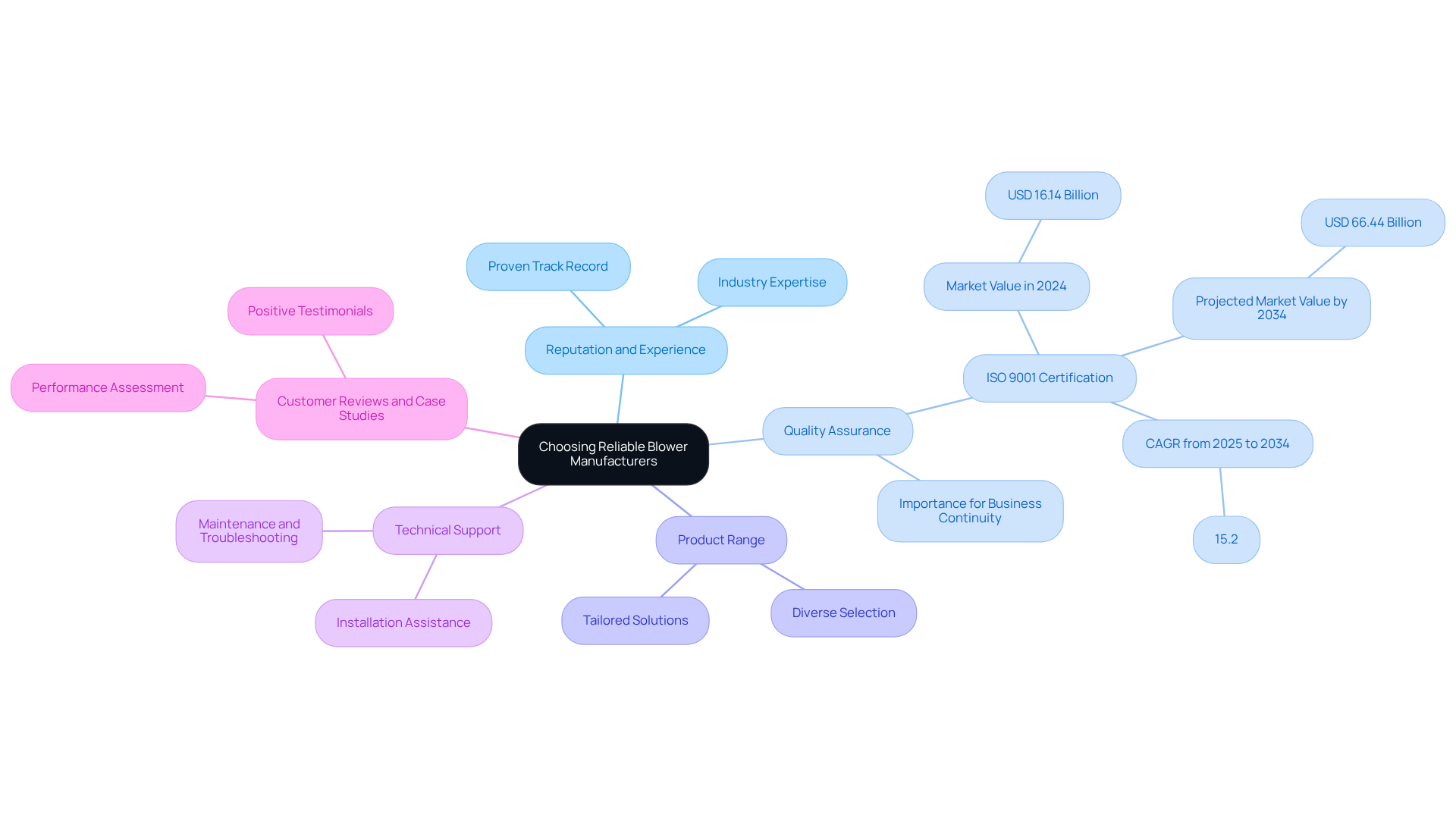

Reputation and Experience: Choose manufacturers with a proven track record in the industry. Established blower manufacturers typically possess the expertise required to produce reliable and efficient products, ensuring that your investment is sound.

-

Quality Assurance: It is crucial to verify that the manufacturer adheres to stringent quality control standards and holds certifications such as ISO 9001. This certification reflects a commitment to maintaining high-quality processes and products. Notably, the ISO 9001 certification market was valued at approximately USD 16.14 billion in 2024 and is projected to reach USD 66.44 billion by 2034. Such figures underscore its significance across various industries, including fan production. Moreover, ISO 9001 is often mandated by companies from their partners and suppliers, making it essential for business continuity and competitiveness.

