Overview

This article underscores the critical importance of managing blower static pressure within HVAC systems to significantly enhance performance and efficiency. It is essential to maintain optimal static pressure, ideally around 0.5 inches of water column. Excessive resistance can result in increased energy consumption and accelerated equipment wear. Conversely, effective management strategies, including:

- Duct optimization

- Regular maintenance

can substantially improve system reliability while also reducing operational costs. By implementing these strategies, HVAC professionals can ensure their systems operate at peak efficiency and longevity.

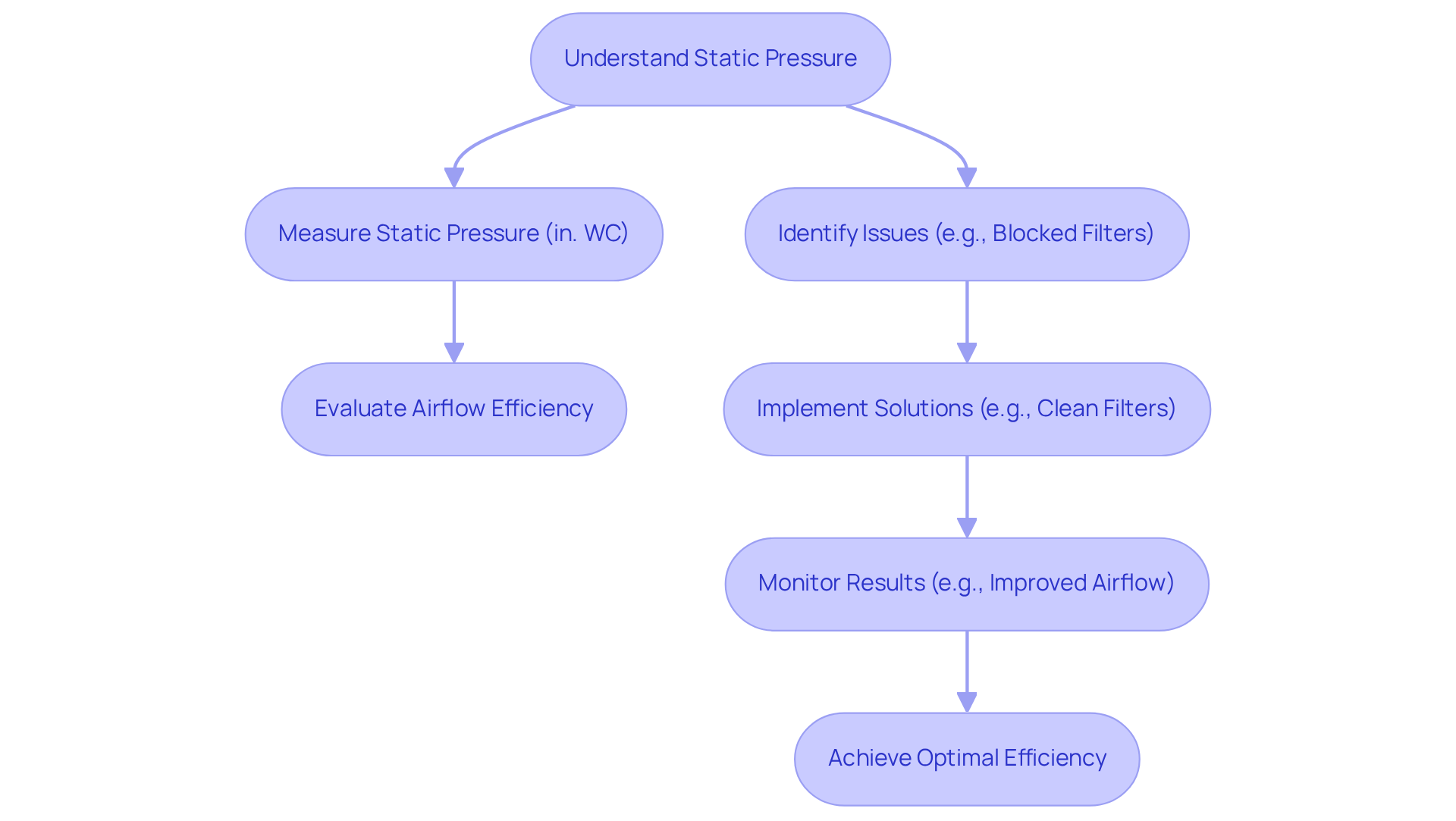

Introduction

Understanding static pressure is essential for optimizing HVAC systems, as it directly influences airflow efficiency and energy consumption. Mastering the intricacies of blower static pressure enables readers to uncover strategies that enhance performance and extend the lifespan of their systems.

