Overview

This article examines the essential features of high power air blowers crucial for engineers, emphasizing:

- Energy efficiency

- Portability

- Noise levels

- Safety features

Each of these aspects significantly enhances performance, reduces operational costs, and ensures user safety. Consequently, high power air blowers emerge as critical components in various engineering applications, particularly within the electronics and manufacturing sectors.

Introduction

High power air blowers serve as indispensable tools for engineers, particularly within the electronics industry, where effective cooling and airflow management are paramount. As technology continues to evolve, the demand for reliable, efficient, and versatile air blower solutions has surged, presenting engineers with a unique opportunity to elevate their projects. Yet, with a plethora of options available, how can professionals discern the key features that will genuinely optimize performance and ensure enduring reliability?

This article explores ten critical characteristics of high power air blowers, equipping engineers with the insights necessary to make informed decisions in their pursuit of excellence.

Gagner-Toomey Associates: Innovative Solutions for High Power Air Blowers

The firm excels in delivering innovative solutions tailored for engineers in the electronics industry, particularly emphasizing high power air blower devices. These devices, including the high power air blower, are essential for applications that demand effective cooling and optimal airflow management.

By collaborating with leading manufacturers, the company guarantees that clients benefit from cutting-edge technologies that significantly enhance performance and reliability in electronic systems. Notably, the integration of high-capacity air fans can lead to energy consumption reductions of up to 30%, positioning them as a vital component in modern cooling strategies.

Successful implementations in data centers have proven that these systems not only enhance thermal management but also contribute to reduced operational costs and prolonged equipment lifespan.

As the demand for efficient cooling solutions continues to rise, Gagner-Toomey remains at the forefront, ensuring engineers have access to the latest advancements in high power air blower technology.