-

Product Range: A manufacturer that offers a diverse selection of fans can provide tailored solutions designed for specific applications. This variety enhances design adaptability and addresses distinct project requirements, ensuring that engineers have the right tools for their tasks.

-

Technical Support: Reliable manufacturers should offer comprehensive technical support, including assistance with installation, maintenance, and troubleshooting. This support ensures that engineers can effectively utilize their products, thereby enhancing operational efficiency.

-

Customer Reviews and Case Studies: Investigating customer feedback and case studies is vital for assessing the performance and reliability of the manufacturer’s products in real-world applications. Positive testimonials and documented success stories from blower manufacturers can significantly influence your decision-making process. Additionally, ISO 9001 certified companies are recognized for providing reliable production scheduling and excellent customer service, further informing your evaluation.

By applying these criteria, engineers can confidently select manufacturers that align with their project requirements, ensuring quality and reliability in their ventilation systems.

Understand Compliance and Safety Standards in Blower Manufacturing

Compliance with safety and performance standards is paramount in blower manufacturing, shaped by several key regulations and guidelines that define industry practices:

-

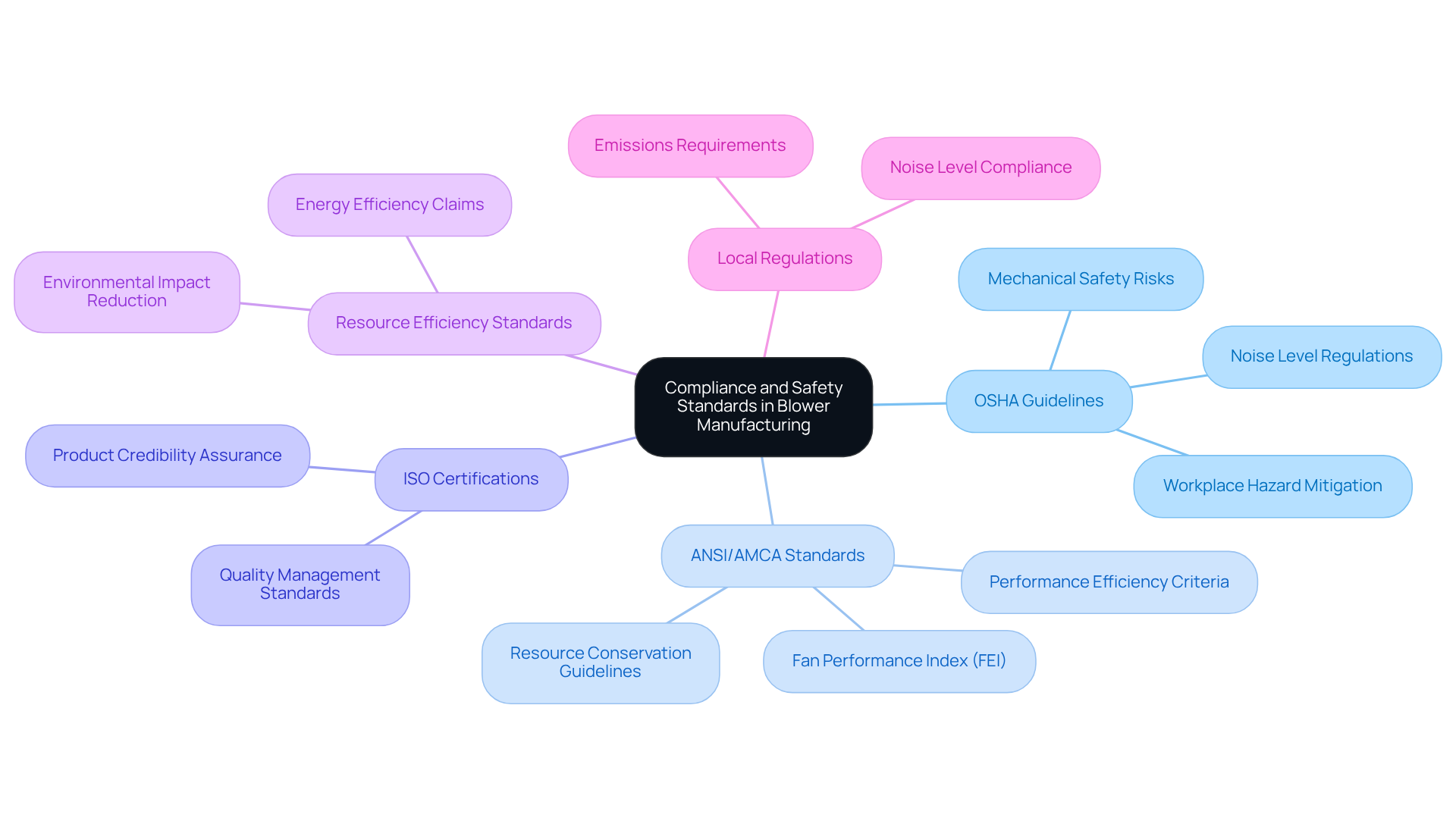

OSHA Guidelines: These guidelines are critical for ensuring that ventilation systems are designed to mitigate workplace hazards, including excessive noise levels and mechanical safety risks. OSHA mandates that equipment must not only operate effectively but also safeguard workers from potential dangers.

-

ANSI/AMCA Standards: The Air Movement and Control Association (AMCA) sets stringent guidelines for blower performance, ensuring that products satisfy specific efficiency and safety criteria. Adherence to these standards is reflected in the fan performance index (FEI), a metric in power codes since 2019. For instance, AMCA’s standards require fans to operate within defined efficiency ranges, promoting resource conservation and reliability in performance.

-

ISO Certifications: Manufacturers are strongly encouraged to obtain ISO certification, which signifies compliance with international quality management standards. This certification not only enhances product credibility but also assures customers of consistent quality and safety in manufacturing processes.

-

Resource Efficiency Standards: Compliance with resource efficiency regulations is vital for reducing operational costs and minimizing environmental impact. The Department of Energy (DOE) has established standards mandating adherence to energy efficiency claims effective October 30, 2023, ensuring that ventilation units align with sustainable practices.

-