However, a significant challenge arises in managing the delicate balance of airflow resistance. What occurs when static pressure levels exceed optimal ranges? More importantly, how can one effectively address these issues to maintain both comfort and efficiency?

Define Static Pressure in HVAC Systems

Static force in HVAC setups signifies the resistance to airflow within ductwork and components, measured in inches of water column (in. WC), equivalent to pounds per square inch (psi). This measurement is vital for assessing the effectiveness of air circulation throughout the system. Elevated air resistance often indicates obstructions, such as blocked air filters and insufficient ductwork, which can lead to higher energy usage and operational stress on components like the blower motor. Conversely, low atmospheric force may suggest inadequate airflow, potentially causing inconsistent heating or cooling across an area.

Understanding fixed force is crucial for enhancing HVAC efficiency, particularly in relation to blower static pressure. An optimal equilibrium force for residential systems is approximately 0.5 in. WC (0.5 psi), striking a balance between airflow and energy efficiency. When the fixed force exceeds this limit, the blower motor may operate more intensely, resulting in and potential equipment breakdown. Routine maintenance, which includes cleaning filters and inspecting ductwork annually or more frequently if necessary, is essential for sustaining ideal airflow levels.

Real-world instances underscore the importance of maintaining consistent force. For example, a facility experienced inconsistent temperatures and higher energy expenses due to elevated resistance caused by unclean coils and obstructed vents. After addressing these issues, the facility reported improved airflow and reduced energy bills. Such interventions not only enhance comfort but also extend the lifespan of HVAC components, underscoring the significance of managing blower static pressure proactively. As one HVAC specialist noted, “Static force isn’t merely a figure—it’s a crucial performance measure for your HVAC setup.