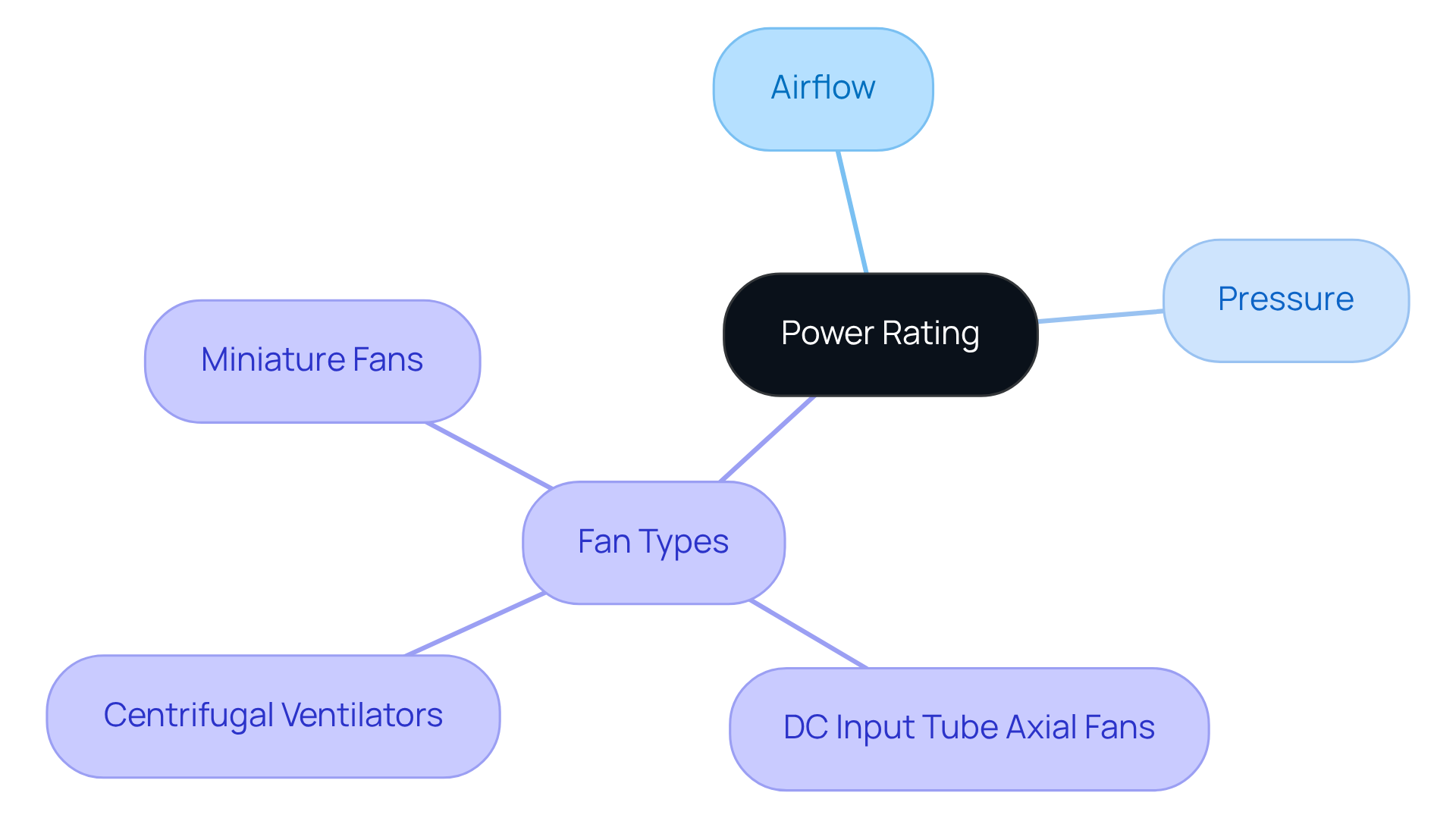

Power Rating: Essential for Optimal Performance

The capacity rating of a high-capacity air fan denotes its ability to operate efficiently under load. Engineers must carefully consider the necessary airflow and pressure when selecting a fan, as these elements are directly influenced by the capacity rating.

Gagner-Toomey Associates offers an extensive range of DC input tube axial fans and centrifugal ventilators, optimized for performance and efficiency, capable of managing demanding applications. A fan with increased capacity ensures optimal performance in critical cooling and ventilation tasks, particularly in electronics, automotive, and industrial sectors.

With options ranging from miniature fans designed for tight spaces to larger solutions addressing extensive cooling needs, selecting the appropriate device is crucial for achieving effective thermal management.