Local Regulations: Beyond national standards, local regulations may impose additional requirements, particularly regarding emissions and noise levels. Engineers must remain informed of these local mandates to ensure comprehensive compliance and avoid potential penalties.

Understanding these compliance requirements is essential for engineers to design blower systems that meet the standards set by blower manufacturers, ensuring they are not only safe and efficient but also legally compliant, ultimately enhancing workplace safety and operational effectiveness.

Conclusion

Blowers are integral components in electronics engineering, essential for ensuring optimal airflow and cooling across various applications. Understanding the different types of blowers, such as centrifugal and positive displacement fans, is crucial for enhancing performance and reliability in electronic systems. By familiarizing themselves with these devices, engineers can make informed decisions that significantly impact their projects.

Key insights include evaluating blower manufacturers based on criteria such as:

- Reputation

- Quality assurance

- Product range

- Technical support

- Customer feedback

Compliance with safety and performance standards, including OSHA guidelines and ISO certifications, is vital for ensuring that blower systems operate efficiently and safely. Grasping these factors empowers engineers to select the most suitable blowers for their applications, ultimately leading to improved functionality and safety in electronic devices.

In light of these insights, engineers are encouraged to prioritize thorough research when selecting blower manufacturers and to stay informed about compliance standards. By doing so, they can enhance the reliability and efficiency of their ventilation systems, contributing to the overall success of their engineering projects. Embracing these principles not only fosters innovation but also ensures that electronic devices operate safely and effectively in a rapidly evolving technological landscape.

Frequently Asked Questions

What is the primary function of blowers in electronics engineering?

Blowers are mechanical devices designed to move air or gas by increasing its pressure and velocity, playing a crucial role in various electronic applications, such as component cooling and airflow management.

How do blowers operate?

Blowers operate on the principle of transforming mechanical energy into kinetic energy to enhance the movement of air or gas.

What are the main types of blowers mentioned in the article?

The main types of blowers discussed are centrifugal fans and positive displacement devices.

How do centrifugal fans work?

Centrifugal fans utilize a rotating impeller to significantly increase air velocity.

What is the function of positive displacement devices?

Positive displacement devices effectively capture and expel air, making them suitable for various scenarios in electronics engineering.

Why is it important for engineers to understand blowers?

Familiarity with the different types of blowers and their functions allows engineers to make informed decisions when integrating fans into their designs, optimizing performance and reliability.