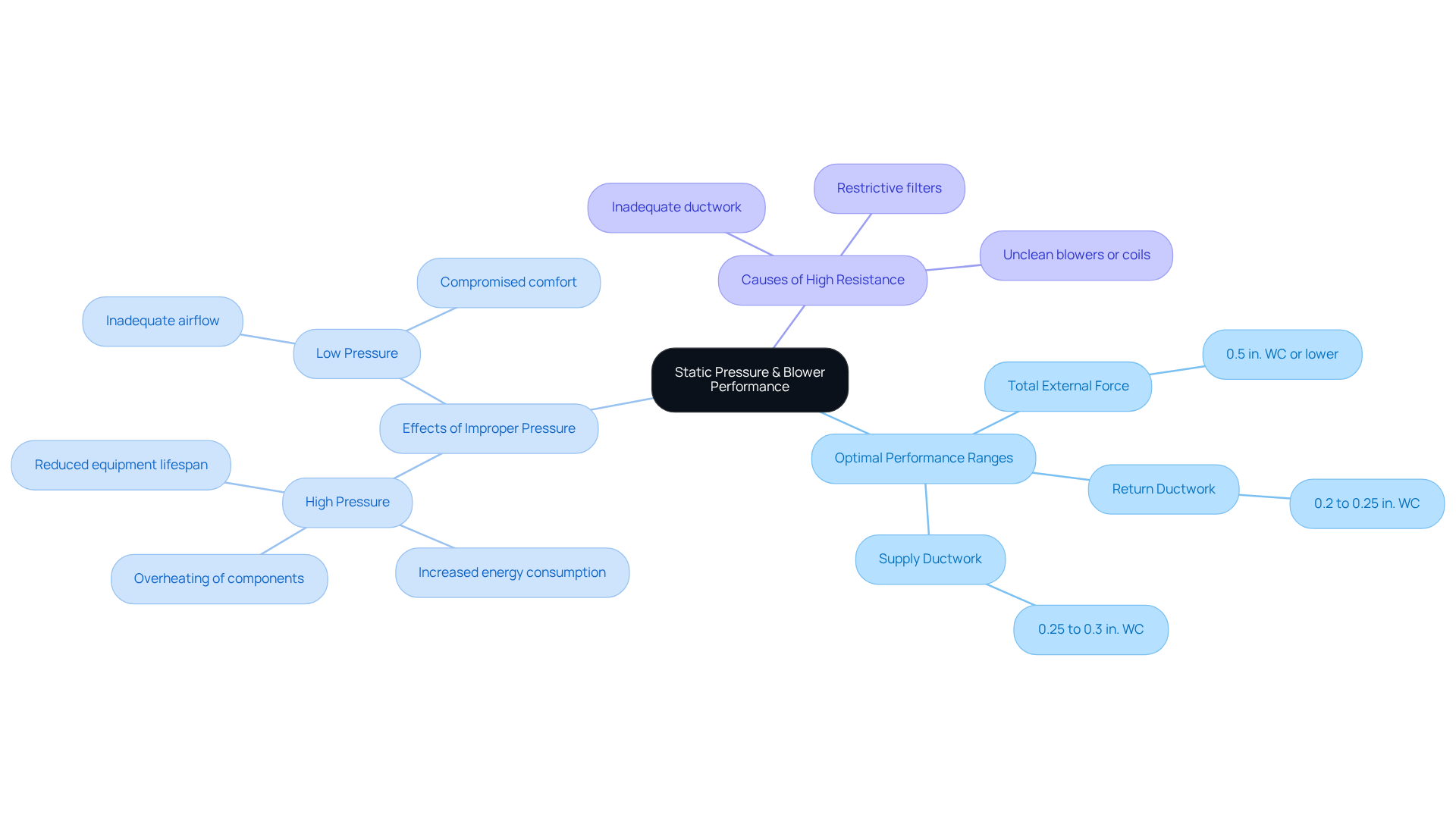

Analyze the Effects of Static Pressure on Blower Performance

Static force is pivotal in optimizing the efficiency of blowers by considering blower static pressure within HVAC systems. Increased ambient resistance can obstruct airflow, compelling blowers to work more intensively and consequently escalating energy consumption. A standard residential HVAC unit should maintain a total external force of 0.5 in. WC or lower to ensure peak performance. The ideal fixed range for return ductwork is between 0.2 to 0.25 in. WC, whereas for supply ductwork, it stands at 0.25 to 0.3 in. WC. Excessively elevated ambient force can lead to overheating and increased wear on components, ultimately jeopardizing functionality. Conversely, insufficient atmospheric force can result in inadequate airflow, compromising comfort and system efficiency.

By analyzing blower performance curves, engineers can pinpoint the optimal fixed force range tailored to their specific applications. This analysis is essential, as it facilitates the identification of inefficiencies and the implementation of corrective measures. Common causes of elevated resistance include:

- Inadequate ductwork

- Restrictive filters

- Unclean blowers or coils

For example, consistent monitoring and adjustments of fixed force can significantly enhance blower efficiency, leading to improved airflow and reduced operational costs. Case studies, such as ‘Steps to Reduce High Static Pressure,’ illustrate that proactive management of elevated conditions not only boosts reliability but also extends the lifespan of HVAC components. Therefore, maintaining the appropriate fixed force is crucial for achieving and ensuring the overall functionality of HVAC systems, particularly in relation to blower static pressure.

Implement Strategies to Manage Static Pressure Challenges

To effectively manage static pressure challenges in HVAC systems, several strategies can be implemented:

- Duct Design Optimization: Appropriately sized and configured ductwork reduces bends and limitations, considerably raising resistance. Ensuring that ducts are adequately sized for airflow requirements is crucial for maintaining efficiency. The optimal total external static pressure (TESP) for residential installations is generally 0.50 inches water column (in. w.c.).