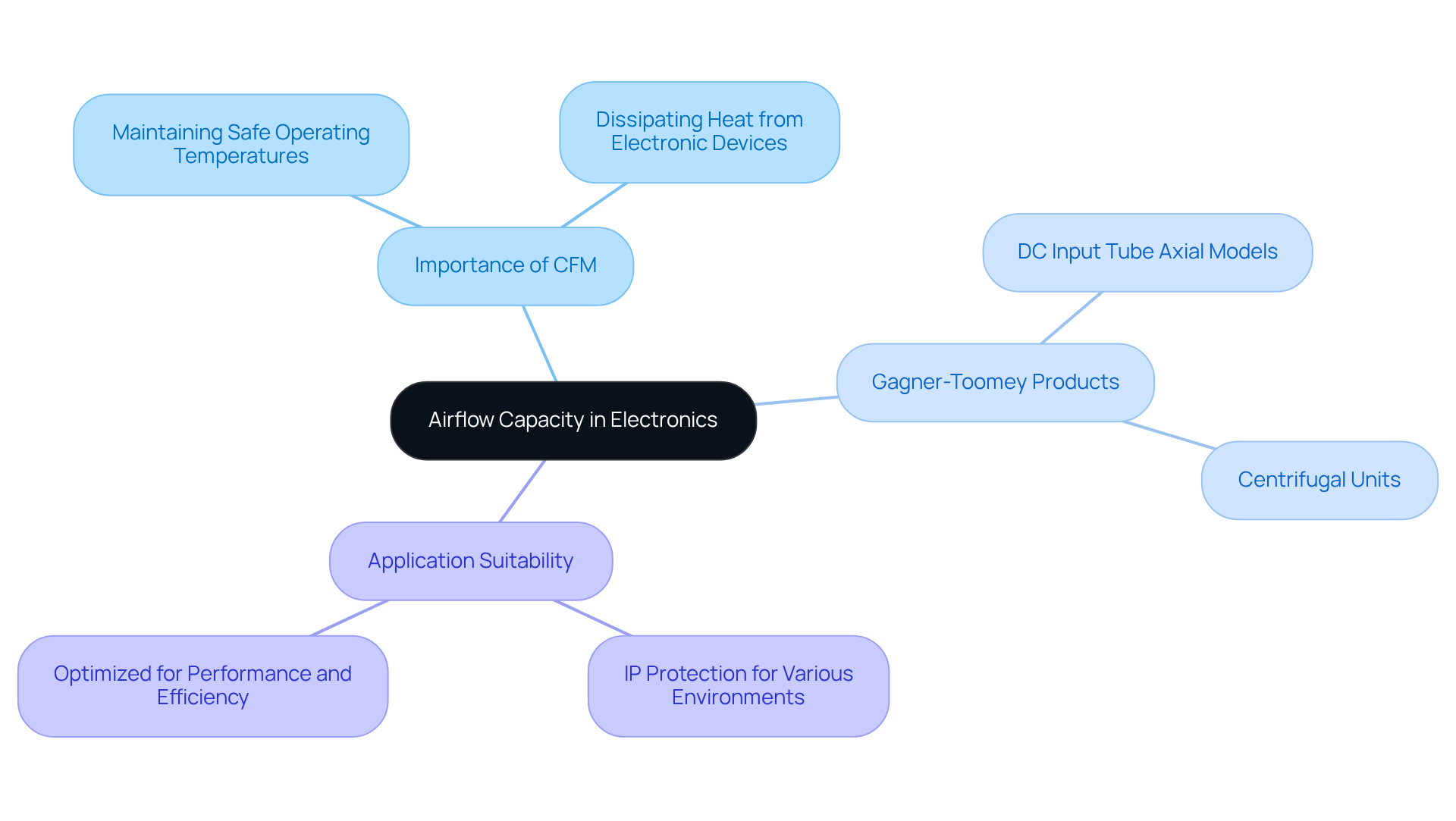

Airflow Capacity: Maximizing Efficiency in Electronics

Airflow capacity, quantified in cubic feet per minute (CFM), is essential for maintaining the safe operating temperatures of electronic components. As the leading producer of both standard and custom air-movers, Gagner-Toomey offers high power air blower units that are meticulously optimized for performance, efficiency, and minimal noise. These fans act as a high power air blower designed to deliver substantial airflow, which is critical for effectively dissipating heat generated by electronic devices.

Furthermore, numerous models feature IP protection, making them suitable for a variety of environments. Engineers are encouraged to select fans from Gagner-Toomey’s comprehensive portfolio, which encompasses:

- DC input tube axial models

- Centrifugal units

This ensures that the airflow capacities are aligned with the thermal requirements of their specific applications to maximize overall efficiency.

Portability: Enhancing Usability for Engineers

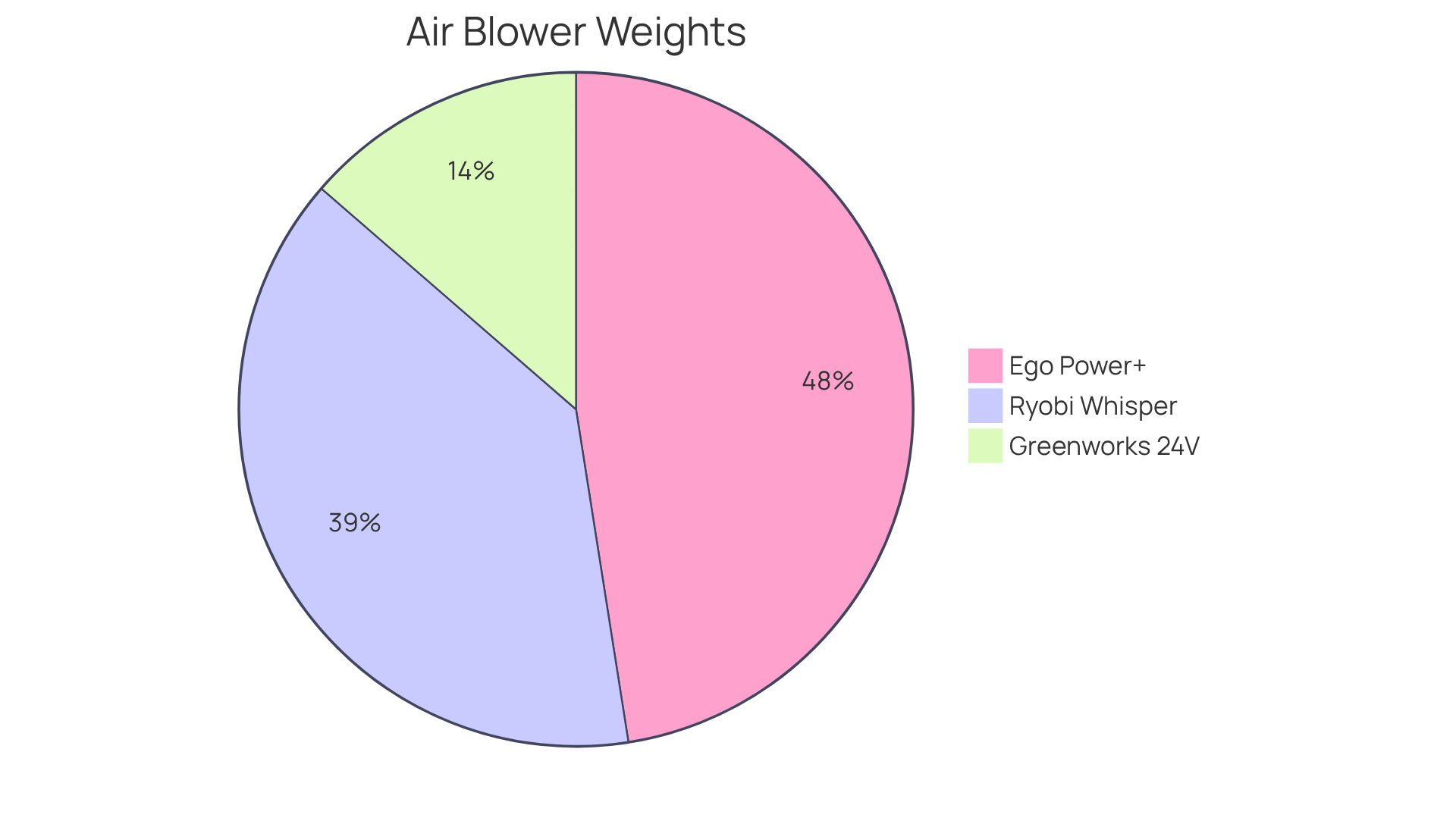

Portability in a high power air blower is essential for professionals, facilitating convenient transport and deployment across diverse job sites. Lightweight designs, exemplified by the Greenworks 24V Axial Leaf Blower at a mere 3.7 pounds, significantly enhance usability, enabling extended operation without fatigue. Ergonomic handles further bolster user comfort, simplifying maneuverability during prolonged use.