- Regular Maintenance: Routine inspections and maintenance of filters, fans, and ducts are essential to prevent blockages that elevate static pressure levels. Consistently changing air filters and cleaning ducts assists in preserving optimal circulation and system performance. As Rob Minnick, an educator at the National Comfort Institute, states, “Using the right air filter guarantees proper circulation of air.”

- Variable Speed Drives: Employing variable speed drives on blowers enables flexible modifications to the flow of air according to live readings of fixed resistance. This not only enhances efficiency but also improves comfort by ensuring consistent air distribution.

- Air Distribution Optimization: Applying air distribution optimization methods guarantees uniform air spread across the system, minimizing regions of elevated resistance. This can involve adjusting dampers or adding return vents to optimize airflow.

- Utilization of Force Sensors: Incorporating force sensors for ongoing observation of fixed force allows for prompt modifications when levels stray from the ideal range. This proactive approach aids in and preventing potential problems.

By implementing these strategies, engineers can efficiently control fixed force, which results in improved blower static pressure, better blower performance, increased energy efficiency, and overall system dependability. A proactive HVAC maintenance program that identifies static pressure issues can significantly reduce energy consumption and prolong equipment lifespan.

Conclusion

Understanding and managing static pressure is essential for optimizing the performance of HVAC systems. Recognizing that static pressure directly influences airflow and energy efficiency highlights the necessity of maintaining an ideal balance, crucial for both comfort and operational cost savings. This article underscores the importance of routine maintenance, proper duct design, and the implementation of innovative technologies to mitigate static pressure challenges and enhance blower performance.

Key insights from this discussion emphasize the significance of maintaining static pressure within specified ranges, such as 0.5 in. WC for residential systems. Elevated static pressure can lead to increased energy consumption and potential equipment failures, while insufficient pressure can compromise heating and cooling effectiveness. Strategies such as regular maintenance, employing variable speed drives, and optimizing air distribution are vital for sustaining optimal airflow and ensuring system reliability.

Ultimately, addressing static pressure not only improves the efficiency of HVAC systems but also contributes to a more sustainable approach to energy consumption. Proactive management of static pressure challenges transcends technical necessity; it embodies a commitment to enhancing indoor comfort and prolonging the lifespan of HVAC equipment. Implementing the strategies outlined empowers engineers and technicians to create more efficient, reliable systems that meet the demands of modern living while minimizing energy waste.

Frequently Asked Questions

What is static pressure in HVAC systems?

Static pressure in HVAC systems refers to the resistance to airflow within ductwork and components, measured in inches of water column (in. WC), which is equivalent to pounds per square inch (psi).

Why is measuring static pressure important?

Measuring static pressure is vital for assessing the effectiveness of air circulation throughout the HVAC system. High air resistance can indicate obstructions, leading to increased energy usage and operational stress on components.

What can elevated static pressure indicate?

Elevated static pressure often indicates obstructions such as blocked air filters or insufficient ductwork, which can lead to higher energy usage and stress on the blower motor.

What does low static pressure suggest?

Low static pressure may suggest inadequate airflow, potentially causing inconsistent heating or cooling across an area.

What is the optimal static pressure for residential HVAC systems?

The optimal static pressure for residential HVAC systems is approximately 0.5 in. WC (0.5 psi), which balances airflow and energy efficiency.

What happens if static pressure exceeds the optimal limit?

If static pressure exceeds the optimal limit, the blower motor may operate more intensely, resulting in increased utility costs and a higher risk of equipment breakdown.

How can static pressure be maintained at ideal levels?

Routine maintenance, including cleaning filters and inspecting ductwork annually or more frequently if necessary, is essential for sustaining ideal static pressure levels.

Can you provide an example of the impact of static pressure on HVAC performance?

One example is a facility that experienced inconsistent temperatures and higher energy expenses due to elevated resistance from unclean coils and obstructed vents. After addressing these issues, the facility reported improved airflow and reduced energy bills.

What is the significance of managing blower static pressure?

Managing blower static pressure is crucial for enhancing HVAC efficiency, improving comfort, and extending the lifespan of HVAC components.