Engineers must prioritize models that achieve a balance between power and portability, such as the Ego Power+ LB6504 Cordless, which functions as a high power air blower while merging robust performance with a manageable weight of 12.9 pounds. Additionally, the Ryobi Whisper Series Leaf Blower operates at a noise level of 59 dB(A) and offers a battery life of up to 85 minutes, making it a quiet yet effective choice for professionals.

Industry experts underscore the critical nature of portability; even a slight increase in weight can adversely affect comfort and efficiency during operation. Colleen Sullivan asserts, “Even an extra pound or two can make a real difference in how comfortable your blower is to operate.”

With the transition towards all-electric tools, professionals can explore options that not only meet their energy needs but also adhere to ergonomic principles, thereby enhancing overall productivity. When strength and usability are comparable, lighter models are preferred, underscoring the necessity for engineers to consider these factors in their selections.

Noise Levels: Ensuring a Quiet Working Environment

Noise levels in high power air blowers can significantly impact the working environment. Engineers must prioritize fans that incorporate noise reduction features, including sound-dampening materials and optimized motor designs. The company provides an extensive range of DC input Tube Axial fans, from 15 to 280mm, and Centrifugal Blowers, from 15 to 225mm, all optimized for performance and low noise, including a high power air blower to ensure quieter operation.

Selecting machines with lower decibel ratings is essential, particularly in settings such as laboratories or offices where concentration is paramount. With a variety of options tailored for diverse applications—ranging from electronics to automotive and industrial uses—Gagner-Toomey’s innovative cooling solutions are specifically designed to meet the unique requirements of electronics engineers.

Durability: Ensuring Long-Lasting Performance

Durability in high power air blower devices is paramount, achieved through the utilization of robust materials such as corrosion-resistant metals and advanced composites, along with construction techniques that ensure long-lasting performance. Engineers must prioritize devices featuring sturdy housings, specifically designed to endure harsh operating conditions across diverse applications, including the electronics and automotive sectors.

The company’s comprehensive portfolio showcases both standard and tailored solutions, encompassing:

- DC input tube axial fans

- Centrifugal fans available in sizes ranging from 15mm to 910mm

This extensive variety ensures that each device not only delivers consistent performance but also minimizes downtime and maintenance expenses. A robust fan from the manufacturer guarantees optimal airflow and cooling solutions, meticulously customized to meet specific engineering requirements.

Energy Efficiency: Reducing Operational Costs

The high power air blower devices from Gagner-Toomey Associates are meticulously engineered to deliver maximum airflow while consuming minimal power. Featuring a diverse range of products, including DC input tube axial fans and centrifugal ventilators, engineers can select from various sizes optimized for performance and low noise.

By opting for devices equipped with high-efficiency motors and advanced control systems, organizations can significantly reduce operational expenses while simultaneously supporting sustainability initiatives. This strategic choice not only positively impacts the budget but also aligns seamlessly with the environmental objectives of contemporary engineering practices.

Safety Features: Protecting Users During Operation

Safety features in high power air blower devices are paramount, encompassing:

- Thermal overload protection

- Automatic shutoff mechanisms

- Safety guards designed to prevent accidental injuries

The world’s largest manufacturer of standard and custom air-movers underscores the critical importance of these safety features in their designs. Engineers must prioritize high power air blowers that integrate these safety mechanisms to ensure user protection during operation. Furthermore, adherence to established safety standards not only guarantees user safety but also enhances the overall reliability of the equipment. This commitment reflects the company’s dedication to performance and efficiency across their extensive product range.

Versatility: Adapting to Multiple Applications

High power air blowers from Gagner-Toomey Associates are engineered for versatility, adept at addressing a wide spectrum of applications, from cooling electronic components to facilitating drying processes in manufacturing. Their extensive product lineup includes:

- DC input tube axial fans ranging from 15 to 280mm

- Centrifugal devices from 15 to 225mm

This enables engineers to identify tailored solutions that prioritize performance, efficiency, and low noise. These devices can be seamlessly adapted for various tasks, ensuring they meet the evolving demands of diverse projects. Such adaptability not only boosts efficiency but also maximizes return on investment, positioning Gagner-Toomey’s innovative cooling solutions as indispensable across multiple applications. Furthermore, IP protection is available for most models upon request, enhancing their suitability for a variety of operational environments.

Warranty and Support: Ensuring Peace of Mind

When investing in high-performance air fans, professionals must prioritize the warranty and support options provided by manufacturers. A robust warranty not only safeguards against manufacturing defects but also instills confidence in the equipment’s longevity. Furthermore, reliable customer support ensures that technical staff can access assistance when needed, thereby enhancing the overall user experience and satisfaction.

Gagner-Toomey Associates, a recognized leader in energy conversion products, offers a comprehensive range of cooling solutions, including:

- High power air blowers

- Both standard and custom fans tailored for diverse applications

Their expertise in power conversion and EMI solutions guarantees that engineers can depend on high-quality products designed for:

- Medical applications

- Industrial applications

- Server applications

These products include:

- DC/DC converters

- RFI/EMI filters

Conclusion

High power air blowers are indispensable tools for engineers, especially within the electronics industry, where effective cooling and airflow management are paramount. This article underscores the innovative solutions offered by Gagner-Toomey Associates, highlighting the critical importance of selecting the appropriate blower based on various factors, including:

- Power rating

- Airflow capacity

- Portability

- Noise levels

- Durability

- Energy efficiency

- Safety features

- Versatility

- Warranty support

Each of these elements is vital for ensuring optimal performance and reliability across diverse applications.

Key insights reveal the necessity of comprehending power ratings to achieve the desired airflow and pressure, alongside the significance of choosing blowers that minimize noise while maximizing energy efficiency. Furthermore, the versatility of these devices empowers engineers to adapt them for a broad spectrum of tasks, thereby enhancing productivity and return on investment. The focus on safety features and robust warranty options further emphasizes the commitment to user protection and satisfaction.

In conclusion, the importance of high power air blowers cannot be overstated. They not only fulfill the technical demands of contemporary engineering but also contribute to cost savings and sustainability initiatives. Engineers are urged to consider these essential features when selecting air blowers, ensuring alignment with their specific needs and project requirements. By prioritizing performance, efficiency, and safety, professionals can fully leverage the capabilities of high power air blowers, fostering innovation and excellence within their fields.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative solutions for engineers in the electronics industry, particularly focusing on high power air blower devices used for effective cooling and optimal airflow management.

How do high power air blowers benefit electronic systems?

High power air blowers enhance performance and reliability in electronic systems, and their integration can lead to energy consumption reductions of up to 30%, making them essential components in modern cooling strategies.

What advantages do high power air blowers provide in data centers?

In data centers, high power air blowers improve thermal management, reduce operational costs, and prolong equipment lifespan.

What is the importance of power rating in selecting air fans?

The power rating of a high-capacity air fan indicates its ability to operate efficiently under load, and engineers must consider the necessary airflow and pressure when selecting a fan, as these factors are influenced by the capacity rating.

What types of fans does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a wide range of DC input tube axial fans and centrifugal ventilators that are optimized for performance and efficiency, suitable for various applications in electronics, automotive, and industrial sectors.

How is airflow capacity measured and why is it important?

Airflow capacity is measured in cubic feet per minute (CFM) and is crucial for maintaining safe operating temperatures of electronic components. It ensures effective heat dissipation from electronic devices.

What features do Gagner-Toomey’s high power air blower units offer?

Gagner-Toomey’s high power air blower units are optimized for performance, efficiency, and minimal noise, and many models feature IP protection, making them suitable for a variety of environments.

How can engineers ensure they select the right fan for their application?

Engineers should select fans from Gagner-Toomey’s comprehensive portfolio, which includes DC input tube axial models and centrifugal units, ensuring that the airflow capacities align with the thermal requirements of their specific applications to maximize overall efficiency.